Bamboo carbon dacron fiber, woolen fiber and cashmere fiber blended yarn and producing method thereof

A bamboo charcoal polyester fiber, wool fiber technology, applied in the direction of yarn, textiles and paper making, can solve the problems of no adsorption and deodorization function and health care function, achieve good hygroscopicity, prevent fiber damage, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

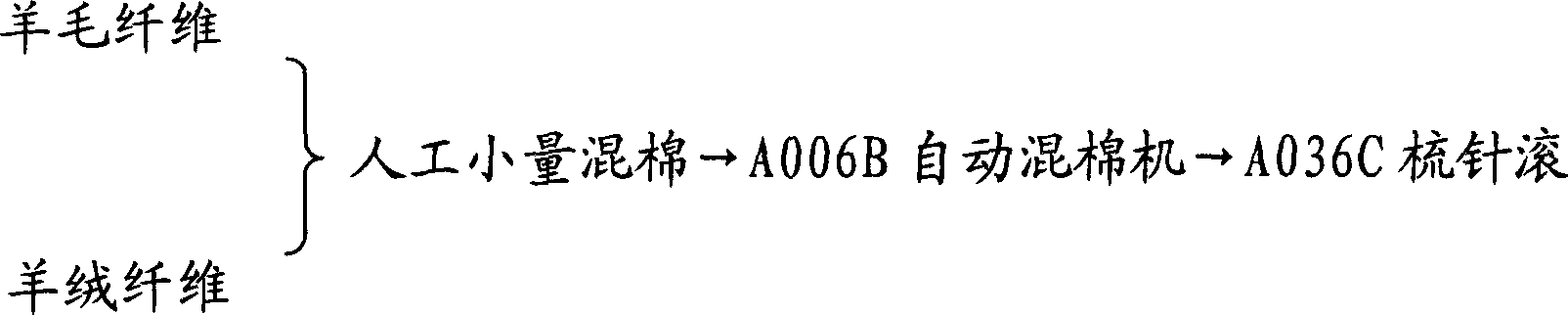

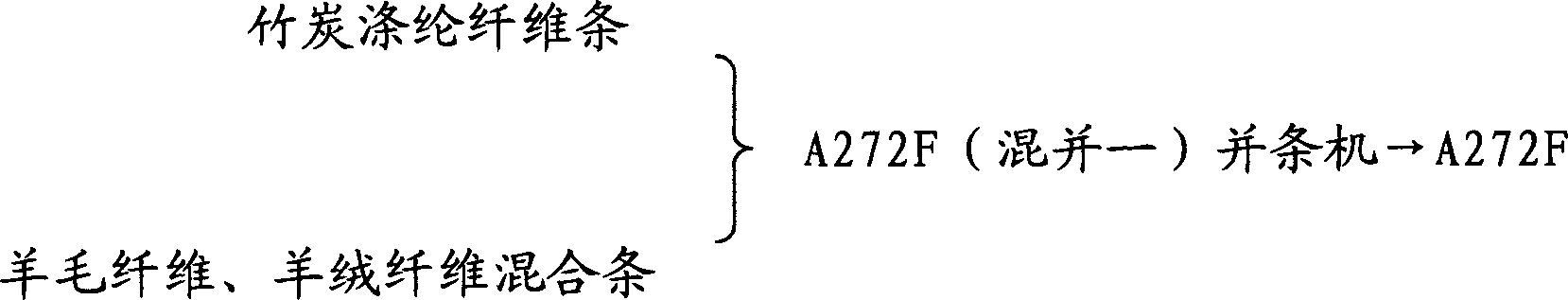

Method used

Image

Examples

Embodiment 1

[0043] Taking 40 lbs as an example, the blended weight percentage of bamboo charcoal polyester fiber, wool fiber and cashmere fiber is 20:60:20. The cotton opener adopts the comb beater, that is, the A036C comb roller opener, the speed of the card beater is 500-600 rpm, and the single beater, that is, the A076C single beater lap machine, the The speed of machine comb needle beater is 700-900 rev / min. The cylinder speed of the carding machine is 270-350 rpm, the licker-in roller speed is 700-800 rpm, and the five-point distance between the cylinder and the cover plate is easy to enlarge. From the inlet to the outlet, they are 0.30mm, 0.28mm, and 0.28mm respectively. , 0.28mm, 0.30mm; the draw frame adopts three draw frames, and each draw frame adopts 8 sliver feeding and 8 times drafting. Through the spinning process flow provided by the present invention and the processed 40-count blended yarn, its single yarn breaking strength is 13.3cN / tex after testing, and the single yarn...

Embodiment 2

[0045]Take the 40 lbs as an example, the blending weight percentage of bamboo charcoal polyester fiber, wool fiber and cashmere fiber is 30:55:15. The cotton opener adopts the comb beater, that is, the A036C comb roller opener, the speed of the card beater is 500-600 rpm, and the single beater, that is, the A076C single beater lap machine, the The speed of machine comb needle beater is 700-900 rev / min. The cylinder speed of the carding machine is 270-350 rpm, the licker-in roller speed is 700-800 rpm, and the five-point distance between the cylinder and the cover plate is easy to enlarge. From the inlet to the outlet, they are 0.30mm, 0.28mm, and 0.28mm respectively. , 0.28mm, 0.30mm; the draw frame adopts three draw frames, and each draw frame adopts 8 sliver feeding and 8 times drafting. The 40-count blended yarn spun through the spinning process flow provided by the present invention and processed, its single yarn breaking strength is 13.6cN / tex after testing, the single y...

Embodiment 3

[0047] Take 40 lbs as an example, the blending weight percentage of bamboo charcoal polyester fiber, wool fiber and cashmere fiber is 40:50:10. The cotton opener adopts the comb beater, that is, the A036C comb roller opener, the speed of the card beater is 500-600 rpm, and the single beater, that is, the A076C single beater lap machine, the The speed of machine comb needle beater is 700-900 rev / min. The cylinder speed of the carding machine is 270-350 rpm, the licker-in roller speed is 700-800 rpm, and the five-point distance between the cylinder and the cover plate is easy to enlarge. From the inlet to the outlet, they are 0.30mm, 0.28mm, and 0.28mm respectively. , 0.28mm, 0.30mm; the draw frame adopts three draw frames, and each draw frame adopts 8 sliver feeding and 8 times drafting. The 40-count blended yarn spun through the spinning process flow provided by the present invention and processed, its single yarn breaking strength is 14.3cN / tex after testing, the single yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com