Continuous type colored loose fiber machining device

A processing device and technology for dispersing fibers, applied in the field of continuous dispersive fiber processing devices, can solve the problems of long dyeing cycle, high cost, poor dyeing uniformity, etc., and achieve the effect of shortening the processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

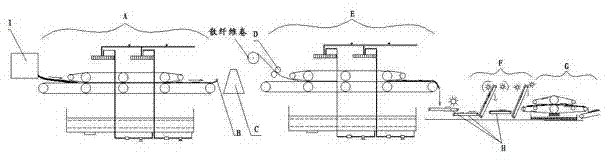

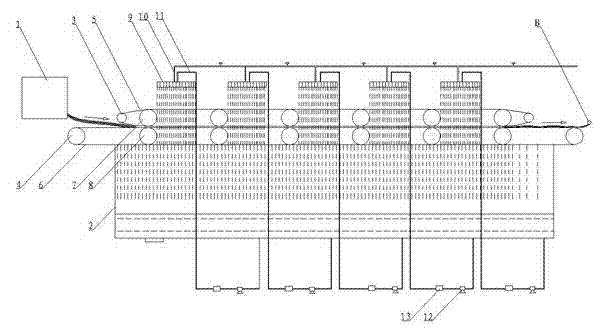

[0027] In this embodiment, the continuous fiber processing device with dispersion is combined with figure 1 , including the sequentially installed drenching pad dyeing machine A, coiling roll B, cold pile color fixing device C, cotton conveying roller D, drenching pad washing machine E, feeding belt H and water rolling device G, the loose fiber is in the drenching Spray dyeing is completed at the pad dyeing machine A, and the lapping roll B is installed behind the pad dyeing machine A, and the dyed loose fiber is rolled into a loose fiber roll, and the loose fiber roll is transferred to the cold pile color fixing device C After cold stacking and color fixing, the loose fiber rolls are transported to the rolling washing machine E through the cotton conveying roller D, and are sprayed and cleaned on the rolling washing machine E. The cleaned loose fibers are It falls on the feeding belt H behind the shower rolling washing machine E, and is sent to the water rolling device G thro...

Embodiment 2

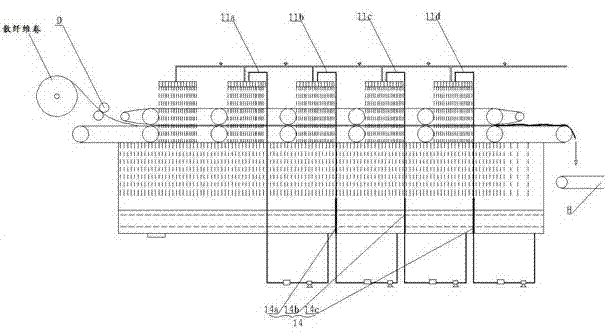

[0034] In this embodiment, circulation components are arranged below the lower guide belts of the shower pad dyeing machine A and the shower pad washing machine E. 13. According to the specific use situation, multiple return pipes 11 can be set to reuse the liquid in different areas to a suitable position, such as image 3 As shown in , in the structure of the pouring type water washing machine F, as the cleaning process proceeds, the dye liquor on the loose fiber gradually decreases, and when it reaches the last few upper rollers - lower rollers, the liquid squeezed out from the loose fiber It is still very clear, and it would be wasteful to discard it directly. Therefore, a partition 14 can be set in the sump at a position corresponding to the upper upper roll-lower roll, and a partition 14a and a partition 2 14b can be provided as required. And partition plate 3 14c, the liquid collection tank is divided into four independent areas, wherein, the first area is the area with ...

Embodiment 3

[0036] In this embodiment, an opening device F is arranged between the feeding belt H and the water rolling device G, and the opening device F includes a cotton stripper, a nail conveying curtain and a cotton opener, and the cotton stripper and the cotton opener are respectively located Before and after the nail conveying curtain, the cotton stripping beater will strip off the excess accumulated loose fiber to ensure the uniform supply of loose fiber on the nail conveying curtain; the nail conveying curtain and the cotton opening beater will loosen the loose fiber. In this embodiment , also can be set before the cotton stripping beater 16, be used for cake opening, the loose fiber group of bulk is broken into the loose fiber group of small piece; Groups are respectively cotton stripper one 17a, nail conveying curtain one 18a, cotton opening beater one 19a, cotton stripping beater two 17b, nail conveying curtain two 18b and cotton opening beater two 19b.

[0037] Feeding belt H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com