Process for selecting, using and producing cotton straw composite board raw materials

A technology of cotton stalks and composite boards, which is applied in the direction of wood processing equipment, pretreatment and application of molding materials, etc., can solve the problems of limited strength and non-environmental protection, and achieve the effects of improving the strength of boards, simplifying the process flow, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

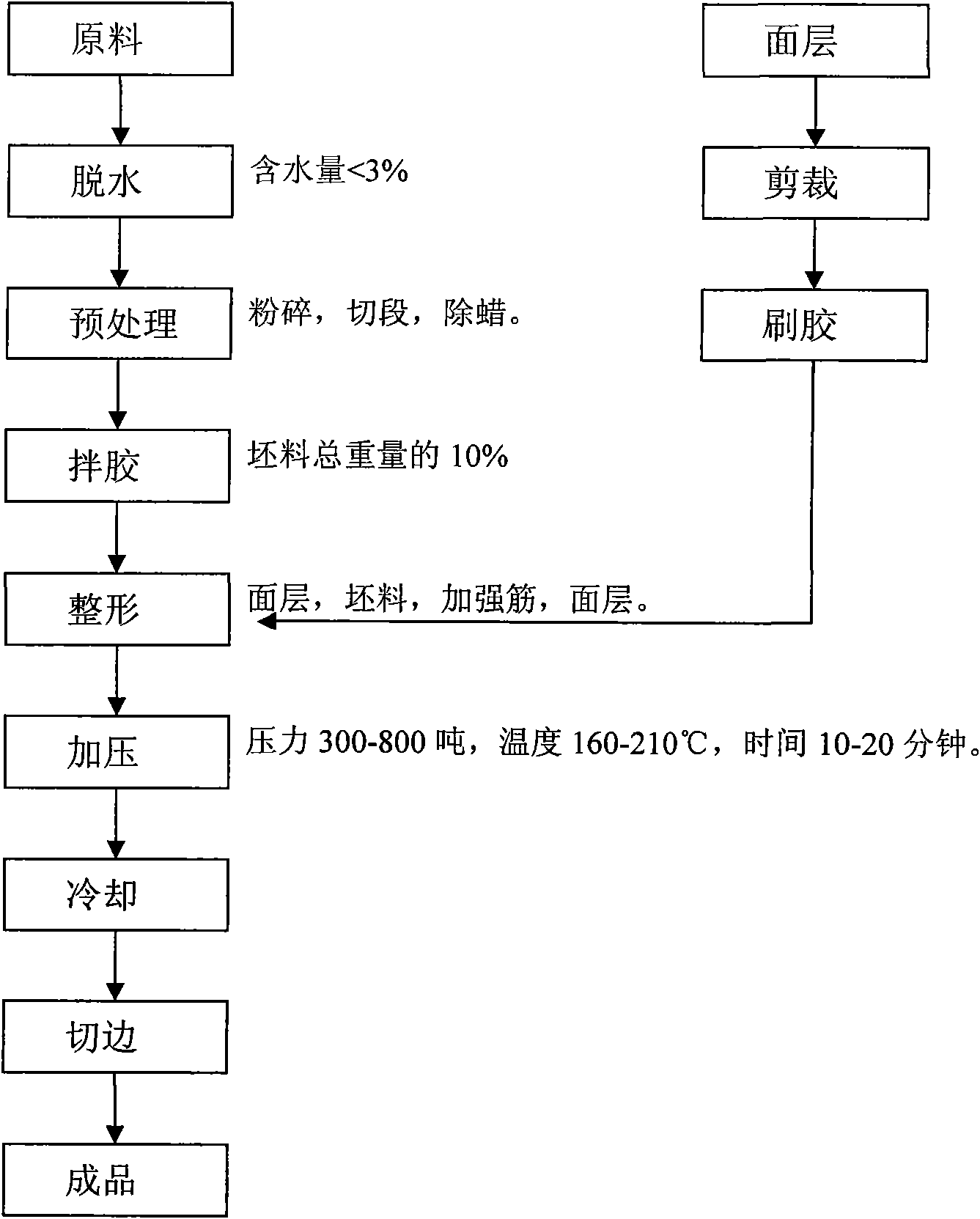

Method used

Image

Examples

Embodiment 1

[0016] Firstly, the raw materials are dehydrated, dried or air-dried, and the water content is less than 3%, and then the cotton stalks are crushed to make them into 1-5mm granules. Then the reeds, corn stalks, and sorghum stalks are split into two halves with self-made equipment, peeled and pulped, and then put into a double-roller machine for rolling and grinding to remove the wax on the surface of the stalks. The wax removal method can also use chemical methods, that is, use acid or gangue to dilute one of them with water to a content between 15-20%, put it in a special pool, and then cut off the reeds, corn stalks, The sorghum stalks are immersed in the pool for 1-4 hours, then taken out and sent to the double-roll machine for deacidification and gangue removal, and then put into the clean water pool for 1-2 hours, and then sent to the double-roll machine for dehydration. Then dry or air-dry to make the water content <3%. Then enter the glue mixing process, that is, pour ...

Embodiment 2

[0018] The raw materials are dried or air-dried, and the moisture content is less than 3% to ensure that the board does not foam. Cotton stalks are crushed, reeds, corn stalks, and sorghum stalks are dewaxed, bamboo strips are broken, and then cut to length, sizing, stirring, and surface Brush or spray glue layer by layer, and then carry out plastic paving. First, lay the surface layer that has been cut and glued on the formwork, and then lay the first layer of blanks, with a layer thickness of 5-10mm. Then lay reeds or corn stalks or sorghum stalks or bamboo strips with reinforcing ribs. The reinforcing ribs should be arranged in a criss-cross pattern. Lay a layer of blanks and lay a layer of reinforcing ribs. Lay five layers and finally lay 90 grams of corrugated paper, and then lay the formwork. Enter press, press 10 sheets at a time, be pressed into 16mm thick sheet, pressure 600 tons, temperature 180 ℃, time 18 minutes, other technological conditions are the same as exampl...

Embodiment 3

[0020] Use 0.8mm thick wooden flakes (the round wood is cut according to the specifications and processed on the rotary cutting machine) as the upper and lower veneers of the board, and hot-pressed with the blank at one time to produce cotton straw composite boards, cotton straw crushed products and desiccated materials. Reeds cut to length, corn stalks, sorghum stalks or bamboo strips processed by wax must be dehydrated so that the water content is less than 3%. After surface layer cutting, gluing, mixing, paving and shaping, etc., firstly, the wooden sheet cut into 2440×1220mm in length and width is glued and laid on the formwork, and then the first layer of blanks is laid, with a layer thickness of 5-10mm and then laid. Reinforcing ribs, sorghum rods, and reinforcing ribs are laid in a criss-cross arrangement, one layer of blanks and one layer of reinforcing ribs, and 17 layers are laid repeatedly. A 20mm thick plate is pressed, 5 pieces are pressed each time, the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com