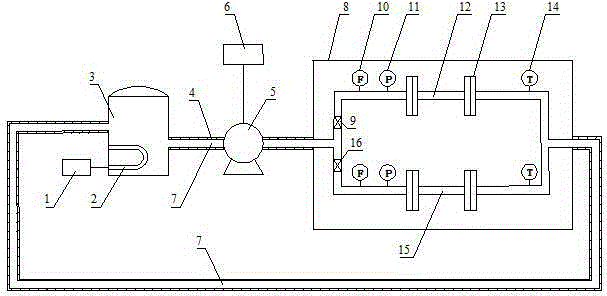

Apparatus and method for dynamic simulation of petroleum pipe scaling and wax precipitation

A dynamic simulation, oil pipe technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of reducing the interference of fluid temperature, reducing the impact, and low shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Implementation example 1: fouling test method and steps:

[0038] Step 1: Based on the operating parameters of the oil field and using similar principles, calculate the pipeline pressure, flow rate and pipe diameter required for the experiment, and complete the design of the experiment scheme;

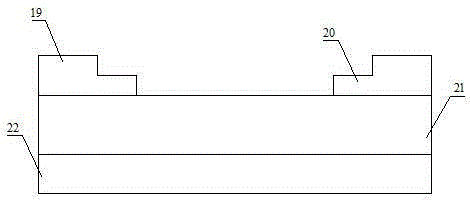

[0039] Step 2: Take two identical pipes as the first test tube 11 and the second test tube 17 respectively, and according to figure 2 The second test tube 17 is machined as shown;

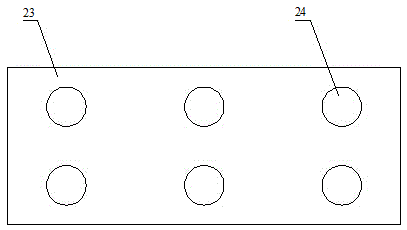

[0040] Step 3: Based on image 3 The processing cover plate 23 shown in the figure ensures a reasonable distance between adjacent Class A through-holes 24, and avoids the influence of the change of flow state on the formation and adsorption of scale crystals;

[0041] Step 4: processing and grouping the coupon samples 25, and grinding the coupon samples 25 with metallographic sandpaper of different meshes;

[0042] Step 5: cleaning, drying, and measuring the quality and wall thickness of the coup...

Embodiment 2

[0048] Implementation example 2: wax deposition experimental method and steps:

[0049] Step 1: Based on the operating parameters of the oil field and using similar principles, calculate the pipeline pressure, flow rate and pipe diameter required for the experiment, and complete the design of the experiment scheme;

[0050] Step 2: Take two identical pipes as the first test tube 11 and the second test tube 17 respectively, and according to figure 2 The second test tube 17 is machined as shown;

[0051] Step 3: Based on image 3 The processing cover plate 23 shown in the figure ensures a reasonable distance between the adjacent A-type through holes 24, and avoids the influence of the change of flow state on the formation and adsorption of wax crystals;

[0052] Step 4: processing and grouping the coupon samples 25, and grinding the coupon samples 25 with metallographic sandpaper of different meshes;

[0053] Step 5: cleaning, drying, and measuring the quality and wall thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com