Process for preparing organic modified clay and styrene butadiene rubber nano composite material

A nano-composite material and styrene-butadiene rubber technology, which is applied in the field of preparing clay and styrene-butadiene rubber nano-composite materials, can solve problems such as no effect, and achieve the effects of increased tensile strength, less waste liquid, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Stir 500 g of natural sodium-based bentonite in 10 L of water, the stirring speed is 1600 rpm, and the time is 5 hours. After mixing evenly, let it stand for 96 hours to obtain a clay water suspension with a solid content of 1.82%. Dissolve 4 g of hexaalkyltrimethylammonium bromide in 100 milliliters of water to obtain an aqueous solution of the modifier; mix 550 g of the clay aqueous suspension with the aqueous modifier and stir at 70° C. for 30 minutes at a stirring speed of 600 rpm Minutes to obtain the clay / quaternary ammonium salt suspension; the clay / quaternary ammonium salt aqueous solution and 493g styrene-butadiene rubber latex (model 1502, solid content is 20.31%) were carried out stirring and mixing at room temperature for 10 minutes, and the stirring speed was 1600 rpm; Then 1% (mass) dilute sulfuric acid was added dropwise to carry out flocculation, and the final consumption of dilute sulfuric acid was 104 milliliters. Rinse the floc 10 times with clear wat...

Embodiment 2

[0040] The operating steps are the same as in Example 1. The clay and water suspension after being stirred for 5 hours were placed for 48 hours to obtain a clay suspension with a solid content of 2%; 5 g of modifier hexadecyltrimethylammonium bromide was dissolved in 100 ml of water to obtain a modifier The aqueous solution of above-mentioned clay aqueous suspension 500g and modifier aqueous solution are mixed; The amount of flocculant used is 100ml. Other processing conditions are with embodiment 1. The mechanical properties of the prepared composites are listed in Table 2. The results of the X-ray diffraction curve of the composite material are shown in Figure 5 (a).

Embodiment 3

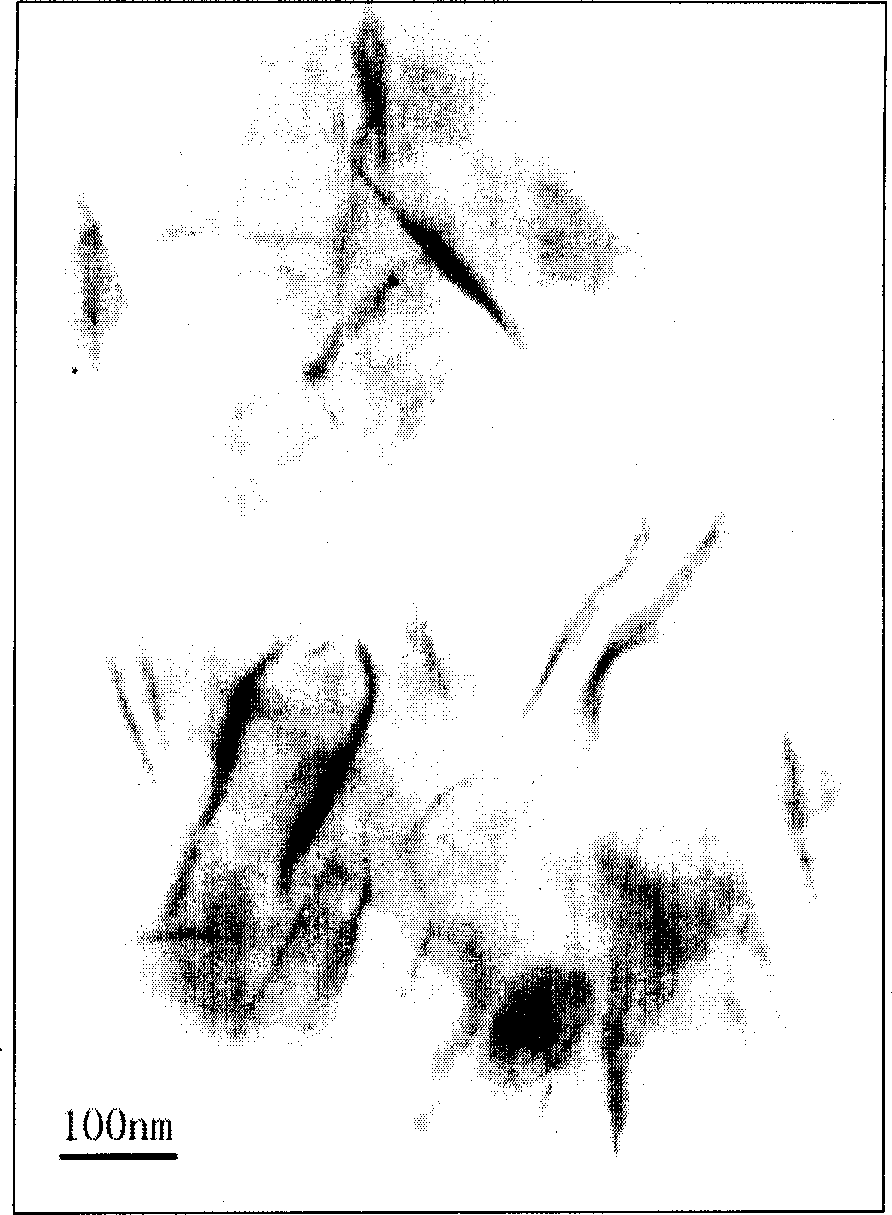

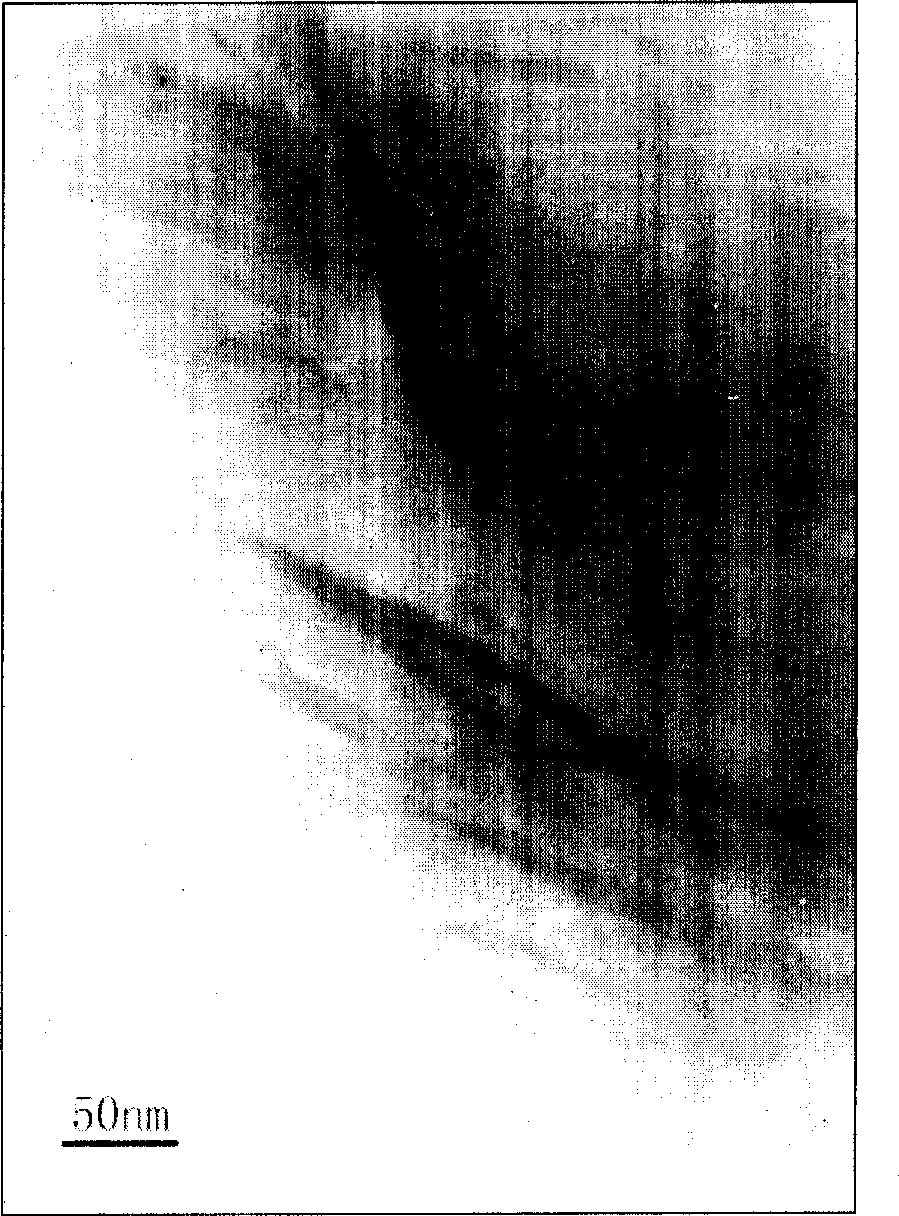

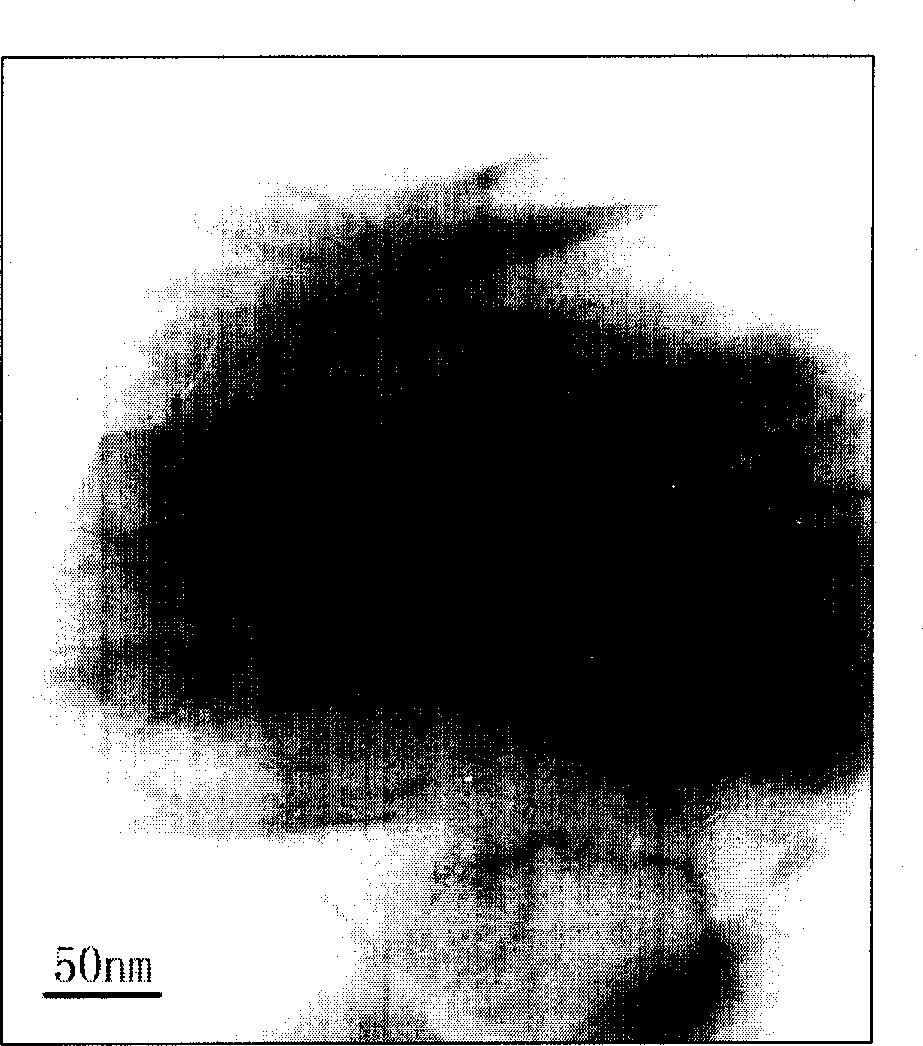

[0042] The operating steps are the same as in Example 1. The clay and the water suspension after being stirred for 5 hours were placed for 25 hours to obtain a clay water suspension with a solid content of 2.2%; 1.0 g of modifier octadecyl vinyl dimethyl ammonium chloride was dissolved in 100 ml of water, The aqueous solution of the modifier was obtained; 455 g of the above-mentioned clay aqueous suspension was mixed with the aqueous modifier; the amount of the flocculant used was 100 ml. Other processing conditions are with embodiment 1. The mechanical properties of the prepared composites are listed in Table 2. The transmission electron micrographs of the composites are shown in figure 2 . It can be seen from the transmission electron microscope photos that in the styrene-butadiene rubber matrix, the thickness of the clay sheet is between 10nm and 20nm, and the dispersion is uniform and fine. In the styrene-butadiene rubber matrix, the distance between some clay sheets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com