A Quick Test Method for Accuracy of Flying Probe Machine Capacitance Method

A test method, capacitance method technology, applied in printed circuit testing, electronic circuit testing, electrical measurement, etc., can solve the problem that the accuracy of the capacitance method of flying probe machine cannot be measured or quantified, so as to prevent leakage, open and short circuit defects, and ensure high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make people in the technical field better understand the technical scheme of the present invention, the product of the present invention will be further explained in detail below with reference to the examples and drawings.

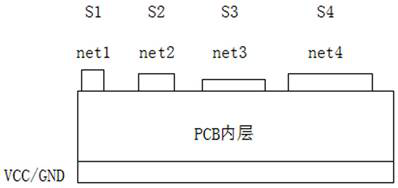

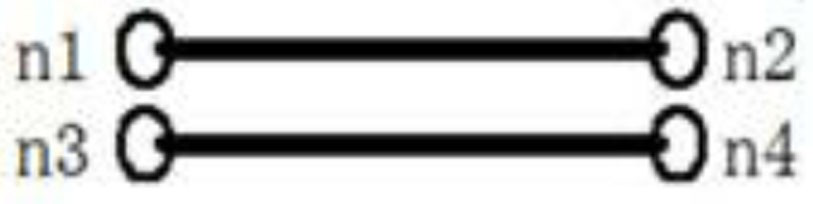

[0061] According to the principle of flying needle capacitance detection, a flying needle capacitance detection board with more than four layers is designed, and then the flow of flying needle capacitance detection board is made according to the design data. After the test board is made, the flying needle capacitance accuracy is detected, and the flying needle capacitance accuracy is judged. Finally, the flying needle capacitance accuracy comprehensive evaluation and on-site quality control are carried out.

[0062] Furthermore, the design of the capacitive testing board of the flying needle machine includes the overall design of the testing board including the inner structure design, the outer graphic design of the testing board, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com