Pelletizing and calcination method for vanadium-containing stone coal ash

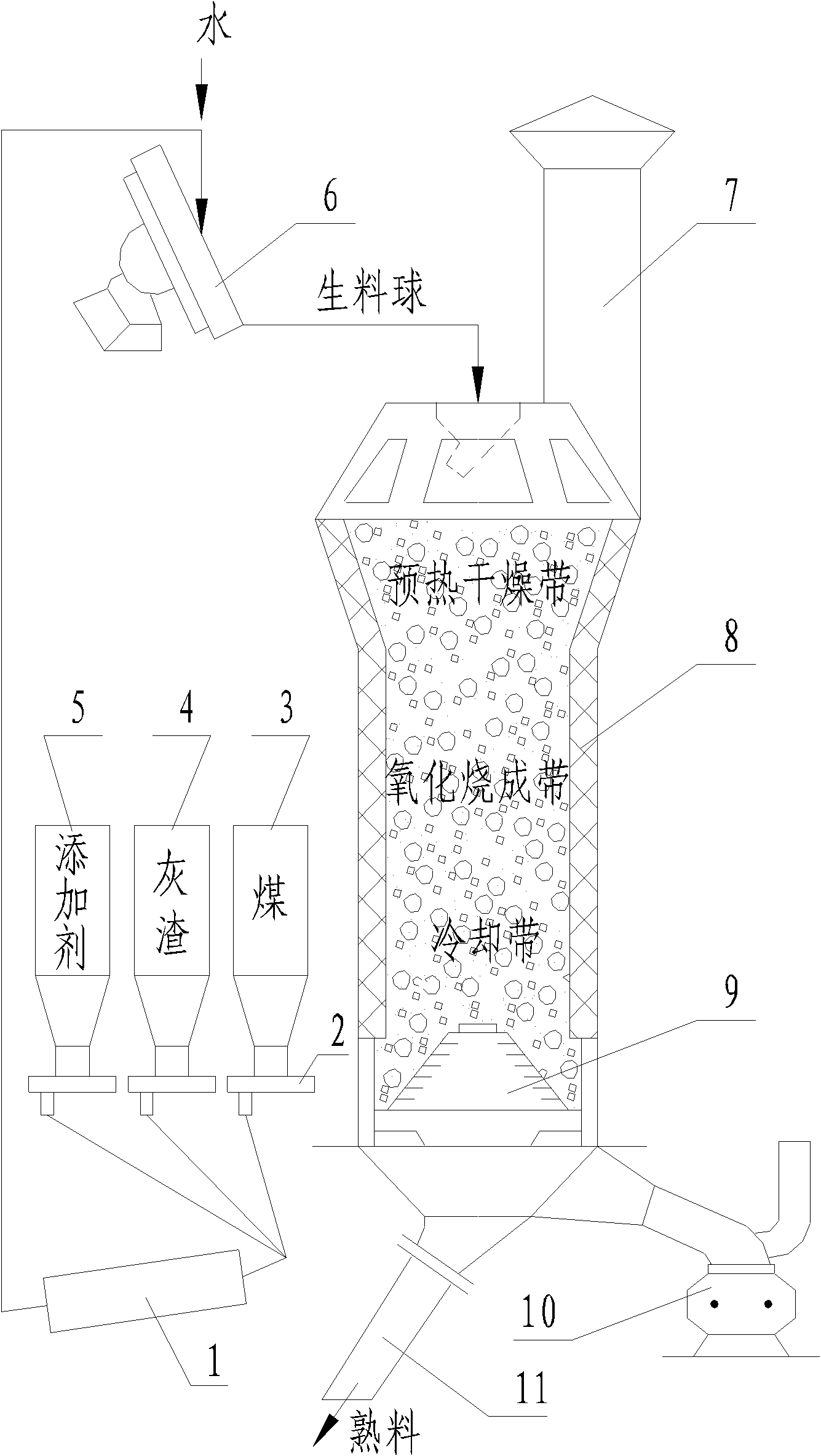

A coal ash slag and pelletizing technology, which is applied in the field of pelletized roasting of vanadium-containing coal ash slag, can solve problems that are not conducive to large-scale continuous mechanized material distribution and discharge, increase the complexity of equipment systems, and irregular shapes of wet raw materials and other problems, to achieve the effects of easy mechanized unloading, easy control of roasting time and temperature, and high utilization rate of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 15kg of lime ash after burning and decarburizing at 890-910°C in the 1MW large-scale circulating fluidized bed test bench of Zhejiang University Thermal Engineering Institute (its chemical composition is: V 2 o 5 1.39%, SiO 2 67.04%, Fe 2 o 3 7.65%, Al 2 o 3 17.84%, CaO 1.64%, MgO 1.94%), adding composite additives, including 0.3kg of NaCl, 0.75kg of CaF 2 and 2.1 kg of CaCO 3 , plus 1.05kg of anthracite, the calorific value of the mixed material is 1898kJ / kg, mix evenly and grind to a size below 80 mesh to obtain raw meal powder, then add water to form a ball, the ball contains 17% moisture, and the ball diameter is 5-8mm. Fill the ball into the top of the laboratory moving bed roasting test furnace with an inner diameter of 120mm and a height of 1000mm, roast at 830-850°C for 2 hours, and discharge the clinker after cooling at the lower part of the roaster. Mass (kg) to liquid volume (L) ratio of 1: 2.5 dilute sulfuric acid solution at room temperature...

Embodiment 2

[0040] Take 15kg of lime ash after burning and decarburizing at 890-910°C in the 1MW large-scale circulating fluidized bed test bench of Zhejiang University Thermal Engineering Institute (its chemical composition is: V 2 o 5 1.39%, SiO 2 67.04%, Fe 2 o 3 7.65%, Al 2 o 3 17.84%, CaO 1.64%, MgO 1.94%), adding composite additives, including 0.3kg of NaCl, 0.75kg of CaF 2 and 2.1 kg of CaCO 3 , plus 0.9kg of anthracite, the calorific value of the mixed material is 1626kJ / kg, mix evenly and grind to below 80 mesh to obtain raw meal powder, then add water to form a ball, the ball contains 14.5% moisture, and the ball diameter is 5-8mm. Fill the top of the laboratory moving bed roasting test furnace with an inner diameter of 120mm and a height of 1000mm, roast at 820-840°C for 2.5 hours, and discharge the clinker after cooling at the lower part of the roaster. After the clinker is ground, the volume concentration is 2%, The ratio of solid mass (kg) to liquid volume (L) is ...

Embodiment 3

[0042] Take 15kg of lime ash after burning and decarburizing at 890-910°C in the 1MW large-scale circulating fluidized bed test bench of Zhejiang University Thermal Engineering Institute (its chemical composition is: V 2 o 5 1.39%, SiO 2 67.04%, Fe 2 o 3 7.65%, Al 2 o 3 17.84%, CaO 1.64%, MgO 1.94%), adding composite additives, including 0.3kg of NaCl, 0.75kg of CaF 2 and 2.1 kg of CaCO3 , plus 3.575kg of stone coal before decarburization, the calorific value of the mixed material is 1643kJ / kg, mix evenly and grind it to below 80 mesh to get raw meal powder, then add water to form a ball, the ball contains 16.5% moisture, and the ball diameter is 5-8mm . The balls are added to the top of the laboratory moving bed roasting test furnace with an inner diameter of 120mm and a height of 1000mm, roasted at 825-845°C for 2.5 hours, and discharged the clinker after cooling at the lower part of the roaster. After the clinker is ground, the volume concentration is 2%, The rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com