Flame-retardant treatment method for wool fibers

A wool fiber and flame retardant treatment technology, which is applied in the field of wool fiber flame retardant treatment, can solve the problems that permanent flame retardant cannot be achieved, the flame retardant treatment technology is backward, and it is difficult to meet the flame retardant needs of high-end wool products.

Inactive Publication Date: 2012-10-10

TAIYUAN UNIV OF TECH

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Wool is one of the earliest natural fibers used by humans in textiles. It is soft and elastic, with naturally formed wavy curls. The high nitrogen content in the chemical structure of wool fiber has certain flame retardant properties, but it still cannot meet the needs of some high-efficiency flame retardant products, and it is easy to cause fires and cause great harm to the human body. Therefore, wool fibers must be treated efficiently. Flame retardant treatment can ensure personal safety and expand the use range of wool fiber

[0003] At present, the flame retardant treatment technology of wool fiber is relatively backward, and it is difficult to meet the flame retardant needs of high-grade wool products. 25.4%, failed to meet the flame retardant standard; some use copolymerization to improve the flame retardant performance of wool fiber, but to achieve a higher flame retardant effect requires a large amount of flame retardant, which greatly increases the production cost; some use sol to The wool fiber is treated with flame retardant, but the washing resistance becomes poor, and the permanent flame retardant effect cannot be achieved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

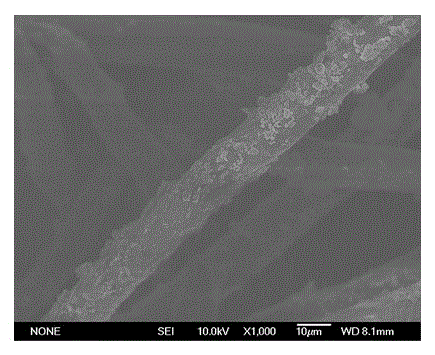

[0078] figure 2 Shown is the topography of wool fiber after being washed 30 times after flame retardant treatment. It can be seen from the figure that after washing 30 times, there are irregular carbon ball layers on the surface of wool fiber, and a small amount is washed off. It can be seen that wool fiber has good Wash resistance.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

Abstract

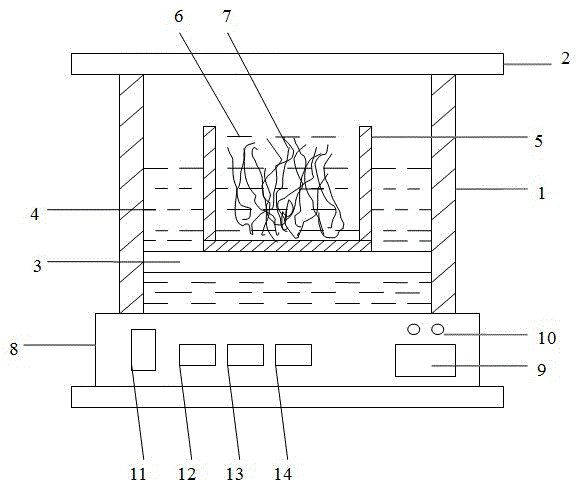

The invention relates to a flame-retardant treatment method for wool fibers. The flame-retardant treatment method includes aiming at flammability of the wool fibers, microwave irradiating the wool fibers in the microwave reactor, impregnating the postirradiation wool fibers into carbon-ball suspension made of deionized water, gamma-mercaptopropyl triethoxysilane and nitric acid modified carbon balls serving as a flame retardant, and performing flame-retardant treatment in a supersonic disperser. The flame-retardant treatment method is short in process procedure and accurate and real in data, the wool fibers are flame-retardant and fine in resistance to washing, the limit oxygen index of the wool fibers after being washed for 30 times is 34%, and the flame retardancy of the wool fibers can be improved by 36%. Besides, the flame-retardant treatment method for the wool fibers is high in efficiency.

Description

technical field [0001] The invention relates to a flame retardant treatment method of wool fiber, which belongs to the technical field of the flame retardant method of wool fiber and its application. Background technique [0002] Wool is one of the earliest natural fibers used by humans in textiles. It is soft and elastic, with naturally formed wavy curls. The high nitrogen content in the chemical structure of wool fiber has certain flame retardant properties, but it still cannot meet the needs of some high-efficiency flame retardant products, and it is easy to cause fires and cause great harm to the human body. Therefore, wool fibers must be treated efficiently. Flame retardant treatment can ensure personal safety and expand the use range of wool fiber. [0003] At present, the flame retardant treatment technology of wool fiber is relatively backward, and it is difficult to meet the flame retardant needs of high-grade wool products. 25.4%, failed to meet the flame retarda...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06M10/06D06M10/08D06M101/12

Inventor 牛梅侯文生王欣戴晋明王淑花陈旭红薛宝霞

Owner TAIYUAN UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com