Self-anchored thermal insulation decorative assembly type wallboard and counter-attack preparation process thereof

A prefabricated and thermal insulation board technology, applied in lamination devices, building components, lamination, etc., can solve the problems of shedding of outer leaf wall panels, large consumption of stone resources, and many hot and cold bridge positions, so as to avoid buckling The effect of dislocation of parts, alleviating the shortage of stone resources, and improving the safety factor of structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

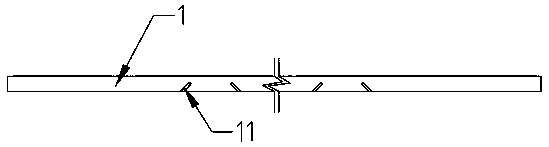

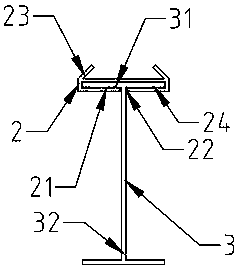

[0029] The self-anchor thermal insulation and decorative assembled wallboard and its anti-beating preparation process provided in this embodiment, specifically, as shown in the figure, the self-anchor thermal insulation decorative assembled wallboard includes a concrete structure layer 5, thermal insulation layer and a finish layer, the insulation layer is a fiber reinforced foamed cement board, the finish layer is a hard thin plate 1, and at least one inner anchor 2 is embedded in the back of each hard thin plate 1, the said The inner anchor 2 includes a pre-embedded frame 21 with a cavity 24 in the middle, and on one side in the width direction of the pre-embedded frame 21 is provided a veneer clip 23 protruding toward the back of the hard thin plate 1 and embedded in the hard thin plate 1 An outer anchor 3 is plugged into the pre-embedded frame 21 of each inner anchor 2, and the outer anchor 3 is I-shaped, and is fixed on the middle part of the transverse baffle 31 by the tr...

PUM

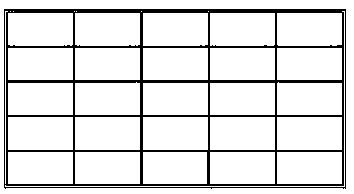

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com