Preparation method of polyimide paper honeycomb core

A technology of polyimide paper and honeycomb core, which is applied in papermaking, cardboard articles, textiles and papermaking, etc., can solve the problems of use and cannot be used as a wave-transmitting material, and can expand the field of use, reduce permeability, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

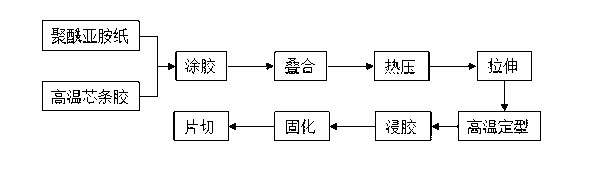

[0031] Such as figure 1 Shown, a kind of preparation method of polyimide paper honeycomb core, the cell size of this polyimide paper honeycomb core is 2.75mm, and density is 72kg / m 3 , the preparation method specifically includes the following steps:

[0032] (1) Use the polyimide fiber paper with a thickness of 0.08mm as the raw material paper to apply the glue with the glue roller dipped in the core strip glue, then stack the multi-layer glued raw paper in staggered layers, and finally use hot pressing Machine hot pressing to make honeycomb stack. The core strip glue is a high temperature core strip glue with a viscosity of 20s / 50ml. When hot pressing, first preheat at 70°C-100°C for 30min-60min, then gel at 120°C-160°C for 90min-150min, and finally cure at 170°C-190°C for 2h-5h, and the hot pressing pressure is 5MPa-7MPa.

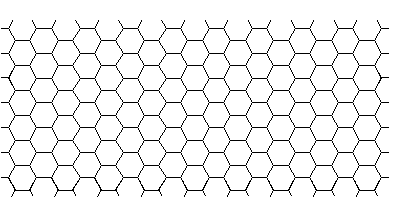

[0033] (2) After stretching the honeycomb stack with a stretching machine at a stretching speed of 5mm / min-25mm / min, it is formed as figure 2 The r...

Embodiment 2

[0040] Such as figure 1 Shown, a kind of preparation method of polyimide paper honeycomb core, the cell size of this polyimide paper honeycomb core is 1.83mm, and density is 32kg / m 3 , the difference between the preparation method and Example 1 is:

[0041] The thickness of polyimide paper is 0.04mm. The viscosity of the high-temperature core strip glue used in step (1) of the preparation method of this embodiment is 35s / 50ml, and the number of dipping times in step (3) is one time.

Embodiment 3

[0043] Such as figure 1 Shown, a kind of preparation method of polyimide paper honeycomb core, the cell size of this polyimide paper honeycomb core is 3.67mm, and density is 40kg / m 3 , the difference between the preparation method and Example 1 is:

[0044] The thickness of polyimide paper is 0.05mm. The viscosity of the high-temperature core strip glue used in step (1) of the preparation method of this embodiment is 40s / 50ml, and the number of dipping times in step (3) is two times.

[0045] It should be noted that in the preparation method of the present invention, the type of honeycomb cell formed in the stretching process is not limited to the regular hexagon in Examples 1-3, and may also be rectangular, rhombus or flexible honeycomb. In the dipping solution, the selection of the organic solvent is not limited to that described in the examples. The hot press, dipping machine and stretching machine can all be selected from the corresponding equipment commonly used in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com