Mechanical overload protection device

An overload protection and mechanical technology, applied in the direction of mechanical equipment, transmission devices, automatic clutches, etc., can solve the problems of motor burnout, end rotating parts damage, transmission jamming, etc., and achieve the effect of avoiding transmission jamming and preventing fault escalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

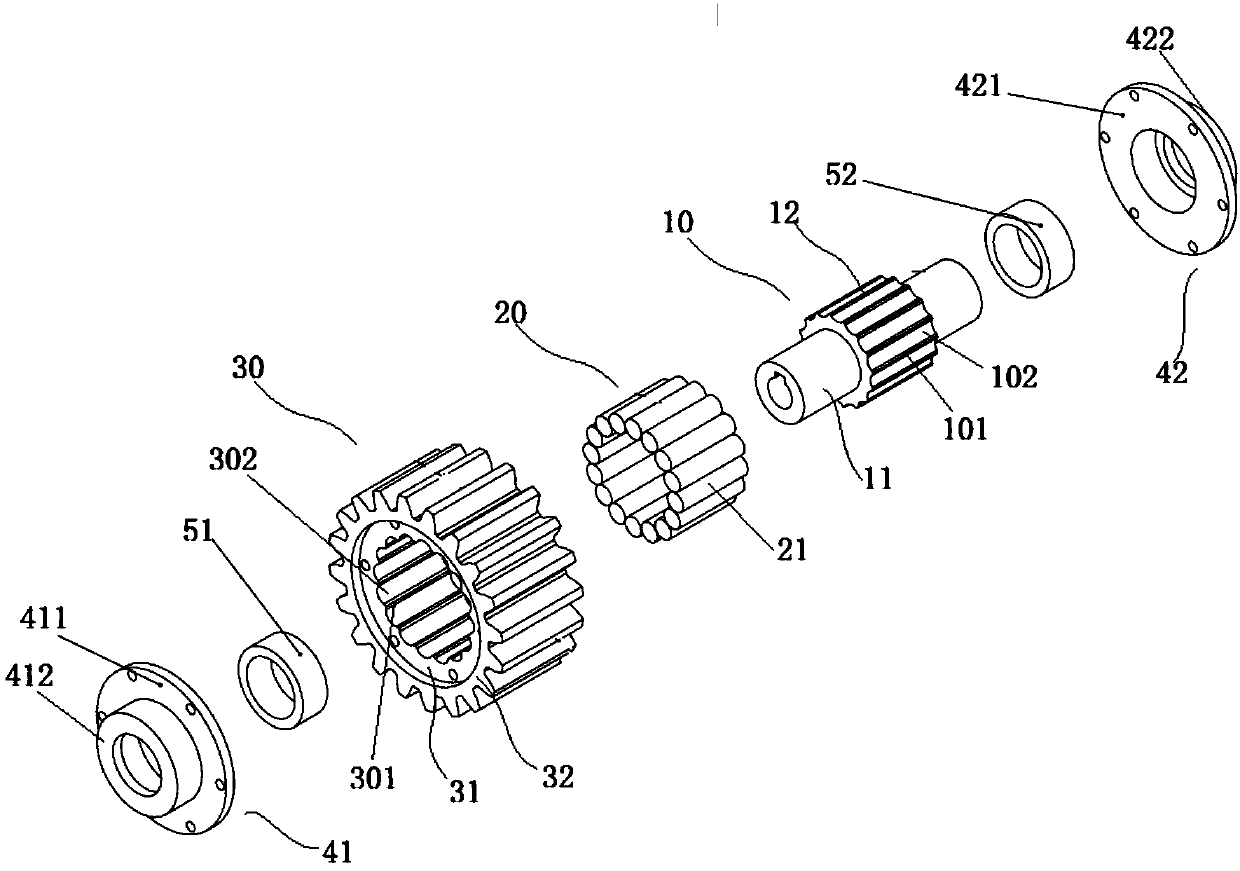

[0031] The invention provides a mechanical overload protection device with simple structure and capable of cutting off the transmission of torque when the load is overloaded, thereby effectively solving the problems of transmission jamming, damage to end rotating parts caused by motor stalling, and motor burnout.

[0032] see figure 1 , the mechanical overload protection device includes a drive pinion 10, an overload protection member 20 and a driven pinion 30, wherein the drive pinion 10 is used to connect with a power source to input power, where the power source is generally a motor, and the drive pinion 10 is connected with the output end of the motor, so as to input the power provided by the motor to the transmission system. The driven ring gear 30 is used to connect with an external load, so as to output power to the outside, and the driven ring gear 30 is sleeved on the outside of the driving gear shaft 10 .

[0033] In the prior art, the driven ring gear 30 is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com