High-sealing bus duct

A busway and high-sealing technology, applied in the field of busway, can solve the problems of easy contact by small animals or insects, unsatisfactory heat dissipation effect, short service life, etc., to increase connection rigidity, prevent connection loosening, and prevent short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

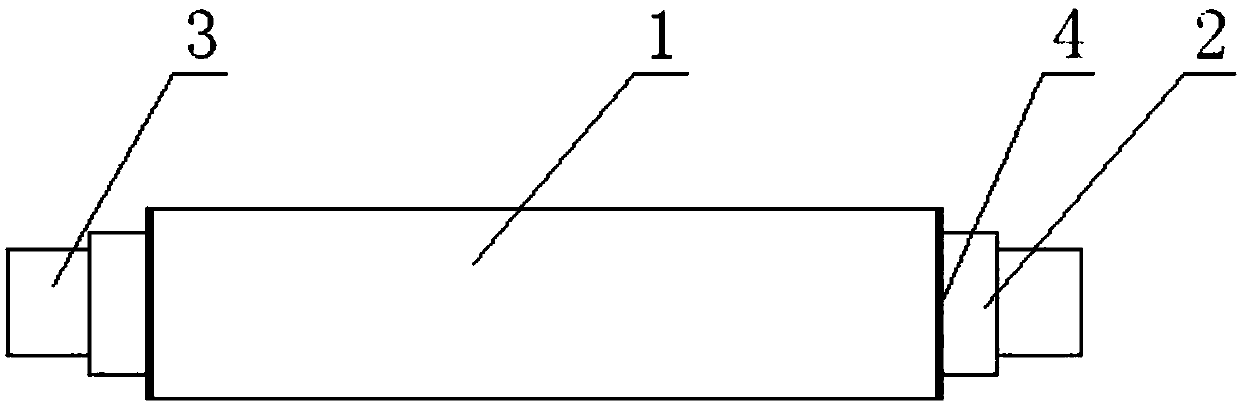

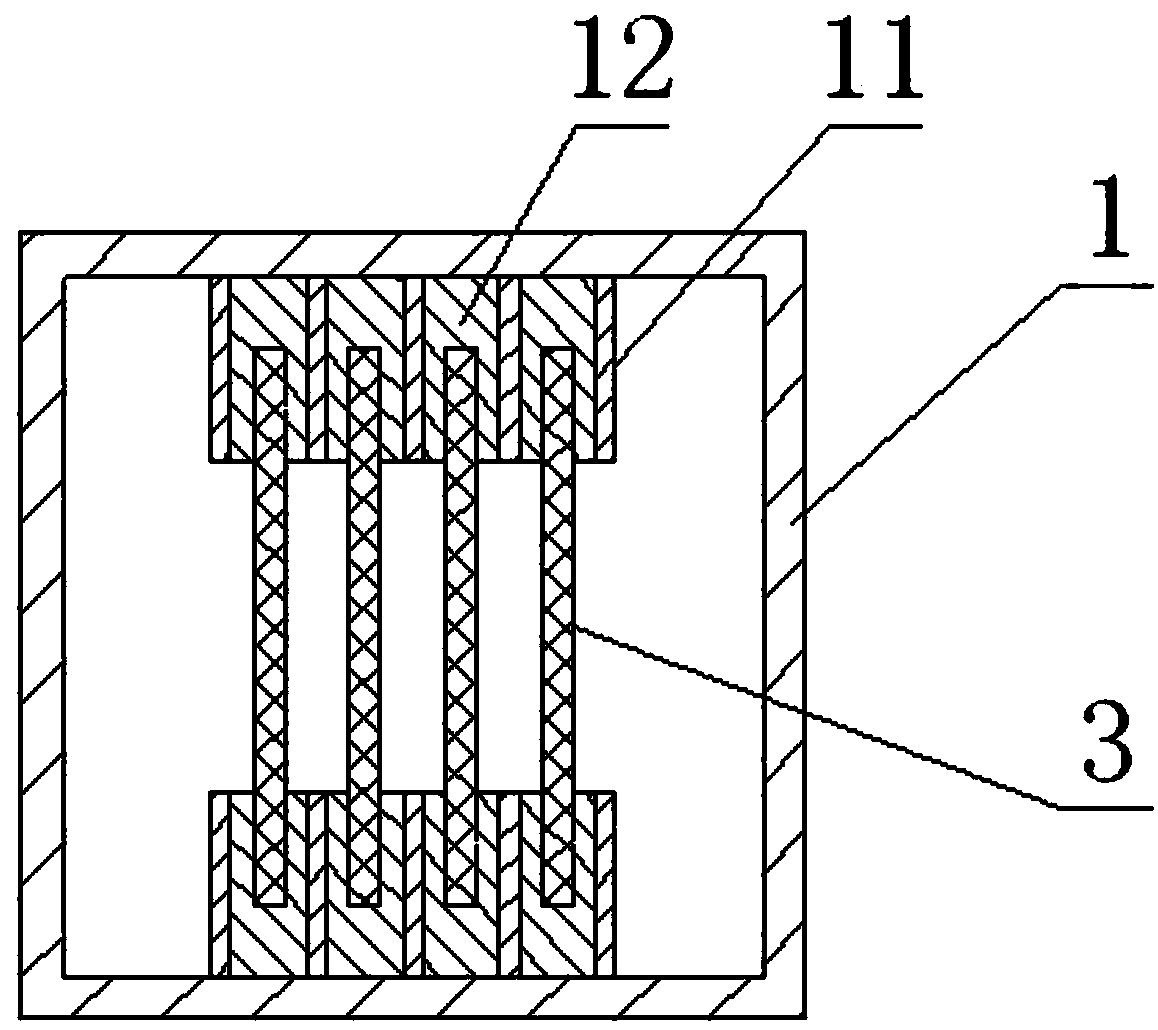

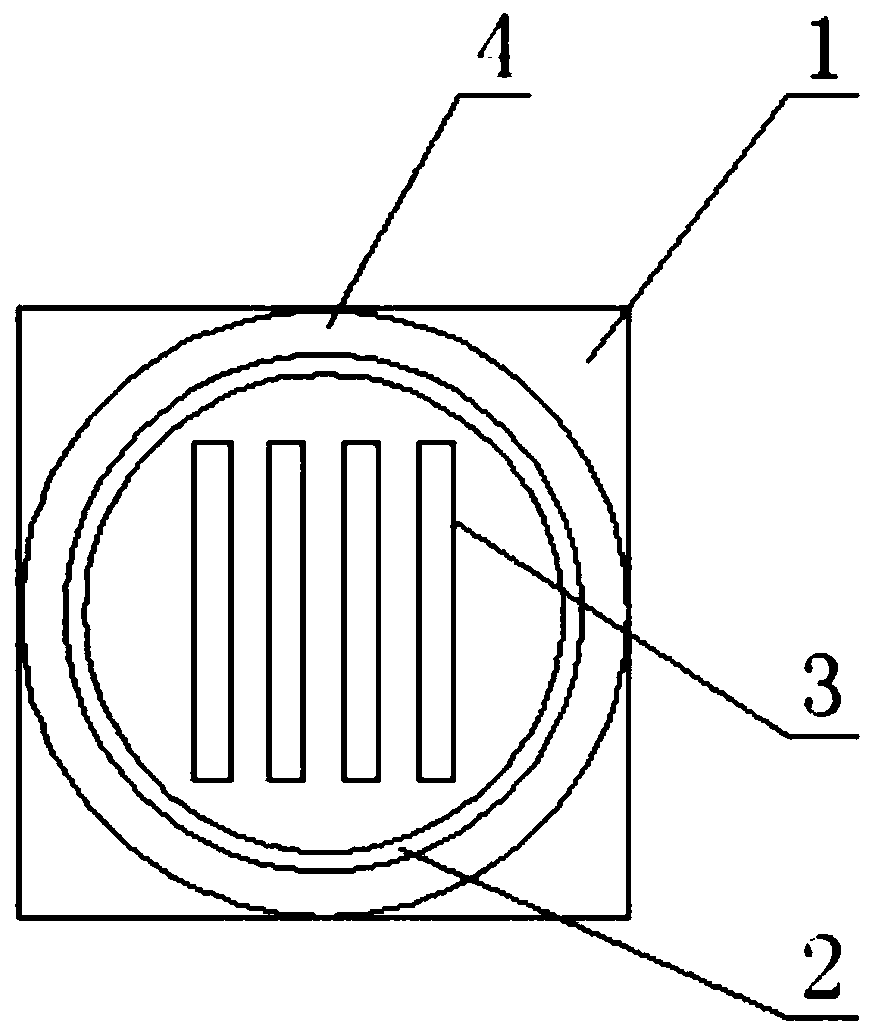

[0034] Such as figure 1 As shown, a busway with good sealing performance includes an outer sheath 1 and several conductive bars 3 arranged in the outer sheath 1. The outer side of each conductive bar 3 is covered with an insulating layer, and the conductive bars 3 are arranged at intervals to conduct electricity. One end of the row 3 is provided with a groove 31, and the other end of the conductive row 3 is provided with a bump 32 that can be installed in an interference fit with the groove 31, and the two ends of the outer shell 1 are provided with connecting studs 2, and the two bus ducts are connected When installing the bump 32 and the groove 31 with an interference fit, the connection strength between the conductive bars can be improved. The connecting stud 2 is provided with an external thread, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com