Tube fitting with indicating means

A technology for pipe joints and joint bodies, which is applied in the field of pipe joints and can solve problems such as the uselessness of checking and reinstalling joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

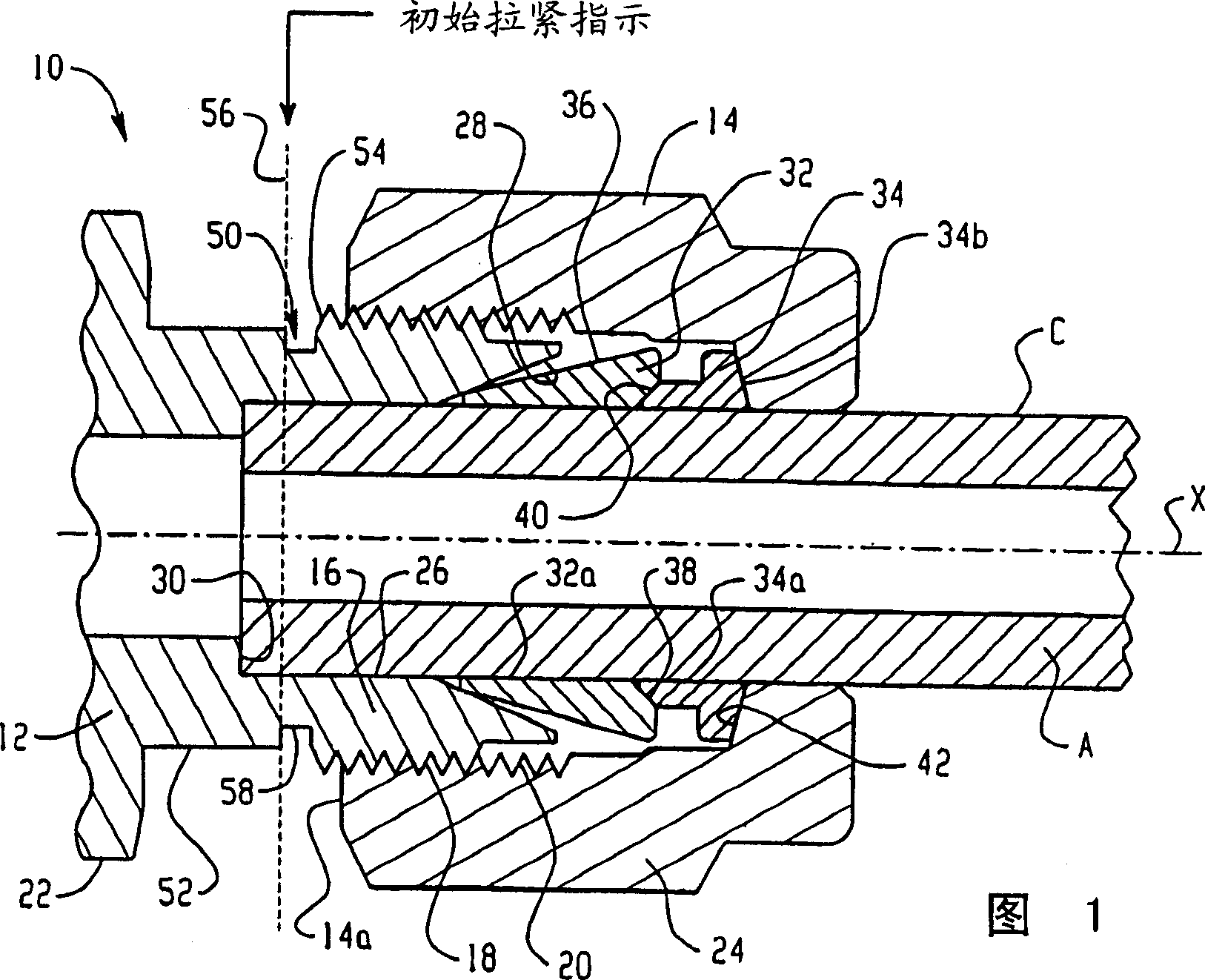

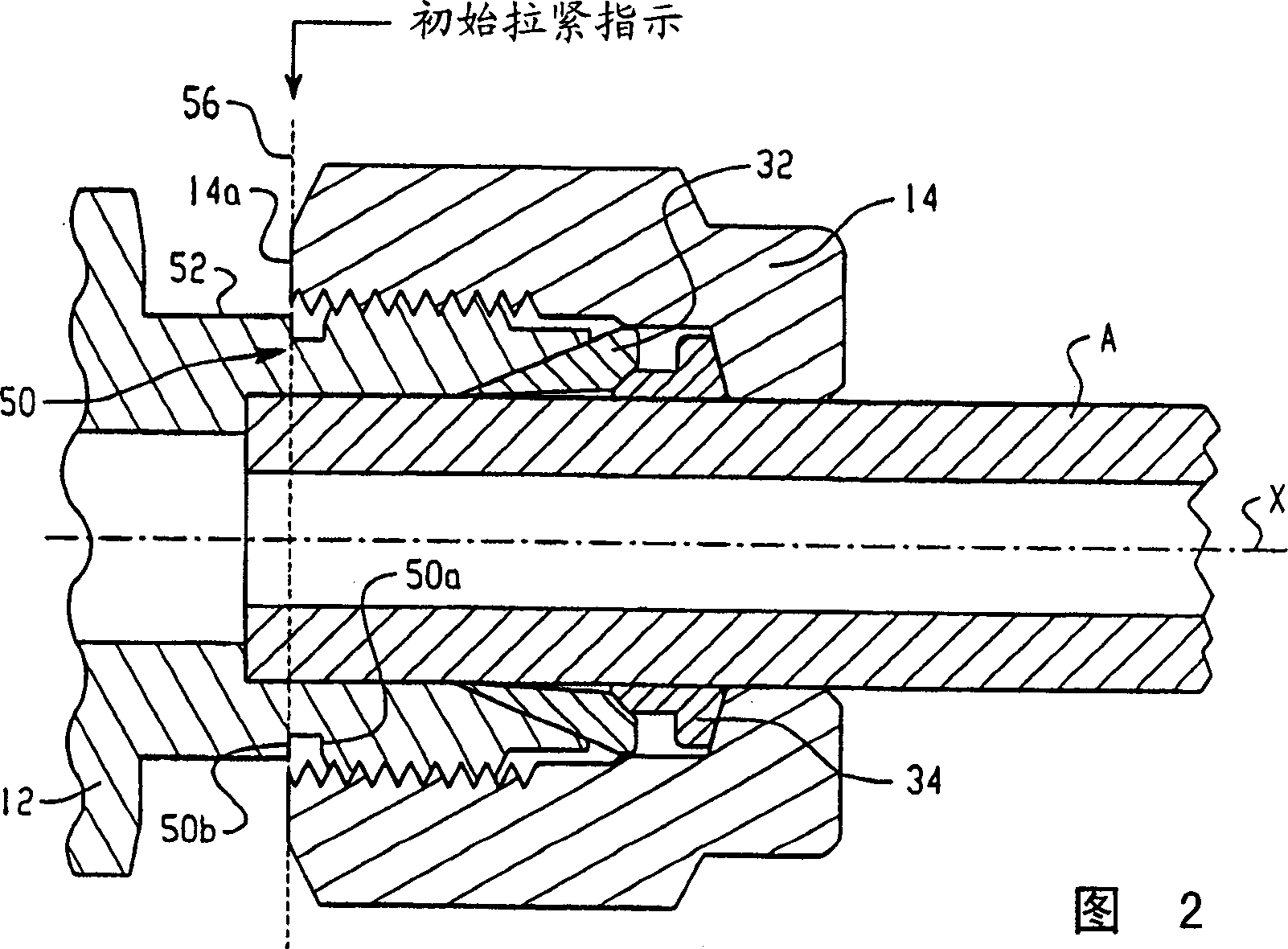

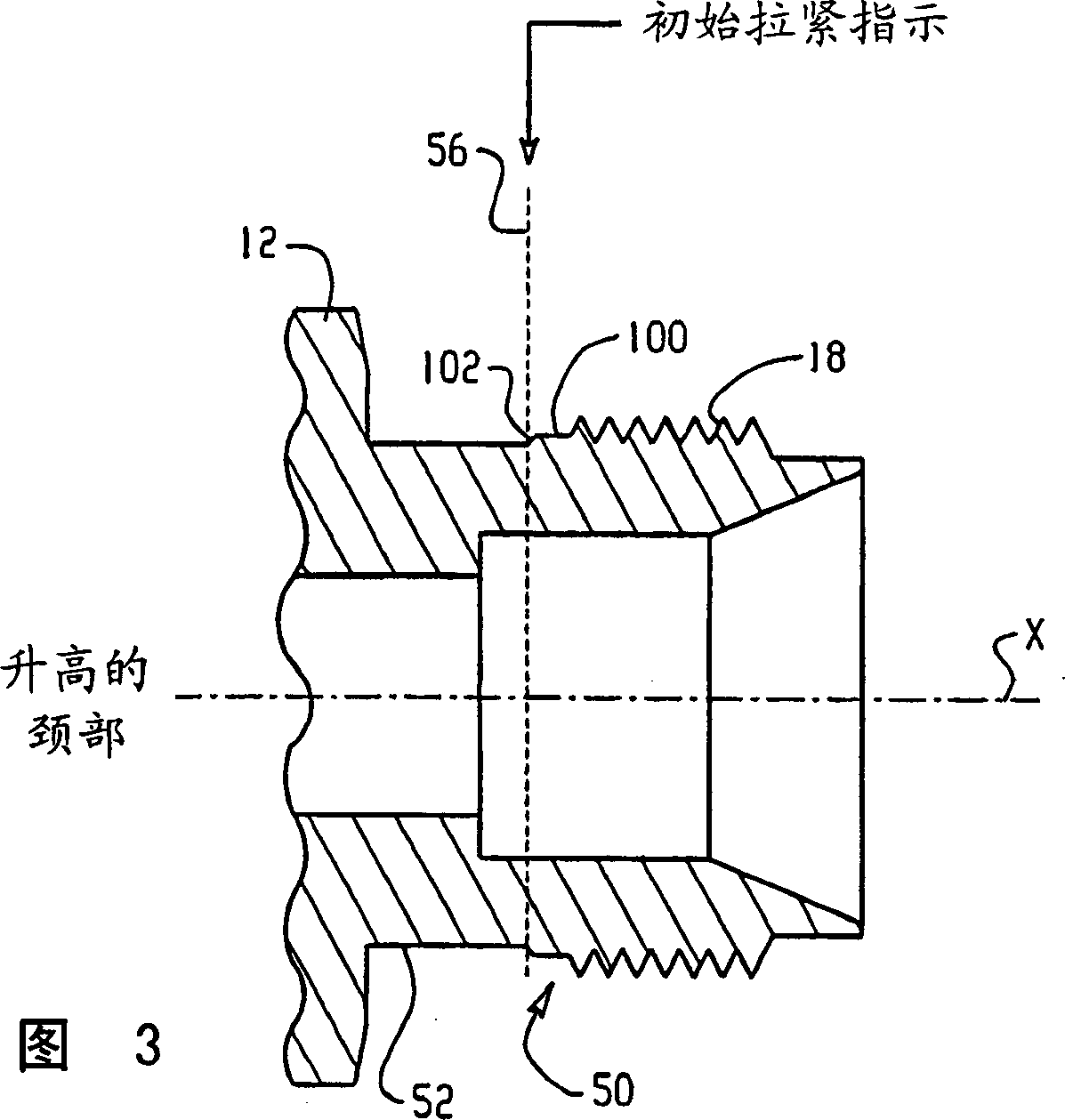

[0044] Referring to Figure 1, the present invention is described herein by way of example in conjunction with a standard two ferrule fitting assembly. However, this description is intended to explain or illustrate the concepts and advantages of the present invention by way of example only, and therefore should not be regarded in a limiting sense. Those of ordinary skill in the art will readily appreciate and appreciate that the present invention may be practiced in a wide variety of fittings and quick-disconnect fittings that are rotated relative to each other for assembly. For example, and not by way of limitation, the present invention may be conveniently used with a single tube fitting or a fitting having any two connectors, where their proper assembly is partially accomplished by relative rotation between the two threaded parts determined.

[0045] A standard fitting assembly 10 includes a fitting body 12 and a fitting nut 14 . The fitting body 12 includes a first end 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com