Wax solvent for metal workpiece and preparation method of wax solvent

A technology for metal workpieces and wax removal water, applied in the field of cleaning agents, can solve the problems of high cost of use, short replacement cycle of wax removal water, unsatisfactory washing ability and defoaming performance, etc., and achieve long replacement cycle and good wax removal effect , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

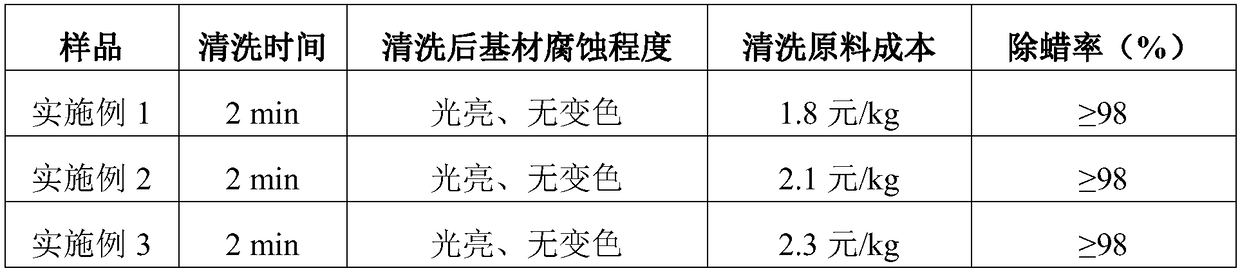

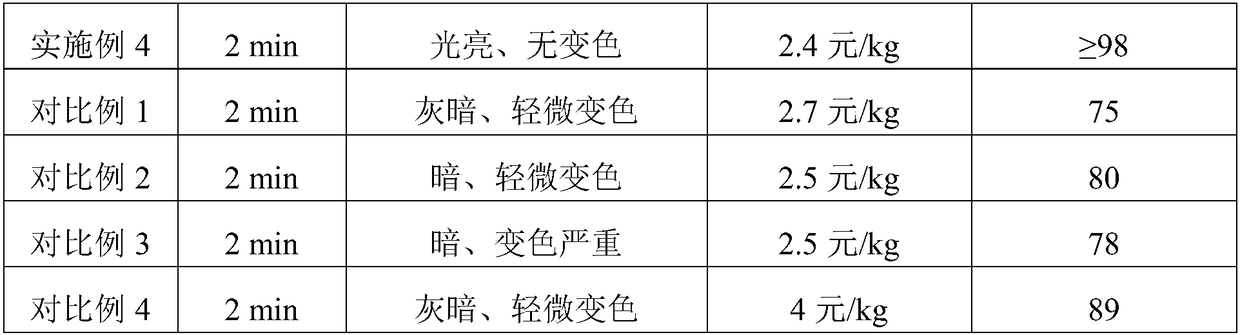

Examples

Embodiment 1

[0040] The present embodiment provides a kind of dewaxing water for metal workpiece, and preparation method comprises the following steps:

[0041] (1) Add part of water into the stirring tank and heat to 60°C;

[0042] (2) Add 20 grams of Tween 80, 20 grams of sodium carbonate, 30 grams of triethanolamine, 20 grams of sodium tripolyphosphate, 10 grams of disodium EDTA, 0.5 grams of sodium hydroxide, and 90 grams of sodium dodecylbenzenesulfonate , 60 grams of lauric acid diethanolamide and 30 grams of octylphenol polyoxyethylene ether;

[0043] (3) Add water to 1L and stir well.

Embodiment 2

[0045] The present embodiment provides a kind of dewaxing water for metal workpiece, and preparation method comprises the following steps:

[0046] (1) Add part of water into the stirring tank and heat to 60°C;

[0047] (2) Add 25 grams of Tween 80, 25 grams of sodium carbonate, 35 grams of triethanolamine, 30 grams of sodium tripolyphosphate, 20 grams of disodium EDTA, 0.5 grams of sodium hydroxide, and 90 grams of sodium dodecylbenzenesulfonate , 90 grams of lauric acid diethanolamide;

[0048] (3) Add water to 1L and stir well.

Embodiment 3

[0050] The present embodiment provides a kind of dewaxing water for metal workpiece, and preparation method comprises the following steps:

[0051] (1) Add part of water into the stirring tank and heat to 70°C;

[0052] (2) Add in turn 30 grams of Tween 80, 30 grams of sodium carbonate, 40 grams of triethanolamine, 40 grams of sodium tripolyphosphate, 30 grams of disodium EDTA, 1 gram of sodium hydroxide, and 90 grams of sodium dodecylbenzenesulfonate , 90 grams of octylphenol polyoxyethylene ether;

[0053] (3) Add water to 1L and stir well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com