Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Solve the breathability problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal polyporous material with gradient pore structure and preparation thereof

The invention provides a metal porous material with a gradient pore structure, which is formed by at least two porous layers with different pore diameter. The pore diameter of the metal porous material gradually decreases or gradually increases with the thickness direction of the material; a bottom layer of the porous layers is a macropore layer used as a support body; a surface layer of the porous layers is a pore layer used as a filtering precision control layer; the material of the macropore layer is a composite wire gauze, a metal fiber felt or a powder sintered metal porous material; and the material of the pore layer is superfine metal powder or superfine metal fiber. A method for preparing the metal porous material comprises a step of using spraying, dipping or centrifugal coating method to manufacture at least one pore layer on the surface of the support body. Compared with the prior metal porous material in the same grade, the metal porous material with the gradient pore structure has the advantages of obviously raising permeability coefficient, well solving the contradiction between the pore diameter and relative permeability coefficient of the metal porous material and having a simple process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Planting method of famous and precious Chinese herb medicine dendrobium officinale

InactiveCN103004421AConducive to accumulation of emissionsAccelerate evaporationHorticultureFertilizer mixturesPlant rootsEvaporation

The invention relates to a planting method of famous and precious Chinese herb medicine dendrobium officinale, and the method is characterized in that a cultivation bed of a plantation trough with an undulated bottom is established under a certain facility environment, multiple mixed organic matrixes mainly comprising pine bark are paved, a nondestructive planting technology for stretching tissue culture seedling roots is adopted, and scientific and reasonable dendrobium officinale planting method adopting comprehensive cultivation measures such as a photo and temperature control technology, a fertilizer control technology, an insect and harmful organism nuisanceless control technology and a sustainable harvesting technology is adopted in different growth seasons and for different plants according to the biological characteristics of the dendrobium officinale; and due to the adoption of the method, the ventilation, moisture evaporation and moistening functions of a plant root environment can be enhanced, and harmful substances influencing the growth of the plant can be eliminated in time, so that the plant can grow strong, active components are highly concentrated, the resistance is enhanced, a purpose of high yield and excellent quality can be realized, the high yield and stable yield of the dendrobium officinale can be guaranteed, the product quality is excellent, sustainability for harvesting the dendrobium officinale for multiple years can be realized, and super high yield of fresh products about 600kg per Mu every year can be realized after the method is put into production.

Owner:MAOMING HUISHENGYUAN BIOLOGICAL SCI & TECH

Nano silver antibacterial latex pillow or mattress and preparation method thereof

InactiveCN102010528AUnique antibacterial propertiesAntimicrobial properties provide unique antimicrobial properties uniquePillowsStuffed mattressesChaetomiumPaecilomyces

The invention discloses a nano silver antibacterial latex pillow or mattress and a preparation method thereof. Tiny air holes are fully distributed on the surface of the nano silver antibacterial latex pillow or mattress, and air is filled into the tiny air holes; and the silver antibacterial latex pillow or mattress has bacterial resistance on aspergillus niger, aspergillus flavus, discolored aspergillus, penicillium citrinum, paecilomyces varioti, herbarium cladosporium, trichoderma viride and chaetomium globasum. The preparation method comprises the following steps of: uniformly mixing nano sliver with natural latex; then respectively adding sulphur, bi(triethoxy propylsilane)tetrasulfide and 2,6-butylethylene-4-methylphenol; uniformly stirring; adding soap and air to generate foams; then adding gelatin; and compressing for moulding. The nano silver antibacterial latex pillow or mattress of the invention combines air permeability, high elasticity and soft touch feeling of the latex with efficient bacterial resistance and broad spectrum sterilizing performance of nano silver and can effectively overcome the defects of easy bacterial generation, difficult air permeation, and the like of a common pillow on the market.

Owner:SOUTH CHINA UNIV OF TECH

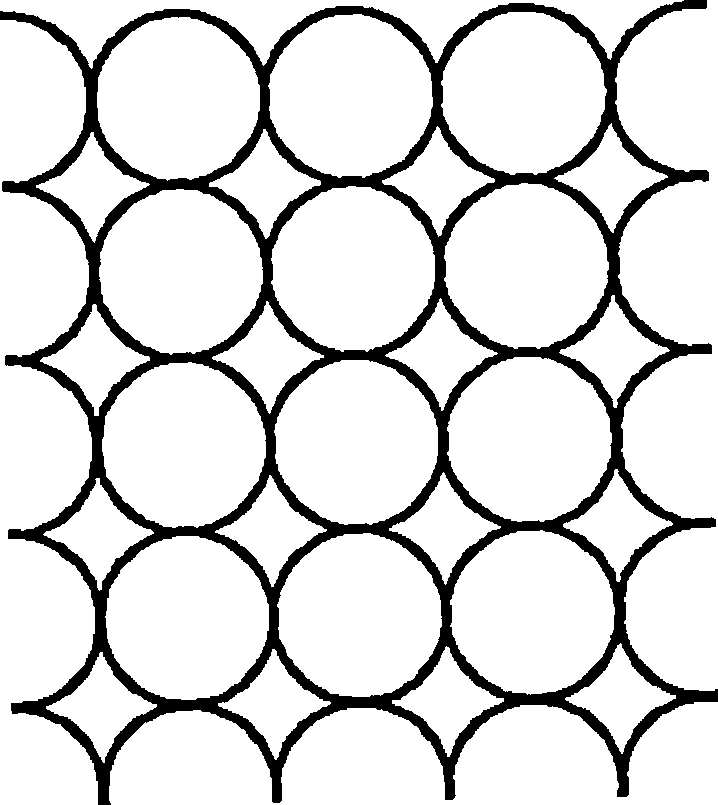

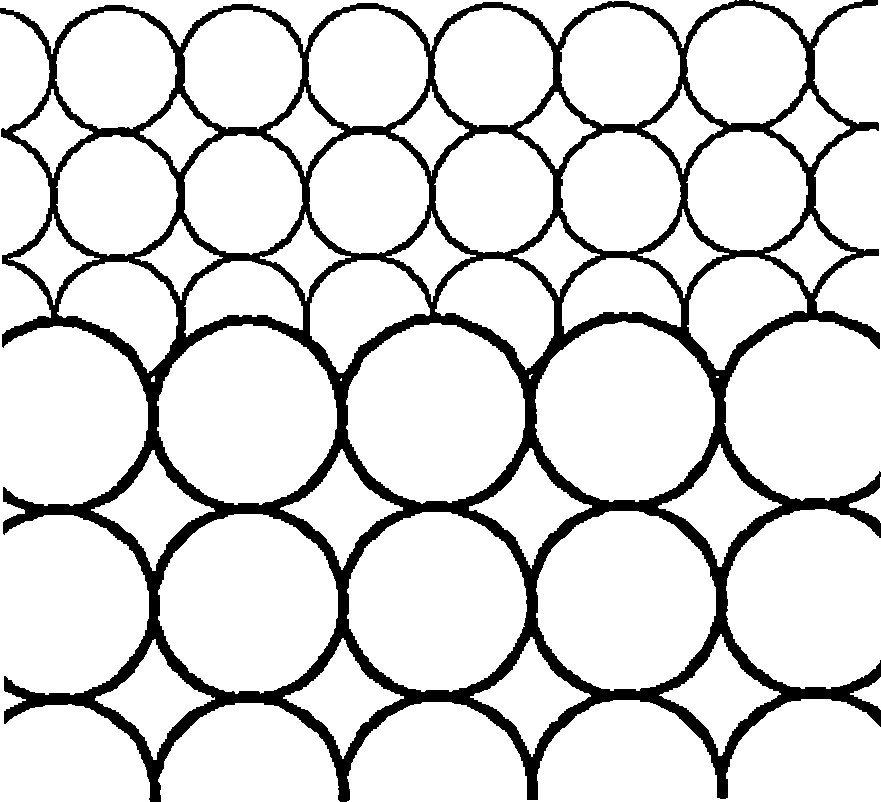

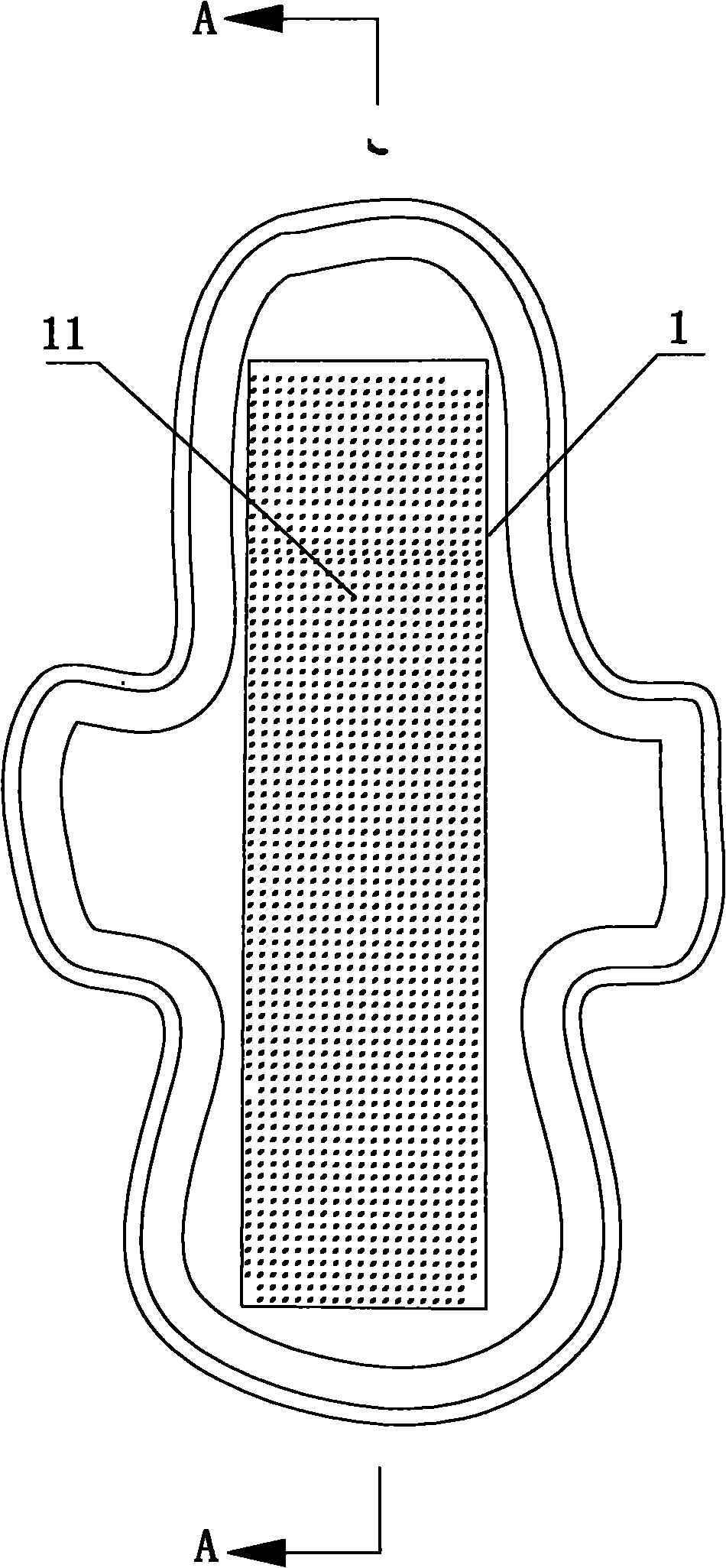

Hygienic article surface coating layer and use thereof

The invention relates to a hygienic article, in particular to a hygienic article surface coating layer and use thereof. The hygienic article surface coating layer comprises a perforated non-woven fabric and a perforated PE film which are compounded into a whole through heat sealing and adhesive bonding, wherein the non-woven fabric is positioned on the outermost layer; and holes on the non-woven fabric are communicated with holes on the PE film. The surface coating layer can be used as the surface coating layer of a baby diaper, an adult diaper, an adult nursing material, a sanitary towel or a sanitary cushion, and has various models, shapes and dimensions. Due to the novel technical scheme, compared with the conventional hygienic article surface coating layer, the surface coating layer has the advantages of softness, comfortableness, dryness, high tensile strength, contribution to absorbing large viscous contaminants and blocks by an absorption core layer, capacity of effectively solving the technical problems of stuffiness, impermeability and irritation, and wide application to the hygiene care article industry.

Owner:重庆百亚卫生用品股份有限公司

Method for producing fruit breeding bag paper with high water resistance

InactiveCN102517988AImprove water resistanceImprove breathabilityReinforcing agents additionPaper/cardboardFiberPesticide pollution

A method for producing a fruit breeding bag paper with high water resistance. The method comprises steps of: preparation of water repellent agent, preparation of wet strength agent, beating, slurry blending, formation through a net part, squeezing and dehydration, drying, reeling and cutting and winding. The method of the invention uses waste paper pulp as a main fibrous raw material and uses the self-made water repellent agent; the produced fruit breeding bag paper has good water resistance, water resistant endurance and high breathability; the method has advantages of simple production process and low cost, and solves problems of domestic fruit breeding bag paper, such as substandard production technology for the opposite technological indexes of breathability and water resistance and subsequent higher and lower of the two technological indexes. The method of the invention can be applied to production of fruit breeding bag paper, which can satisfy growth demand of fruits, prevent pesticide pollution and erosion by wind and rain, and improve surface color of the fruits.

Owner:山西中宝纸业股份有限公司

Sponge and preparation method thereof

The invention provides a sponge and a preparation method thereof. The sponge is prepared from the following raw materials in parts by mass: 45-60 parts of toluene diisocyanate, 25-35 parts of diisocyanate, 4-6 parts of water, 1-2 parts of a polymerization catalyst, 45-60 parts of polyether glycol, 3-4 parts of a flame retardant and 3-4 parts of a foaming agent. The preparation method comprises the following steps: (A) mixing and foaming toluene diisocyanate, 2.5-3 parts of water and 1-2 parts of the foaming agent, thereby obtaining polymeric sponge; (B) uniformly stirring diisocyanate, the rest water, stannous octoate, polyether glycol and the flame retardant, thereby obtaining a first mixture; and (C) fixing the polymeric sponge on the top of a mold, putting the first mixture into the mold, mixing and foaming the first mixture with the residual foaming agent to form an emulsion sponge, performing polymerization reaction on the emulsion sponge with the polymeric sponge, and forming, cooling and cutting, thereby obtaining a product. The preparation method has the advantages that the operation is simple, no adhesive is adopted for adhesion, and the like.

Owner:SHENZHEN AIRLAND HOME CO LTD

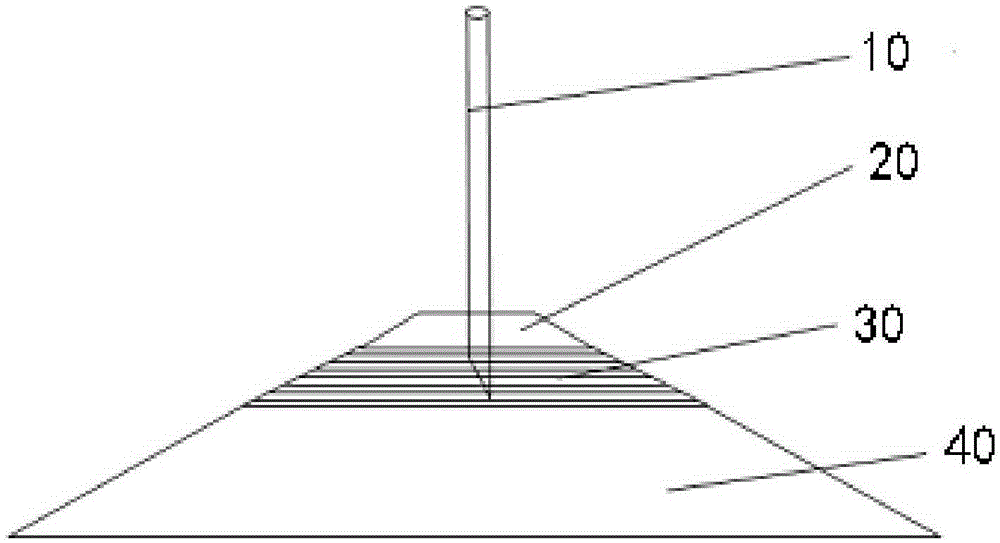

Cinnamomum camphora cutting propagation method

ActiveCN105409700AAvoid infectionSolve the breathability problemPlant cultivationCultivating equipmentsDiseaseCinnamomum camphora

The present invention relates to a cinnamomum camphora cutting propagation method. The method comprises the following steps: (1), treating a cutting seedbed; (2), preparing cutting slips; (3), processing cutting slips; (4), performing cuttage; (5), performing post-cutting administration; and (6), transplanting nursery plants. The Cinnamomum camphora cutting propagation method disclosed by the present invention has the following beneficial effects: 1, a specific slip protecting liquid protects the slip skin so as to prevent the disease from a wound infection; and 2, the problems that the permeability of the seedbed is poor and the nutrients are insufficient, thereby improving the success rate of cutting propagation.

Owner:广西南宁向科农业科技有限公司

Low-cost tantalum carbide coating preparation method

The invention discloses a low-cost tantalum carbide coating preparation method. The method comprises the following steps that a matrix is pretreated at first, then, tantalum carbide, sintering aids, adhesives and solvents are adopted for preparing turbid liquid, the turbid liquid is uniformly sprayed or brushed to the surface of the matrix, and finally the matrix with the sprayed or brushed matrix is subjected to pre-temperature or sintering treatment, and a tantalum carbide coating with the uniform thickness and dense structure can be obtained on the matrix. The surface of the matrix is coated with the TaC coating with the completely dense structure, and the surface of the matrix can be isolated and protected to a large extent due to the coating; the method can be used for crystal and semiconductor production device or components, and the phenomenon that crystal defects are caused due to the fact that device or component surface layer particles enter crystals during crystal growth is avoided. Compared with the CVD deposition technology, the technological process is low in cost, and the method is simpler, easy to implement, good in repeatability and capable of directly forming the compact and crack-free coating on the surface of a material.

Owner:BEIJING CENTURY GOLDRAY SEMICON CO LTD

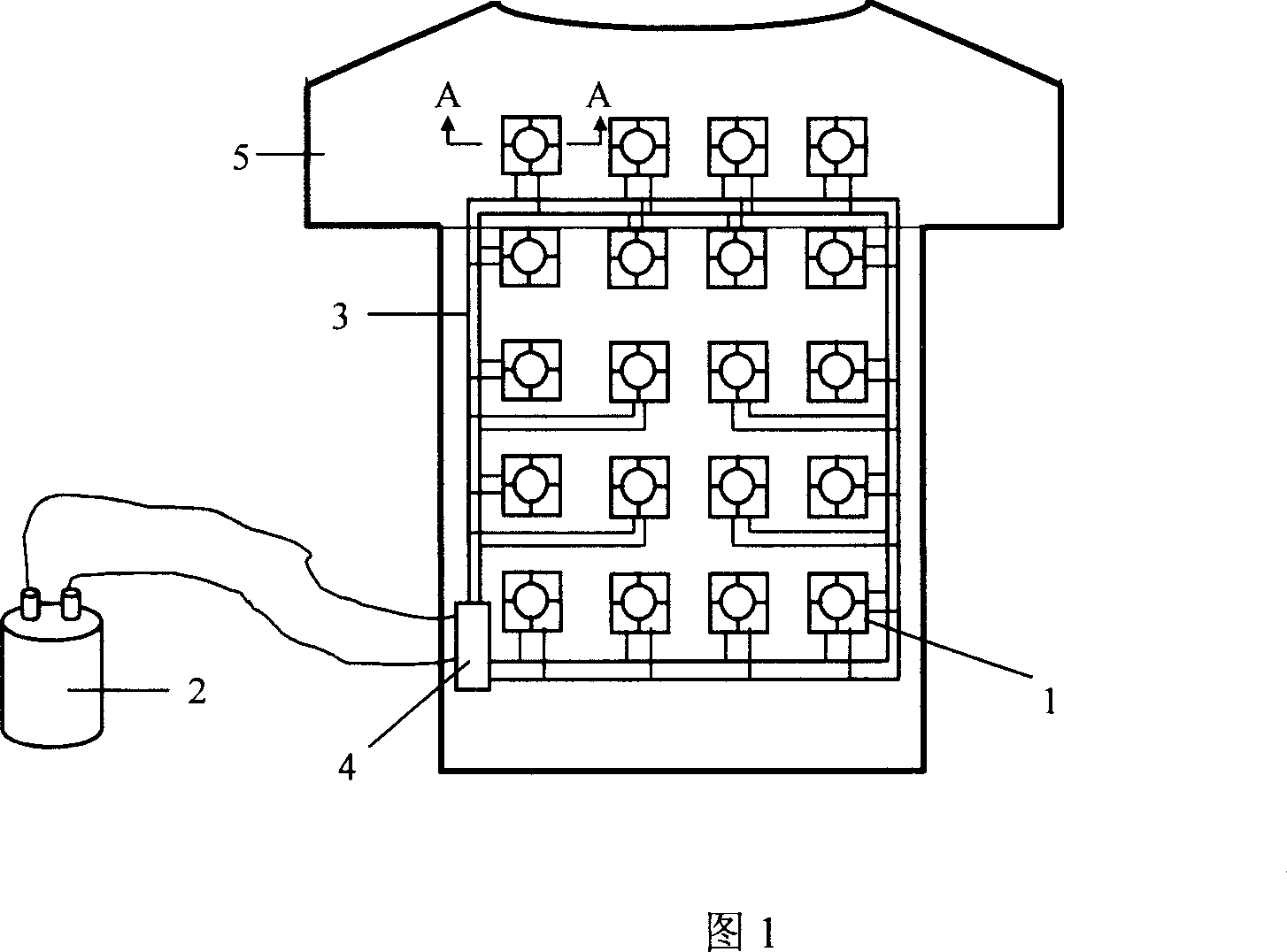

Body temperature lowering air conditioning clothing driven with micron and nanometer fan array

InactiveCN1931044ACompact structureHigh cost performanceProtective garmentAir conditioningForced convection

The body temperature lowering air conditioning clothing driven with micron and nanometer fan array includes one micro fan array; and the micro fan array consists of at least one micro fan woven into clothing. The micro fan is connected to the outer micro power source through the circuit lines woven into clothing; the micro power source has voltage of 3-12V; and there is switch set in the circuit lines for controlling the on-off of the micro fan. The power source driven fan can realize the local temperature regulation of human body by means of local forced convection and evaporating heat dissipation. The present invention has compact structure and high reliability and has import application value in high temperature environment.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

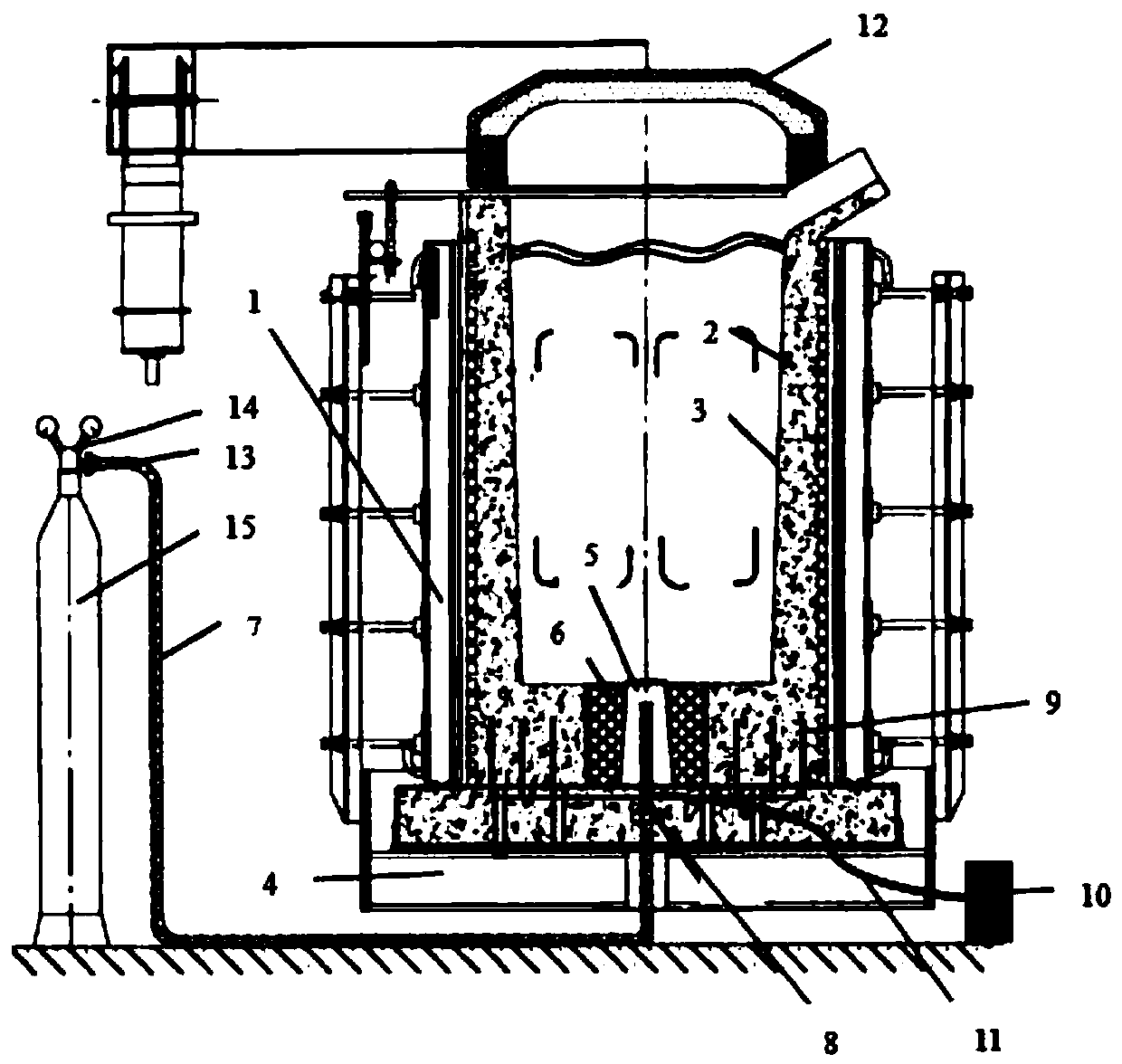

Furnace protecting method of iron-smelting blast furnace

InactiveCN102433405ASolve the breathability problemAddressing the effects of enhanced smeltingBlast furnace detailsBlast furnace smeltingTitanium

The invention belongs to the field of blast furnace smelting and particularly relates to a furnace protecting method of an iron-smelting blast furnace. The invention provides a furnace protecting method of an iron-smelting blast furnace. The technical scheme is as follows: a titanium-containing material is jetted into a blast furnace from a tuyere. In the invention, the titanium-containing material is added into the blast furnace, a high-melting-point substance TiCN is generated at the furnace bottom by utilizing a Ti element contained in the titanium-containing material so as to protect the furnace bottom from being eroded; and in addition, the titanium-containing material is added from the tuyere other than sintering burdening of a furnace top, which dose not influence the quality of sintering ore and eliminates the influences of the titanium-containing material on the air permeability of the blast furnace and intensified smelting of the blast furnace when the titanium-containing material is added from the furnace top.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

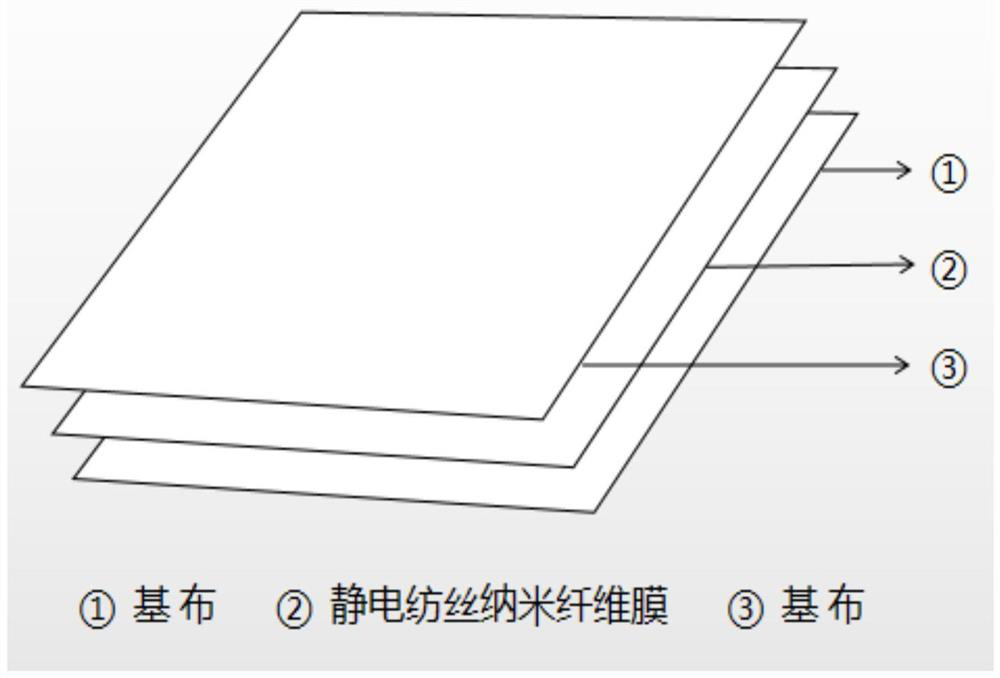

Method for manufacturing medical nanometer fiber protective clothing fabric based on electrospinning technology

InactiveCN111962211ASmall diameterSmall apertureMonocomponent polyurethanes artificial filamentElectro-spinningTextile fiberSpinning

The invention discloses a method for manufacturing medical nanometer fiber protective clothing fabric based on the electrospinning technology. According to the method, spunbond, or traditional fabricor other textile fiber materials is used as base fabric, by utilizing the electrospinning technology, in combination with a doping and modifying technology and a long-acting electret technology, nanometer fiber membranes with different functionality are sprayed to the surface of the base fabric, and then the medical nanometer fiber protective clothing fabric integrating a protective function, a comfort function, an anti-microbial function, an anti-static function, a heat conducting function and the like and combining thermal-wet comfort and protective safety is manufactured and obtained. The method mainly solves the problem that an existing protective clothing fabric is large in filtration resistance, and poor in air permeability and comfort, and the method has the technological features that the manufacturing technology is simple, cost is low, and functional finishing combination is easy. Compared with a traditional process of manufacturing the protective clothing fabric, such as a compact fabric technology, a coating technology and a composite microporous membrane technology, the method omits the procedures of spinning, machine weaving, coating and the like, greatly simplifies the technological process of forming the protective clothing fabric, and enables industrialized production to be easily achieved.

Owner:河南中纤新材料科技有限公司

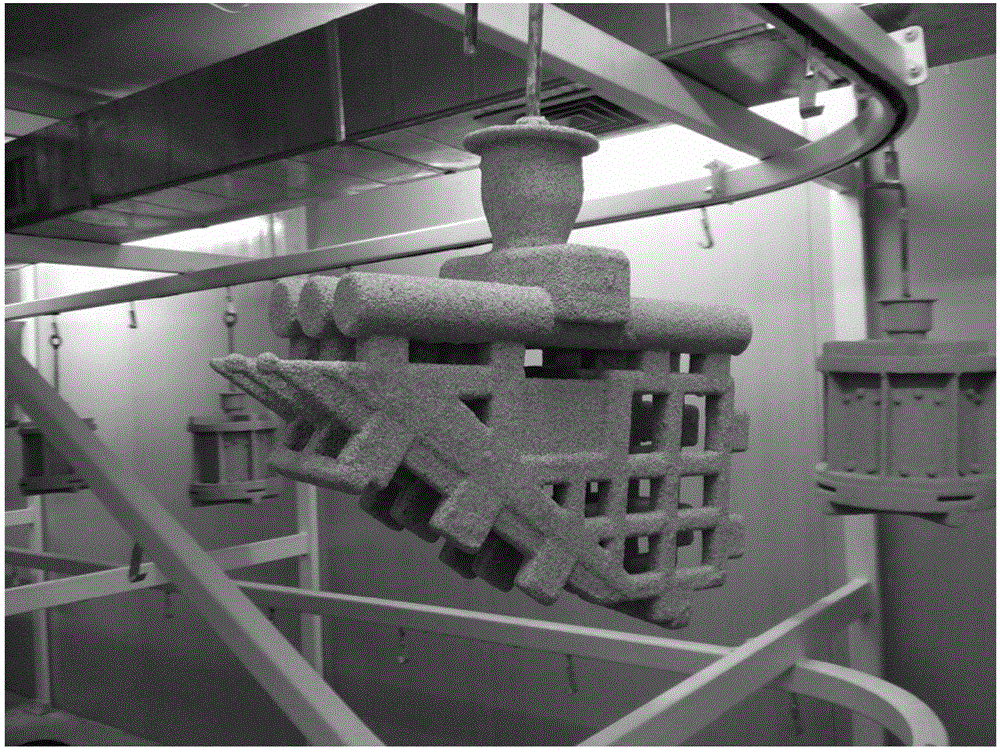

3D printing forming casting method for large-scale complex thin-wall high-temperature metal component

InactiveCN107598095ASolving the Difficulties of Investment Casting Shell ManufacturingAchieve rapid productionAdditive manufacturing apparatusFoundry mouldsWaxInvestment casting

Owner:安徽恒利增材制造科技有限公司

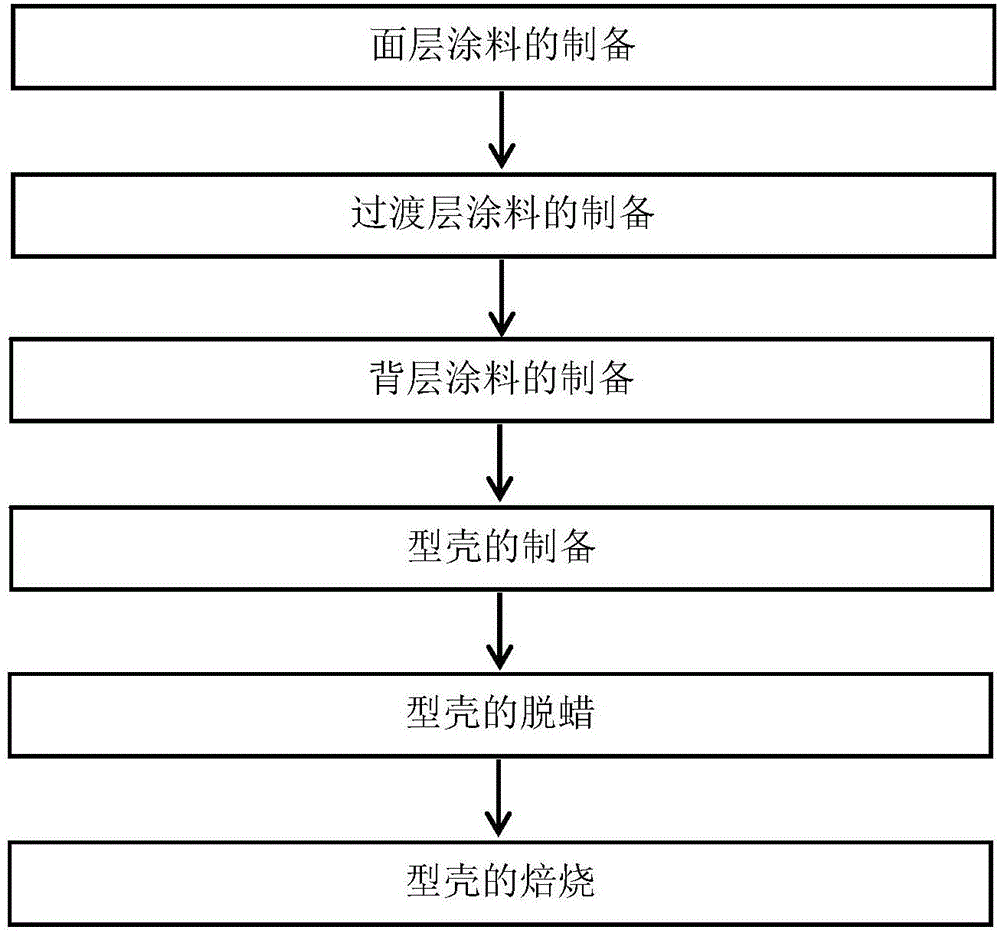

Preparation method of yttrium oxide moulding shell used for casting

ActiveCN106493287ASolve the problem of water back dissolutionSolve the breathability problemFoundry mouldsFoundry coresHuman healthTitanium alloy

The invention discloses a preparation method of an yttrium oxide moulding shell used for titanium alloy precision casting. A moulding shell surface layer coating comprises yttrium oxide refractory powder, ammonium zirconium carbonate binder, a wetting agent and a defoaming agent. The preparation method includes the steps of preparation of the surface layer coating, preparation of a back layer coating, preparation of the moulding shell, dewaxing, calcinations and the like. By means of the yttrium oxide moulding shell used for titanium alloy precision casting and the preparation method thereof, the problems that an existing moulding shell is prone to redissolution under the influence of water in the preparation and dewaxing processes, and steam dewaxing cannot be achieved are solved. The binder used for the coating is made of ammonium zirconium carbonate and is low in price, and the prepared coating is stable and reliable and cannot generate redissolution after being dried under the influence of water. The prepared surface layer coating is good in smearing performance and high in refractoriness, steam dewaxing is adopted, no pollution is caused to the environment, and the prepared surface layer moulding shell has no influence on the human health. The prepared yttrium oxide moulding shell is wide in application range, an interface reaction layer is small, titanium alloy casts are high in precision, performance is excellent, and later-period finishing is conducted easily.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

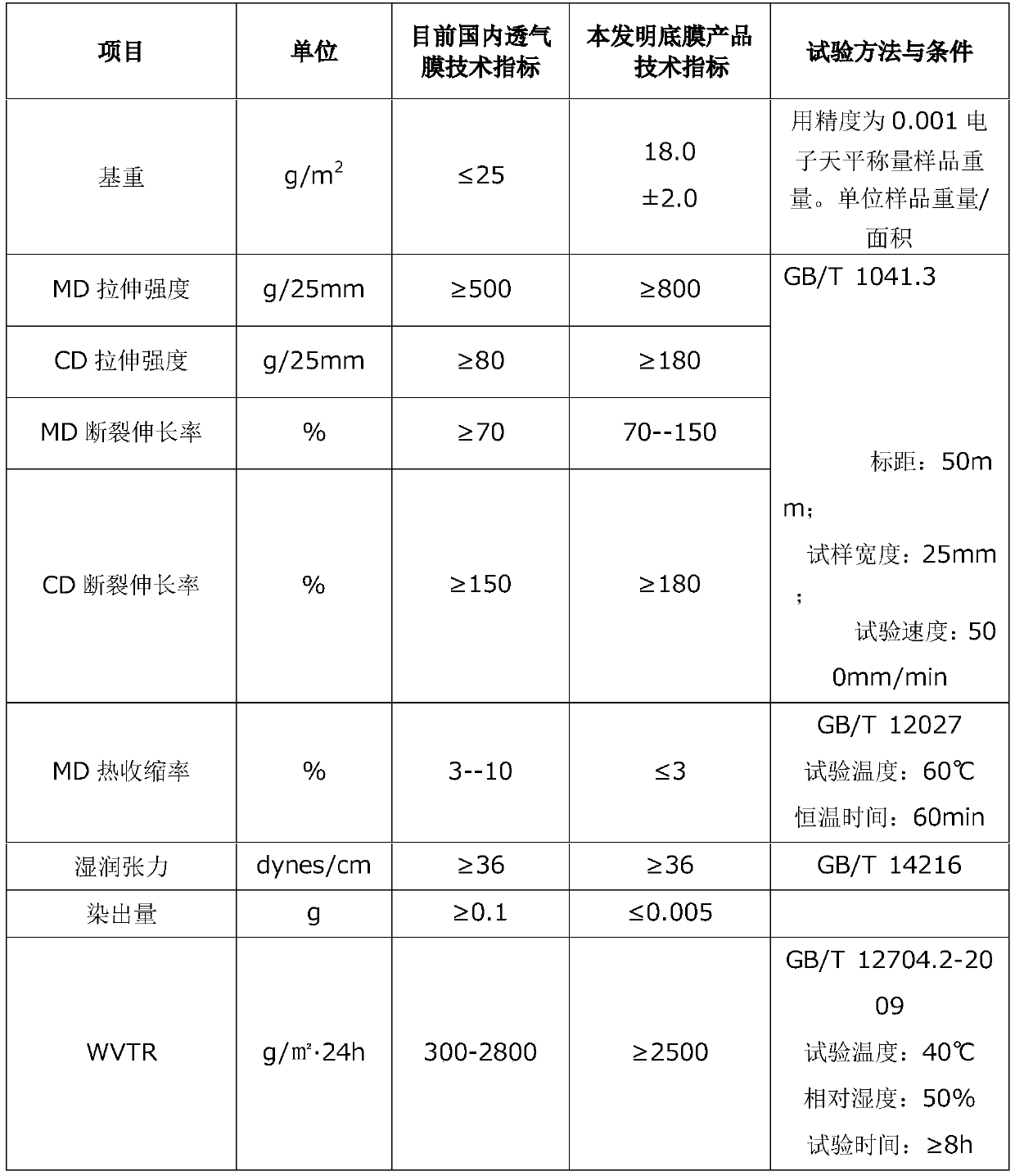

Skin-friendly extremely-thin high-permeability zero-leakage bottom film

PendingCN110079001AImprove temperature stabilityGood dimensional stabilityLow-density polyethylenePolyolefin

The invention discloses a skin-friendly extremely-thin high-permeability zero-leakage bottom film. The skin-friendly extremely-thin high-permeability zero-leakage bottom film consists of the followingraw materials in percentages by weight: 30-50% of nano-scale heavy CaCO3, 10-15% of metallocene polyolefin mLLDPE and the balance of low-density polyethylene. A high-multiple multi-stage distributionand stretching technology is adopted, so that the stress of the product in the longitudinal direction is uniform, meanwhile, the air permeability of the film is improved, the formed apertures are uniform and consistent, and the characteristic of zero leakage of the product is guaranteed.

Owner:FOSHAN HUAHAN SANITARY MATERIAL

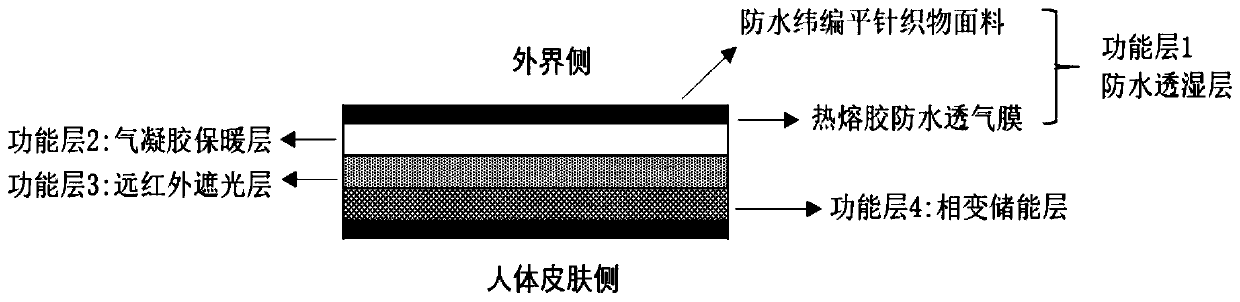

Aerogel based high-heat retention textile composite and preparation method thereof

InactiveCN110077063ASolve the problem of falling powderAvoid destructionMaterial nanotechnologySynthetic resin layered productsInsulation layerThree-dimensional space

The invention relates to an aerogel based high-heat retention textile composite and a preparation method of the aerogel based high-heat retention textile composite, and the aerogel based high-heat retention textile composite sequentially comprises a waterproof and moisture permeable layer, an aerogel heat insulation layer, a far infrared light shielding layer, a phase change energy storage layer and a waterproof and moisture permeable layer from outside to inside. The aerogel based high-heat retention textile composite solves the problem that a powder of an aerogel falls off when the aerogel is used as a heat insulation material, the aerogel is prevented from being dried again in the application process of the aerogel to break the three-dimensional space structure, the advantage of the heat conductivity coefficient is protected against damages, the defect of high loss of the thermal radiation heat of the aerogel, as a main body of the heat insulation material, is improved, the serviceability and the heat retention of the material are further improved, the material achieves the self-temperature regulation function, and the aerogel based high-heat retention textile composite has an excellent market application prospect.

Owner:上海驰纺材料科技有限公司

Regenerated brick prepared from papermaking sludge and preparation method thereof

InactiveCN103130492AHigh densityIncrease profitCeramic materials productionClaywaresBreaking strengthBrick

The invention relates to a regenerated brick prepared from papermaking sludge and a preparation method thereof. the invention solves the problem of restricted utilization ratio of bricks prepared from papermaking sludge, and overcomes the defects of low compression resistance, low breaking strength, poor air permeability and the like in the bricks prepared from papermaking sludge. The preparation method comprises the following steps: mixing and stirring 35-40 parts by weight of papermaking sludge with the water content of 45-55%, 20-25 parts by weight of power plant sintering ash, 40-45 parts by weight of clay, 2.5-4 parts by weight of flame-retardant permeable fiber monofilament, 3-5 parts by weight of blind coal, 3-5 parts by weight of water-soluble resin and 4-7 parts by weight of water to obtain a wet material; and extruding with an extruding machine to obtain a blank strip, cutting into green bricks, naturally drying in air, and sintering in a kiln.

Owner:FUJIAN YIYUAN WASTE UTILIZATION

Synchronous coloring burn-out printing and moire infiltrating burn-out printing technique for denim fabrics

InactiveCN103031753AComfortable to wearModel features are perfectBiochemical fibre treatmentDyeing processPre treatmentBurning out

The invention belongs to the field of post technique of burn-out printing on fabrics in the textile industrial production, in particular to a synchronous coloring burn-out printing and moire infiltrating burn-out printing technique for denim fabrics. The technique is characterized in that the burn-out printing pretreatment is implemented firstly, that is, grey fabrics of the denim fabrics are desized by using amylase at the temperature of 40-60 DEG C, and are printed by screens to produce synchronous coloring burn-out printing screens or moire infiltrating burn-out printing screens with different styles, and burn-out printing size is prepared; and then, the synchronous coloring burn-out printing and moire infiltrating burn-out printing processing is implemented on the grey fabrics of the denim fabrics by adopting the prepared burn-out printing size through the synchronous coloring burn-out printing screens or the moire infiltrating burn-out printing screens. The technique achieves that products thereof are more beautiful and unique than original denim products, are comfortable to wear, and are perfect in style and characteristics; and the labor force and the secondary production pollution are reduced in the production link, so that the production cost is reduced, and the novel way of environmental friendliness of the denim fabrics is achieved.

Owner:王志刚

Method for manufacturing light and thin suit

The invention discloses a method for manufacturing light and thin suit. The method comprises the following steps of: cutting out a front interfacing, a side interfacing, a rear interfacing and an integrated liner, wherein a straight tape is ironed on the side vent where the side interfacing is connected with the rear interfacing; the upper end point of the straight tape is positioned at the corner of the top end of the side vent of the side interfacing, the lower end point of the straight tape is positioned on the bottom hemline, and the lower chamfer of the side interfacing is halved into two sections; the convex part of the side vent of the side interfacing is sewn along the upper end part of the straight tape after the straight tape is folded in half, the folded edge of the hem of the side vent is folded in half along the bottom hemline, and then sewn; the edge of a rear seam of the side interfacing, the folding outer edge of the side hem of the side interfacing and the folding edge of the lower chamfer are integrally wrapped; after the front interfacing presses a main liner, the shoulder presses an auxiliary liner, a reinforcing liner presses the lapel and the lower hem; the main liner presses the lapel of the integral liner; and the front interfacing, the side interfacing and the rear interfacing are sewn, and then sewn with the integral liner. The suit provided by the invention realizes that the weight of the suit is reduced and the ventilation and moisture-penetrability of the suit are increased while the shape of the suit is maintained.

Owner:报喜鸟控股股份有限公司

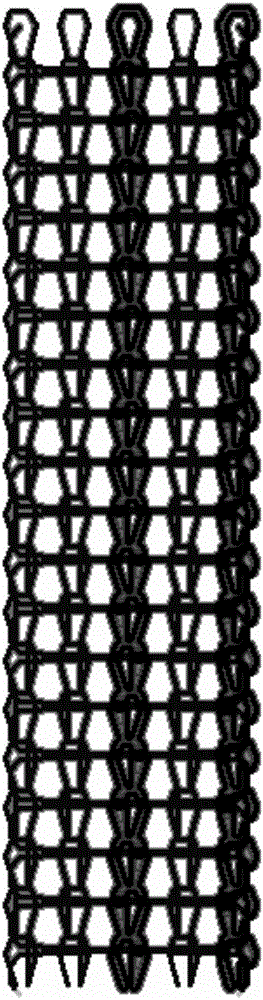

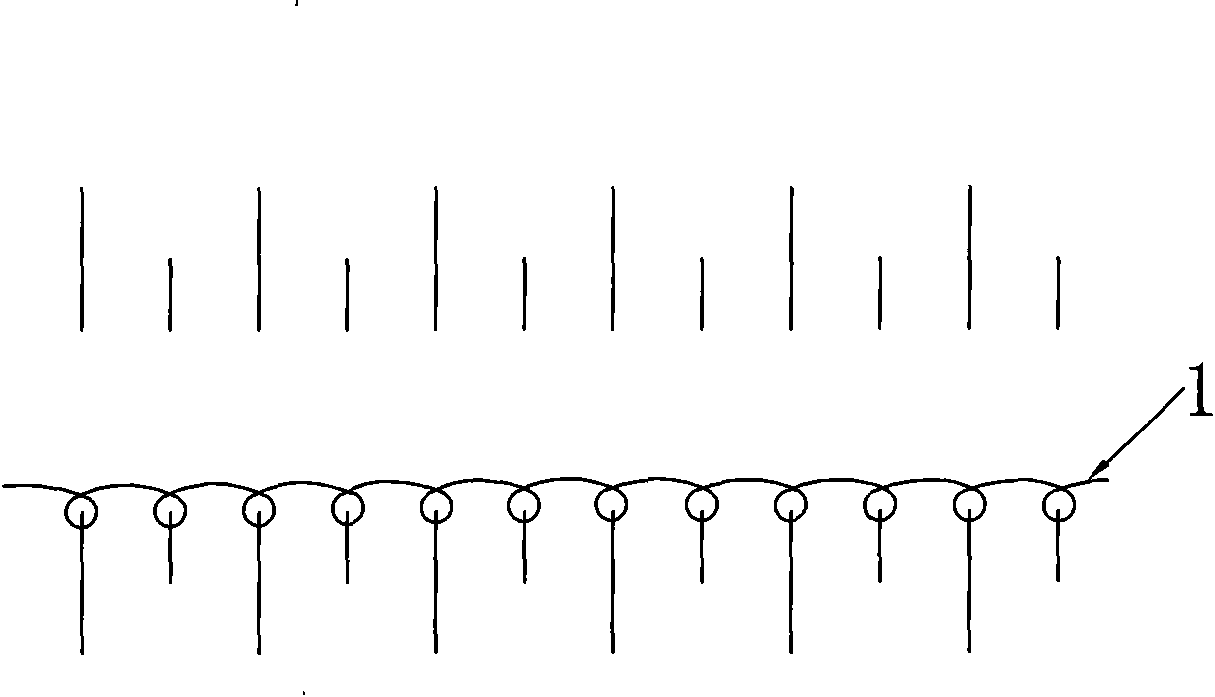

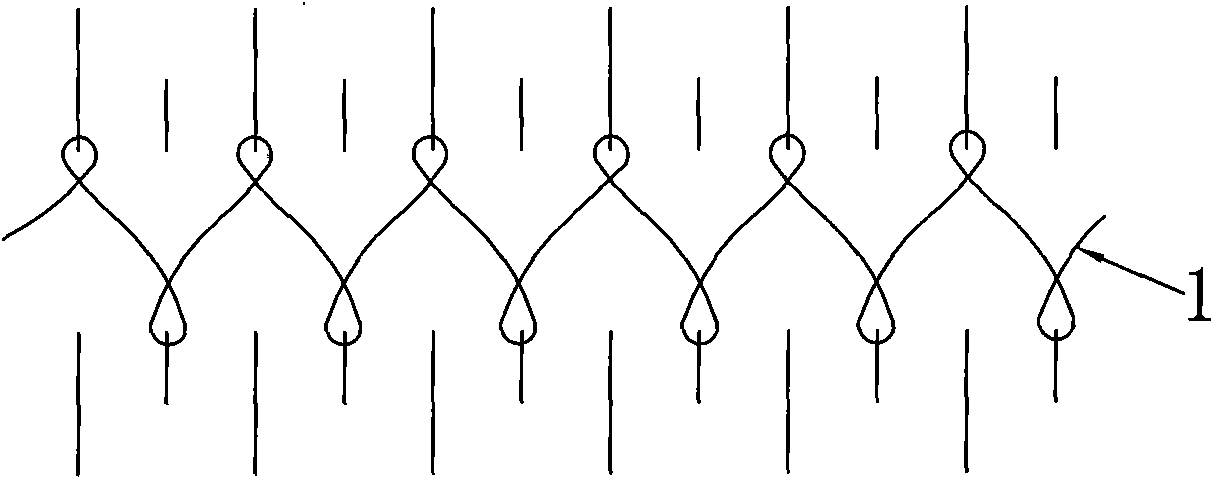

Two-color gradually-varied-mesh gas-guiding three-layer mesh fabric production method and mesh fabric

ActiveCN105970469AImprove stabilitySolve backflowWarp knittingHeating/cooling textile fabricsSurface layerEngineering

The invention provides a two-color gradually-varied-mesh gas-guiding three-layer mesh fabric production method and a mesh fabric. The production method comprises the steps that braiding is conducted through a two-needle bar braiding machine, braiding is conducted through six guide bars which are arranged in sequence from a front needle bar to a rear needle bar, the surface layer is the guide bars from first to third, the needle bar GB1 adopts a one-threading four-empty threading mode on the machine, the guide bar GB2 adopts a one-threading four-empty mode on the machine, and the guide bar GB3 adopts a full-threading threading mode on the machine; the connecting layer is the fourth guide bar, and the guide bar GB4 adopts a full-threading threading mode; the bottom layer is the fifth guide bar and the sixth guide bar, and the guide bar GB5 and the guide bar GB6 both adopt a two-threading two-empty threading mode. The produced mesh fabric is good in air permeability, capable of reducing countercurrent of hot air, high in fabric strength, good in stability, firm and durable, and two-color and gradually-varied-mesh effects can be achieved.

Owner:SINCETECH FUJIAN TECH CO LTD

Closed isolation composition applied to treatment of gangue hill and implementation method thereof

The invention provides a closed isolation composition applied to the treatment of a gangue hill and an implementation method thereof, and belongs to the technical field of environmental treatment andmine ecological restoration. The closed isolation composition comprises inorganic substances, a polymer, fiber, an additive and water, the weight ratio of the inorganic substances is 20-75%, the weight ratio of the polymer is 0.2-5%, the weight ratio of the fiber is 0.05-5%, the weight ratio of the additive is 0.05-2%, and the weight ratio of the water is 20-75%; the above materials are mixed according to a certain ratio to prepare a mixed slurry, the slurry is sprayed on the surface of the gangue hill for sealing of the gangue hill and isolation from a vegetation area to completely eliminatethe hazard of the gangue hill, and the disturbance influence of vegetation on the gangue hill is eliminated. The closed isolation layer has the advantages of airtightness, seepage resistance, heat insulation, firmness and durability, the used materials are all environmentally friendly, the construction is simple, the efficiency is high, and the cost is low.

Owner:山西智德生态环保股份有限公司

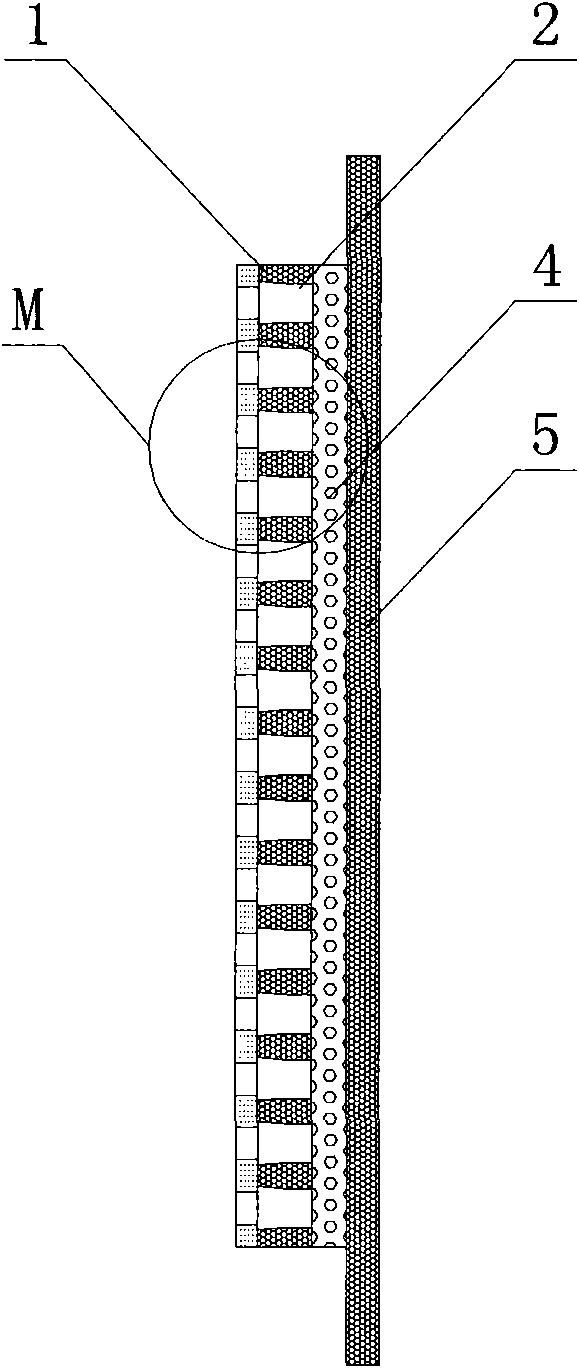

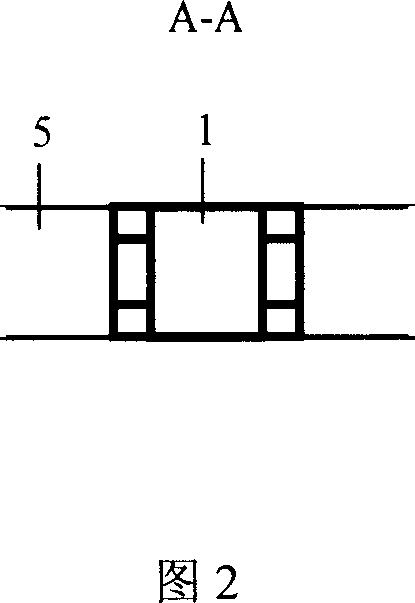

Improved structure of breathable heat insulating fabric

InactiveCN101880934ASolve thin and lightSolve the breathability problemWeft knittingYarnSurface layer

The invention discloses an improved structure of a breathable heat insulating fabric. The surface layer of the fabric is yarn with hygroscopicity; the lining of the fabric is woven by the yarn with heat insulation and heat generation and the yarn with hygroscopicity; the surface layer of the fabric and the lining of the fabric are woven together by the yarn with hygroscopicity; the fabric structure after the surface layer of the fabric and the lining of the fabric are woven is a double-surface air layer structure; the double-surface air layer structure is woven by cotton yarn with full withdrawing of the needle at a bottom cylinder and by far infrared yarn on an upper dial plate with full withdrawing of the needle, and is formed by mutually interweaving and connecting the cotton yarns with single withdrawing of the needle on the upper dial plate and the bottom cylinder. The fabric of the invention has soft feeling, light weight, thinness, good heat insulating ability and breathability and fine style.

Owner:JIANGSU

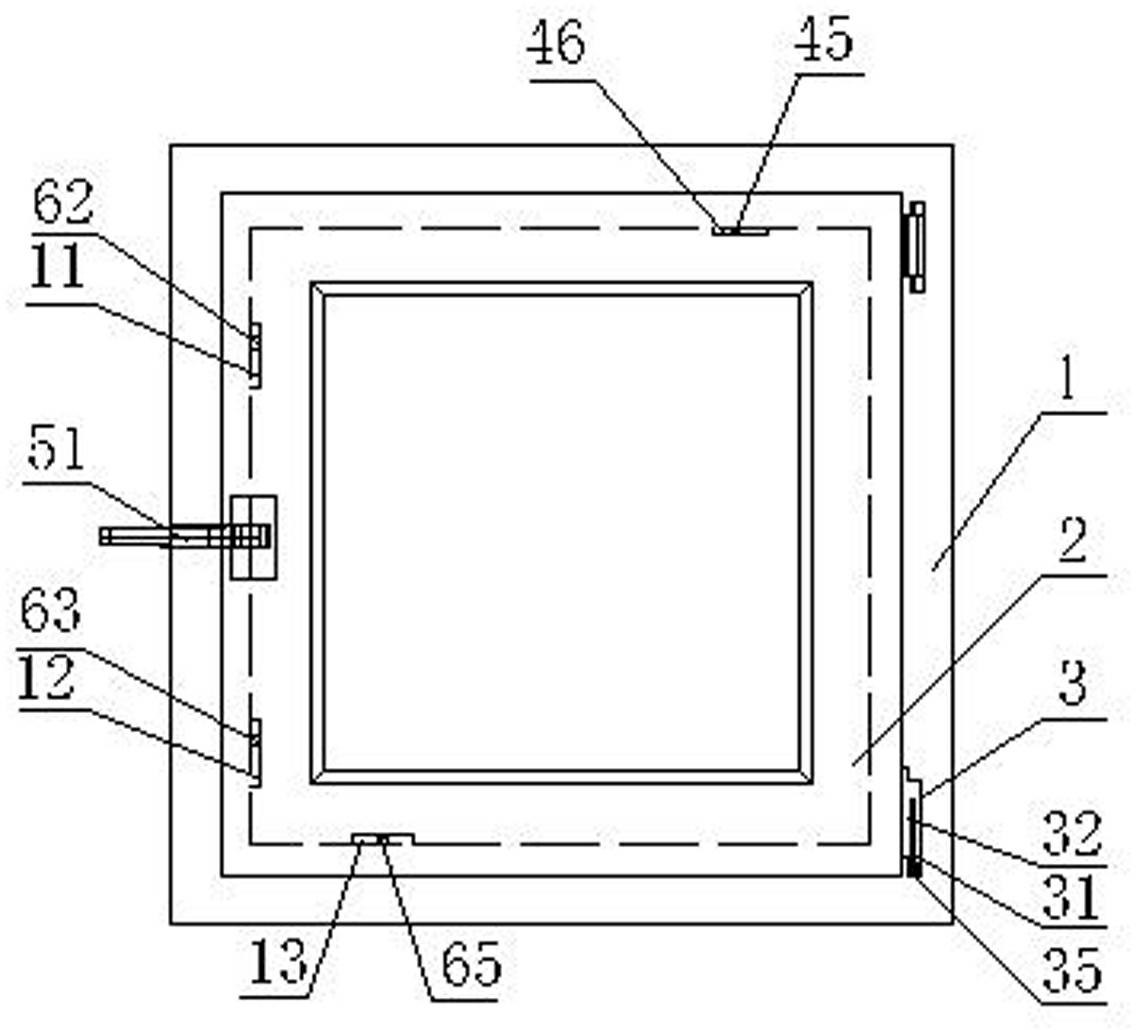

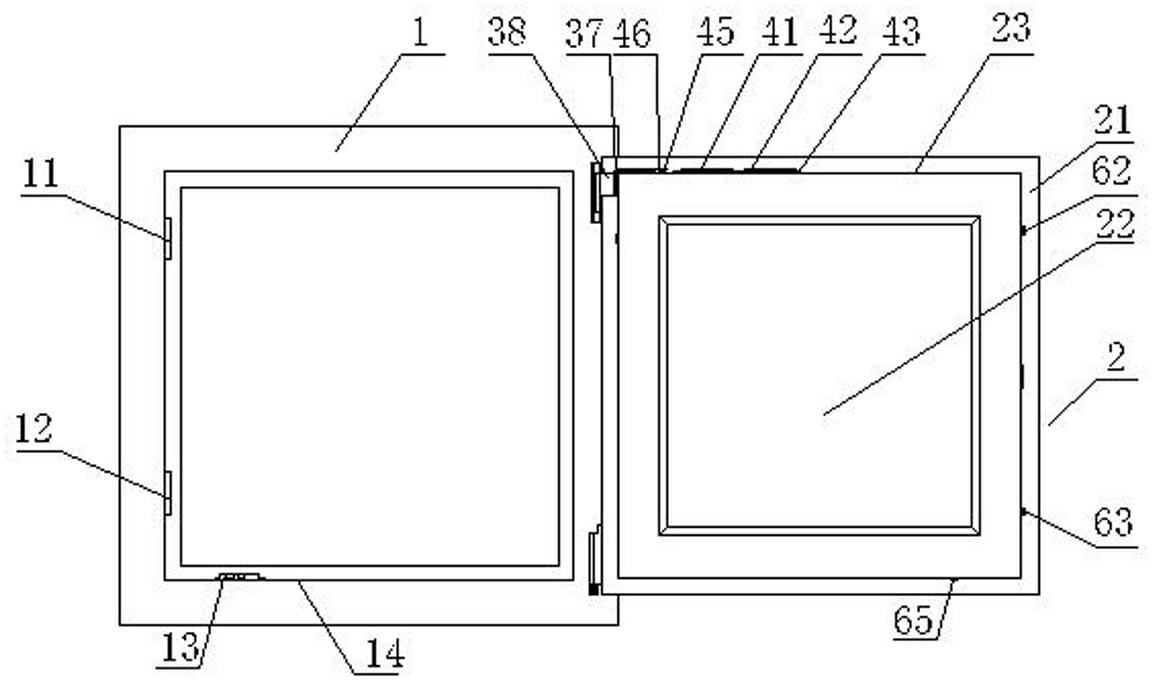

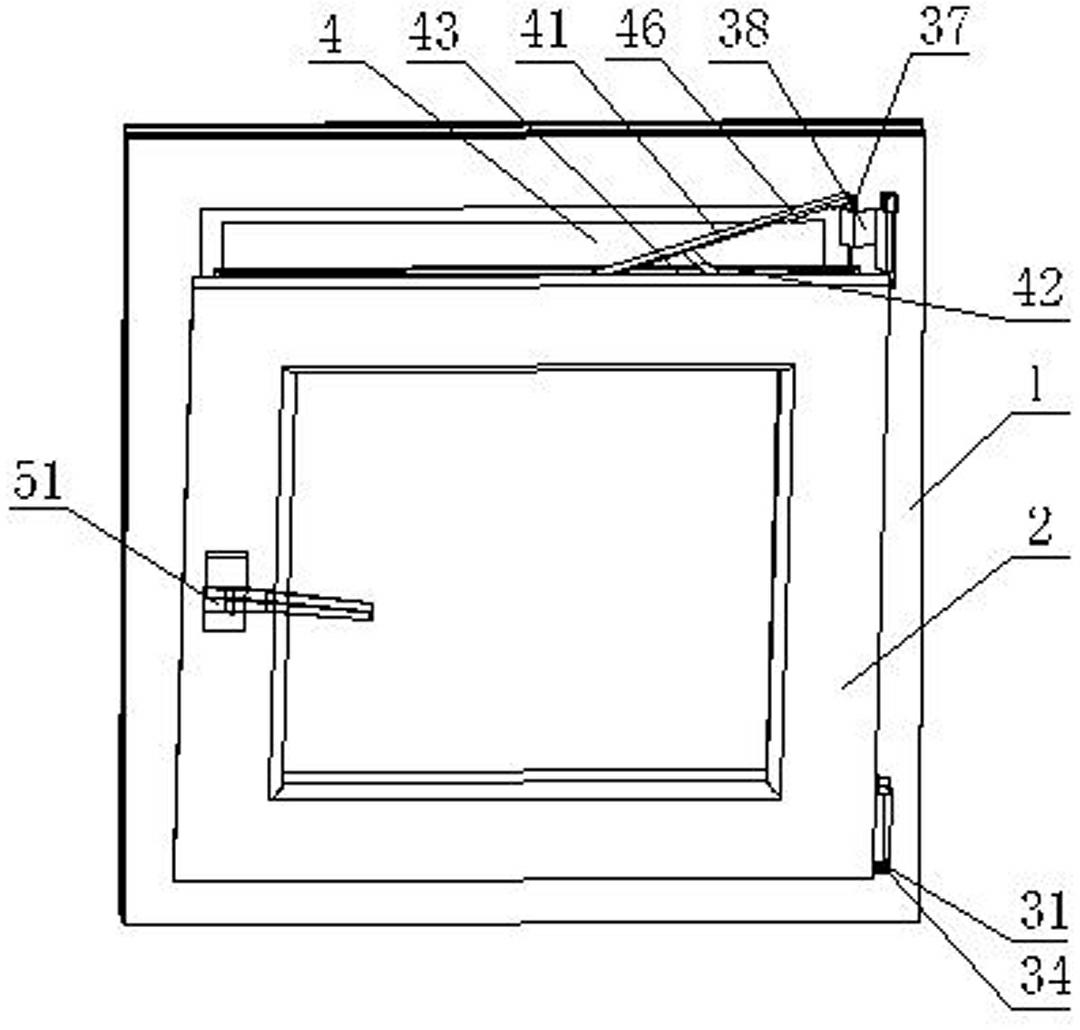

Multifunctional door and window device

InactiveCN102352720ASolve usabilitySolve the breathability problemConstruction fastening devicesWing arrangementsNatural ventilationElectrical and Electronics engineering

The invention relates to a multifunctional door and window device, which comprises a door frame and a door and window sash which can be arranged on the door frame in the manner of opening and closing. The multifunctional door and window device is characterized in that the door and window sash can be horizontally rotated indoors and turned vertically to be connected onto the door frame through a hinged structure, and moreover, the upper parts of the door and window sash and the door frame are also provided with an opening and closing control mechanism which can enable the upper end of the doorand window sash to be turned indoors to form an upper air vent. In the multifunctional door and window device, as a structure that the door and window sash can be horizontally rotated indoors and turned vertically to be connected onto the door frame through the hinged structure and the door and window sash is provided with the opening and closing control mechanism which can enable the upper end of the door and window sash to be turned indoors to form the upper air vent is adopted, the multifunctional door and window device not only can enable the door and window sash to be horizontally rotated indoors by 180 degrees at ordinary times so as to fully meet the requirements of indoor lighting and natural ventilation, but also can only enable the upper end of the door and window sash to be turned indoors by a certain angle in windy and rainy days so as to form the upper air vent which can prevent rainwater from entering indoors and can be used for ventilation, therefore, the multifunctional door and window device is extremely convenient in use.

Owner:郭妍文

Ladle bottom argon blowing air brick for smelting high-purity high manganese steel

The invention discloses ladle bottom argon blowing air brick for smelting high-purity high manganese steel. The air brick is prepared from the following materials: forsterite sand, fused magnesia, corundum, sodium silicate, sodium permanganate, an explosion-proof admixture, a polycarboxylate dispersion water reducing agent and water. Uniformly-distributed tiny pores can be formed in the air brickdisclosed by the invention, and the permeation volume is 1.5 times or more than 1.5 times of the permeation volumes of slit and diffuse air bricks; argon is permeated in molten steel through the plurality of pores, so that the purification rate of the molten steel is obviously increased, and the contents of oxygen and hydrogen in the molten steel are reduced; the problems that a small number of straight thick holes are caused by slag-clearing iron oxygen burning, the argon intensively passes through the molten steel and quickly escapes from the liquid level and the like are solved; the purification rate of the molten steel is obviously increased.

Owner:广西长城机械股份有限公司

Smooth memory knitted fabric and preparation method

ActiveCN103556377AFunction increaseThe preparation process is scientific and environmentally friendlyWeft knittingDeodorantEngineering

The invention relates to a smooth memory knitted fabric and a preparation method thereof. The smooth memory knitted fabric comprises an outer layer and an inner layer, the outer layer is composed of super fine denier polyester fibers, and the inner layer is composed of Modal fiber staple yarns and polyurethane fiber filaments. The preparation method includes that (1) after structural design, a weft knitting single-sided multi-needle-track high needle pitch knitting machine is used for weaving with weft knitting number 28-32G to obtain a knitted fabric, and (2) the obtained knitted fabric is subjected to presetting, pre-processing, polyester fiber dyeing, Modal fiber overdyeing, color fixing, water scrubbing, repeatedly setting and finally drying. The smooth memory knitted fabric has the advantages that the smooth memory knitted fabric is highly elastic, fine, smooth, quickly dry when absorbing water, antimicrobial, deodorant, not prone to deformation after washed, light, convenient and comfortable if a user wears clothes made of the fabric, and capable of overcoming defects of poor hand feel, creased cloth surfaces, insufficient wet permeability, tendency to stink and the like in terms of traditional fabrics.

Owner:NINGBO DAQIAN TEXTILE

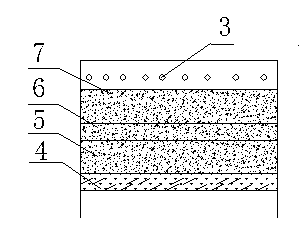

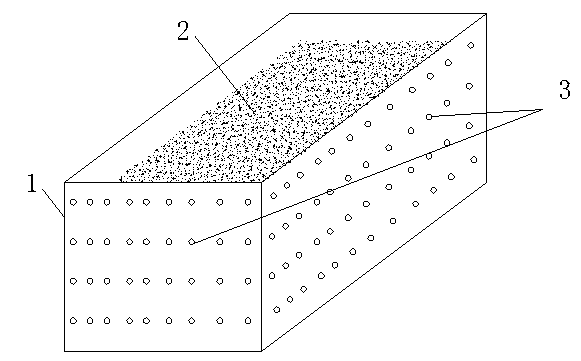

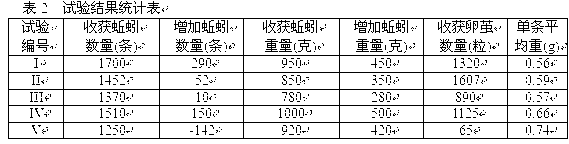

Breeding bed for earthworm

InactiveCN103070140ASolve the breathability problemEnsure safetyAnimal feeding stuffRice strawMunicipal sewage

The invention discloses a breeding bed for earworm. A bed body of the breeding bed for the earthworm is a rectangular frame of which the depth is 25-35cm, the length is 45-55cm and the width is 30-40cm; dense and uniform ventilation holes with aperture of 0.5-1.0cm are respectively formed in four walls and the bottom; a bed layer of the breeding bed for the earworm comprises four layers which sequentially include a dry straw layer, a lower lime sludge layer, a cow dung or pig dung layer and an upper lime sludge layer from bottom to top; the dry straw layer comprises dry straw with the length of 2-3cm and the thickness of 2-3cm; the lower lime sludge layer comprises sludge with the thickness of 5-10cm; the cow dung or pig dung layer comprises cow dung or pig dung with the thickness of 2-13cm; the upper lime sludge layer comprises sludge with the thickness of 5-10cm; and the bottom of the breeding bed is overhead, and the breeding bed is 5-8cm away from the ground. The breeding bed disclosed by the invention has the advantages of simple structure, low manufacturing cost, simplicity in operation, easiness for maintenance and suitability for breeding the earworm for treating residual sludge of municipal sewage.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Production method of breathable leather

ActiveCN103898773AImprove hydrolysis resistanceReduce manufacturing costLaminationLamination apparatusProduction lineSurface layer

The invention relates to a production method of breathable leather. The condition that in a production method of the breathable leather, environment pollution in the production process is free and the problem of product breathability is available can be solved at present can not be splved. The production method comprises the following steps: (1) preparing a sizing agent, wherein the sizing agent consists of polyurethane resin and color chips in a weight ratio of 100:1.2, and the viscosity of the sizing agent is adjusted to be 1500cps; (2) mounting release paper onto a PU (Polyurethane) production line, firstly, drying the release paper at 100 DEG C, subsequently coating the release paper with the sizing, and furthermore, drying at 140 DEG C so as to obtain a half-finished product; (3) printing a dry method surface layer of the release paper with patterns and glossiness by using a three-edition printing machine; (4) compounding the release paper with a piece of base cloth by using a binding agent; and (5) washing in water by using a graining machine; and (6) inspecting to be qualified to obtain a breathable leather product. By adopting the production method, the product breathability can be solved.

Owner:ZHEJIANG SHENTENG COATED FABRICS

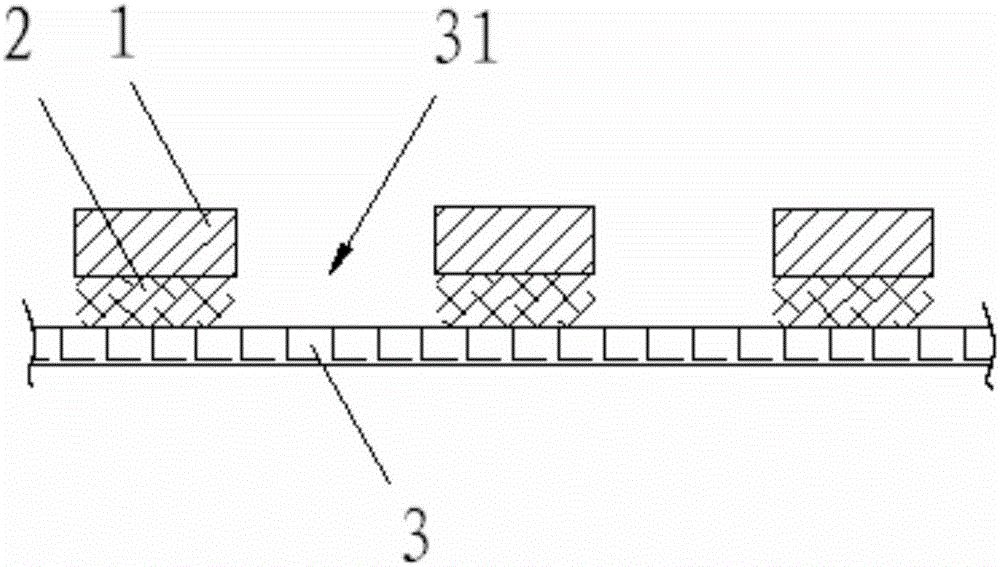

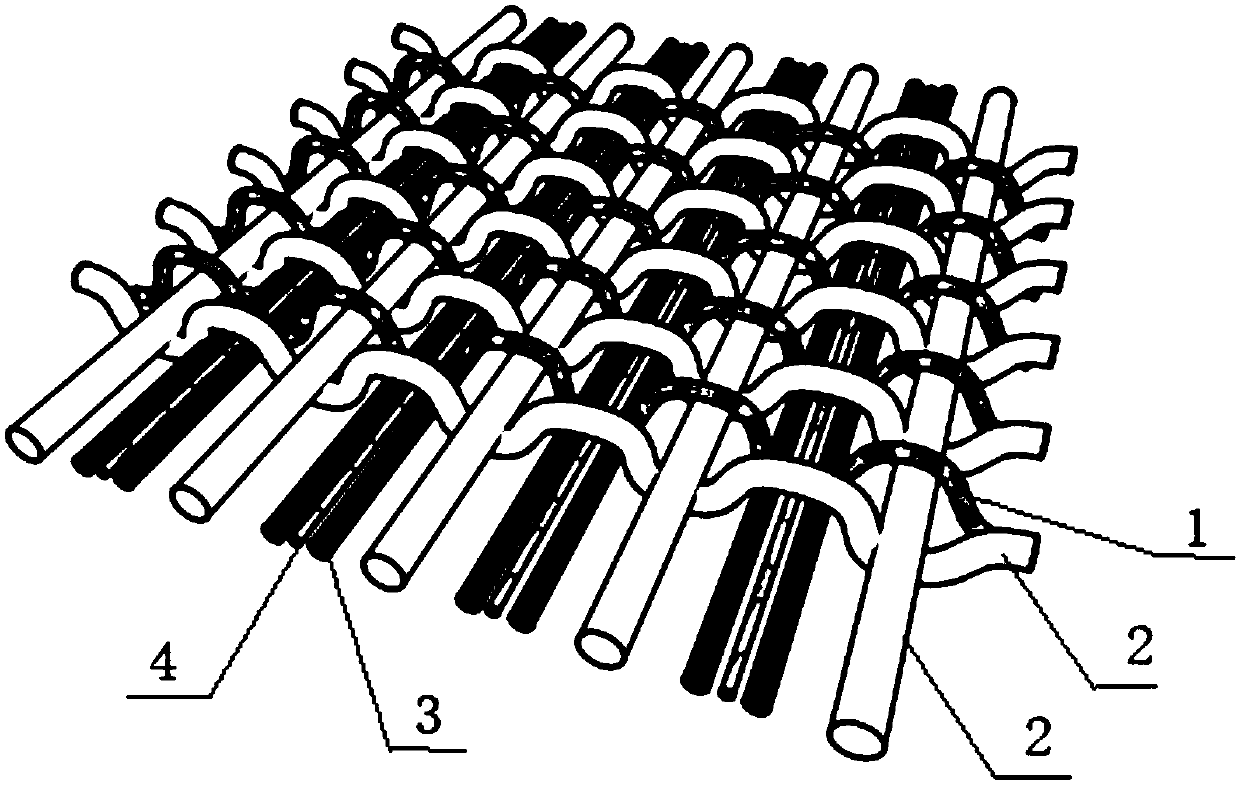

Friction nanometer power generation sensor array with fabric structure

ActiveCN110864827ASolution flexibilityAddress flexibilityForce measurementFriction generatorsFiberFabric structure

The invention provides a friction nanometer power generation sensor array with a fabric structure. The friction nanometer power generation sensor array is characterized in that the fiber electrode isformed by weaving insulating space lines, low electrophilic friction power generation fiber electrodes, high electrophilic friction power generation fiber electrodes and other non-conductive fibers ina warp-weft staggered mode, one high electrophilic friction power generation fiber electrode and two insulating space lines form a group of fiber groups, the high electrophilic friction power generation fiber electrode is located between the two insulating space lines, and the diameter of each insulating space line is larger than that of each high electrophilic friction power generation fiber electrode; the other non-conductive fibers and the low electrophilic friction power generation fiber electrodes are distributed at intervals in one direction, and the fiber groups and the other non-conductive fibers are distributed at intervals in the other direction; in the weaving process, the interface pressure of a single warp and a weft is 0.5kPa-5MPa, and the tension range of the single warp is10(-3)N-10N. The pressure shape and size can be sensed, and the friction nanometer power generation sensor array can be suitable for any working plane, and is light, flexible and wearable.

Owner:CHONGQING UNIV

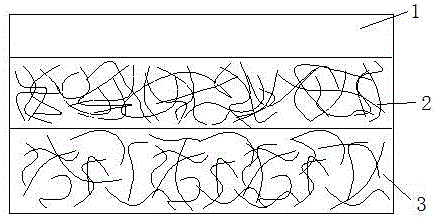

Process for preparing composite nonwoven wallpaper

ActiveCN105821698ASolve moisture-proneSolve the breathability problemLamination ancillary operationsLaminationNoise reductionMechanical property

The invention discloses a process for preparing composite nonwoven wallpaper. The composite non-woven wallpaper is of a three-layer structure including a coated material at the upper layer, a wet-laid nonwoven material at the intermediate layer and a needle-punched nonwoven material at the lower layer. A surface density of the upper layer is 10 to 20g / m<2>; the intermediate layer is prepared by adopting wet forming and a spunlaced or thermo-bonding technology, and has a surface density of 100 to 200g / m<2>; the lower layer is prepared by adopting a carded web forming and a punched or thermo-bonding technology and has a surface density of 300 to 400g / m<2>; the three layers of materials are composited by adopting ultrasonic waves and a spunlaced technology, or the like. The composite non-woven wallpaper disclosed by the invention has excellent mechanical properties, favorable air permeability and dampproof and anti-fouling properties, excellent sound absorption property and certain antibacterial property. According to the process disclosed by the invention, defects that a traditional wallpaper material is likely to be affected by damp, is air-impermeable, and is free of sound insulation and noise reduction and the like are solved by adopting wet forming, punched and other nonwoven machining technologies, such that the composite nonwoven wallpaper is applied more widely.

Owner:江苏金三发卫生材料科技有限公司

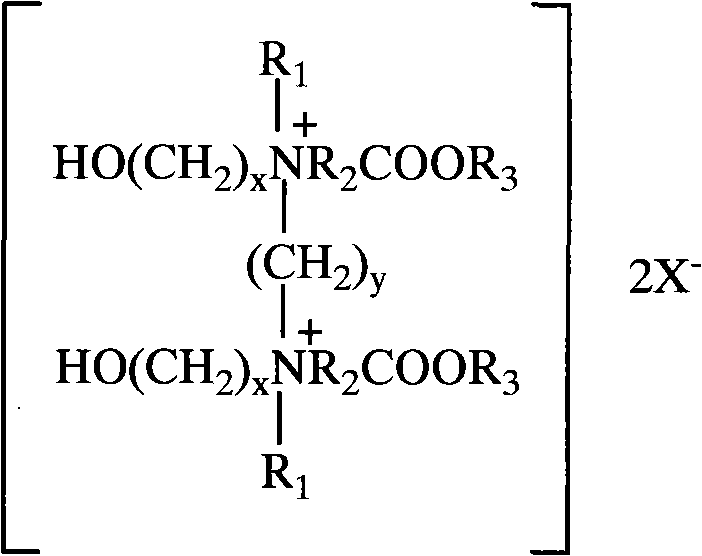

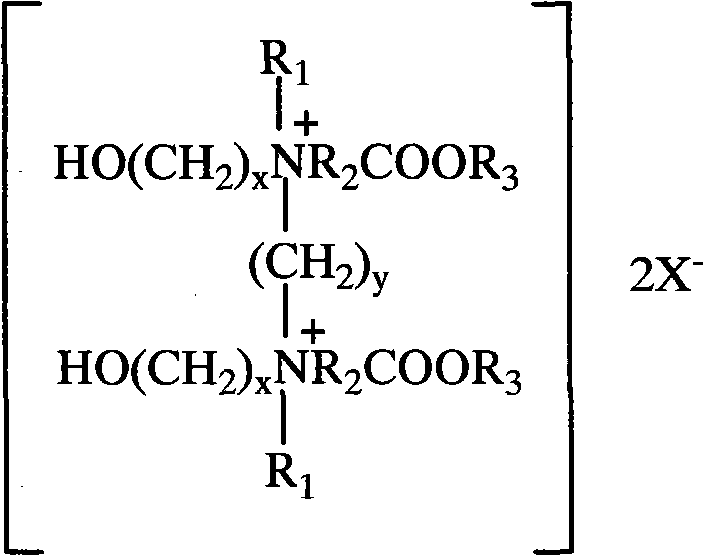

Method for preparing fabric softening agent

InactiveCN102162189AOutstanding advantagesHighlight positive effectsOrganic compound preparationFibre treatmentSolubilityQuaternary ammonium cation

The invention discloses a method for preparing fabric softening agent. The method is characterized in that: long-chain fatty alcohol and unsaturated acid undergo esterification reaction, then the esterification product and alcohol amine undergo addition reaction to form secondary amine, the secondary amine and halogenated hydrocarbon undergo substitution reaction to form tertiary amine, and the tertiary amine and a quaternization reagent are reacted to form the fabric softening agent; and the fabric softening agent has the following structure, wherein R1 is alkyl of C1 to C4 or -CH2CH(OH)CH3, R2 is straight-chain or branch-chain alkyl of C1 to C3, R3 is saturated alkyl with 12 to 22 carbon atoms, x and y are 2 to 6, and X represents negative ions combined with positive ions. The product prepared by the method is a double-ester Gemini quaternary ammonium salt softening agent; by using the Gemini structure and introducing the alcohol ethyl, the problems of poor dissolubility, strong greasy feeling and poor wetting property and air permeability of the conventional softening agent (D1821) are solved; and the softening agent has more excellent softening performance and antistatic performance compared with common ester-based quaternary ammonium salts.

Owner:HENAN TITANING CHEM TECH

Low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather and preparation method thereof

ActiveCN107354760AReduce volatilityLow mobilityCoatingsTextiles and paperPolyvinyl chlorideUltimate tensile strength

The invention discloses a low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather and a preparation method thereof, wherein the artificial leather comprises a base cloth layer, a PVC foaming layer, a PVC compact layer and a paint layer. According to the present invention, the low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather prepared by using the formula and the preparation method has characteristics of good mechanical strength, strong toughness, wear resistance and strong low-temperature-deflection resistance, further has advantages of gas permeability and comfort similar to the leather, and further has characteristics of good hand feeling and high security.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com