Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Wax Solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraffin inhibitor compositions and their use in oil and gas production

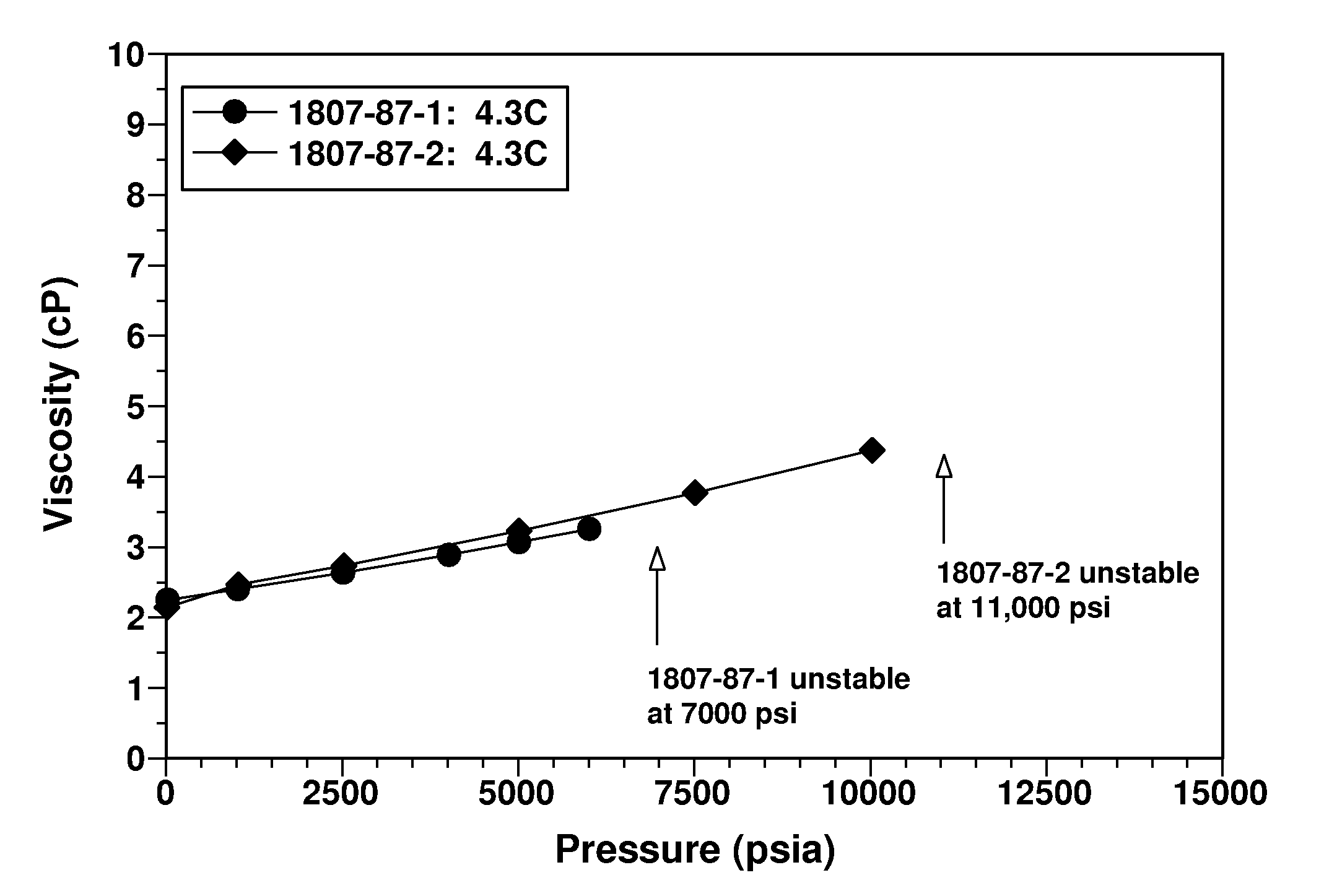

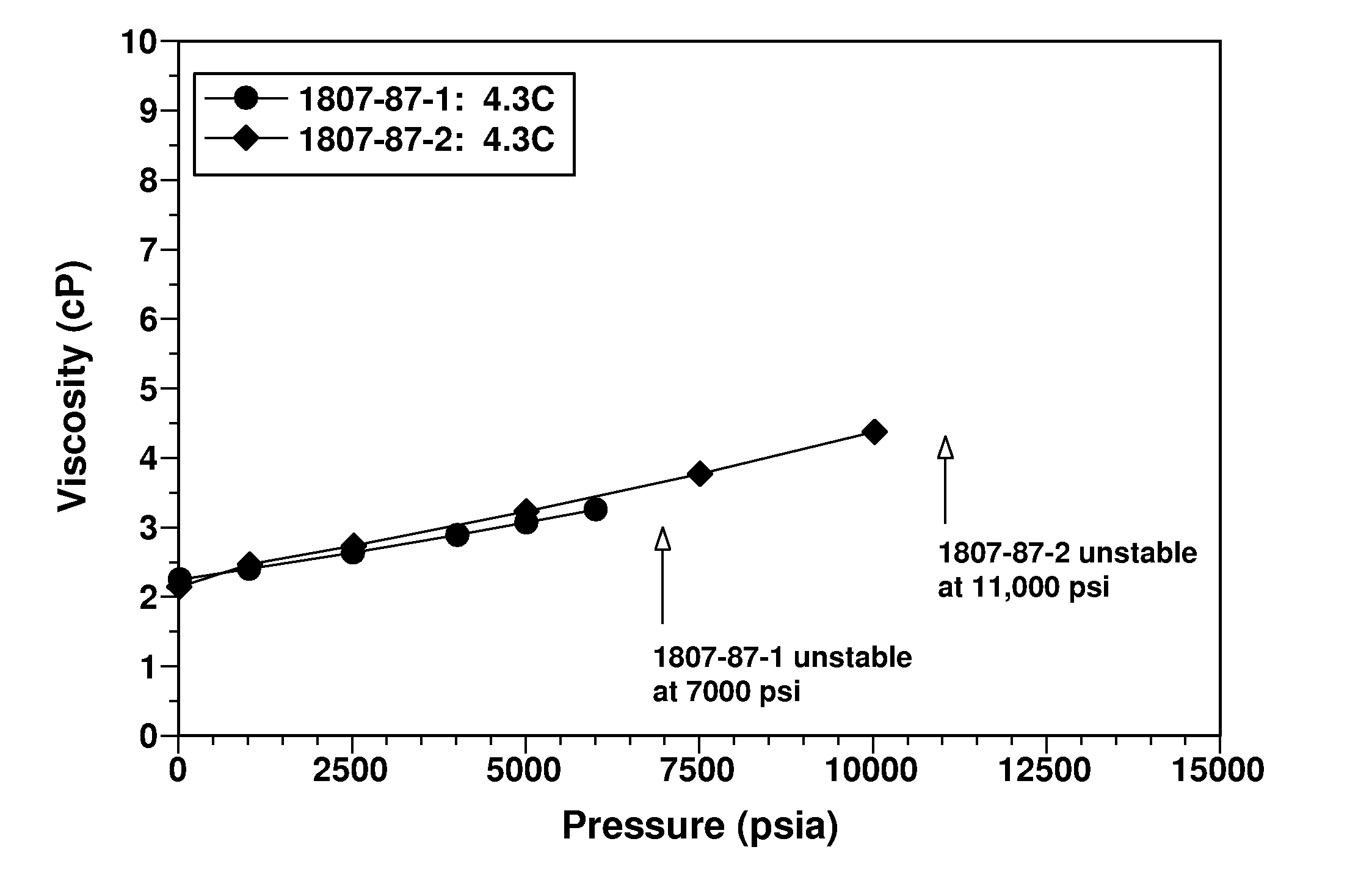

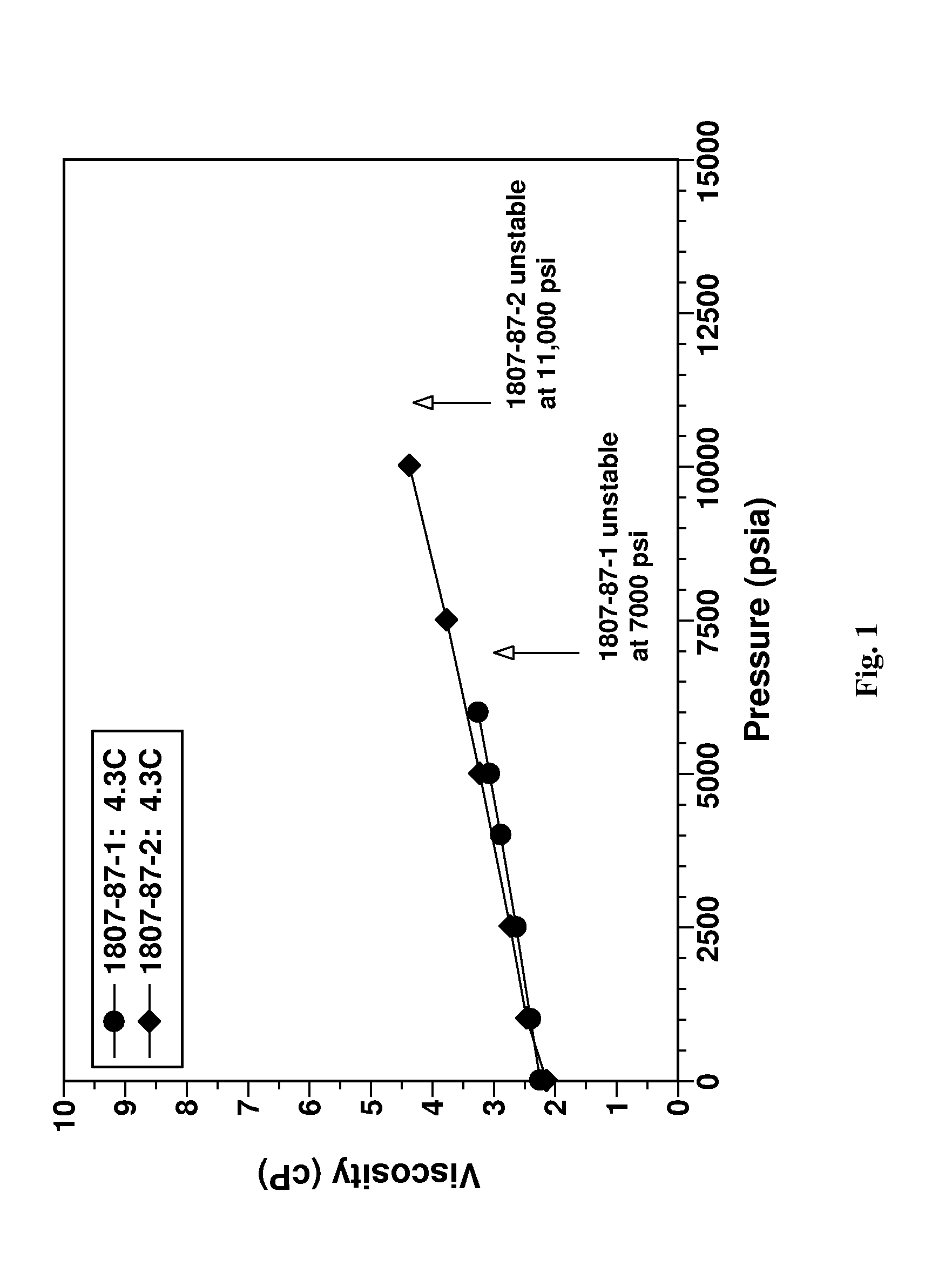

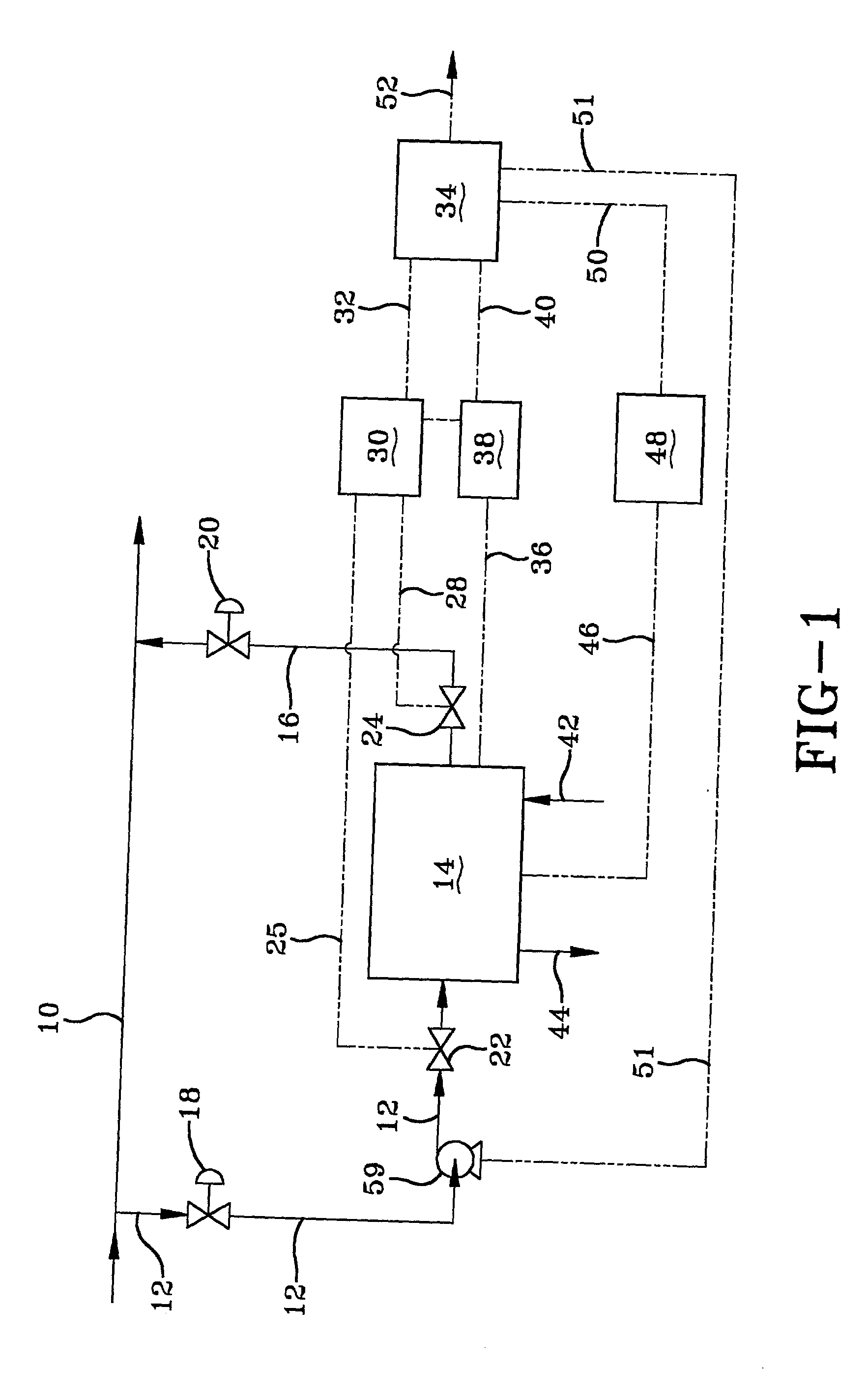

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

Paraffin Inhibitor Compositions and Their Use in Oil and Gas Production

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

Paraffin inhibitor compositions and their use in oil and gas production

InactiveUS20040058827A1Desirable utilityReciprocating drilling machinesOther chemical processesSolubilityParaffin wax

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone.

Owner:BAKER HUGHES INC

Glass wax solvent and adhesive wax cleaning method

PendingCN109370801AHigh cloud pointImprove emulsificationInorganic/elemental detergent compounding agentsCationic surface-active compoundsInorganic saltsAdhesive

The invention provides a glass wax solvent which comprises 2-6wt% of weakly alkaline inorganic salt, 3-6wt% of chelating agents, 10-25wt% of surfactants, 2-10wt% of cosolvents and the balance water. The surfactants are anionic surfactants and nonionic surfactants, and the weight ratio of the anionic surfactants to the nonionic surfactants is (2-8):(10-20). The glass wax solvent is designed according to characteristics of adhesive wax, a formula of the glass wax solvent is free from strongly alkaline auxiliaries such as sodium hydroxide and potassium hydroxide, the anionic surfactants and the nonionic surfactants are compounded, the turbidity point of the wax solvent can be increased under the combined action of the components of the wax solvent, and the emulsifying and cleaning capacity ofthe wax solvent can be improved. The invention further provides an adhesive wax cleaning method.

Owner:LENS TECH CHANGSHA

Wax solvent for cleaning magnesium alloy or aluminum alloy workpiece

The invention discloses a wax solvent for cleaning a magnesium alloy or aluminum alloy workpiece. The wax solvent is formed by mixing the following components in part by weight: 15 to 20 parts of triethanolamine, 20 to 30 parts of oleic acid, 6 to 10 parts of detergent agent, 8 to 12 parts of anionic surfactant, 10 to 15 parts of coconut diethanolamide, 3 to 6 parts of absolute ethanol and 2 to 5 parts of penetrant. The wax solvent has the wax removal efficiency of over 97 percent and is high in wax removal speed, and the using cycle (which is reflected by using frequency) of the wax solvent is prolonged, so that the working efficiency is effectively improved, and the production cost is obviously saved; and the wax solvent cannot corrode base materials.

Owner:GUANGDONG REDSUNSTAR IND

On-line determination of wax crystallization temperature of waxy solvent stream

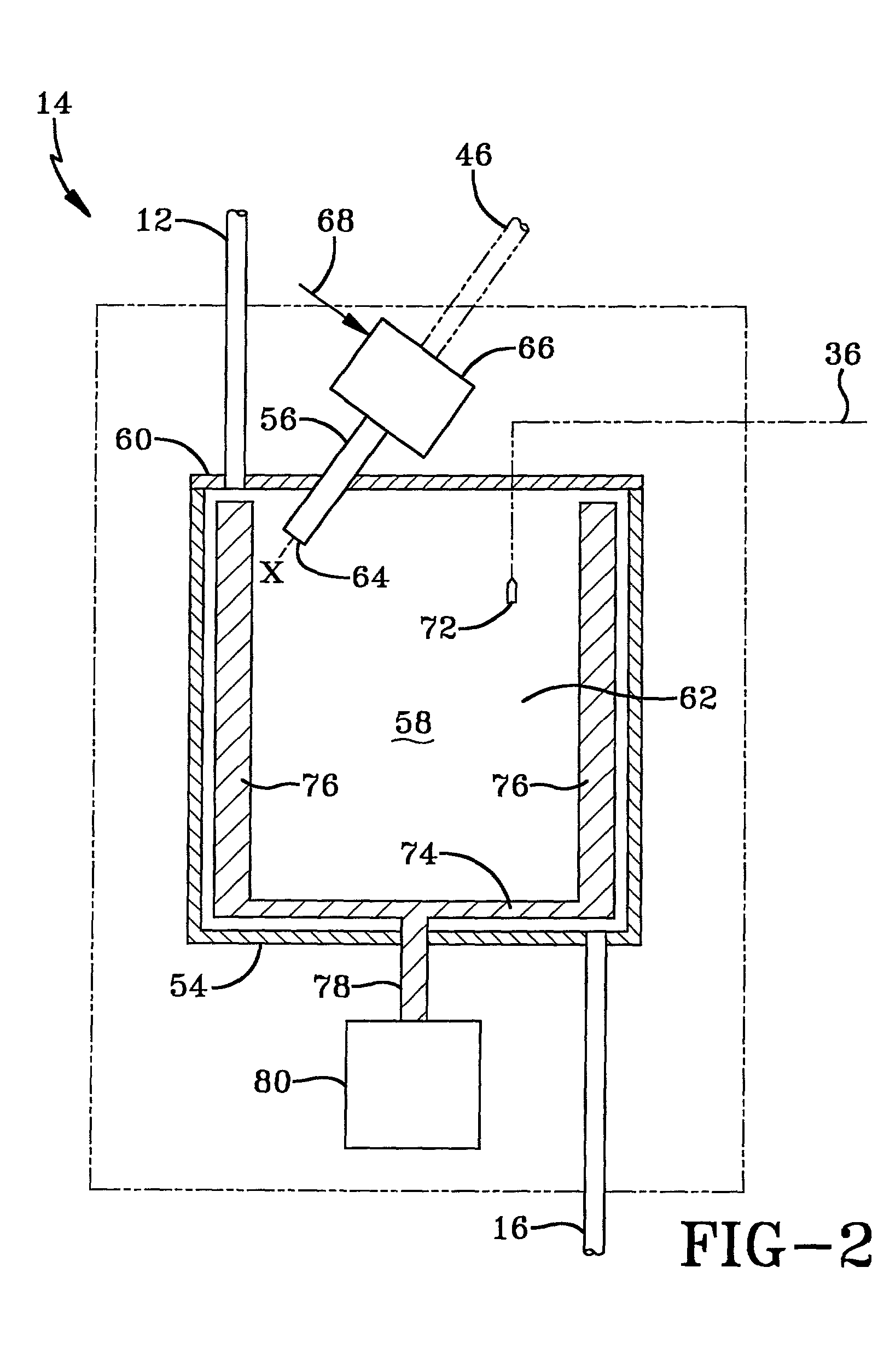

InactiveUS20030075478A1Material crystallisationScattering properties measurementsRemote controlCrystallization temperature

A laser beam reflected by wax crystals is used in determining the wax crystallization temperature of a hot dewaxing solvent upstream of solvent chillers. This is automatically achieved by an on-line method from a remote control point, in which a slipstream of solvent is passed through an attached solvent loop into a sample chamber in the loop, without being exposed to ambient conditions. As the sample is cooled, the beam reflections are detected and indicate the wax to crystallization temperature. Corrective measures can then be taken to prevent fouling of the chillers, if need be.

Owner:EXXON RES & ENG CO

Method for preparing white micro-crystalline wax

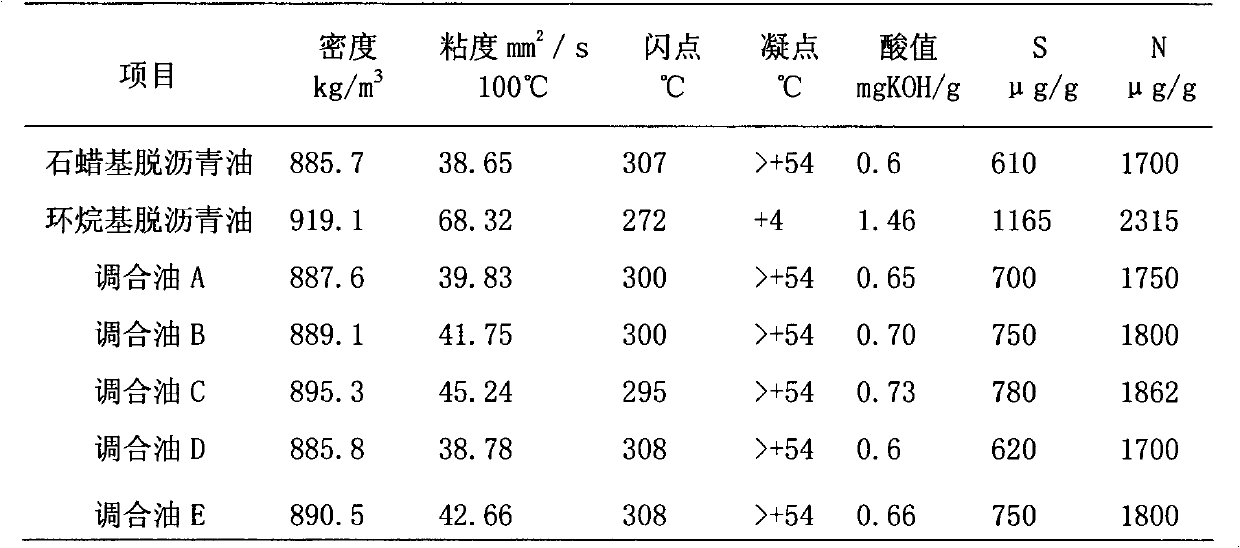

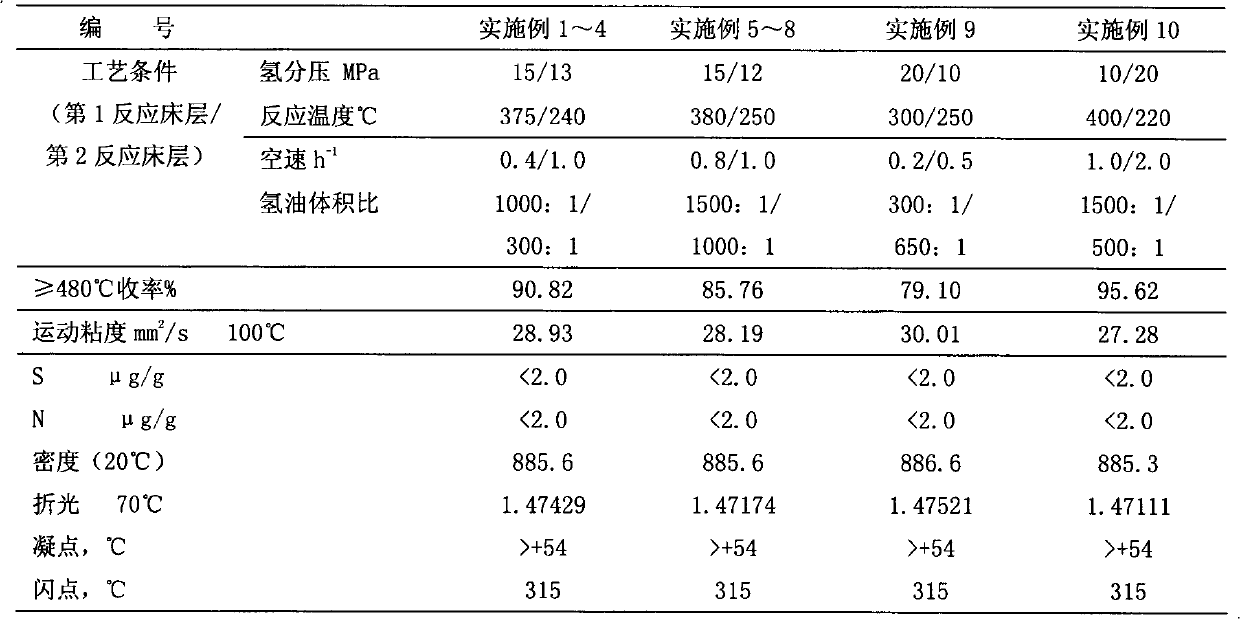

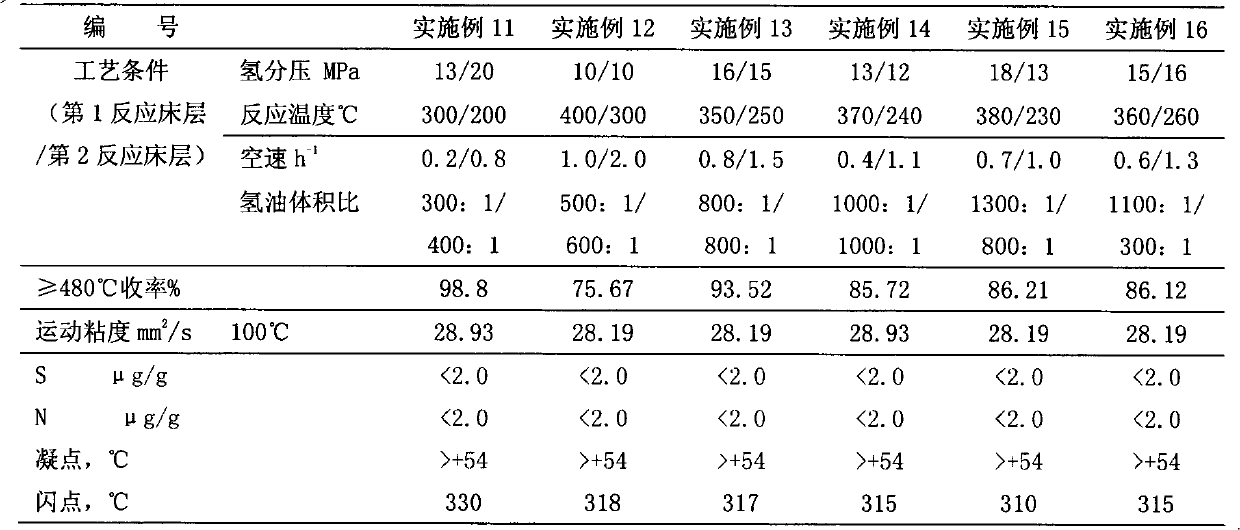

The invention relates to a method for preparing white micro-crystalline wax. The method comprises the following steps of: feeding blended oil of paraffin base vacuum residue deasphalted oil and naphthenic base vacuum residue deasphalted oil serving as a raw material into a first reaction bed to perform hydrogenation modification reaction and feeding the raw material into a second reaction bed to perform hydrorefining reaction; cutting the obtained hydrogenated oil by using an atmospheric and vacuum fractionation device to obtain a heavy lubricating oil component of between 480 and 750 DEG C; mixing the heavy lubricating oil component and an acetone benzol dewaxing solvent; cooling the mixture to below -15 DEG C; and filtering to obtain dewaxed filtrate and deoiled wax, wherein the deoiled wax is the white micro-crystalline wax; the Saybolt color number of the white micro-crystalline wax is +20; the drip melting point ranges from 77 to 82 DEG C; the penetration is 23 to 30 (1 / 10mm); the oil content ranges from 0.85 to 3.8 percent; the sulfur / nitrogen content is below 2mu g / g; the heavy metal content and arsenic content are less than 1mg / kg; and the product quality can reach SH0009-90 cosmetic-grade paraffin industry standard.

Owner:PETROCHINA CO LTD

Fischer-Tropsch synthetic wax as well as preparation method and preparation system thereof

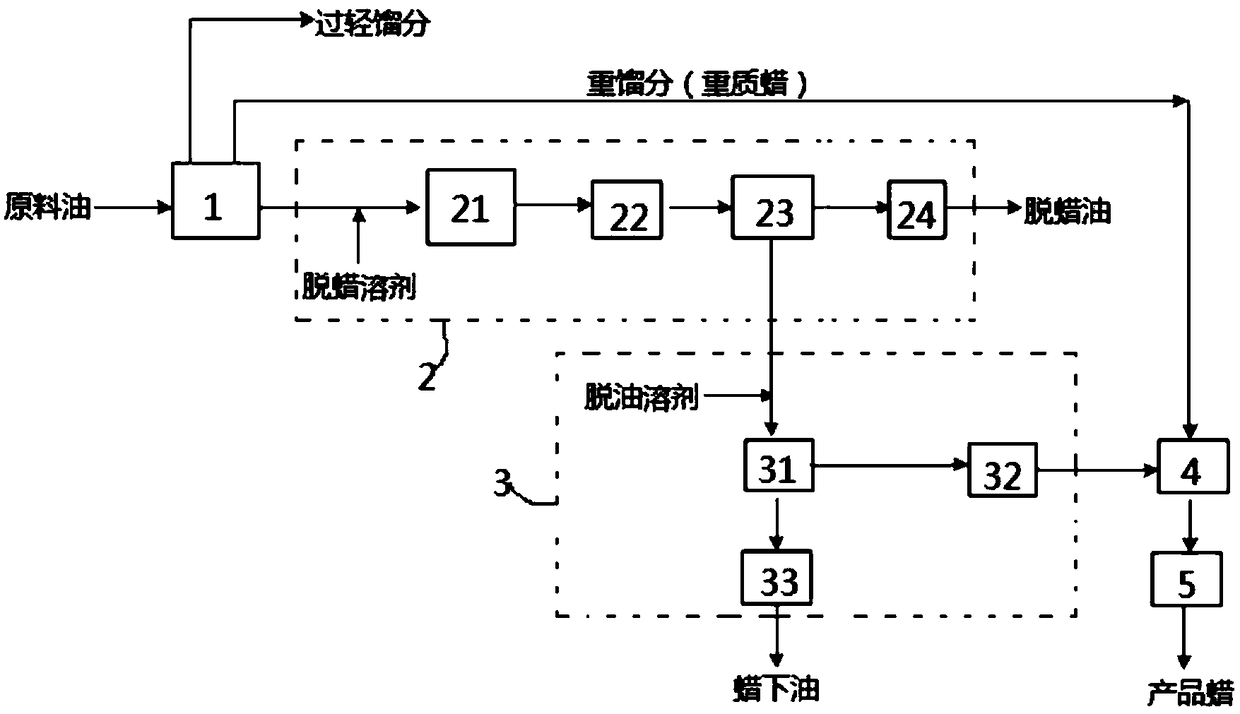

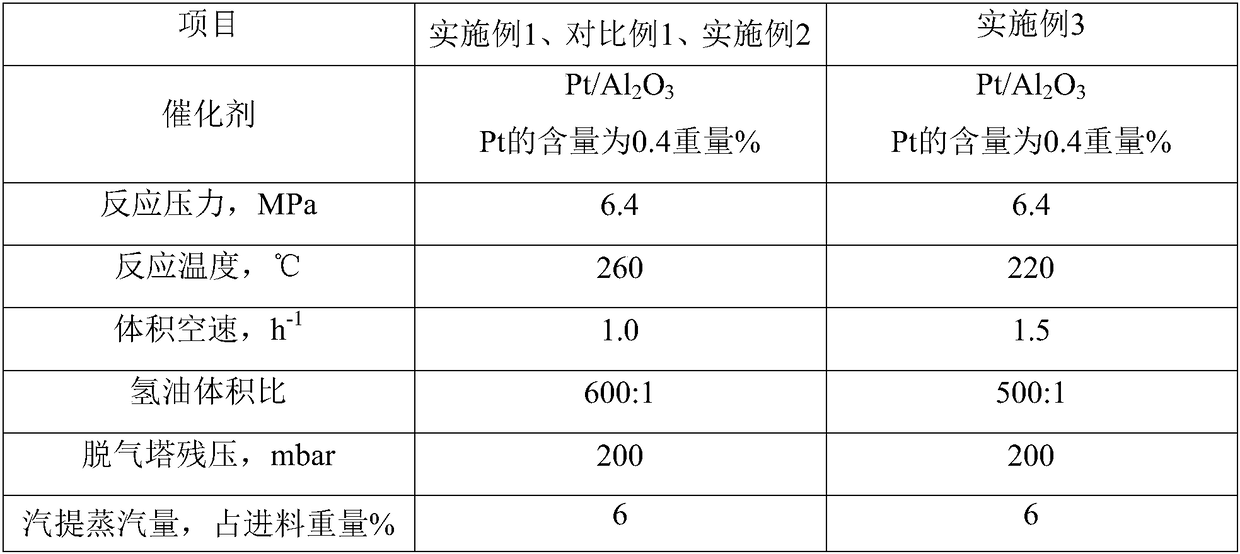

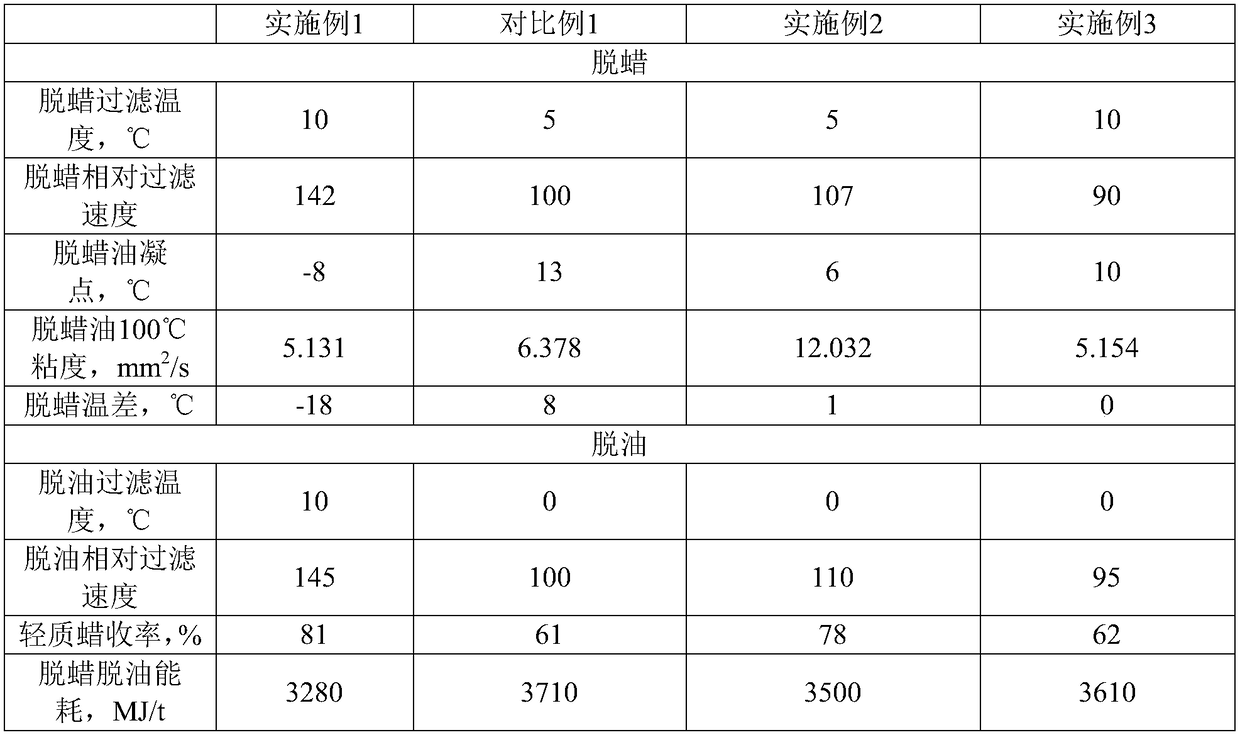

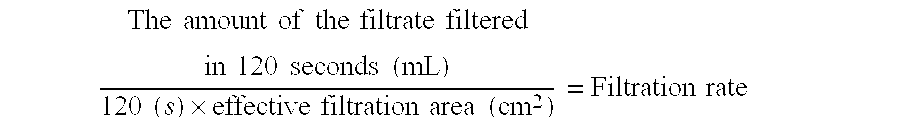

The invention relates to the field of Fischer-Tropsch synthetic wax, in particular to a Fischer-Tropsch synthetic wax as well as a preparation method and a preparation system thereof. The method comprises the following steps: pre-fractionating raw oil, collecting an over-light fraction with boiling point less than t, a light fraction with boiling point between t and t<f>, and a heavy fraction with boiling point more than t<f> to serve as heavy wax, and performing solvent dewaxing on the light fraction with a dewaxing solvent to obtain dewaxing oil and wax paste; performing solvent de-oiling on the wax paste with a de-oiling solvent to obtain light wax and wax oil; mixing the heavy wax and the light wax to obtain blended wax; and performing hydro-refining on the blended wax. The preparation method of the Fischer-Tropsch synthetic wax disclosed by the invention can simply prepare the Fischer-Tropsch synthetic wax with low oil content at high yield, and has the advantages of flexible quality control, low energy consumption in the production process and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

General electrolytic degreasing agent of precision electron member steel, stainless steel, aluminum, copper and zinc mixed workpiece

The invention discloses a general electrolytic degreasing agent of a precision electron member steel, stainless steel, aluminum, copper and zinc mixed workpiece, and the general electrolytic degreasing agent is characterized by comprising the following raw material: by mass, 0.5-1% of potassium hydroxide, 2-4% of sodium carbonate, 2-4% of trisodium phosphate, 3-5% of sodium tripolyphosphate, 2-4% of anhydrous potassium metasilicate, 1-2% of ethylenediamine tetraacetic acid disodium salt (EDTA-2Na), 2-4% of a strong alkali resistant electrolytic degreasing special low foam surfactant, 1-2% of a wax solvent special surfactant, 0.5-1% of penetrating agent JFC, 0.5-1% of a defoaming agent and the balance of water. The general electrolytic degreasing agent may not corrode electrolytic cleaning equipment, and can quickly and completely remove oils and fats on the surface of the precision electron member steel, stainless steel, aluminum, copper and zinc mixed workpiece within 1.5-3min.

Owner:DALIAN SANDAAOKE CHEM

Wax solvent for cleaning magnesium alloy or aluminum alloy workpiece

The invention discloses wax removal water for cleaning magnesium alloy or aluminum alloy workpieces. The wax removal water is prepared by mixing the following components in parts by weight: 15-20 parts of triethanolamine, 20-30 parts of oleic acid, and 6 parts of soap oil ~10 parts, 8~12 parts of anionic surfactant, 10~15 parts of coconut oil diethanolamide, 3~6 parts of absolute ethanol, 2~5 parts of penetrating agent. The wax removal efficiency of the wax removal water of the present invention reaches more than 97%, the wax removal speed is fast, and the service cycle (reflected in the number of uses) is increased, thereby effectively improving work efficiency and significantly saving production costs. The material is not corroded.

Owner:GUANGDONG REDSUNSTAR IND

Electrolytic ultrasonic united cleaning and removing agent for plastic die high temperature hardening plastic film residues

InactiveCN103740513AStrengthening effect is goodIncrease surface tensionSurface-active non-soap compounds and soap mixture detergentsOleic Acid TriglycerideSodium hydroxide

The invention discloses an electrolytic ultrasonic united cleaning and removing agent for plastic die high temperature hardening plastic film residues, the electrolytic ultrasonic united cleaning and removing agent comprises the following raw materials: by mass, 5-10% of potassium hydroxide, 5 ~10% of sodium hydroxide, 3-5% of ethylenediaminetetraacetic acid disodium salt, 3-5% of oleic acid triethanolamine, 3-5% of diethylene glycol monobutyl ether, 3 ~5% of dipropylene glycol methyl ether, 6-8% of acetone, 1-2% of a carbon deposit removing surfactant, 1-2% of a wax solvent special surfactant, 1-2% of a strong alkali resistant electrolytic degreasing special low foaming surfactant, 0.1-1% of a defoaming agent and the balance of water. The electrolytic ultrasonic united cleaning and removing agent can be generally used in electrolytic and ultrasonic cleaning, is convenient to use, and does not contain hydrochloric acid, sulfuric acid or oxalic acid and other strong corrosive acids, the selected additives, corrosion inhibitors and the like are reasonable in matching, the electrolytic ultrasonic united cleaning and removing agent has optimal effective pickling solution concentration, additive strengthening effect, surface tension, viscosity coefficient, vapour pressure in ultrasonic equipment, and the like, can avoid corrosion of electrolytic and ultrasonic stainless steel cleaning equipment, and can quickly and completely remove the plastic die high temperature hardening plastic film residues.

Owner:DALIAN SANDAAOKE CHEM

Novel dewaxing aid

The present invention relates to dewaxing aids comprising the mixture of two or more polyalkyl(meth)acrylates having an exothermic heat initiation temperature within the specific range when chilled at 30° C. / minute rate, to be added together with the wax-containing hydrocarbon oil to the dewaxing solvent. The dewaxing aid according to the present invention can be used in the solvent dewaxing method containing the stage in which the chilling rate during the chilling is 30° C. / minute or higher, is effective for heavy type wax-containing hydrocarbon oils, and is chlorine-free.

Owner:TOHO CHEM IND

Ultrasonic wave cleaning agent for body of stainless steel electric kettle and production method

InactiveCN102586789AGood additive strengthening effectIncrease surface tensionCleaning using liquidsPhosphoric acidSurface-active agents

The invention discloses an ultrasonic wave cleaning agent for a body of a stainless steel electric kettle. The ultrasonic wave cleaning agent comprises the following raw materials according to mass percents: 1-8% of phosphoric acid, 2-12% of citric acid, 1-3% of oxalic acid, 1-6% of butanone, 2-4% of surface active agent special for removing a wax solvent, 2-4% of surface active agent special for removing oil and wax, 61-3% of NP, 1-4% of organic silicon deforming agent and the rest of water. The production method comprises the following steps of: adding a calculated amount of water to a reaction kettle, starting a stirrer, controlling a revolving speed to be 120 / min, and then sequentially adding the calculated amount of phosphoric acid, citric acid, oxalic acid, butanone, surface active agent special for removing a wax solvent and surface active agent special for removing oil and wax to the reaction kettle, stirring while adding the raw materials till when a solution is a uniformly transparent liquid, emptying and packaging.

Owner:DALIAN SANDAAOKE CHEM

Mechanical antiwear restoration lubricant

The invention discloses a mechanical antiwear restoration lubricant which comprises the following components in parts by weight: 1-9 parts of wax solvent, 14-25 parts of pickling agent, 1-3 parts of phosphating solution, 1-3 parts of passivation solution, 1-3 parts of vitrification agent, 4-8 parts of calcium hydroxide, 7-10 parts of barium hydroxide octahydrate, 7-16 parts of sodium hydroxide, 5-16 parts of potassium nitrate, 7-15 parts of sodium nitrate, 2-4 parts of sodium sulfite, 1-3 parts of dispersant, 1-3 parts of thickener, 4-6 parts of flame retardant, 4-8 parts of stearic acid, 7-14 parts of stearate, 4-15 parts of stearamide, 1-3 parts of silicon oil and 4-10 parts of oleamide. The invention has the advantages of favorable use effect under high-temperature high-speed working conditions, no toxic or side effect and low manufacturing cost, and can be widely used.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Preparing method for steel component wax solvent

The invention discloses a preparing method for a steel component wax solvent, and belongs to the field of wax solvents. Paraffin thirsty bacteria are mainly cultivated and can metabolize, so that a biological surface active agent, an organic solvent and other substances with surface activity are generated, meanwhile, polyvinyl alcohol is utilized as a carrier, and after an additive is added in a water solution of the polyvinyl alcohol, gelatinization happens, and accordingly, microorganisms are embedded and fixed in the gel network; and sodium alginate is added so that ballability of the carrier can be improved; the carrier surface property can be improved through calcium alginate generated through the reaction of the sodium alginate and calcium salt, the gel strength is improved, and accordingly, the microorganisms are more effectively protected; and the calcium alginate can be diffused in the gel network along with proceeding of the reaction, the carrier structure is further optimized, growing and breeding of the microorganisms are facilitated, and accordingly, the dewaxing effect of the wax solvent is further enhanced. The preparing method solves the problems that due to a current existing wax solvent, the original color of the surface of a steel component is prone to being corroded, and the wax solvent is single in dewaxing function.

Owner:闫博文

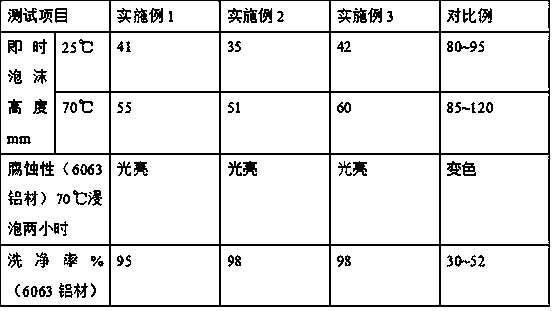

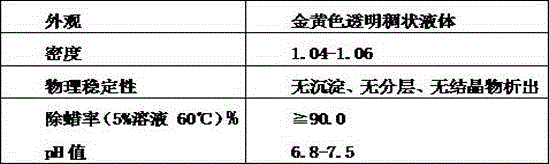

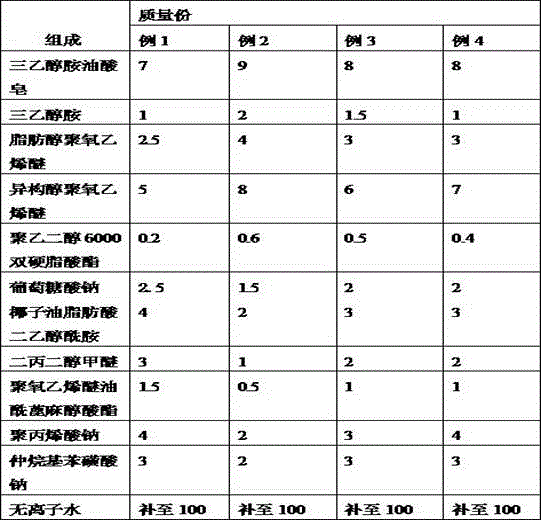

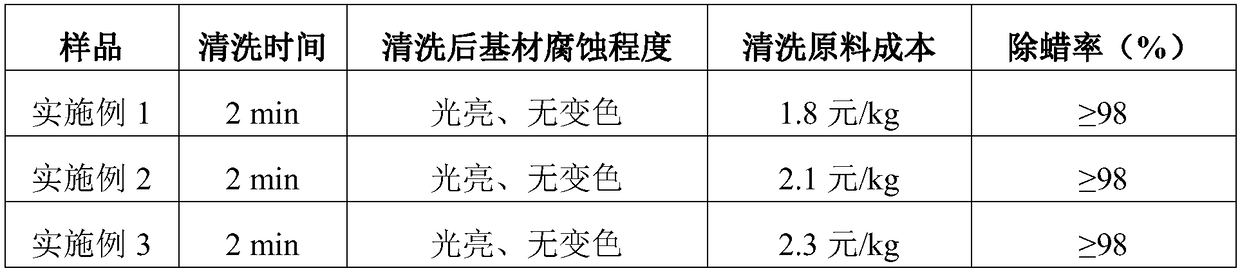

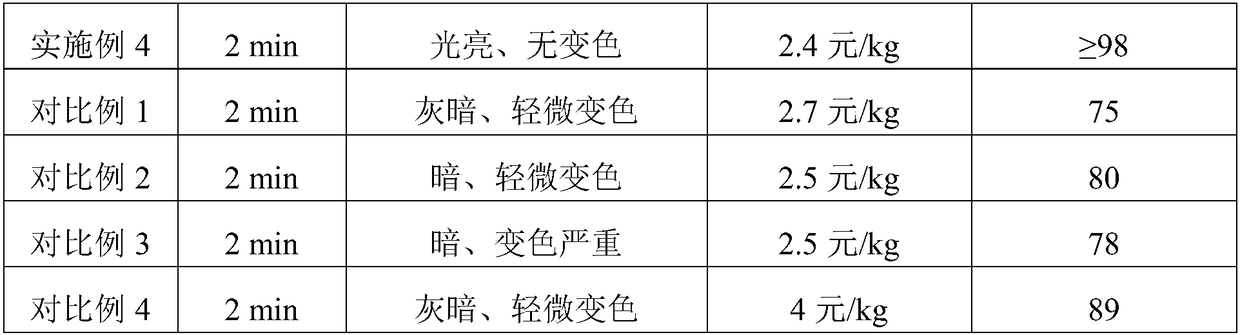

Efficient wax solvent of metal workpiece and preparation method thereof

The invention provides an efficient wax solvent of a metal workpiece and a preparation method thereof. The efficient wax solvent of the metal workpiece comprises the following components in percentage by mass: 8% of triethanolamine oleate, 3% of fatty alcohol-polyoxyethylene ether, 1-2% of triethanolamine, 6% of alcohol alkoxylate, 0.5% of polyoxyethylene glycol(6000) distearate, 2% of sodium gluconate, 3% of coconutt diethanol amide, 2% of dipropylene glycol methyl ether, 1% of polyoxyethylene ether oleoyl ricinoleate, 3% of sodium polyacrylate, 3% of sodium alkylbenzene sulfonate, and the balance deionized water. The efficient wax solvent of the metal workpiece shows good wax removing effect on various metal parts and non-ferrous metal part products; the efficient wax solvent shows good corrosion inhibition and oxidation prevention effects while being used for removing wax of the parts, so that the original color and luster of the metal surface can be protected. The efficient wax solvent of the metal workpiece is extremely high in wax removing capacity, high in efficiency, simple in preparation process, low in cost, low in working temperature, and good in effect.

Owner:江西瑞思博新材料有限公司

Traceless washing-free wax solvent for vehicle

InactiveCN102965220ASave water and electricity resourcesSave electricity resourcesSurface-active non-soap compounds and soap mixture detergentsAlkylphenolFatty alcohol

The invention relates to a traceless washing-free wax solvent for a vehicle, which is prepared from the following raw materials in parts by weight: 10-20 parts of hydrofluoric acid, 15-25 parts of oxalic acid, 1-5 parts of palm wax, 5-10 parts of sodium silicate, 5-10 parts of surfactant AES, 3-8 parts of acetone, 3-8 parts of alkylphenol polyoxyethylene ether TX-10, 1-5 parts of sodium chloride, 1-5 parts of sodium benzoate, 3-8 parts of sodium tripolyphosphate, 1-5 parts of fatty alcohol polyoxyethylene ether AEO-9 and a right amount of pigment and essence. A processing method of the wax solvent comprises the following steps: 1) dissolving the palm wax in the acetone, heating to 50 DEG C, then adding the AES and AEO-9, and thoroughly dissolving; 2) dissolving the sodium tripolyphosphate in the hydrofluoric acid, and then dissolving the TX-10 in the sodium tripolyphosphate and hydrofluoric acid mixed solution; 3) mixing the mixed solutions obtained in the steps 1) and 2), thoroughly stirring until the solutions are completely mixed, then sequentially adding the sodium silicate, sodium chloride, pigment and essence, stirring, and standing; and 4) standing until foam is eliminated, and filling to obtain the finished product, wherein the finished product needs to be used after being diluted in water according to a ratio of 1:100. Thus, the wax solvent provided by the invention has the advantages of low cost and simple manufacturing process, and is convenient, quick and energy-saving to use.

Owner:邹品生

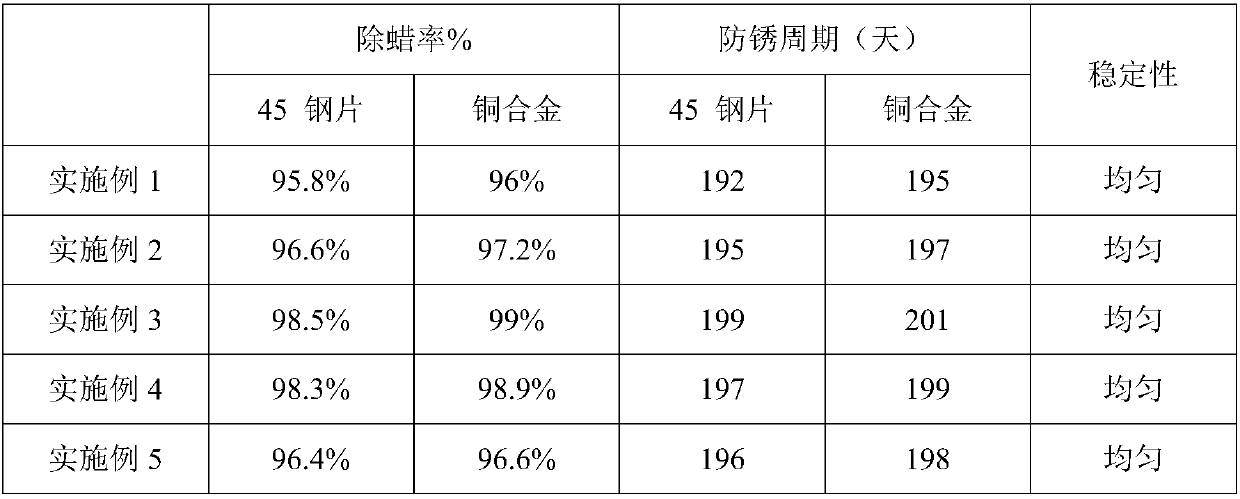

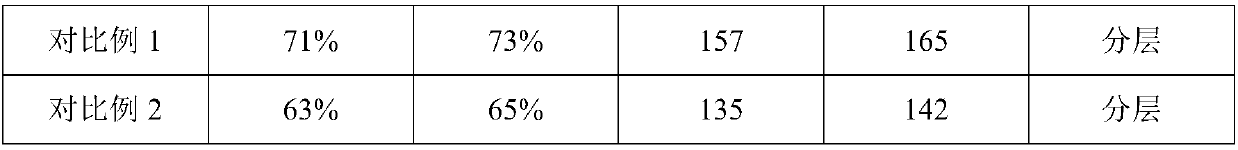

Wax solvent for cleaning steel pieces or copper pieces and preparation method of wax solvent

InactiveCN107604368AImprove wax removal effectClean up thoroughlyDiethylenetriamineOleic Acid Triglyceride

The invention discloses a wax solvent for cleaning steel pieces or copper pieces and a preparation method of the wax solvent and relates to the technical field of metal surface treatment. The wax solvent is prepared from, by weight, 15-25 parts of diethylenetriamine, 8-16 parts of monoethanolamine, 4-12 parts of triethanolamine, 10-20 parts of coconut oil fatty acid diethanolamide, 2-8 parts of methyl alcohol, 15-25 parts of oleic acid, 2-10 parts of nonylphenol polyoxyethylene ether and 10-18 parts of water. The wax solvent has the good wax removing effect on the steel pieces and the copper pieces, has very high solubilizing and dispersing ability and can completely remove wax scales on the workpiece surfaces in a short time, and the wax removing efficiency reaches more than 95%; and meanwhile, a layer of protective film is formed on the surface of each steel piece and each cooper piece by the wax solvent, the corrosion inhibition is achieved, and therefore the antirust period is long.

Owner:宁波际超新材料科技有限公司

Deep oil leakage acid stripping agent before Zn and Fe alloy sheet material workpiece spray cleaning

The invention discloses a deep oil leakage acid stripping agent before Zn and Fe alloy sheet material workpiece spray cleaning, the deep oil leakage acid stripping agent comprises the following raw materials: by mass, 4-8% of phosphoric acid with a concentration of 85%, 1-2% of citric acid, 1-2% of potassium sodium tartrate, 1-3% of sodium dihydrogen phosphate, 0.1-1.5% of ethylene glycol monobutyl ether, 0.1-0.6% of a soaking degreasing oil cleaning special surfactant, 0.1-0.6% of a carbon deposition removing surfactant, 0.1-0.6% of a wax solvent special surfactant, 0.5-1% of penetrating agent JFC and the balance of water. Before spray cleaning, the deep oil leakage acid stripping agent is in advance sprayed on to workpiece surface by an artificial plastic pressure watering can, after 10-20min of placing, a workpiece is hung onto a pretreatment automatic spray line, then deep oil leakage on a Zn and Fe alloy sheet material workpiece can be quickly and completely stripped to meet the technical requirements of spray painting.

Owner:DALIAN SANDAAOKE CHEM

Paint Stripping Compositions

ActiveUS20140206590A1Improve performanceSurface-active detergent compositionsChemical paints/ink removersEtherAlloy

An environmental safety paint stripping composition comprising dichloroethylene, aromatic alcohols and ethers, surfactants, corrosion inhibitors, thickeners, wax solvents and water. This paint stripping composition is particularly useful in stripping paint and other polymeric coatings from metal substrates such as aluminum and it alloys.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

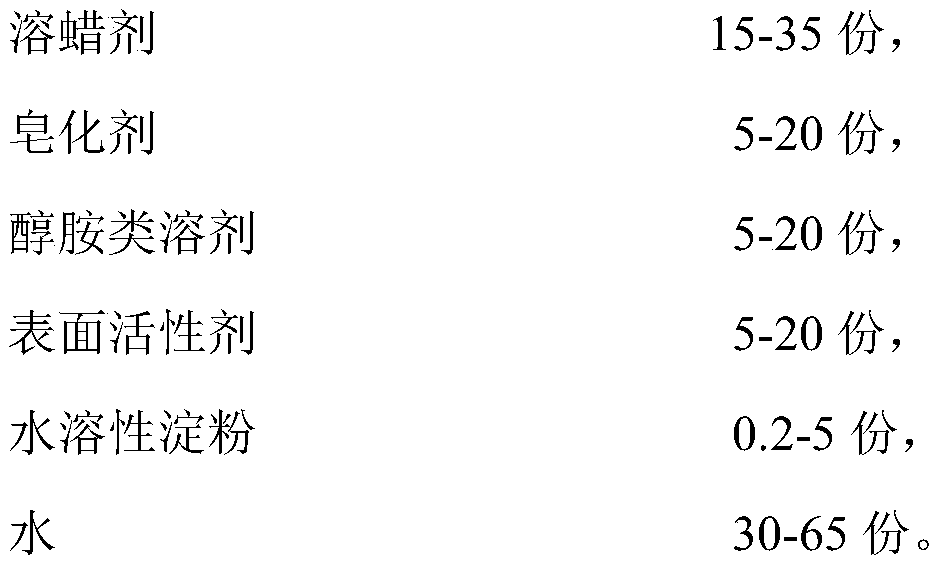

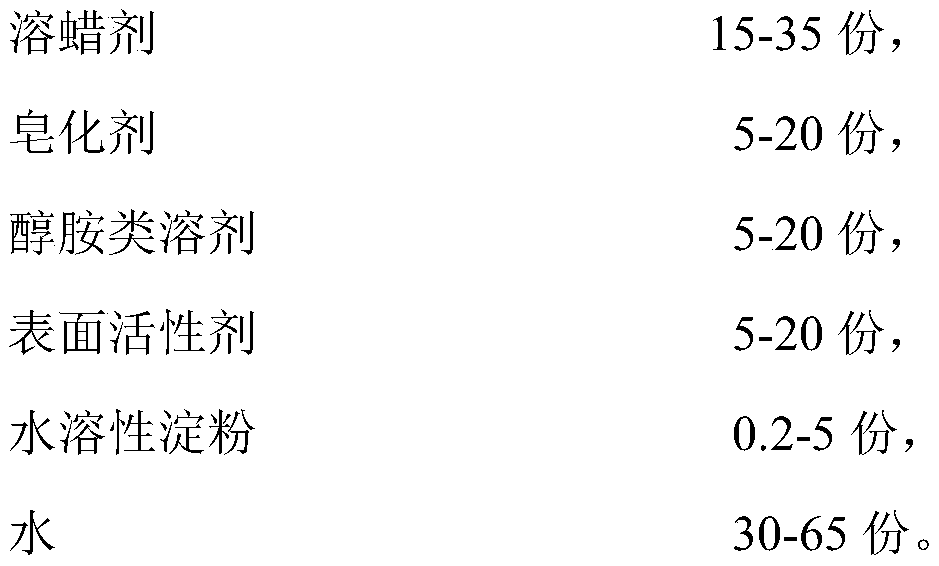

Stainless steel spray wax solvent and preparation method thereof

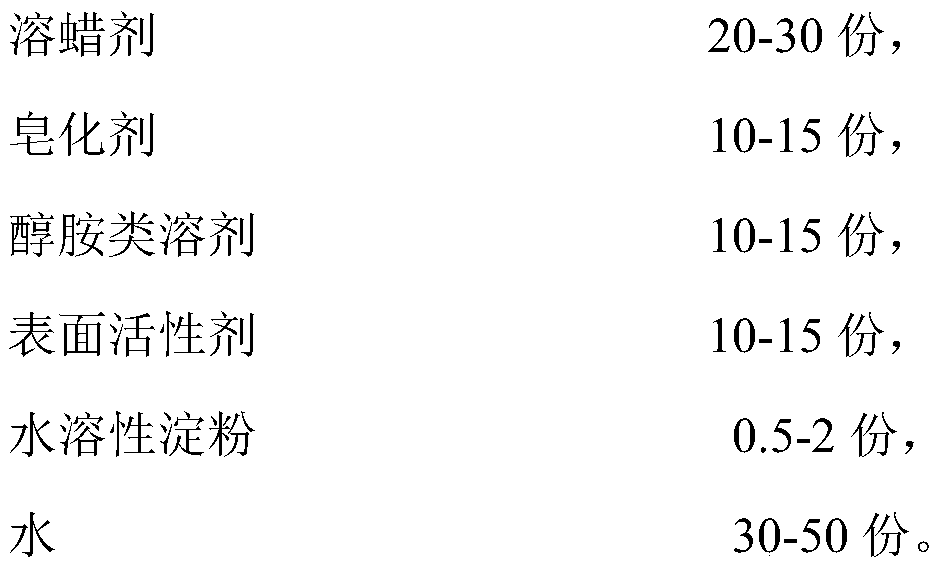

At present, the normal use temperature of a conventional wax solvent is far higher than the temperature maintained by an automatic spray line wax removal tank, so that the wax removal effect is not fully exerted, and the economic benefit is affected. The invention discloses a stainless steel spray wax solvent which is suitable for spraying under a low-temperature condition and has good wax removaleffect. The stainless steel spray wax solvent comprises, by weight, 15-35 parts of a wax dissolving agent, 5-20 parts of a saponifier, 5-20 parts of an alcohol amine solvent, 5-20 parts of a surfactant, 0.2-5 parts of water-soluble starch and 30-65 parts of water. Compared with the prior art, different raw materials, proportioning and manufacturing processes are adopted, and the wax dissolving agent with strong permeability and the surfactant are combined, so that the wax solvent has excellent wax removal effect while keeping low foam, the low-temperature wax removal effect is thorough, the use period is longer, the working efficiency is effectively improved, and the productivity is improved.

Owner:GUANGDONG REDSUNSTAR IND

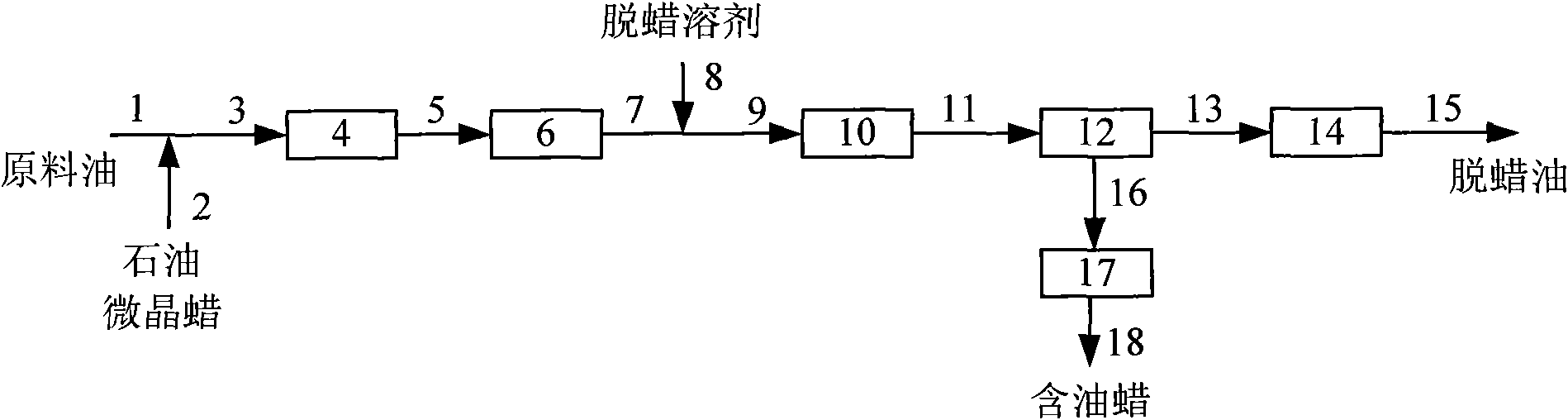

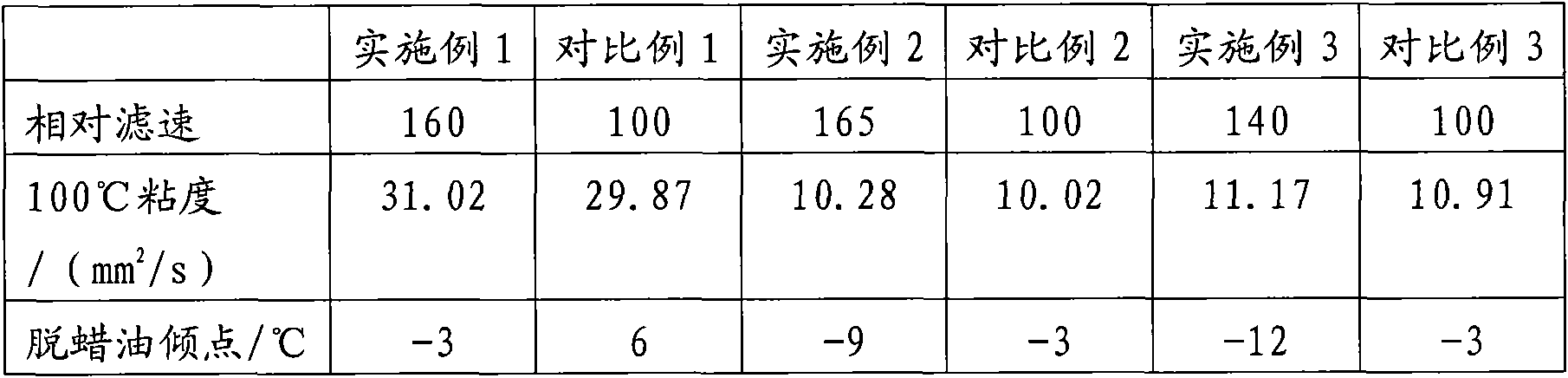

Solvent dewaxing method for low waxy hydrocarbon oil

ActiveCN103468305AReduce filtration performanceIncrease the frequency of warm washingTreatment with plural serial refining stagesMineral wax recovery/refiningMicrocrystalline waxPetroleum oil

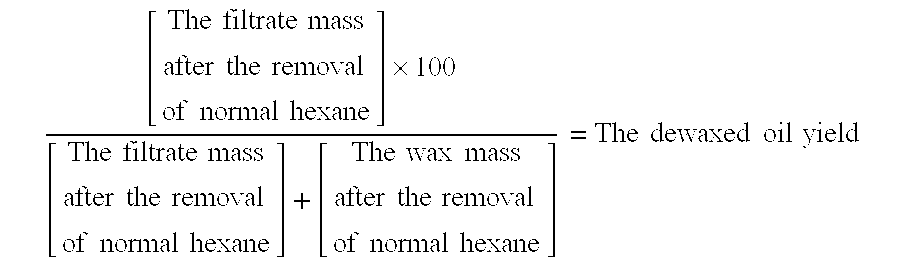

The invention relates to a solvent dewaxing method for low waxy hydrocarbon oil. The method includes mixing raw oil of a crude oil vacuum distillate fraction section, petroleum microcrystalline wax and a dewaxing solvent, cooling the mixture to a filtering temperature, filtering to obtain filtrate and cerate, and removing the solvent from the filtrate to obtain dewaxed oil, wherein the drop melting point of the petroleum microcrystalline wax is 67 DEG C to 92 DEG C, the mass ratio of the petroleum microcrystalline wax to the raw oil ranges from 0.005:1 to 0.2:1. Though use of the solvent dewaxing method, wax in the low waxy hydrocarbon oil can be more effectively removed, the dewaxing temperature difference can be reduced and the filtering speed can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

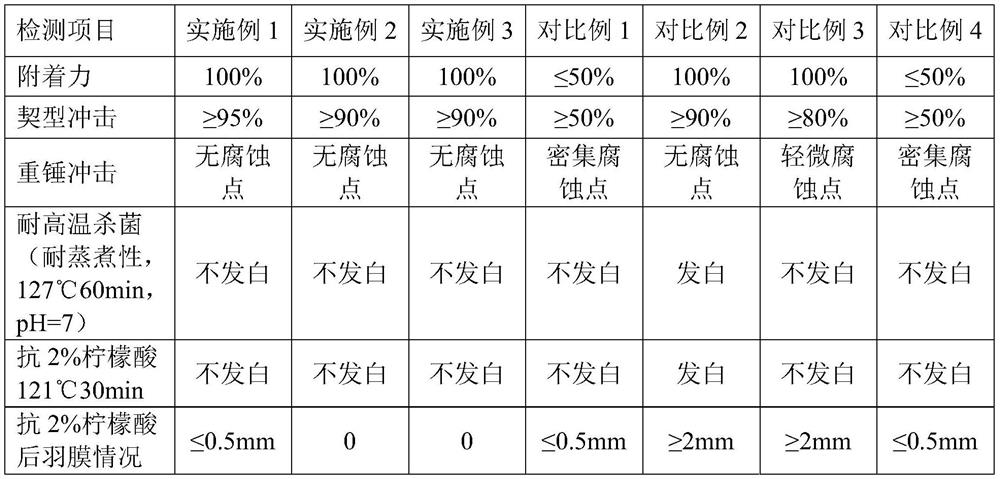

Coiled material coating and preparation method thereof

InactiveCN114133833AHigh activityHigh molecular weightEpoxy resin coatingsPolymer sciencePolymer chemistry

The invention relates to the technical field of coatings, in particular to a coil coating and a preparation method thereof. The coiled material coating is prepared from the following components: epoxy liquid, an acid catalyst, bisphenol A phenolic resin, tert-butyl phenol / bisphenol A mixed modified phenolic resin, highly alkyl etherified benzomelamine resin, a defoaming agent, a flatting agent, wax, a solvent, toning phenolic aldehyde and an adhesion promoter, the coating has the advantages of being good in adhesive force, high in impact resistance, resistant to high-temperature boiling, resistant to acid and small in feather film.

Owner:江苏扬瑞新材料有限公司

Wax solvent for metal workpiece and preparation method of wax solvent

InactiveCN109385639AImprove performanceImprove market competitive advantagePotassium hydroxideWax removal

The invention provides a wax solvent for a metal workpiece. The wax solvent per liter comprises 20 to 30 g of Tween 80, 20 to 30 g of sodium carbonate, 30 to 40 g of triethanolamine, 20 to 40 g of sodium tripolyphosphate, 10 to 30 g of EDTA disodium, 0.5 to 1 g of sodium hydroxide, 180 to 240 g of a composite surfactant and the balance of water. The invention further provides the preparation method of the wax solvent. The preparation method comprises the following steps: firstly, adding part of water into a stirring kettle, heating to 45 to 50 DEG C, and then sequentially adding the Tween 80,the sodium carbonate, the triethanolamine, the sodium tripolyphosphate, the EDTA disodium, the sodium hydroxide and the composite surfactant, finally adding water to a required amount, and stirring the materials uniformly. Compared with commercially available mainstream products in the prior art, the wax solvent provided by the invention has a better wax removal effect, creates a great market competitive advantage for the enterprise, and is high in wax removal speed, long in use period and replacement cycle and relatively low in production cost.

Owner:长沙瑞联材料科技有限公司

Neutral de-waxing degreasing agent used for steel and copper workpieces after polishing and production method thereof

The invention discloses a neutral de-waxing degreasing agent used for steel and copper workpieces after polishing. The neutral de-waxing degreasing agent used for steel and copper workpieces after polishing is characterized in comprising following raw materials, by mass, 8 to 12% of sodium tripolyphosphate, 0.1 to 0.2% of sodium dodecyl sulfate, 6 to 8% of sulfuric acid, 2 to 3% of a wax solvent special-purpose surfactant, 2 to 3% of an accumulated carbon removing surfactant, 2 to 3% of NP-6, 1 to 2% of penetrant JFC, and the balance water. A production method comprises following steps: a powder production stirrer is turned on, according to operating instructions of powder production stirring, weighed sodium tripolyphosphate, and sodium dodecyl sulfate are delivered into the powder production stirrer successively and slowly with stirring; after uniform mixing of an obtained solid product, weighed the wax solvent special-purpose surfactant, the accumulated carbon removing surfactant, NP-6, penetrant JFC, and water are delivered into the powder production stirrer successively and slowly until uniform mixing is realized; and an obtained product is collected and packaged.

Owner:DALIAN SANDAAOKE CHEM

High-efficiency grinding material for semiconductor material chips

InactiveCN103436226AReduce wear rateImprove stabilityOther chemical processesSemiconductor materialsSemiconductor chip

The invention discloses a high-efficiency grinding material for semiconductor material chips, which comprises the following components in parts by weight: 1-9 parts of wax solvent, 14-25 parts of pickling agent, 1-3 parts of phosphating solution, 1-3 parts of passivation solution, 1-3 parts of vitrification agent, 4-8 parts of calcium hydroxide, 7-10 parts of barium hydroxide octahydrate, 7-16 parts of sodium hydroxide, 7-10 parts of potassium sodium tartrate, 7-9 parts of hydrogen peroxide, 1-3 parts of zinc sulfate, 2-4 parts of magnesium sulfate, 3-8 parts of calcium stearate, 4-13 parts of stearic acid and 1 part of dispersant. The chemical mechanical grinding material for semiconductor chips has the advantages of lower dielectric layer wear rate and lower corrosivity, can promote the stability of grinding granules, and remains higher tungsten removal rate. Since the action intensity of mechanical fornce is relatively lowered, the problems of pit, corrosion, loss of the dielectric layer and the like are reduced.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Wax solvent and preparation method thereof

The invention provides a wax solvent. The wax solvent is prepared from, by weight, 10-20 parts of NP-10, 5-25 parts of AEO9, 5-25 parts of triethanolamine, 5-25 parts of monoethanolamine, 5-25 parts of sulfonic acid, 5-25 parts of coconut oil, 5-15 parts of oleic acid and 10-30 parts of a detergent. The wax solvent is prepared through the following steps that triethanolamine, monoethanolamine, sulfonic acid, oleic acid and the detergent are dissolved into water according to the measurement, stirring is conducted until the solution is uniform, NP-10 and AEO9 are added, warming is conduced to reach 60 DEG C, the coconut oil is added under high-speed stirring, stirring is conducted until the mixture is uniform, then cooling is conducted, and the wax solvent is obtained. The prepared wax solvent has the advantages of being low in dosage, good in effect, rapid in wax removal speed, wide in raw material source, simple in making method, easy to operate and the like; meanwhile, the wax solventdoes not combust, storage is easy, and convenience is brought to transportation.

Owner:广州市骏辉环保科技有限公司

Preparation method of polyaniline conductive film

The invention discloses a preparation method of a polyaniline conductive film. Specific preparation steps comprise: 1) preparation of an aqueous solution of an initiator; 2) preparation of a compositesilane solution; 3) preparation of organic modified calcium carbonate; 4) preparation of a wax solvent; 5) preparation of a polyaniline solution; 6) preparation of modified polyaniline; and 7) preparation of the polyaniline conductive film. During the polymerization process of aniline, an acid doping agent is introduced, thus effectively enhancing conducting stability of the polyaniline product.Meanwhile, by adding t-butyl, storage stability of the film can be enhanced.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Wax solvent for steel polishing workpieces and preparation method thereof

The invention relates to a wax solvent for steel polishing workpieces. One liter of wax solvent is prepared from the following raw materials in parts by weight: 50-70g of sodium hydroxide, 150-160g ofmonoethanolamine, 20-50g of sodium tripolyphosphate, 5-15g of EDTA disodium, 180-240g of composite surfactant and the balance of water, and one liter of wax solvent further is prepared from 160-180gof hydrolytic agent, wherein the hydrolytic agent is vegetable oil acid, the surfactant is sodium alcohol ether sulphate, nonyl phenol polyoxyethylene ether and fatty acid methyl ester ethoxylate. A preparation method comprises the following steps of adding part of water into a stirring kettle, heating to 60-70 DEG C; adding the sodium hydroxide, monoethanolamine, sodium tripolyphosphate, EDTA disodium and surfactant in sequence; adding water till a desired volume and stirring uniformly. The wax solvent can remove 97% or more wax, can remove wax rapidly, is available for 150 times, reduces production cost remarkably, and brings a great market competitiveness advantage for the enterprise.

Owner:江门市濠成化工科技有限公司

Wax solvent for automobile aluminum hub

The invention discloses a wax solvent for an automobile aluminum hub. The wax solvent is prepared from 85%-99% triethanolamine, 85%-92% oleic acid, fatty alcohol ether sodium sulfate, fatty acid alkanol amide, absolute methanol, 95%-98% penetrating agent, dodecylbenzene sulfonic acid and glycerinum 6. The wax solvent has the advantage of being widely used for removing wax for aluminum alloy, particularly the automobile aluminum hub, can effectively improve the effect and enhance the using effect, and is nontoxic, easy to biologically degrade and welcomed by the majority of users.

Owner:荆门市易轩表面处理科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com