Convenient-speed-adjusting type screw oil press

An oil press and screw technology, applied in the field of oil press, can solve the problems of low speed, undurable and short service life of the transmission gearbox, and achieve the effect of increasing the instantaneous pressure, increasing the speed of the pressing shaft, and increasing the oil output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments with reference to the accompanying drawings.

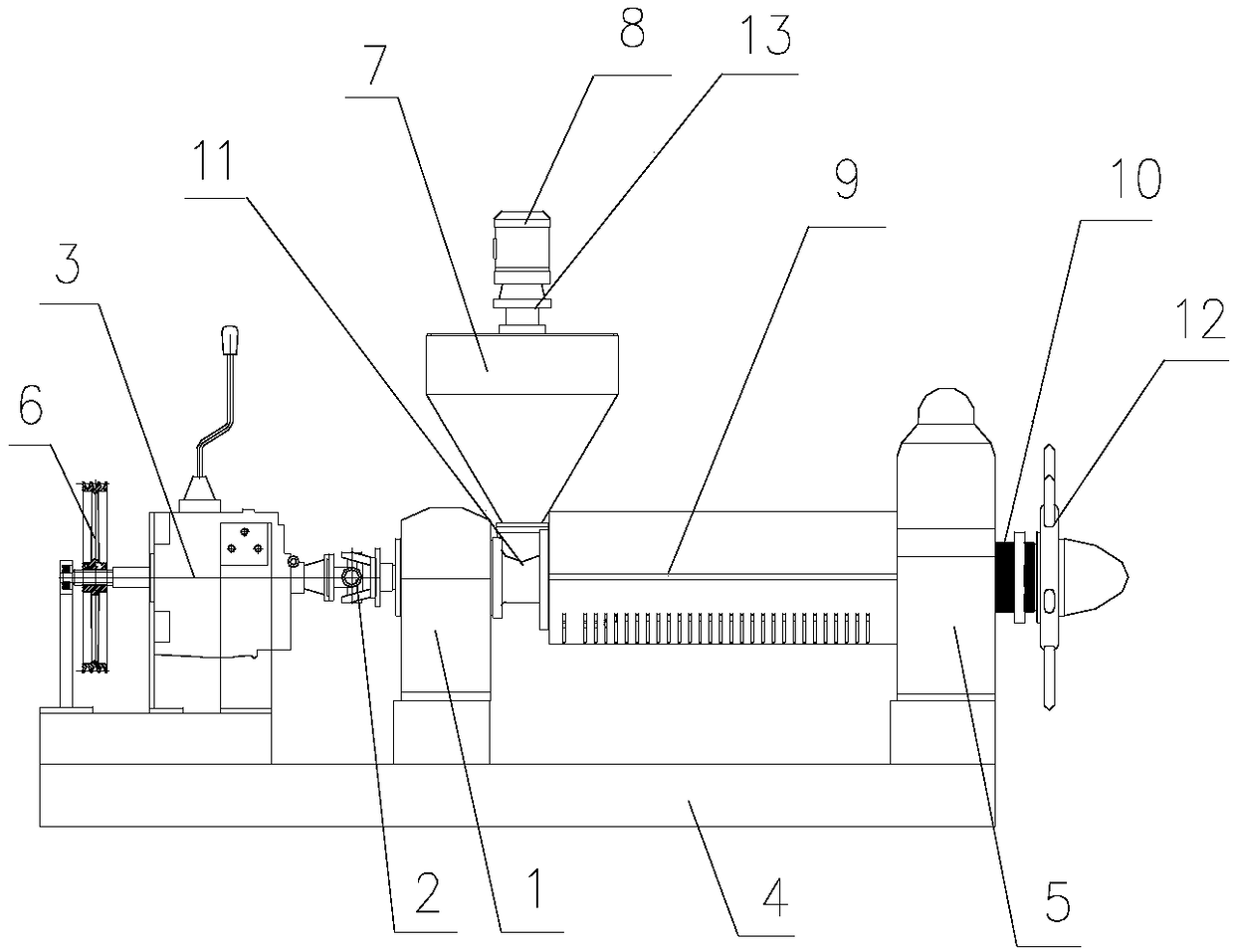

[0035] figure 1 It is a structural schematic diagram showing a screw oil press convenient for speed regulation involved in a specific embodiment of the present invention.

[0036] Such as figure 1 As shown, the screw oil press that is convenient for speed regulation includes a frame 1 and a bottom plate 4, a frame 5 is installed above the right end of the bottom plate 4, a frame 1 is installed in the middle, and a feed nozzle 11 is connected to the right side of the frame 1 A hopper 7 is fixedly installed above the feed nozzle 11, and a feeder 13 and a motor assembly 8 are installed above the hopper 7; the frame 5 and the feed nozzle 11 are fixedly connected to the bar round row assembly 9; The frame 5, the squeeze bar round row assembly 9 and the machine base 1 are equipped with a squeeze screw assembly 10, and the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com