Combined wax pattern-based method of achieving precision investment casting for heat-resistant cast steel thin-wall turbine shell

A technology of heat-resistant cast steel and turbine shell, which is applied in the direction of casting mold, casting mold composition, casting molding equipment, etc. rate, ensure casting accuracy, and improve the effect of filling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

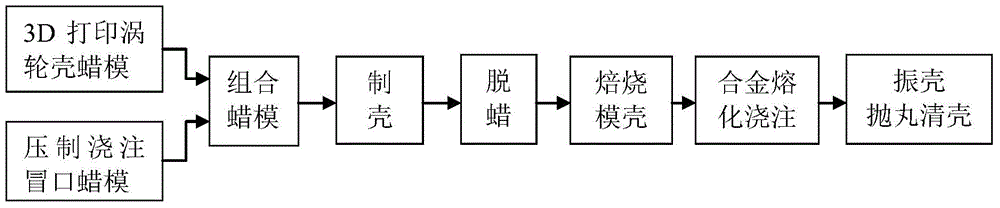

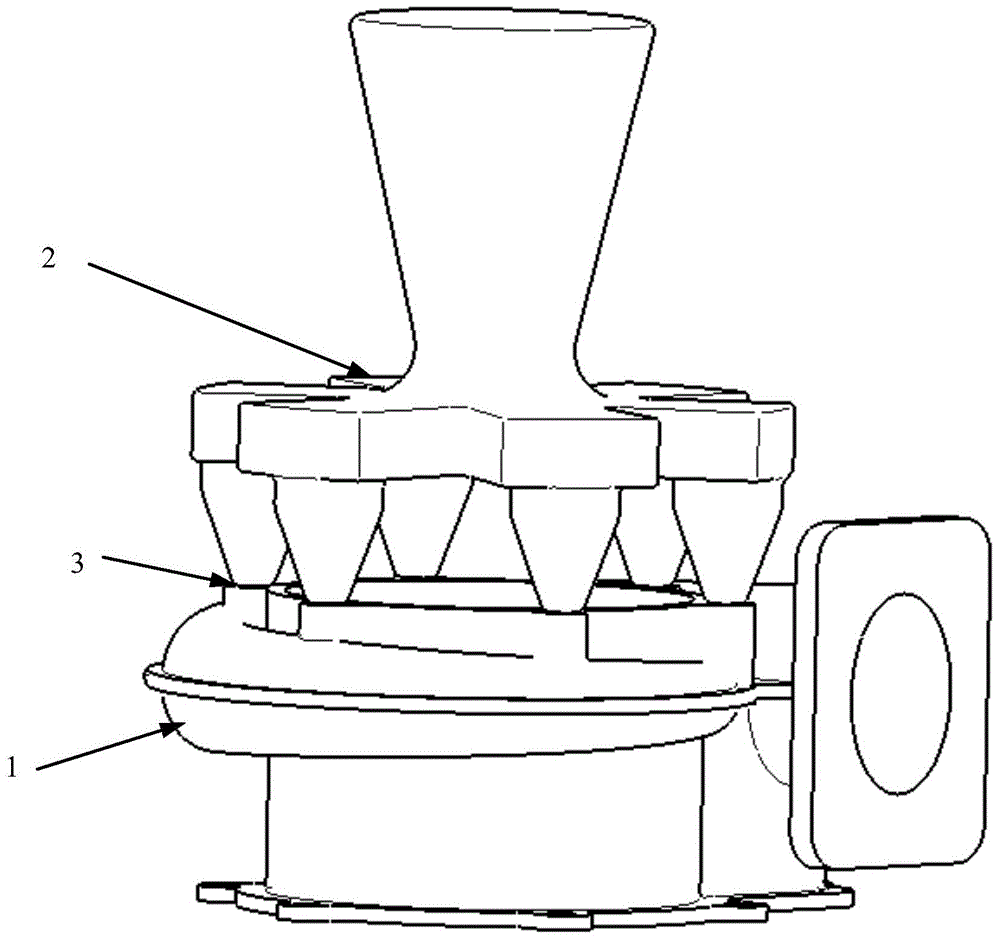

[0035] The overall investment casting structure for the heat-resistant cast steel thin-walled turbine shell described in the present invention is as follows: figure 2 As shown, its process method combines figure 1 , including the following steps:

[0036] a. Select low-temperature wax CP200 as the investment material of the turbine shell, let it stand for dewatering treatment, and use 3D printing technology to form the overall turbine shell wax mold 1.

[0037] b. Using A62 medium-temperature mold material with a softening point of 76°C, an ash content of ≤0.03% by mass, and a melting point of 85°C, put it aside for dehydration treatment, and melt-extrude to form a casting riser wax mold 2.

[0038] c. Combined wax model: use bonding wax to bond and combine the integral turbine shell wax model 1 in step a and the casting riser wax model 2 in step b at the bonding surface 3, and the bonding wax temperature is controlled at 160 ± within 10°C.

[0039] d. Shell made of silica...

Embodiment 2

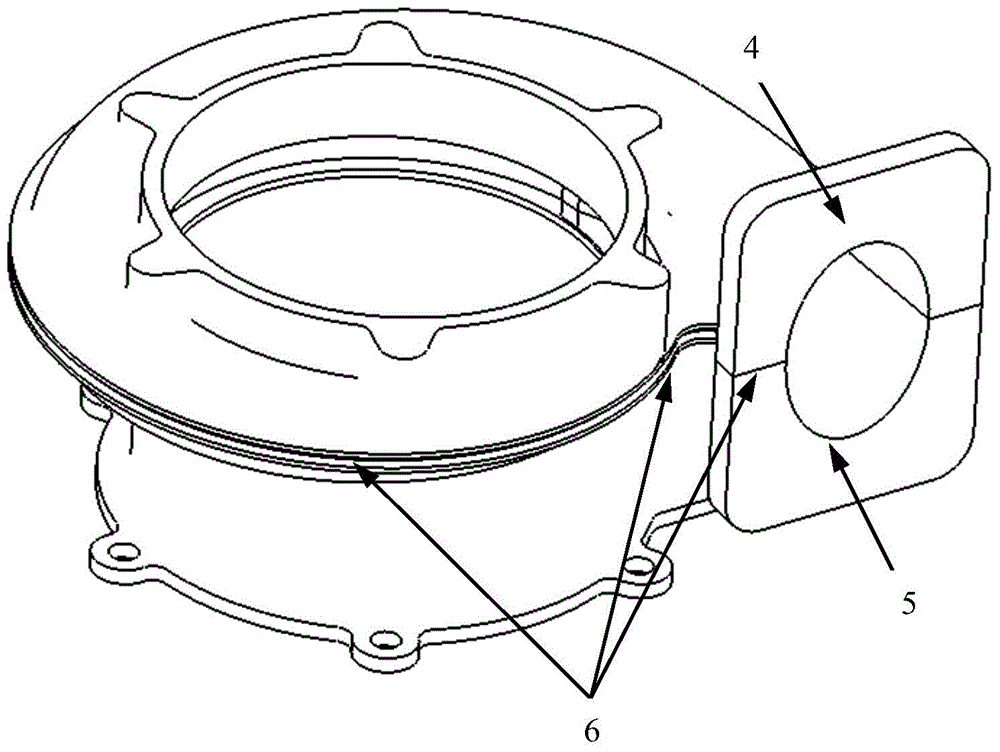

[0045] The shape of the turbine casing for casting according to the present invention is as follows image 3 As shown, its heat-resistant cast steel thin-walled investment casting process method includes the following steps:

[0046] a. Select low-temperature wax CP200 as the investment material of the turbine shell, let it stand for dewatering treatment, and use 3D printing technology to form the 4 wax molds of the upper half shell of the turbine shell.

[0047] b. Using A62 medium-temperature mold material with a softening point of 76°C, an ash content of ≤0.03% by mass, and a melting point of 85°C, put it aside for dehydration treatment, and melt-extrude to form a casting riser wax mold 2.

[0048] c. Use bonding wax to bond and combine the wax mold of the turbine casing upper half shell 4 in step a and the casting riser wax mold in step b, and control the temperature of the bonding wax within the range of 160±10°C.

[0049] d. Select low-temperature wax CP200 as the inves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com