Stainless steel spray wax solvent and preparation method thereof

A technology of stainless steel and wax removal water, which is applied in the field of chemical cleaners, can solve the problems of easy sticking of a layer of wax ash on the surface of the workpiece, short use time of wax removal water, and darkening of the surface of the workpiece, etc., to achieve a thorough wax removal effect at low temperature , increase production capacity, clean oil removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

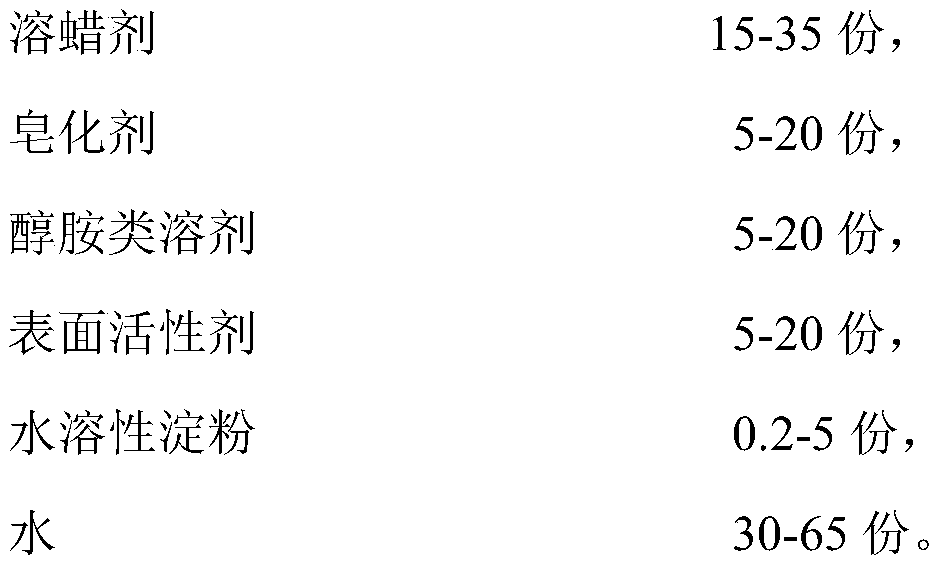

[0049] A kind of stainless steel spray dewaxing water, is made up of the component of following weight:

[0050]

[0051] A preparation method for stainless steel spray wax removal water, comprising the following steps: 1) mixing 2-octenyl succinic anhydride, isomeric decanol polyoxyethylene ether and n-butylamine, stirring at a stirring speed of 60rpm for 30min to obtain a mixed Solution 1; 2) Add octyldiethanolamine to the obtained mixed solution 1, and stir for 30 minutes to obtain mixed solution 2; 3) Add water-soluble starch to water, and stir at a stirring speed of 60 rpm for 20 minutes to obtain mixed solution 3; 4) Mix the obtained solution Liquid three was added to the obtained mixed liquid two, and stirred at a stirring speed of 60 rpm for 30 minutes to obtain stainless steel spray wax removal water.

[0052] Test the cleaning effect of the prepared stainless steel spray wax removal water. The test method is to spray the wax removal water with 5% of the above stai...

Embodiment 2

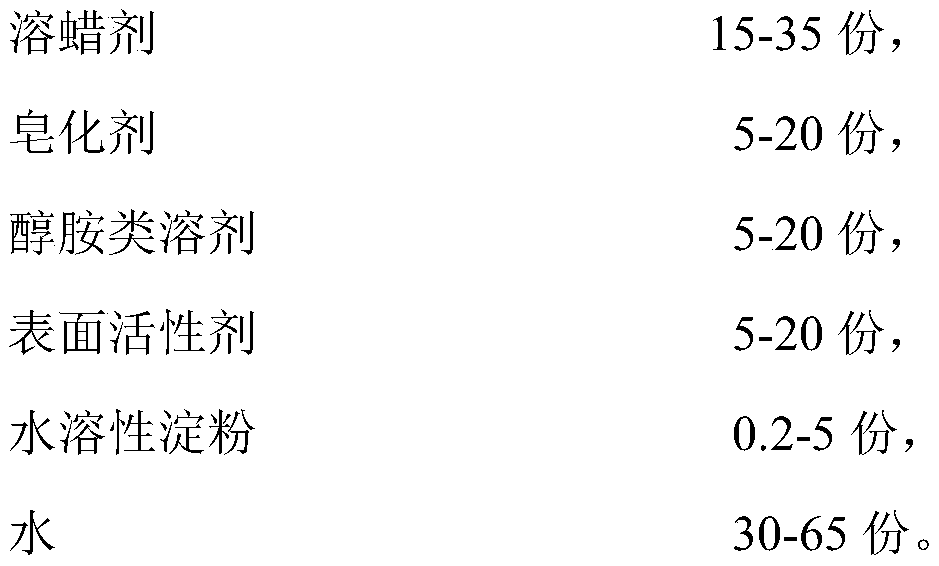

[0054] A kind of stainless steel spray dewaxing water, is made up of the component of following weight:

[0055]

[0056]

[0057] A preparation method for stainless steel spray wax removal water, comprising the following steps: 1) mixing 2-octenyl succinic anhydride, isomeric decanol polyoxyethylene ether and n-butylamine, stirring at a stirring speed of 65rpm for 25min to obtain a mixed Solution 1; 2) Add octyldiethanolamine to the obtained mixed solution 1, and stir for 20 minutes to obtain mixed solution 2; 3) Add water-soluble starch to water, stir at a stirring speed of 65 rpm for 20 minutes to obtain mixed solution 3; 4) Mix the obtained Liquid three was added to the obtained mixed liquid two, and stirred at a stirring speed of 65 rpm for 25 minutes to obtain stainless steel spray wax removal water.

[0058] Referring to the cleaning effect test method of Example 1, the test results are shown in Table 1.

Embodiment 3

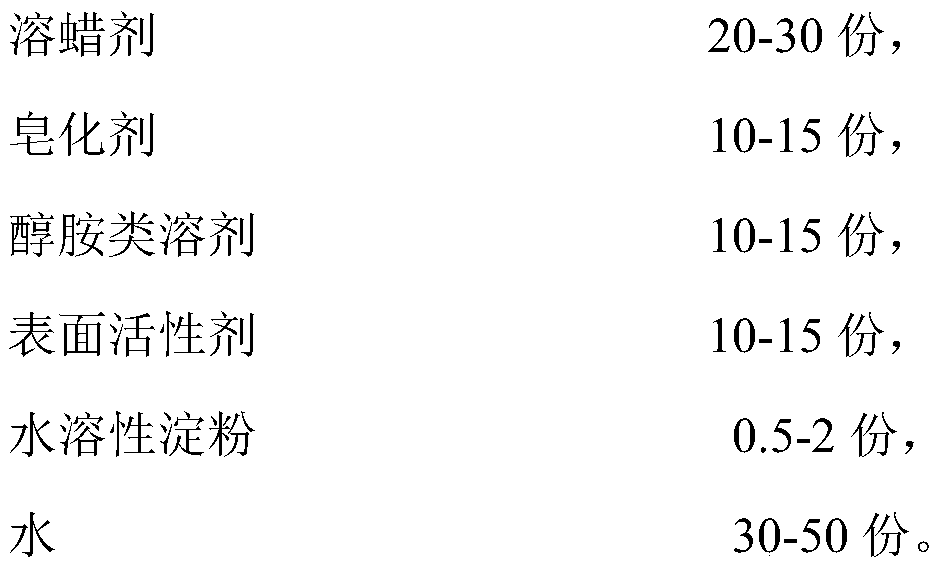

[0060] A kind of stainless steel spray dewaxing water, is made up of the component of following weight:

[0061]

[0062] A preparation method for stainless steel spray wax removal water, comprising the following steps: 1) mixing 2-octenyl succinic anhydride, isomeric decanol polyoxyethylene ether and n-butylamine, stirring at a stirring speed of 80rpm for 10min to obtain a mixed Solution 1; 2) Add octyldiethanolamine to the obtained mixed solution 1, and stir for 10 minutes to obtain mixed solution 2; 3) Add water-soluble starch to water, and stir for 15 minutes at a stirring speed of 80 rpm to obtain mixed solution 3; 4) Mix the obtained solution Liquid three was added to the obtained mixed liquid two, and stirred at a stirring speed of 80 rpm for 10 minutes to obtain stainless steel spray wax removal water.

[0063] Referring to the cleaning effect test method of Example 1, the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com