Pure cotton striped bunch cloth

A slub and stripe technology is applied in the field of textile woven fabrics to achieve the effect of obvious stripes, uniform distribution of slubs and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

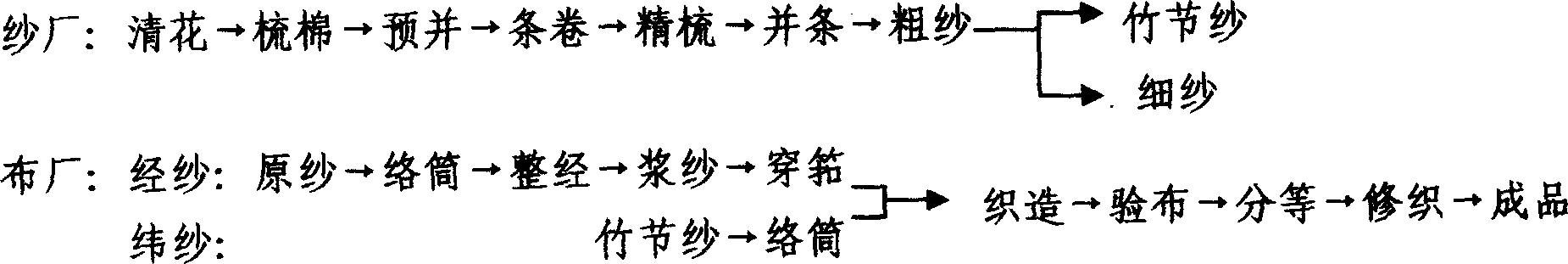

[0007] In order to further understand the content and characteristics of the present invention, the following examples are now used to describe in detail as follows: pure cotton striped slub cloth, warp yarn adopts JC14.5tex, weft yarn adopts JC18.2tex and slub yarn, and the fabric specification is JC14.5tex×JC18. 2tex×276×255.5×168cm1 / 1 plain weave fabric, refer to the production process figure 1 described as follows:

[0008] Spinning mill: Slub yarn and spun yarn are spun into slub yarn and spun yarn after cleaning, carding, pre-combing, sliver coiling, combing, drawing, and roving.

[0009] Cloth factory: Warp yarns are wound, warped, slashed, and reeded; weft yarns are woven through slub yarns, wound, and sent to the cloth factory, and then go through cloth, grading, repairing, and finished products leave the factory.

[0010] The production process of the main process is as follows:

[0011] 1. Slub yarn spinning: The slub yarn is spun with the slub device produced by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com