Hot-melting road mark paint prepared by employing waste plastics

A technology for waste plastics and road markings, which is applied in the recycling of waste plastics and the production of road marking paints by using waste plastics, can solve the problems of high cost, achieve low cost, good shape retention and thixotropy, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

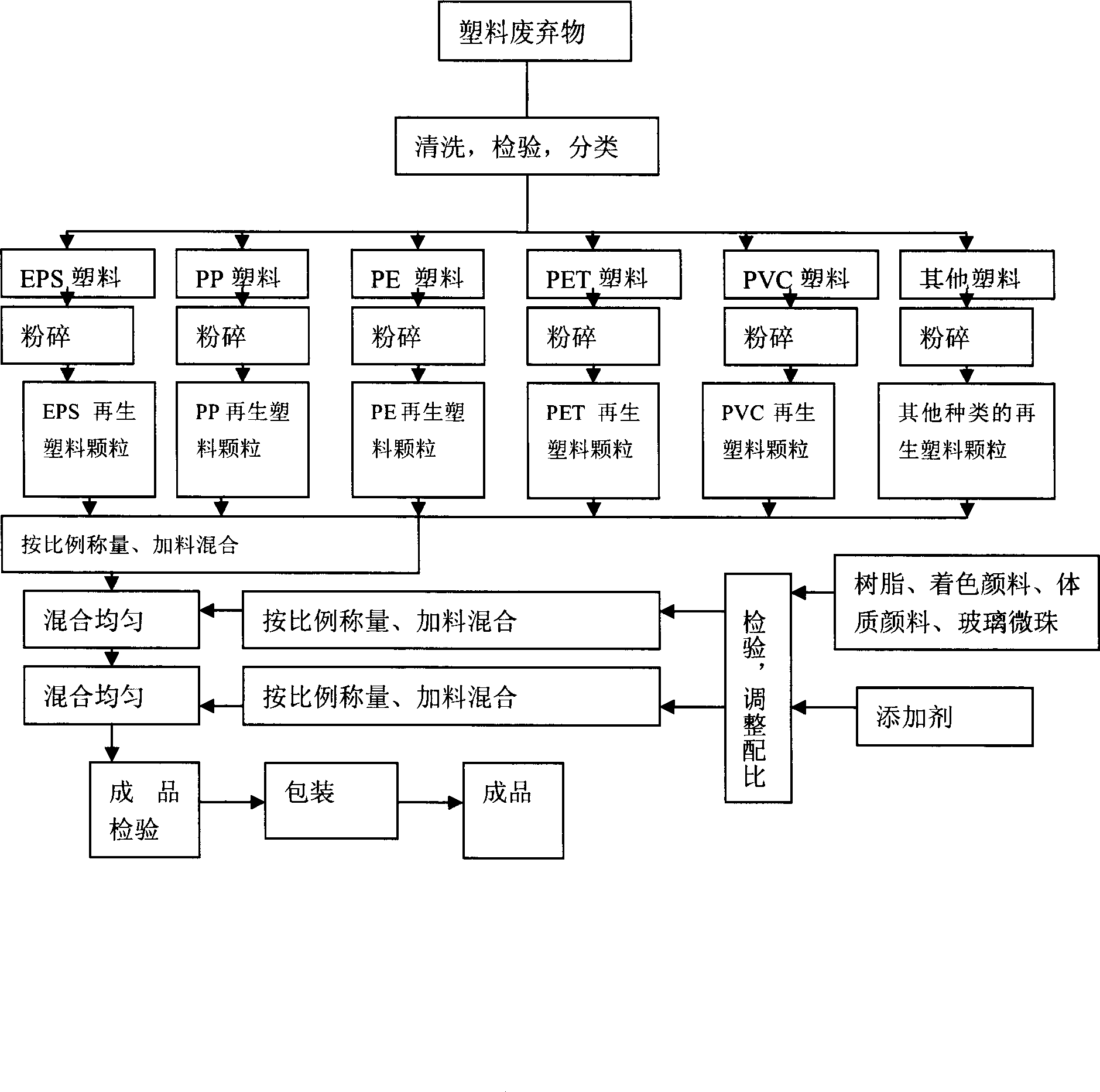

Image

Examples

specific Embodiment 2

[0054] The hot-melt road marking paint prepared from waste plastics is prepared from the following raw materials, and the weight ratio of the raw materials is:

[0055] Recycled EPS plastic particles 6.5~8.5,

[0056] C5 petroleum resin 8.0~10.0,

[0057] Acrylic resin 0.5~1.0,

[0058] Recycled PP plastic particles 0.5~1.5,

[0059] Recycled PE plastic particles 1.0~2.5,

[0060] Glass beads 20.0~22.0,

[0061] Titanium dioxide 3.0~5.0,

[0062] Quartz sand 9.0~11.0

[0063] Light calcium carbonate powder 15.0~17.0,

[0064] Heavy calcium carbonate 24.0~26.0,

[0065] Polyethylene wax 0.5~1.0,

[0066] EVA resin 0.5~1.0,

[0067] Dioctyl phthalate 0.5~1.0,

[0068] Other additives 1.0~1.2,

[0069] This example is a hot-melt white reflective marking paint. The production process is attached figure 1 The recommended heating temperature in the tank during construction is 180-200°C, and the required temperature is slightly lower than that of ordinary hot-melt road m...

specific Embodiment 3

[0070]The difference between this embodiment and the second embodiment is that the energy-saving hot-melt road marking paint is prepared from the following raw materials, and the weight ratio of the raw materials is:

[0071] Recycled EPS plastic particles 14.5~15.5,

[0072] Acrylic resin 13.5~17.0,

[0073] Recycled PP plastic particles 4.5~5.5,

[0074] Recycled PE plastic particles 6.5~8.5,

[0075] Recycled PVC plastic particles 1.5-2.0,

[0076] Glass beads 21.0~22.0,

[0077] Titanium dioxide 3.5 ~ 4.5,

[0078] Quartz sand 9.0~11.0

[0079] Light calcium carbonate powder 15.0~17.0,

[0080] Heavy calcium carbonate 26.0~28.0,

[0081] Polyethylene wax 0.5~1.0,

[0082] EVA resin 3.5~4.0,

[0083] Lithopone 1.0~2.0,

[0084] Dioctyl phthalate 0.5~1.0,

[0085] Other additives 1.8~2.5,

[0086] This example is a hot-melt white rainy night reflective oscillating marking paint, and its manufacturing method and construction method are basically the same as those ...

specific Embodiment 4

[0087] The difference between this embodiment and specific embodiments one, two, and three is that the heavy calcium carbonate of 11% to 16% by weight is subtracted from the raw material, and cadmium yellow pigment of 11% to 16% by weight of the raw material is added to make a yellow color coating. Other raw material proportioning, manufacturing method and construction method are basically the same as embodiment one, two, three.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com