Manufacturing method of light guiding board/ light guiding film mould core

A manufacturing method and technology for light guide plates, which are applied in manufacturing tools, optics, light guides, etc., can solve the problems of slow market adaptability, increased difficulty in implementation, and complicated manufacturing processes, and can shorten the production cycle, sample time, and process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

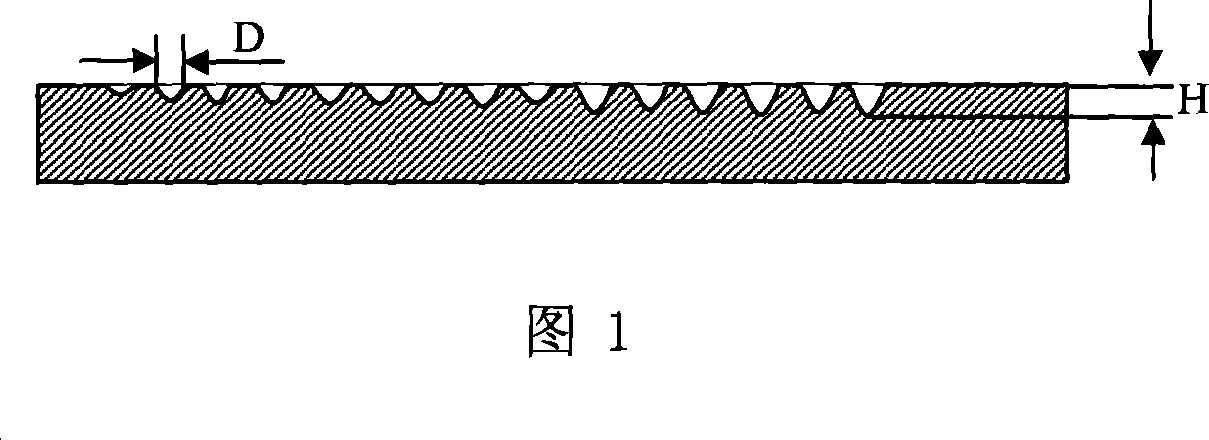

[0020] Embodiment 1: High-power diode-pumped solid-state laser: tripled frequency 351nm / 355nm or quadrupled frequency 263nm / 266nm, single pulse energy > 3mJ. The laser beam emitted by the laser passes through the beam shaping system, then collimates and focuses the optical path, and converges on the surface of the light guide plate substrate placed on the platform, such as PMMA and PC. Microstructure dots with different depths can be obtained by changing the laser energy or changing the etching time on the surface of the light guide plate substrate. Accompanying drawing 1 is the sectional view of the light guide plate of the PC substrate with the same diameter and different etching depths. In this embodiment, the dot diameter D=50um, and the dot depth H=5um-15um.

Embodiment 2

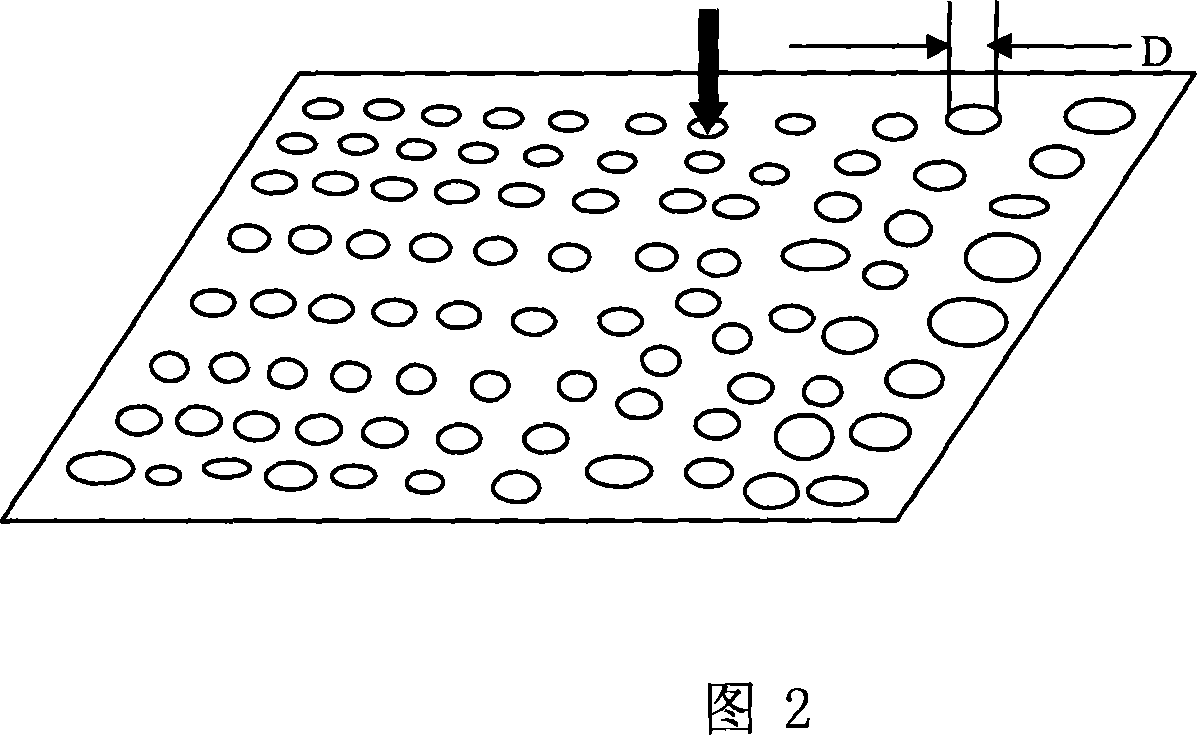

[0021] Embodiment 2: High-power diode-pumped solid-state laser: tripled frequency 351nm / 355nm or quadrupled frequency 263nm / 266nm, single pulse energy > 3mJ. The laser beam emitted by the laser passes through the beam shaping system, then collimates and focuses the optical path, and converges on the surface of the light guide plate substrate placed on the platform, such as PMMA and PC. The spot shape or light intensity distribution can be changed through the beam shaping system, so that dots with different surface shapes and groove shapes can be obtained. Accompanying drawing 2 is the top view of the light guide plate with circular microlens groove-shaped light guide dots after etching, and the dot diameter D=10-100um. While changing the dot diameter, the shape of the light spot and the energy of the laser beam can also be changed in real time to make light guide dots of different shapes and depths, which will not be described in detail.

Embodiment 3

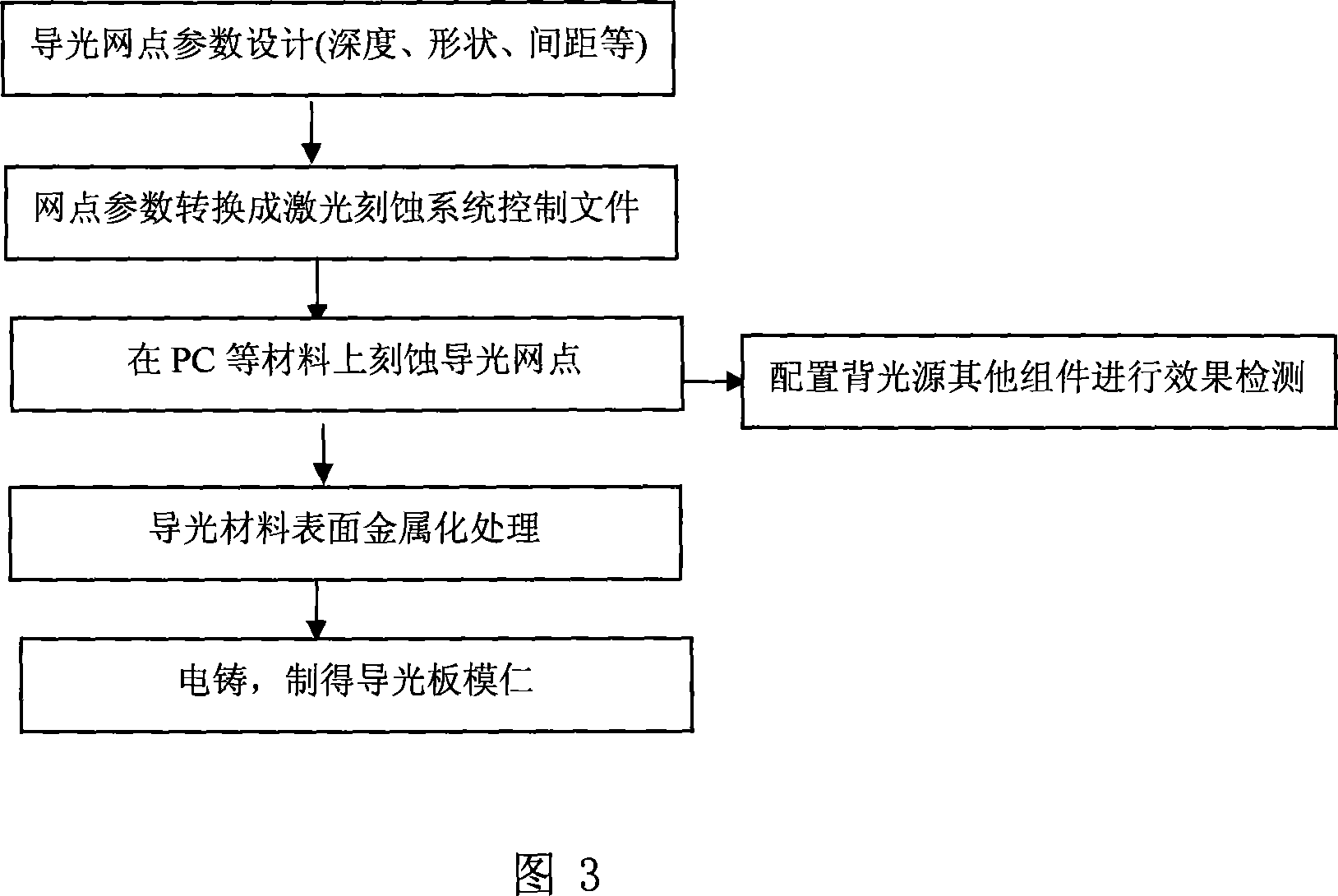

[0022] Embodiment 3: Taking the production of a side-emitting light guide plate (film) used in a mobile phone keyboard backlight module as an example, refer to the accompanying drawing 3, and introduce the process steps of making the mold core of the light guide plate (film) according to the present invention in detail. (1) Design and determine the light guide area according to the application requirements, draw the pattern, use the dot design software to design the dot distribution of the light guide area according to the characteristics of the light source, use the optical simulation software to evaluate the luminance and uniformity of the designed dots, and make dots for the dots further optimization. Determine the dot size, depth and other parameters. (2) Convert the designed dot distribution and dot parameters into controllable files of laser etching equipment. (3) Adjust the optical path of the laser etching equipment, set the corresponding parameters, and perform etchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com