Method for manufacturing light and thin suit

A production method and technology of suits, applied in the field of garment manufacturing, can solve the problems of poor air permeability and moisture permeability of suits, excessive use of auxiliary materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] The invention discloses a method for making a light and thin suit. The chest of the front garment piece of the suit produced by the method does not have a composite chest lining made of black carbon lining, ponytail lining and chest cotton; wherein, the back garment of the suit There is lining on the shoulders, front panels, and sleeves of the garment; there is no lining below the shoulders of the side panels and the rear panels. In the present invention, the light and thin suit does not use chest pads and shoulder pads, and lining is provided on the shoulders of the suit.

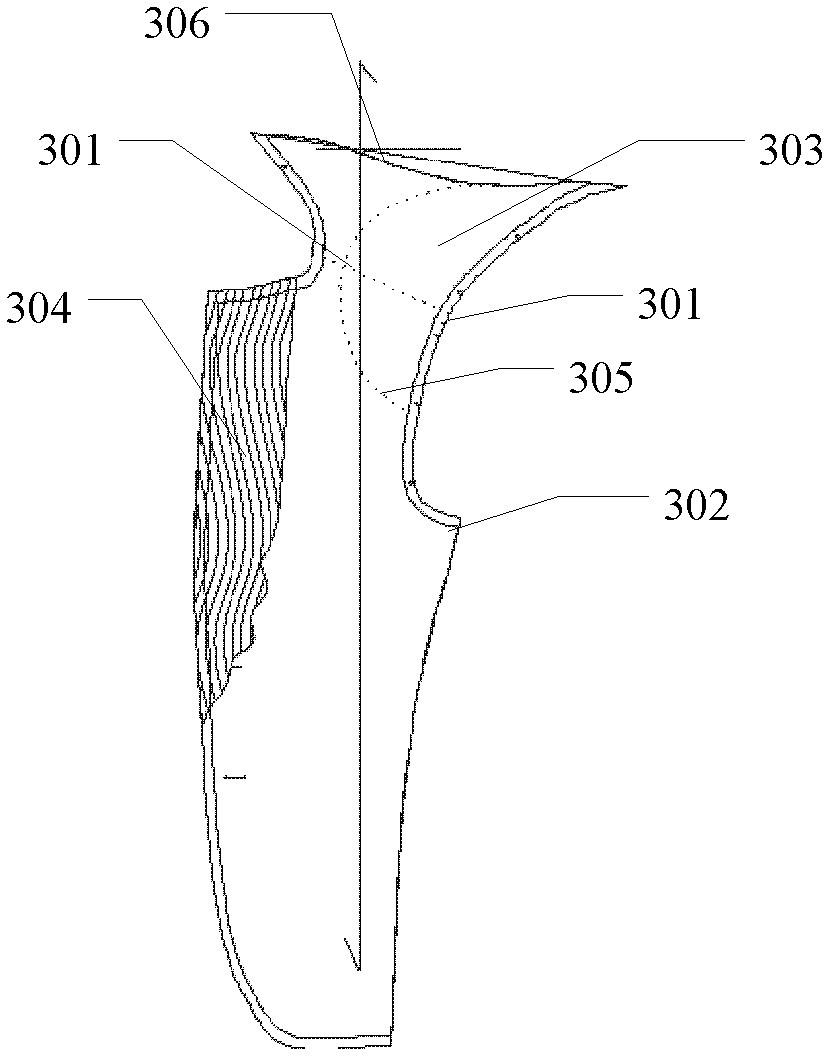

[0019] figure 1 It is a schematic diagram of the lining structure of a light and thin suit in the present invention, such as figure 1 As shown, after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com