Processing technology for electroplating effluent of heavy metal

A technology for electroplating wastewater and treatment process, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Simplicity and the effect of reducing the amount of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The various index analysis results of the mixed waste water (raw water) and the effluent treated by the process of the present invention are shown in Table 1.

[0050] Table 1. Water quality analysis result before and after process treatment of the present invention

[0051]

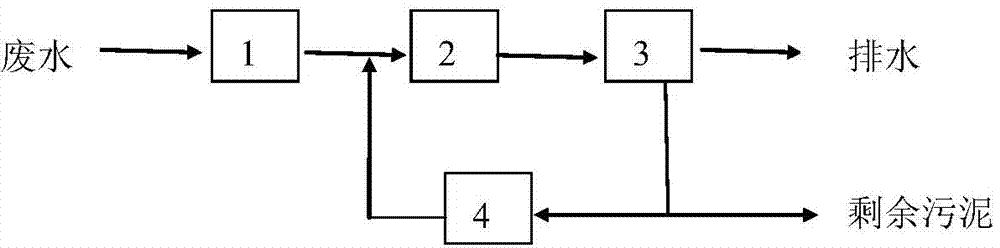

[0052] Such as figure 1 As shown, the present invention includes two series treatment procedures: iron-carbon micro-electrolysis pretreatment procedure and sludge recycling treatment procedure. The iron-carbon micro-electrolysis pretreatment process mainly includes a micro-electrolysis packing tower 1 filled with a large amount of spherical iron-carbon composite materials, and the bottom of the micro-electrolysis packing tower 1 is fed with air for aeration, and the aeration rate is 5L / min. The sludge circulation treatment process is mainly composed of a stirring tank 2, a sedimentation tank 3 and an alkali tank 4.

[0053] After the various wastewater discharged from the electroplating plant...

Embodiment 2

[0056] as attached figure 1 Shown is a heavy metal electroplating wastewater treatment process, the devices involved in this process include an iron-carbon micro-electrolysis treatment device and a sludge circulation treatment device; the iron-carbon micro-electrolysis treatment device includes a micro-electrolysis packing tower 1, and the micro-electrolysis packing tower 1 Filled with a large number of spherical iron-carbon composite materials, the bottom of the micro-electrolysis packed tower 1 is vented with air for aeration; the sludge circulation treatment device includes a stirring tank 2, a sedimentation tank 3 and an alkali tank 4, and the stirring tank 2, sedimentation tank 3 and alkali The tanks 4 are connected to each other in turn to form a sludge circulation; the micro-electrolysis packing tower 1 is connected to the stirring tank 2 .

[0057] A heavy metal electroplating wastewater treatment process, comprising the following steps:

[0058] 1) Wastewater collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com