Mechanical transmission mechanism with overload position capable of being preset

A technology of mechanical transmission and transmission shaft, which is applied to mechanical equipment, transmission devices, gear transmission devices, etc., and can solve the problem that the overload position cannot be preset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

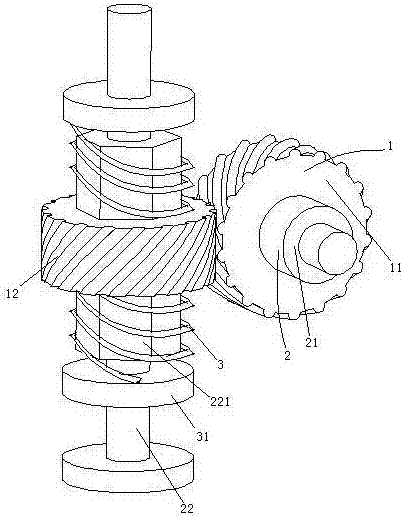

Examples

Embodiment 2

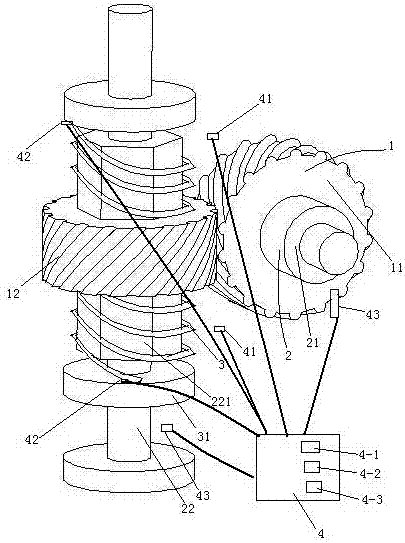

[0028] Embodiment two, the difference with embodiment one is:

[0029] see figure 2 , when an overload occurs, the driving gear 11 and the driven gear 12 are still meshed together.

[0030] It also includes a control device 4 , an overload detection switch 41 , a pressure sensor 42 and an angle detection sensor 43 that are electrically connected together. The control device 4 includes a first control unit 4-1, a second control unit 4-2 and a third control unit 4-3.

[0031] There are two overload detection switches 41, which are respectively used to detect when the driven gear 12 forwardly rotates to the overload position and reversely rotates to the overload position and feeds back to the control device.

[0032] The first control unit 4 - 1 stops the power source providing power to the driving gear 11 from outputting power to the driving gear 11 when the first control unit 4 - 1 detects that the driven gear 12 is in the overload position.

[0033] There are two pressure ...

Embodiment 3

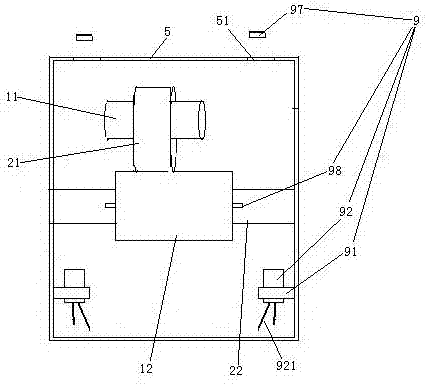

[0038] Embodiment three, the difference with embodiment two is:

[0039] see image 3 , also includes the gear box case 5 and the overload discriminating structure 9. The driving gear 11 and the driven gear 12 are connected in the gearbox housing 5 through the rotating shaft 21 and the driven shaft 22 respectively. The gear box case 5 is provided with two light-transmitting holes 51 .

[0040] There are two overload judging structures 9 . Since the overload position can be set for both directions of rotation, two overload detection structures 9 are required. If the overload bit setting is only performed in one direction of rotation, only one overload judging structure 9 is required.

[0041] The overload judging structure 9 includes a projection board 97 , a light blocking board 98 and a laser diode 92 . The laser diode 92 is provided with a power input pin 921 . The laser diode 92 is fixed on the heat sink 91 . The projection plate 97 is located on the outside of the g...

Embodiment 4

[0047] Embodiment four, the difference with embodiment three is:

[0048] see Figure 5 , one end of the heat conducting sleeve 934 and one end of the heat sink 91 are sealed against the sealing plate 94 , that is, both the heat conducting sleeve and the heat sink can slide relative to the sealing plate 94 . The other end of the heat conducting sleeve 934 and the other end of the radiator 91 are sealed and connected together through the annular liquid storage bag 95 . The annular liquid storage bag 95 is filled with heat-insulating liquid, and the heat-insulating liquid makes the annular liquid storage bag 95 in an elastically expanded state. When the temperature is below 25° C., a sealed cavity 96 is formed among the heat conducting sleeve 934 , the sealing plate 94 , the radiator 91 and the annular liquid storage bag 95 . The sealed cavity 96 communicates with the annular liquid storage bag 95 .

[0049] When in use, when it is lower than 25°C, the cold shrinkage will cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com