Method for preparing fabric softening agent

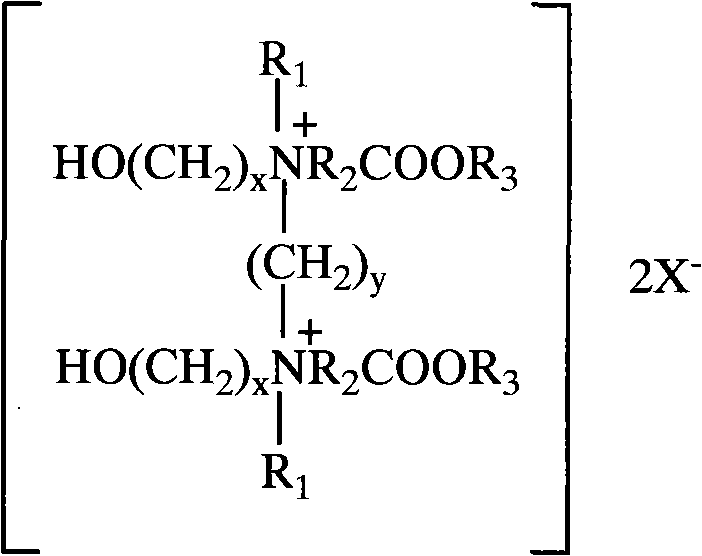

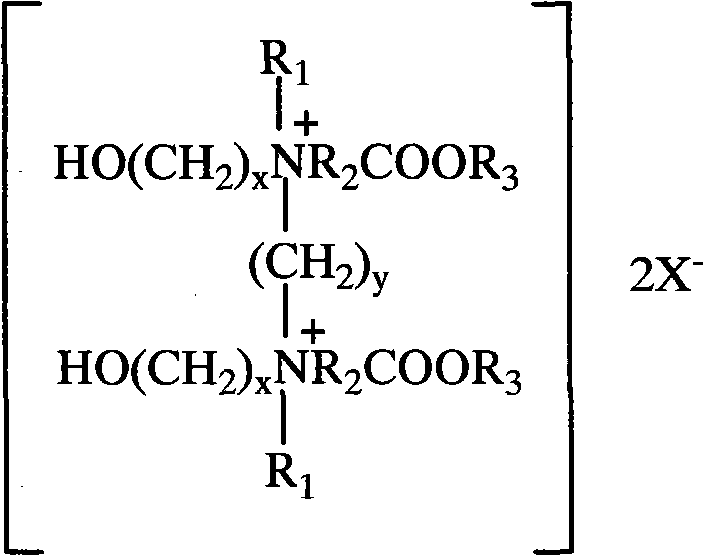

A fabric softener, unsaturated technology, applied in the preparation of fabric softener, the preparation of diester Jimich quaternary ammonium salt fabric softener, can solve the problem of reducing softness and solubility, single diester component, poor biodegradation and other problems, to achieve excellent soft performance and antistatic performance, low ecotoxicity, and to overcome environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: In a 100ml four-neck flask equipped with a thermometer, a stirrer, and a condenser, add 27.05g of stearyl alcohol, and under a nitrogen atmosphere, stir and heat up to 60-80°C to melt it all, then add 0.01 g hydroquinone, 7.21g acrylic acid, 0.87g p-toluenesulfonic acid; continue to pass nitrogen, heat up to 100°C and stir the reaction until the acid value <0.5mgKOH / g to complete the reaction, cool down, neutralize and wash with lye to remove the catalyst, Then, it was washed with water to neutrality, and the obtained product was dried in a vacuum oven at 60° C. to obtain white waxy solid stearyl acrylate.

[0026] In a 100ml four-neck flask equipped with a thermometer, a stirrer, and a condenser, add 32.40g of octadecyl acrylate, weigh 5.81g of ethanolamine and place it in a constant pressure dropping funnel, heat up to 85°C with nitrogen gas, and add ethanolamine dropwise. Reaction at 85°C for 5h gave secondary amine.

[0027] In a 100ml four-necked flask ...

Embodiment 2

[0029] Example 2: In a 100ml four-neck flask equipped with a thermometer, a stirrer, and a condenser, add 27.05g of stearyl alcohol, under a nitrogen atmosphere, stir and heat up to 60-80°C to melt it all, then add 0.0207 g hydroquinone, 14.40g acrylic acid, 1.04g p-toluenesulfonic acid; continue to pass nitrogen, heat up to 135°C and stir the reaction until the acid value <0.5mgKOH / g to complete the reaction, cool down, neutralize and wash with lye to remove the catalyst, Then, it was washed with water to neutrality, and the obtained product was dried in a vacuum oven at 60° C. to obtain white waxy solid stearyl acrylate.

[0030]In a 100ml four-necked flask equipped with a thermometer, a stirrer, and a condenser, add 32.41g of octadecyl acrylate, weigh 7.32g of ethanolamine and place it in a constant-pressure dropping funnel, heat up to 120°C with nitrogen gas, and add ethanolamine dropwise. React at 120°C for 12h to obtain secondary amine.

[0031] In a 100ml four-necked f...

Embodiment 3

[0033] Example 3: In a 100ml four-necked flask with a thermometer, a stirrer, and a condenser, add 27.05g of stearyl alcohol, under a nitrogen atmosphere, stir and heat up to 60-80°C to melt it all, then add 0.024 g hydroquinone, 21.60g acrylic acid, 1.21g p-toluenesulfonic acid; continue to pass nitrogen, heat up to 165°C and stir the reaction until the acid value <0.5mgKOH / g to complete the reaction, cool down, neutralize and wash with lye to remove the catalyst, Then, it was washed with water to neutrality, and the obtained product was dried in a vacuum oven at 60° C. to obtain white waxy solid stearyl acrylate.

[0034] In a 100ml four-neck flask equipped with a thermometer, a stirrer, and a condenser, add 32.40g of octadecyl acrylate, weigh 9.76g of ethanolamine and place it in a constant pressure dropping funnel, heat up to 160°C with nitrogen gas, and add ethanolamine dropwise. React at 160°C for 12h to obtain secondary amine.

[0035] In the 100ml four-necked flask wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com