Coiled material coating and preparation method thereof

A coil coating and phenolic resin technology, applied in the field of coatings, can solve problems such as corrosion, whitening by high-temperature cooking, and substandard plume film, and achieve the effects of excellent comprehensive performance, strong impact resistance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

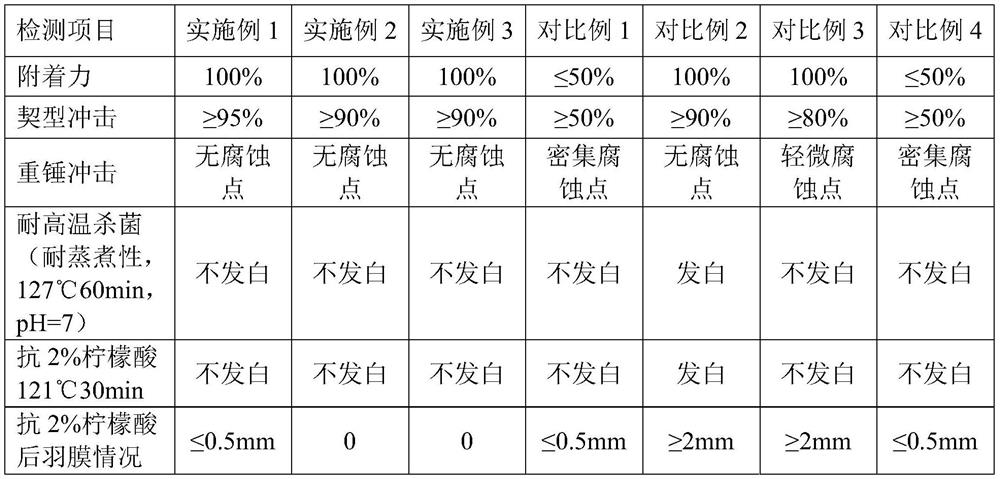

Examples

Embodiment 1

[0041] A coil coating, comprising the following components in parts by weight: 60 parts of epoxy solution, 0.1 part of phosphoric acid, 5 parts of bisphenol A phenolic resin, 5 parts of tert-butylphenol / bisphenol A phenolic resin, height 1 part of alkyl etherified benzomelamine resin, 0.01 part of defoamer BYK-054, 0.1 part of leveling agent BYK-392, 0.6 part of carnauba wax slurry, 6 parts of propylene glycol methyl ether acetate, 1 part of toning phenolic PR307 and adhesion promoter LTW 2 parts.

[0042] The coil coating preparation process is as follows: heat the epoxy solution to 100°C, add phosphoric acid, and keep warm for 1 hour after adding; then add bisphenol A phenolic resin and tert-butylphenol / bisphenol A mixed modified phenolic resin, and keep warm 1 hour; after the heat preservation is over, lower the temperature to below 40°C, first add highly alkyl etherified benzomelamine resin, stir well and then add the remaining materials, turn on the high-speed disperser o...

Embodiment 2

[0044]A coil coating, comprising the following components in parts by weight: 70 parts of epoxy liquid, 1 part of phosphoric acid, 10 parts of bisphenol A phenolic resin, 10 parts of tert-butylphenol / bisphenol A phenolic resin, height 5 parts of alkyl etherified benzomelamine resin, 0.3 parts of defoamer BYK-054, 1 part of leveling agent BYK-392, 3 parts of PE wax, 20 parts of ethylene glycol butyl ether, 5 parts of toning phenolic PR307 and attached Focus on accelerator LTW 5 parts.

[0045] The coil coating preparation process is the same as in Example 1.

Embodiment 3

[0047] A coil coating, comprising the following components in parts by weight: 65 parts of epoxy liquid, 0.5 part of phosphoric acid, 8 parts of bisphenol A phenolic resin, 8 parts of tert-butylphenol / bisphenol A phenolic resin, height 4 parts of alkyl etherified benzomelamine resin, 0.2 part of defoamer BYK-054, 0.5 part of leveling agent BYK-392, 1.5 parts of polytetrafluoroethylene wax, 15 parts of propylene glycol methyl ether acetate, toning phenolic PR307 3 4 parts and adhesion promoter LTW 4 parts.

[0048] The coil coating preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com