Fischer-Tropsch synthetic wax as well as preparation method and preparation system thereof

A Fischer-Tropsch synthetic wax and blending technology, which is applied in the petroleum industry, hydrotreating process, processing of hydrocarbon oil, etc., can solve the problem of not giving the preparation method of Fischer-Tropsch synthetic wax, and achieve high yield and energy consumption in the production process. Low, flexible quality control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

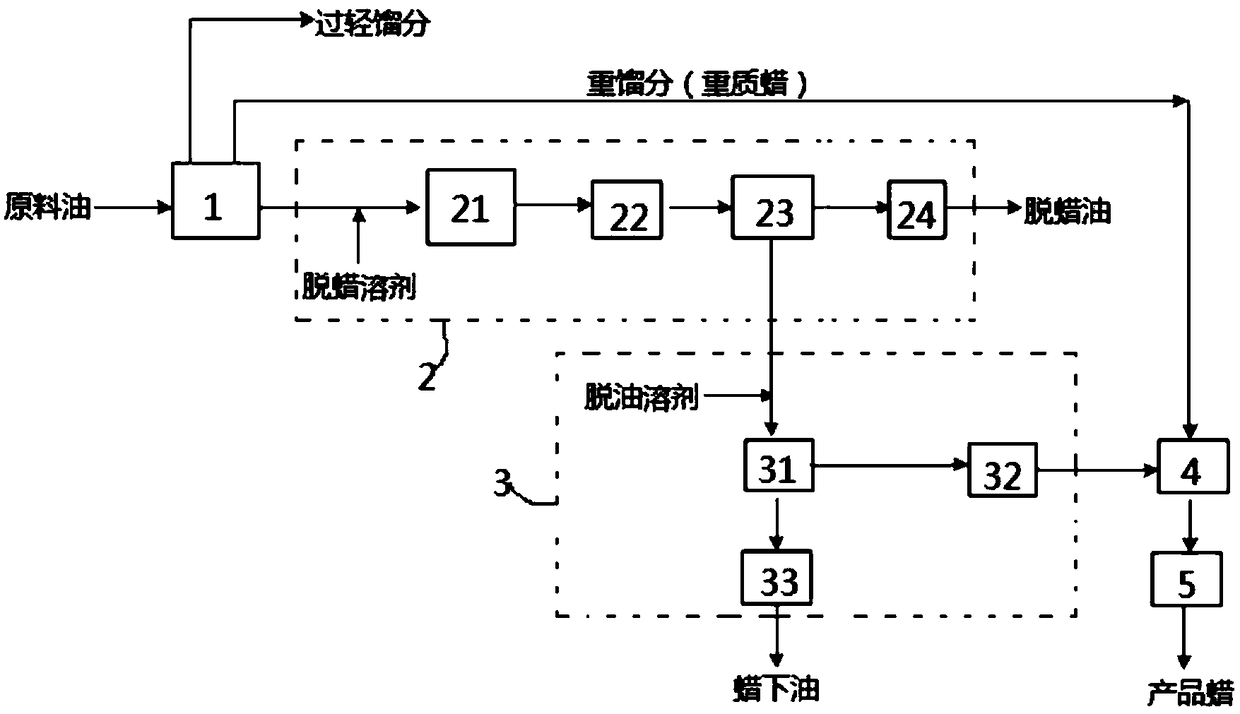

[0033] The invention provides a kind of preparation method of Fischer-Tropsch synthetic wax, the method comprises:

[0034] (1) Carry out pre-fractionation of raw material oil, collect boiling point i The super light fraction, boiling point at t i -t f Light fractions between and boiling points >t f The heavy distillate is used as heavy wax, where, t i is the fraction cut point and t set between 300-400°C f is the fraction cut point set between 480-540°C;

[0035] (2) using a dewaxing solvent to carry out solvent dewaxing to the light fraction to obtain a dewaxing filtrate and a wax paste;

[0036] (3) adopt degreasing solvent to carry out solvent degreasing to described wax paste, obtain light wax and wax lower oil;

[0037] (4) mixing the heavy wax and light wax to obtain blended wax;

[0038] (5) Hydrofining the blended wax.

[0039] The present invention also provides a Fischer-Tropsch synthetic wax preparation system applicable to the above method, the system compr...

Embodiment 1

[0097] This example is used to illustrate the Fischer-Tropsch synthetic wax of the present invention and its preparation method.

[0098] The raw material oil is Fischer-Tropsch synthesis full distillate wax, whose properties are shown in Table 1.

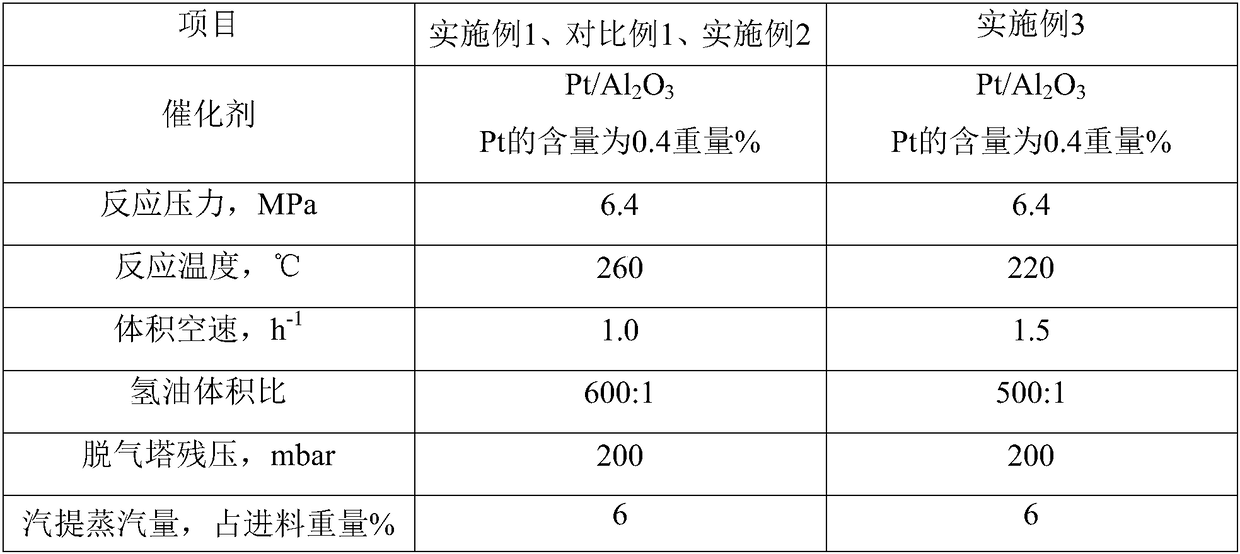

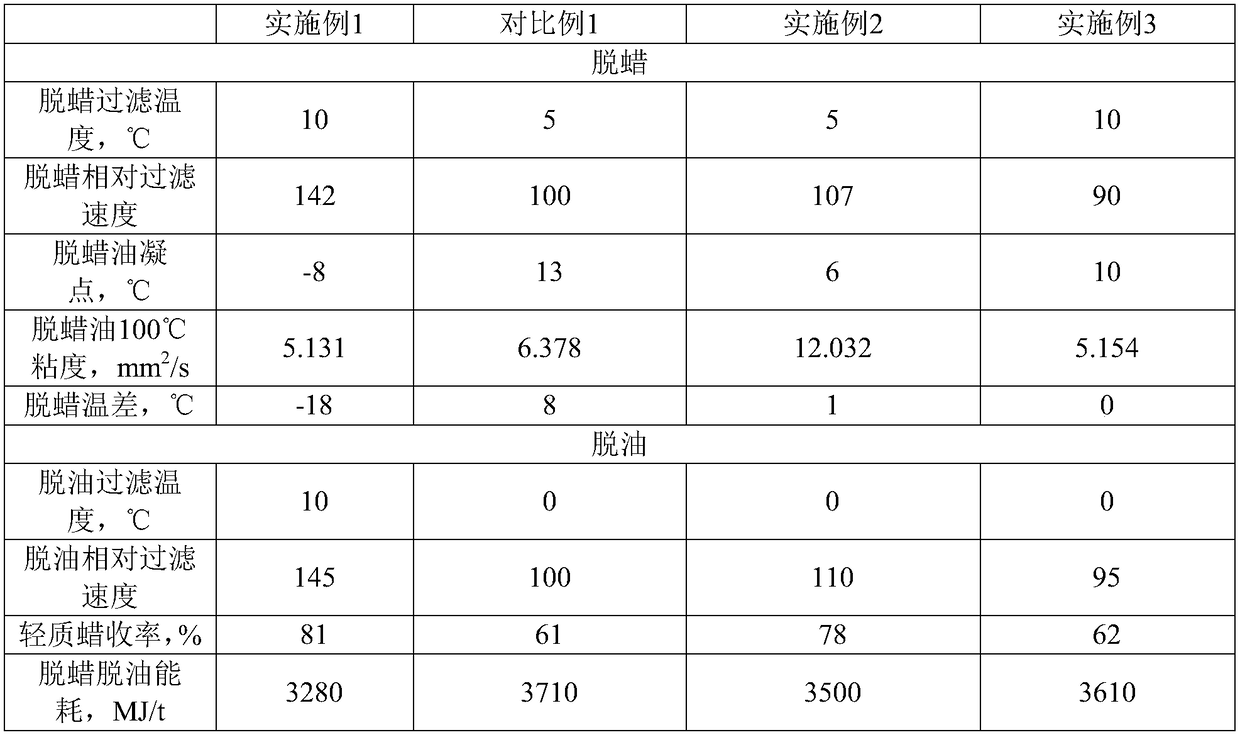

[0099] use figure 1 In the system shown, the raw oil is sent to the fractionation device 1 for fractionation, and 360°C and 500°C are respectively the fractionation cut-off temperature t i and t f , respectively obtain less than 360 DEG C too light distillate (discharge system), 360-500 DEG C light distillate and greater than 500 DEG C heavy distillate (being heavy wax HW1); The light fraction is sent to dewaxing unit 2 and deoiling unit 3 for dewaxing and deoiling respectively;

[0100] Wherein, the dewaxing solvent that adopts is identical with deoiling solvent, is the mixture of methyl ethyl ketone, toluene and secondary solvent, and the total content of methyl ethyl ketone and toluene (the weight ratio of methyl ethyl ketone...

Embodiment 2

[0110] According to the method described in Example 1, the difference is that the dewaxing solvent used is the same as the deoiling solvent, but the secondary solvent is only a mixture of water and ethanol with a weight ratio of 10:90, thereby obtaining light wax LW2, and Blend the wax BW2 to finally obtain the Fischer-Tropsch synthetic wax FT-W2 as the product wax.

[0111] Wherein, the relevant parameters of dewaxing and deoiling process are shown in Table 4;

[0112] Among them, the properties of light wax LW2, blending wax BW2 and Fischer-Tropsch synthetic wax FT-W2 are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com