Waterborne polyurethane adhesive and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as poor peel strength, poor tensile strength, and water-based polyurethane adhesives that cannot get rid of petrochemical resources. Achieve the effect of overcoming poor water resistance and increasing bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

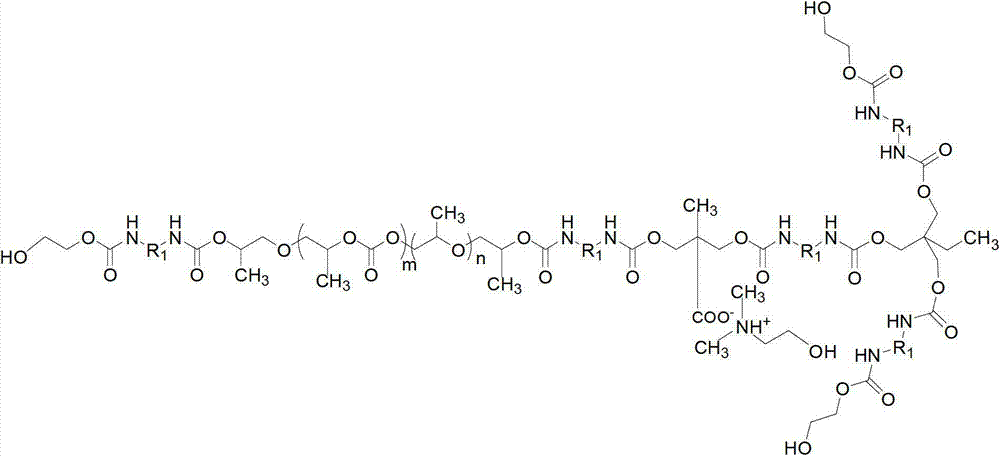

[0046] The present invention also provides a kind of preparation method of waterborne polyurethane adhesive, comprises the following steps:

[0047] A) After removing water from poly(carbonate-ether) diol and trimethylolpropane having the structure of formula (II), react with diisocyanate in a solvent to obtain the first intermediate;

[0048] B) reacting the first intermediate with a catalyst and dimethylolpropionic acid in a solvent to obtain a second intermediate;

[0049] C) reacting the second intermediate with ethylene glycol in a solvent to obtain the third intermediate;

[0050] D) reacting the third intermediate with dimethylethanolamine to obtain an aqueous polyurethane dispersion;

[0051] E) reacting the water-based polyurethane dispersion with a water-based thickener, a water-based leveling agent, a water-based defoamer, a plasticizer, an antioxidant and a water-based curing agent to obtain a water-based polyurethane adhesive;

[0052] The mass ratio of the poly(c...

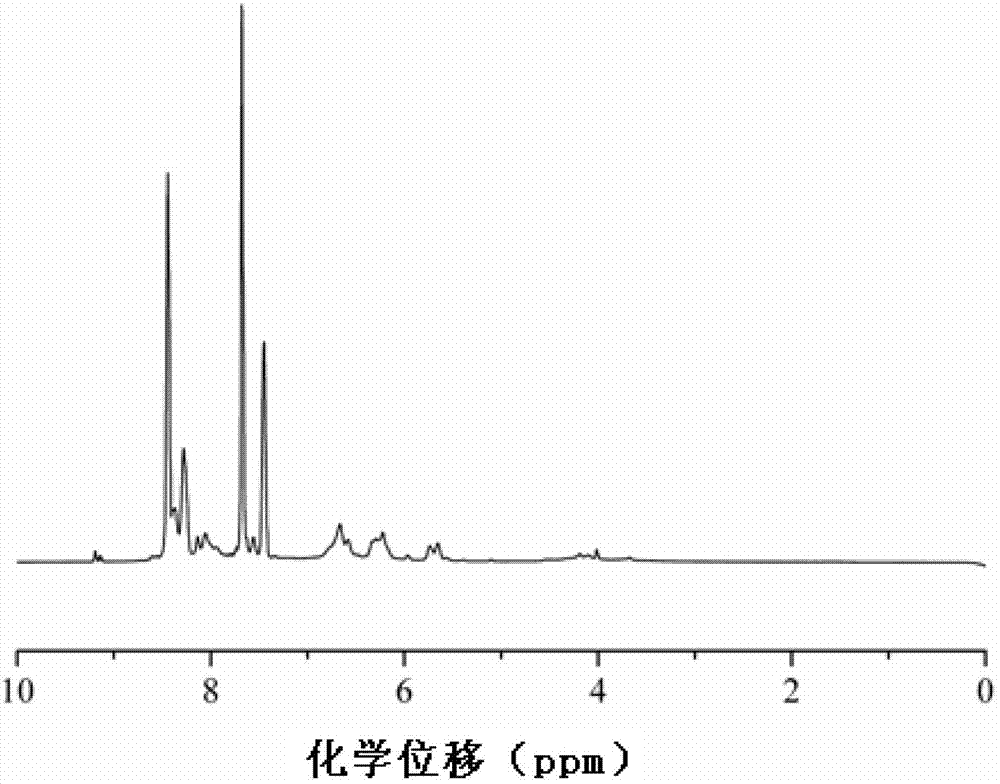

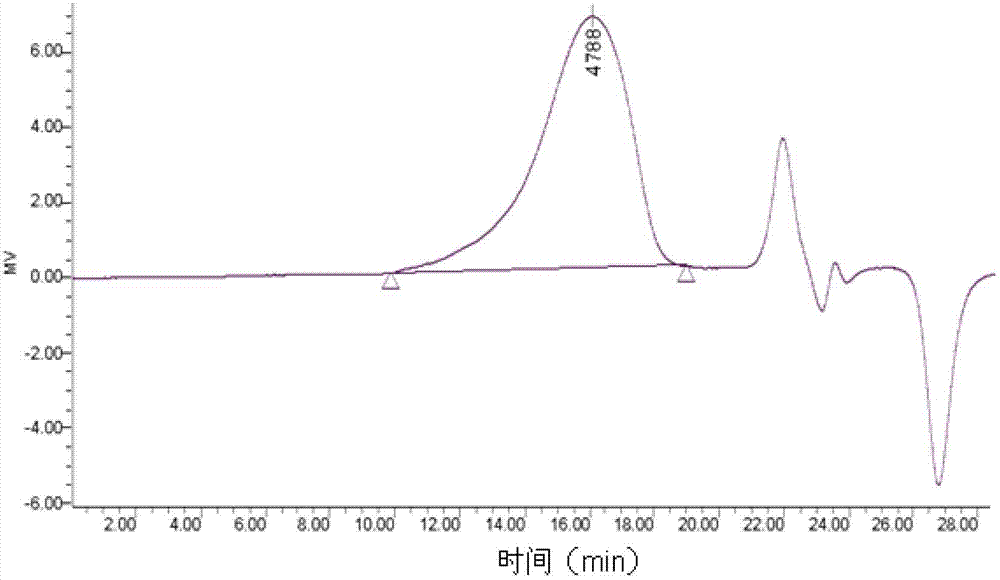

Embodiment 1

[0068] According to the method of Example 11 disclosed in patent 201210086834.X, a poly(carbonate-ether) glycol with a number average molecular weight of 1500 Daltons was prepared.

[0069] 1500 g of poly(carbonate-ether) glycol with a number average molecular weight of 1500 Daltons and 132 g of trimethylolpropane were placed in a three-necked flask, and were distilled under reduced pressure for 1 hour at 110°C. Under the protection of nitrogen, the temperature was lowered to 85° C., 220 mL of butanone was added, and 870 g of 2,4-toluene diisocyanate was added dropwise, and the mixture was reacted for 2.5 hours to obtain the first intermediate.

[0070] Dissolve the first intermediate in 100mL of methyl ethyl ketone, lower the temperature to 75°C, add 0.002g of dibutyltin dilaurate, add 130g of dimethylolpropionic acid in three times, after the addition is complete, react for 0.5 hours to obtain the second intermediate body.

[0071] The second intermediate was dissolved in 1...

Embodiment 2

[0079] A poly(carbonate-ether) glycol with a number average molecular weight of 2000 Daltons was prepared according to the method of Example 9 disclosed in patent 201210086834.X.

[0080] 2000 g of the prepared poly(carbonate-ether) glycol with a number average molecular weight of 2000 Daltons and 158 g of trimethylolpropane were placed in a three-necked flask, and were distilled under reduced pressure for 1 hour at 110°C. Under the protection of nitrogen, the temperature was lowered to 85° C., 360 mL of butanone was added, and 1250 g of diphenylmethane-4,4′-diisocyanate was added dropwise to react for 4 hours to obtain the first intermediate.

[0081] Dissolve the first intermediate in 280 mL of methyl ethyl ketone, lower the temperature to 75°C, add 0.003 g of stannous octoate, and add 165 g of dimethylol propionic acid three times. After the addition, react for 2 hours to obtain the second intermediate.

[0082] The second intermediate was dissolved in 380 mL of butanone, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com