Electrochemical metallographic etching method universal for nickel-based alloys

A metallographic etching, nickel-based alloy technology, applied in the preparation of test samples, etc., can solve the problems of poor metallographic clarity, difficult to distinguish metallographic structure, difficult to control the etching time, etc., to achieve clear grains. , The effect of smooth surface and clear grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

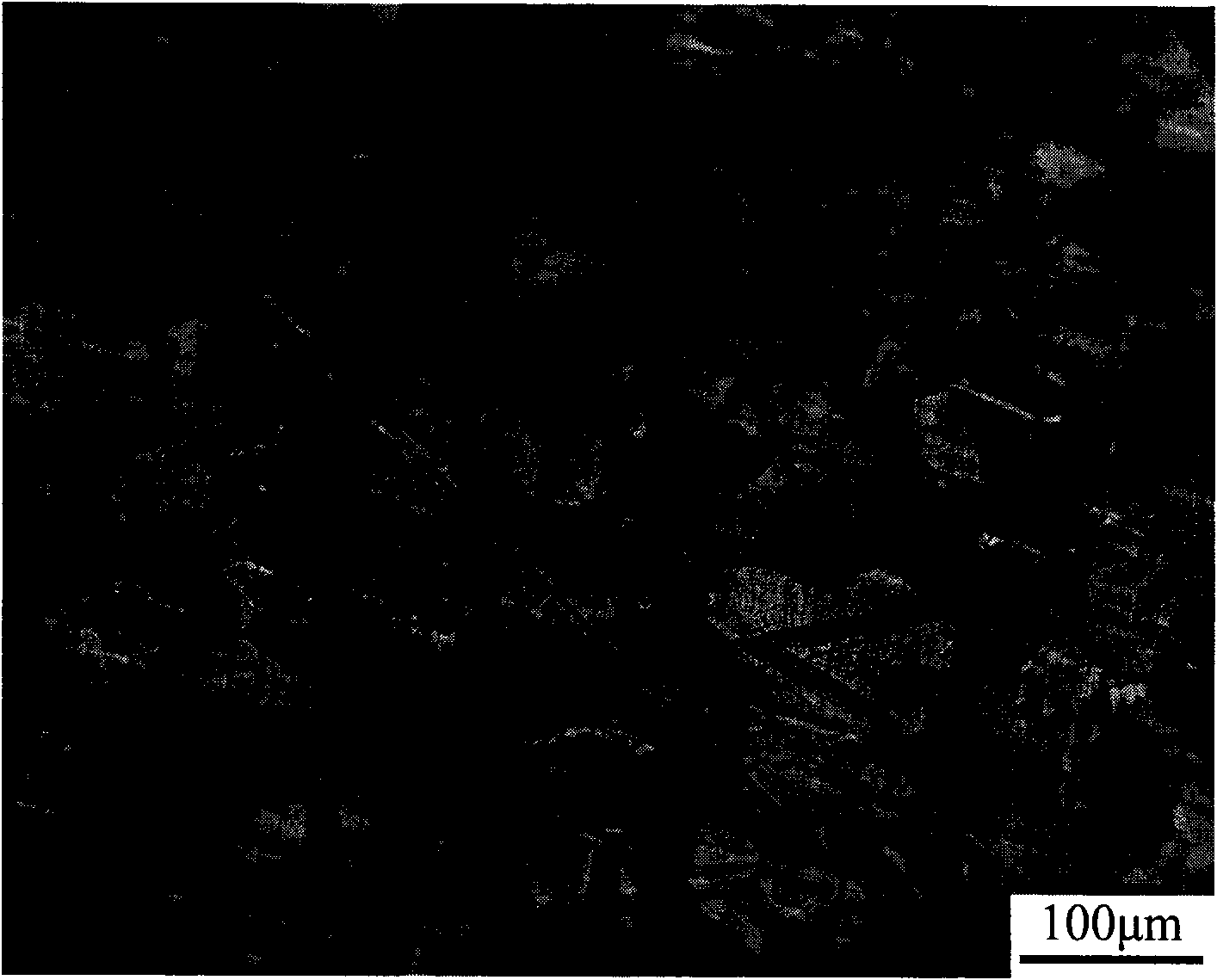

[0016] Example 1: Sampling on the outer surface of the G-3 alloy oil pipe, and performing an electrochemical corrosion metallographic experiment on it

[0017] 1. Use the electric spark cutting method to cut an area of 1x1cm on the outer surface of the G-3 oil pipe in the direction parallel to the axis 2 , a square sample with a thickness of 2mm.

[0018] 2. Weld wires on the back of the sample, and then use ethylenediamine-epoxy resin as the insert material to inlay the sample. A cylindrical sample with a radius of 20 mm was prepared by packaging.

[0019] 3. Grind the sample step by step with water sandpaper until the surface is smooth, and use mechanical polishing to remove the grinding marks left by fine grinding on the grinding surface of the metallographic sample to become a smooth and flawless mirror surface.

[0020] 4. The metallographic etching solution adopts the formula involved in the present invention: 65% phosphoric acid, 15% sulfuric acid, 15% chromic acid,...

Embodiment 2

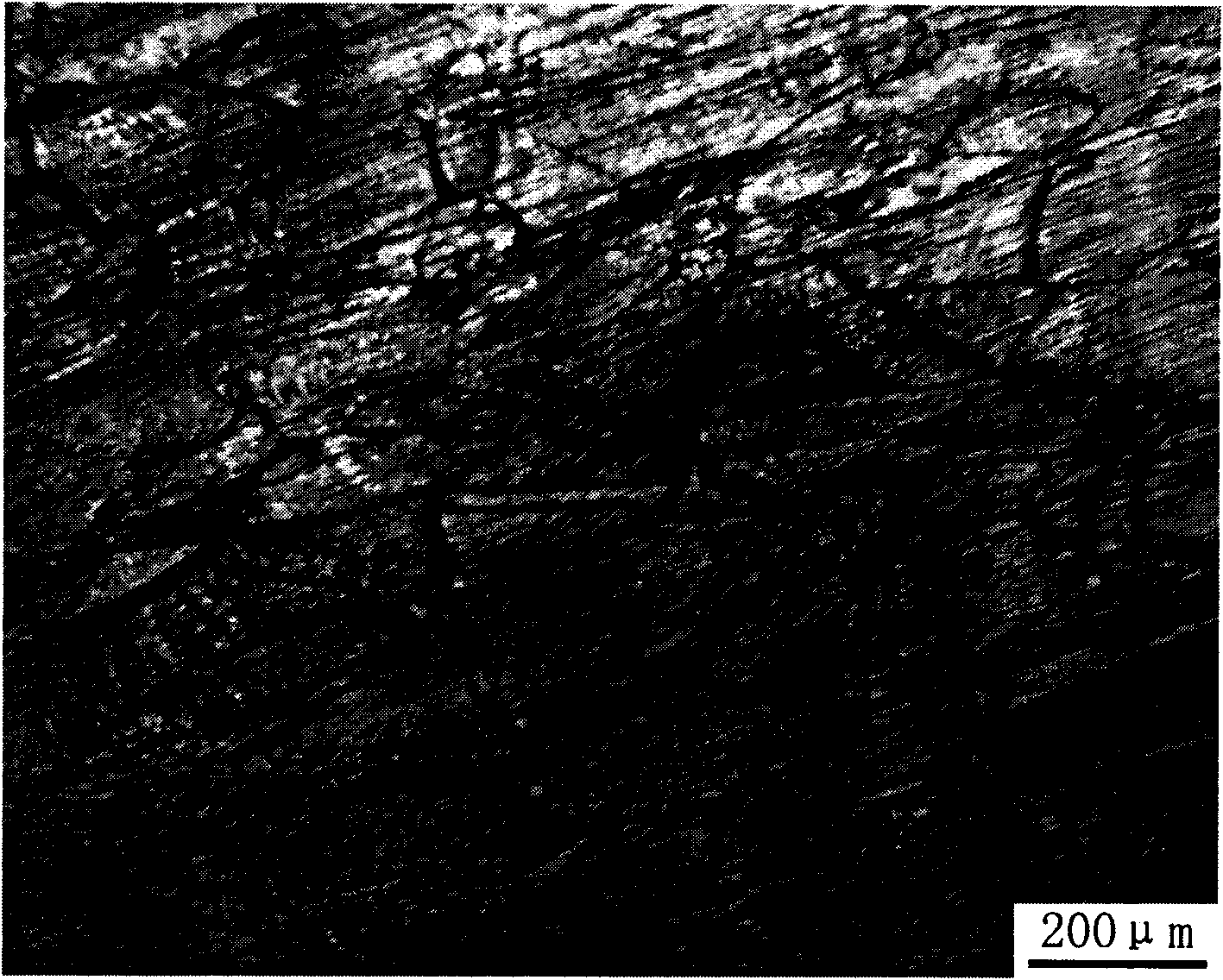

[0022] Embodiment 2: Sampling on the inner surface of the G-3 alloy oil pipe, and carrying out electrochemical corrosion metallographic experiment on it

[0023] 1. Use the electric spark cutting method to cut an area of 1x1cm on the inner surface of the G-3 oil pipe in the direction parallel to the axis 2 , a square sample with a thickness of 2mm.

[0024] 2. Weld wires on the back of the sample, and then use ethylenediamine-epoxy resin as the insert material to inlay the sample. A cylindrical sample with a radius of 20 mm was prepared by packaging.

[0025] 3. Grind the sample step by step with water sandpaper until the surface is smooth, and use mechanical polishing to remove the grinding marks left by fine grinding on the grinding surface of the metallographic sample to become a smooth and flawless mirror surface.

[0026] 4. The metallographic etching solution adopts the formula involved in the present invention: 84% phosphoric acid, 5% sulfuric acid, 8% chromic acid,...

Embodiment 3

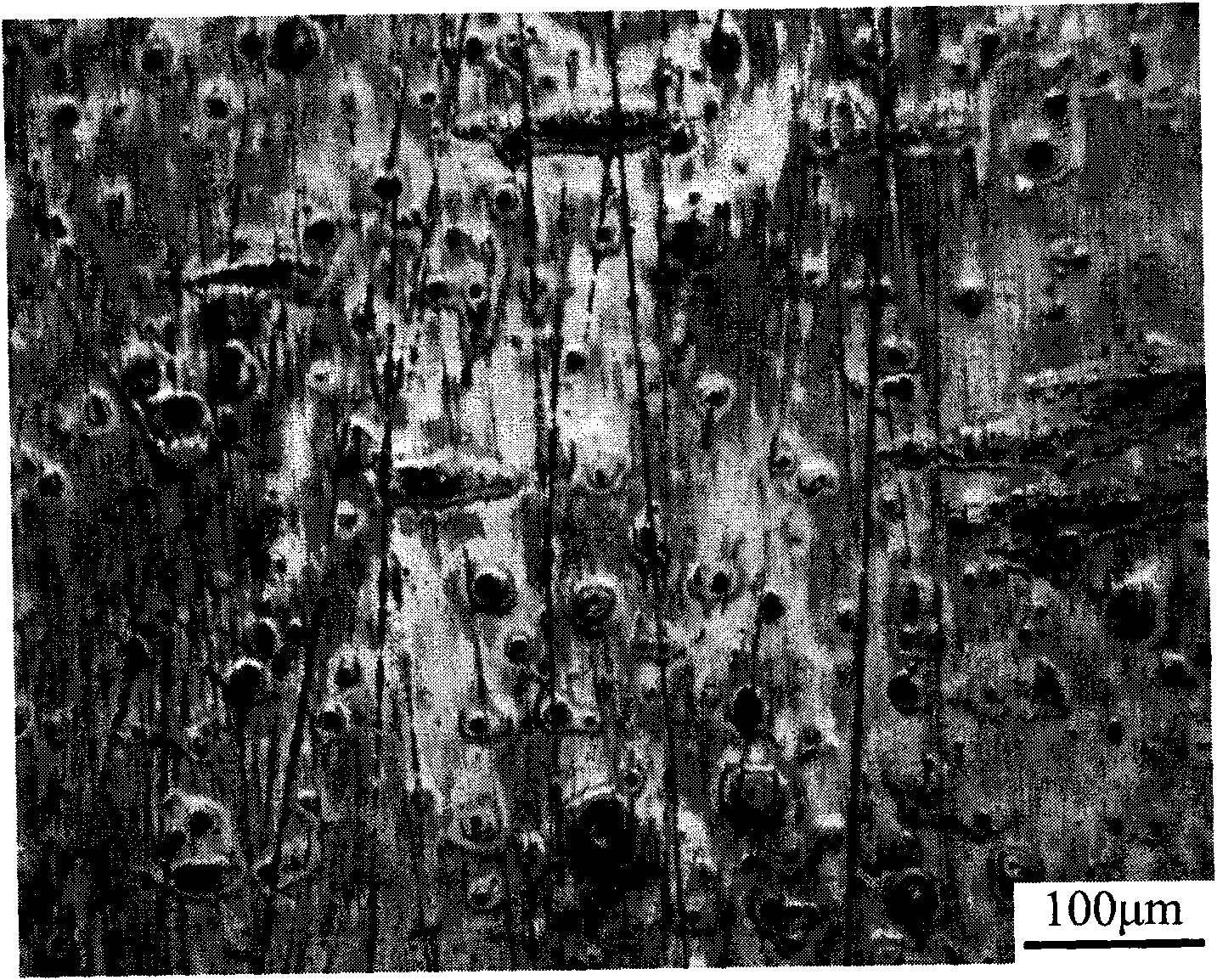

[0028] Embodiment 3: Sampling on the outer surface of the Incoloy 825 alloy oil pipe, adopting the present invention to carry out the electrochemical method etching metallographic experiment on it

[0029] 1. Cut out a square sample with an area of 1x1cm2 and a thickness of 2mm in the direction parallel to the axis of the outer surface of the Incoloy 825 tubing by EDM.

[0030] 2. Weld wires on the back of the sample, and then use ethylenediamine-epoxy resin as the insert material to inlay the sample. A cylindrical sample with a radius of 20 mm was prepared by packaging.

[0031] 3. Grind the sample step by step with water sandpaper until the surface is smooth, and use mechanical polishing to remove the grinding marks left by fine grinding on the grinding surface of the metallographic sample to become a smooth and flawless mirror surface.

[0032] 4. The metallographic etching solution adopts the formula involved in the present invention: 65% phosphoric acid, 5% sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com