Gunite and method for fixing sand through forming covering by gunite

A covering layer and spraying technology, applied in the fields of botanical equipment and methods, soil protection, fertilizer mixture, etc., can solve the problems of polluted environment, inconvenient construction, difficult degradation, etc., and achieve remarkable economic benefits, good treatment effect, The effect of fast greening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

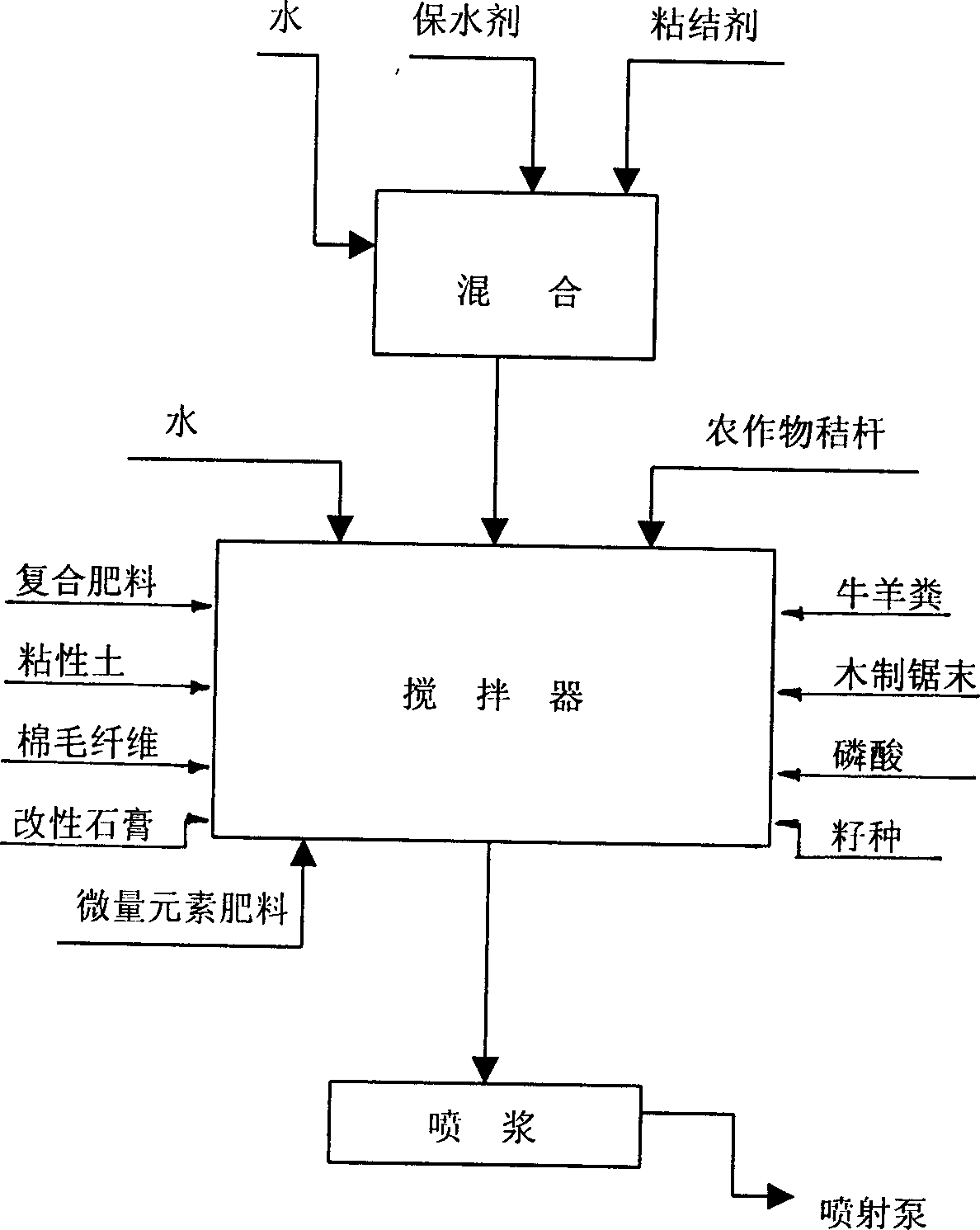

[0038] The spraying slurry in the present invention is composed of crop straw, viscous loess or laterite, plant water-retaining agent, binder, cotton wool fiber, compound fertilizer, trace element fertilizer, modified gypsum, cattle and sheep manure, and wooden sawdust. Among them, according to the geographical conditions of the greening, appropriate adjustments can be made during use, for example:

[0039] Quicksand state and steep slope state, can increase the consumption of binder component, use embodiment A; Reduce the consumption of binder component under mixed type soil condition, use embodiment B; Under alkaline soil condition, can Increase the amount of phosphoric acid component, use Example C; in the steep slope state, you can increase the amount of modified gypsum component, use Example D; in the area with sufficient water source, you can choose economical and applicable trees and shrubs , can choose heat-resistant, cold-resistant, drought-resistant grasses, shrubs p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com