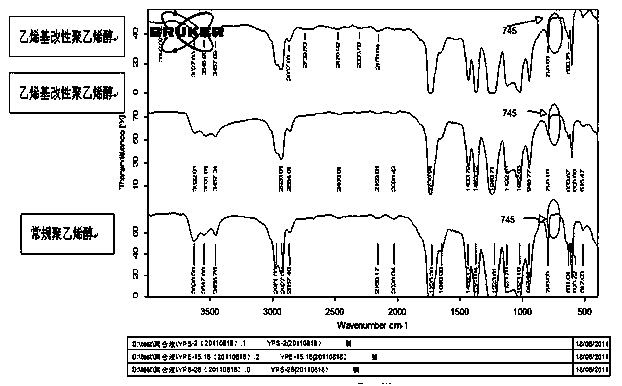

Preparation method for vinyl modified polyvinyl alcohol

A polyvinyl alcohol and vinyl technology, applied in the field of preparation of modified polyvinyl alcohol, can solve the problems of difficult to obtain emulsion polymerization, high surface tension, no water resistance, etc., and achieve good water solubility, good viscosity stability, and water resistance. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

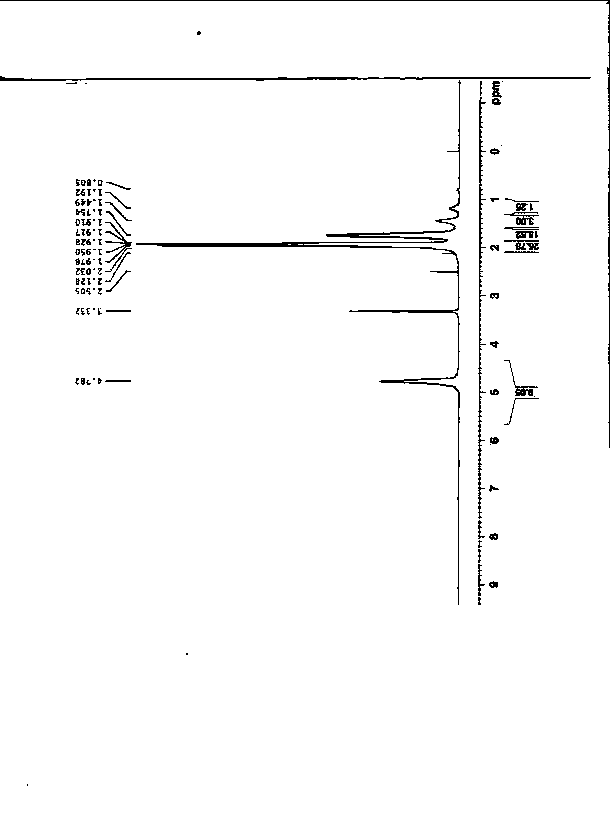

Method used

Image

Examples

Embodiment 1

[0031] The preparation of vinyl modified polyvinyl alcohol, according to the following steps:

[0032] 1), initial feeding

[0033] Add 84-87 parts of soft water, 0.04-0.06 parts of reducing agent sodium bisulfite, and 0.4-0.6 parts of emulsifier sodium vinyl sulfonate into the high-pressure stainless steel reaction kettle, tighten the lid, and stir evenly at room temperature at a speed of 150-210rpm. Stand still for 25-35 minutes;

[0034] 2) Replacement in the kettle

[0035] Use 8~12bar N 2 Replace twice, and then replace twice with 8-12bar ethylene, and each replacement lasts for 3-5min;

[0036] 3) Add monomers and oxidants for polymerization

[0037] After replacing the inside of the kettle, use a high-pressure metering pump to add 20 to 25 parts of vinyl acetate monomer at full speed, and feed in ethylene monomer to control the pressure in the kettle to 3 to 10 bar. Add 0.05-0.06 parts of oxidant ammonium persulfate to the high-pressure metering pump at full speed....

Embodiment 2

[0056] A kind of preparation method of vinyl-modified polyvinyl alcohol, what this preparation method adopted is emulsion polymerization; It comprises the following steps:

[0057] 1. Dissolve 0.08 parts by weight of sodium bisulfite in water and 0.6 parts by weight of sodium vinylsulfonate in water and add them together into a 10L high-pressure reactor. The total amount of water used is 82 parts. Tighten the lid of the feeding port and test for leaks Pressure test, start stirring, set the speed at 210rpm, stir evenly, and let stand for 35min;

[0058] 2. Use 12bar N 2 Substitute twice, and then replace twice with 12bar ethylene, and each replacement lasts for 3 minutes;

[0059] 3. Use a high-pressure metering pump to add 40 parts by weight of vinyl acetate monomer at full speed, feed the vinyl monomer, set the pressure in the kettle to 3 bar, and when the temperature in the kettle reaches 65°C, dissolve 0.045 parts by weight of ammonium persulfate in water , use a high-pre...

Embodiment 3

[0067] A kind of preparation method of vinyl modified polyvinyl alcohol, it carries out according to the following steps:

[0068] 1. Dissolve 0.02 parts by weight of sodium bisulfite in water and 0.2 parts by weight of sodium vinylsulfonate in water and add them together into a 10L high-pressure reactor. The total amount of water used is 88 parts. Tighten the lid of the feeding port and test for leaks Test the pressure, turn on the stirring, set the speed to 150rpm, stir evenly, and let stand for 30min;

[0069] 2. Use 8bar N 2 Replace twice, and then replace twice with 8bar ethylene, and each replacement lasts for 4 minutes;

[0070] 3. Use a high-pressure metering pump to add 10 parts by weight of vinyl acetate monomer at full speed, feed the vinyl monomer, set the pressure in the kettle to 20 bar, and when the temperature in the kettle reaches 55°C, dissolve 0.065 parts by weight of ammonium persulfate in water , use a high-pressure metering pump to pump into the kettle ...

PUM

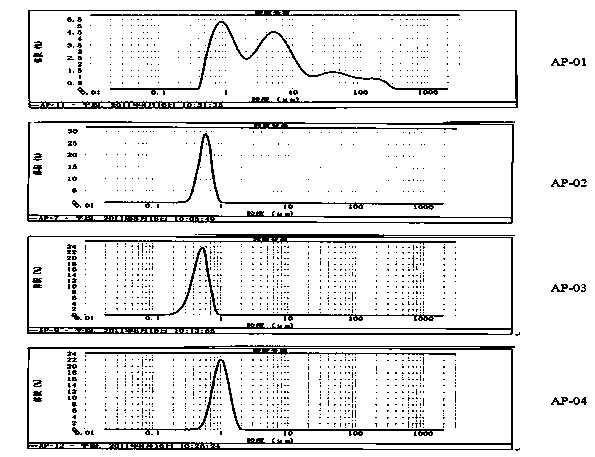

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com