Multi-stage overload protection type shear pin type mechanical overload protection structure

A shear pin type, overload protection technology, applied in mechanical equipment, couplings with safety disconnect joints, belts/chains/gears, etc., can solve the problem that the shear pin type overload protection structure cannot be used, etc. Simple, low production and maintenance costs, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

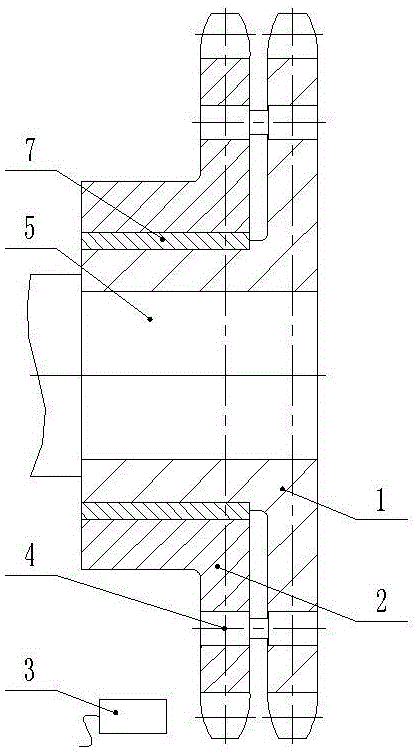

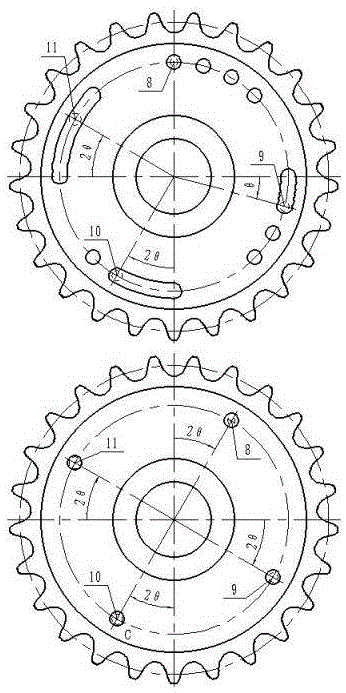

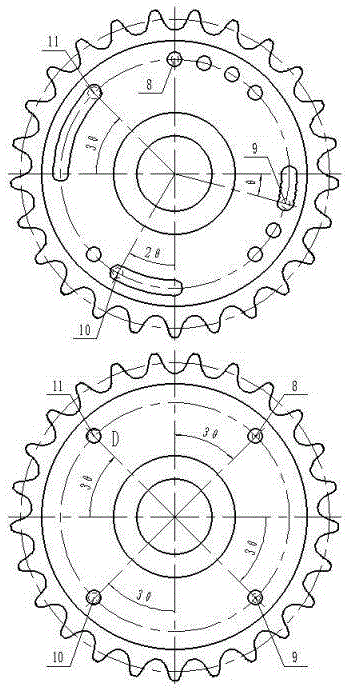

[0025] The following will take the four-stage overload protection structure (drive shaft and driven shaft mode) in the multi-stage overload protection structure as an example to describe in detail with the accompanying drawings:

[0026] In the four-stage overload protection structure, the driving wheel 1 is provided with four shear pin installation holes, and the driven wheel 2 is provided with seven shear pin installation holes and three shear pin installation slide holes of different lengths. The shearing pins are provided with four specifications, namely the primary shearing pin 8 with a shearing diameter d1, the secondary shearing pin 9 with a shearing diameter d2, the tertiary shearing pin 10 with a shearing diameter d3, and the fourth-stage shearing pin 11 with a shearing diameter d4. The cutting diameter relationship is d1<d2<d3<d4, and they are respectively installed at four places a, b, c, and d, so that a total of four levels of overload protection such as primary pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com