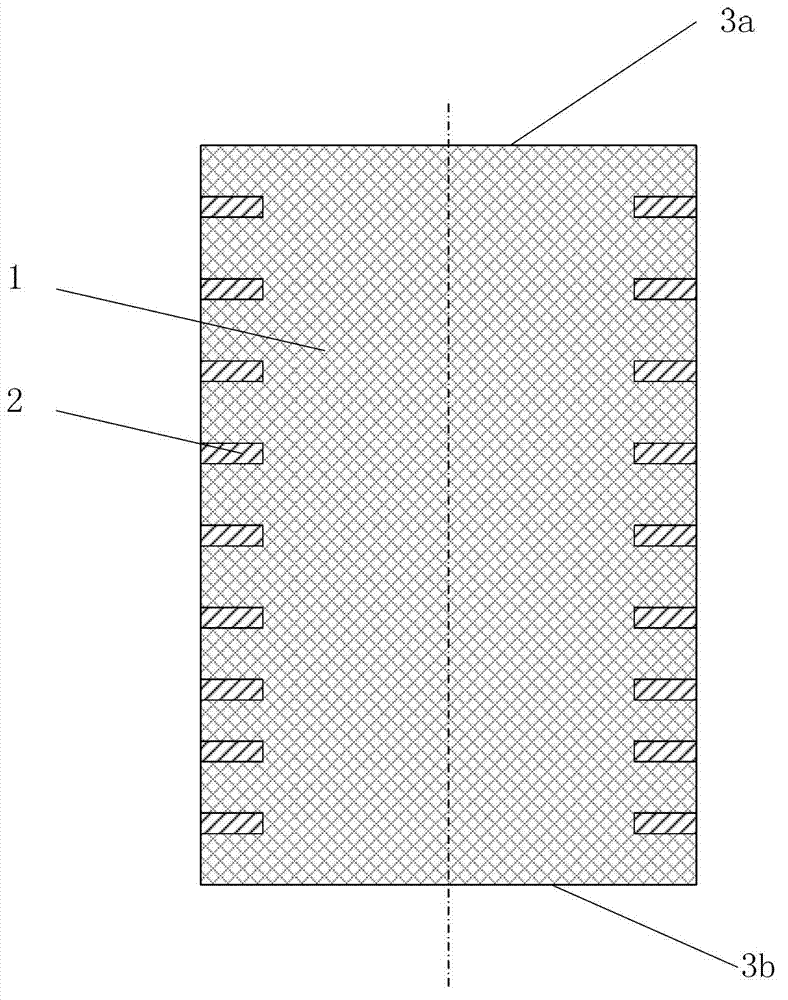

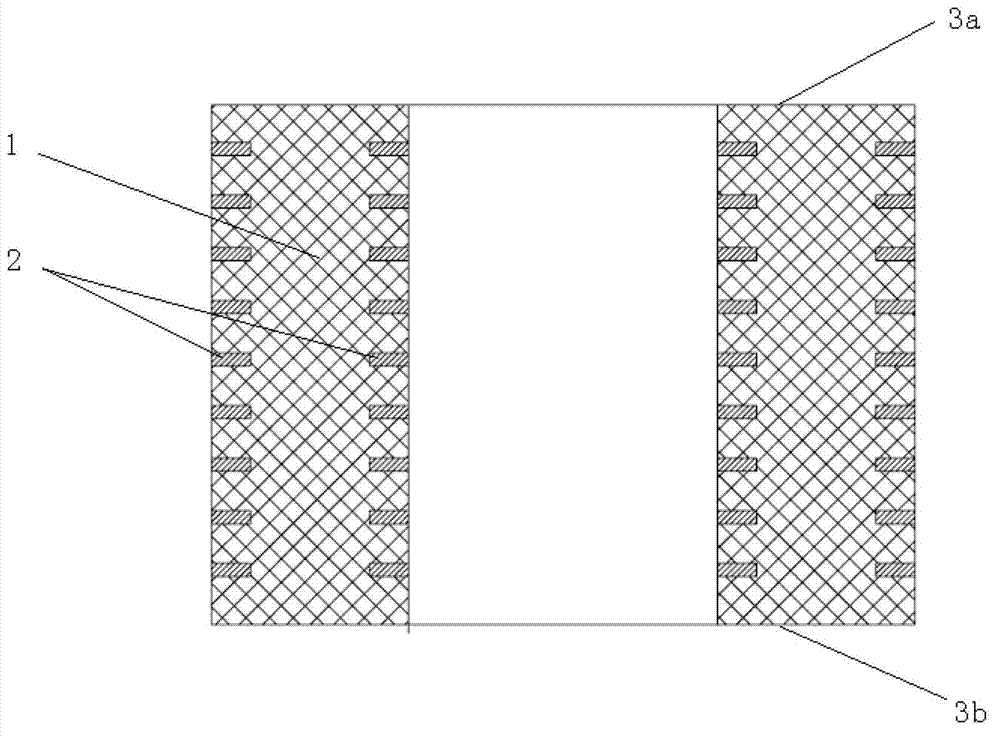

Multi-layer high gradient insulator and manufacturing method thereof

An insulator, high-gradient technology, applied in the direction of insulators, suspension/strain insulators, electrical components, etc., can solve the problems of difficult molding process, high flashover voltage, poor mechanical properties, etc., to improve the vacuum surface flashover characteristics, flashover The effect of high network voltage and overcoming poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

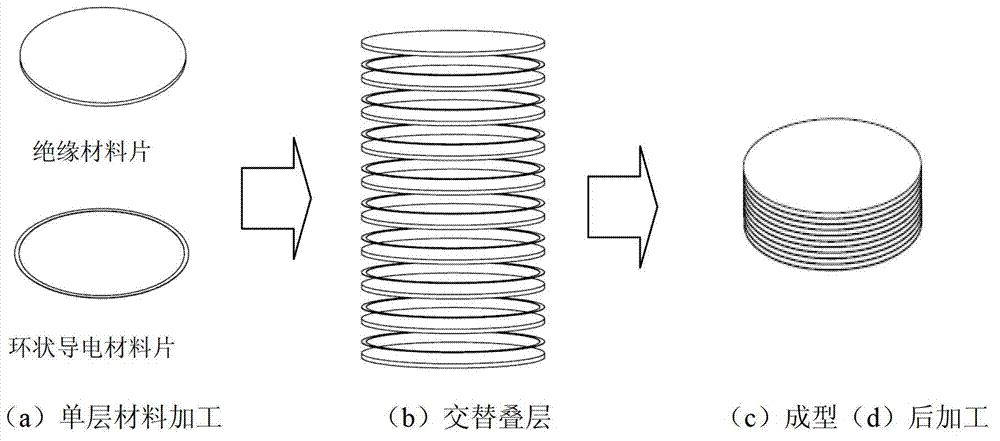

[0048] 1) With 1mm thick polystyrene (PS) sheet as the insulating material and 0.02mm thick stainless steel foil as the conductive material, the PS sheet is cut into Ф40.0mm discs, and the stainless steel foil is cut into outer diameter 40.0mm, wide 1.0mm circular ring; 2) Alternately stack the above PS discs and stainless steel rings one by one, with a total of 10 layers of PS and 9 layers of stainless steel rings, and put them into a mold with an inner diameter of 40.1mm; 3) Put the above mold and materials into In the hot pressing device, heat to 180°C and keep it warm for 2 hours to fully melt the PS material, apply a pressure of 1 MPa on the mold, and heat and solidify the multi-layer materials in the mold; 4) Grind the side of the formed insulator to remove the surface layer Defects, that is, to obtain a multi-layer high-gradient insulator with a total thickness of about 10mm, see the process image 3 .

Embodiment 2

[0050] 1) Use 0.2mm thick polyimide (PI) sheet as the insulating material and 0.01m thick stainless steel foil as the conductive material, cut the PI sheet into Ф40.0mm discs, and cut the stainless steel foil into 40.0mm outer diameter , a ring with a width of 1.0mm; 2) Alternately stack the above-mentioned PI discs and stainless steel rings one by one, with a total of 50 layers of PI and 49 layers of stainless steel rings, and put them into a mold with an inner diameter of 40.1mm; 3) Put the above-mentioned mold and materials Put it into the hot pressing device, heat it to 430°C and keep it warm for 2 hours to fully soften the PI material, apply a pressure of 30MPa on the mold, and heat and solidify the multi-layer material in the mold; 4) Grind the side of the formed insulator to remove Surface layer defects, that is, a multi-layer high-gradient insulator with a total thickness of about 10 mm is obtained. see process image 3 .

Embodiment 3

[0052] 1) Use 1mm thick polystyrene (PS) sheet as the insulating material, cut the PS sheet into Ф40.0mm discs; 2) Use low-temperature cured silver paste as the conductive material, and print on the PS disc by screen printing A ring with an outer diameter of 40.0mm, a width of 1.0mm, and a thickness of 0.01mm, and dried at 100°C; 3) Stack the above-mentioned PS wafers printed with conductive rings layer by layer, a total of 10 layers, and put them into the inner hole with a diameter of 40.1mm In the mold; 4) Put the above mold and materials into the hot pressing device, heat to 180°C and keep it warm for 2 hours to fully melt the PS material, apply a pressure of 1MPa on the mold, and heat and solidify the multi-layer materials in the mold; 5 ) Grind the side of the formed insulator to remove surface layer defects, and obtain a multi-layer high-gradient insulator with a thickness of about 10 mm. see process Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com