Flexible polishing mechanism for blade profile abrasive belt

A technology of flexible polishing and flexible mechanisms, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of flutter lines on the surface of the blade, unstable quality, high working intensity, etc., and avoid deformation of the blade surface and damage, improve the surface quality of the blade, and improve the polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

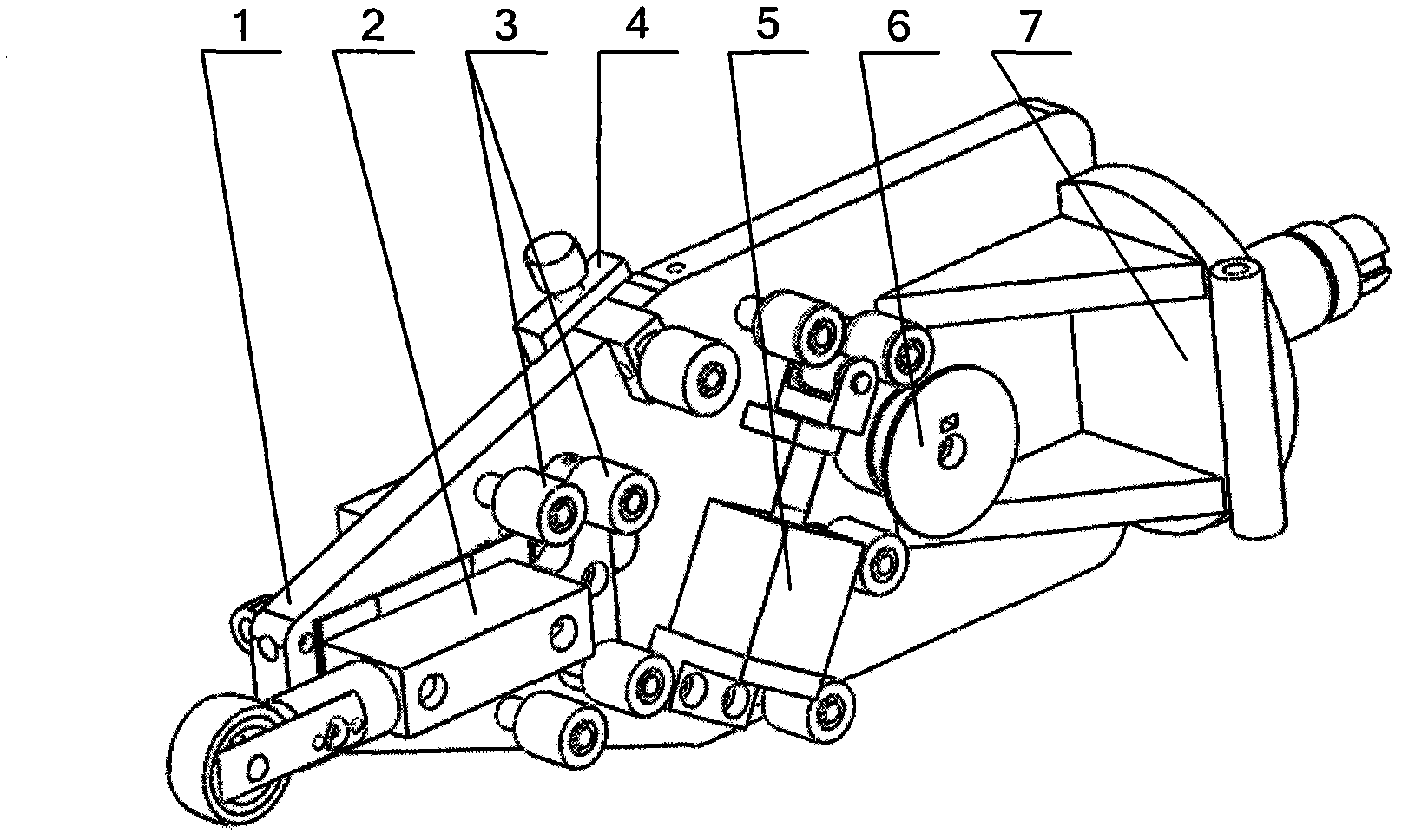

[0026] This embodiment is a flexible abrasive belt polishing mechanism for blade profiles, which includes a substrate 1 , a flexible mechanism 2 , a roller 3 , a deviation correction mechanism 4 , a tensioning cylinder 5 , a driving wheel 6 , and a mounting frame 7 .

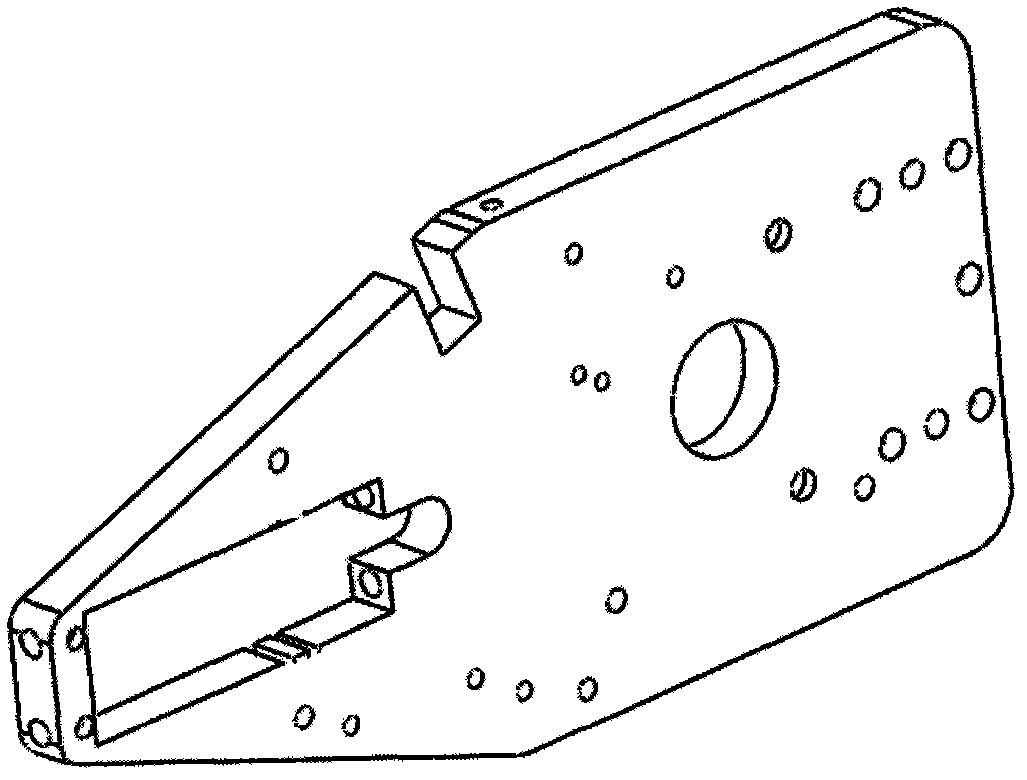

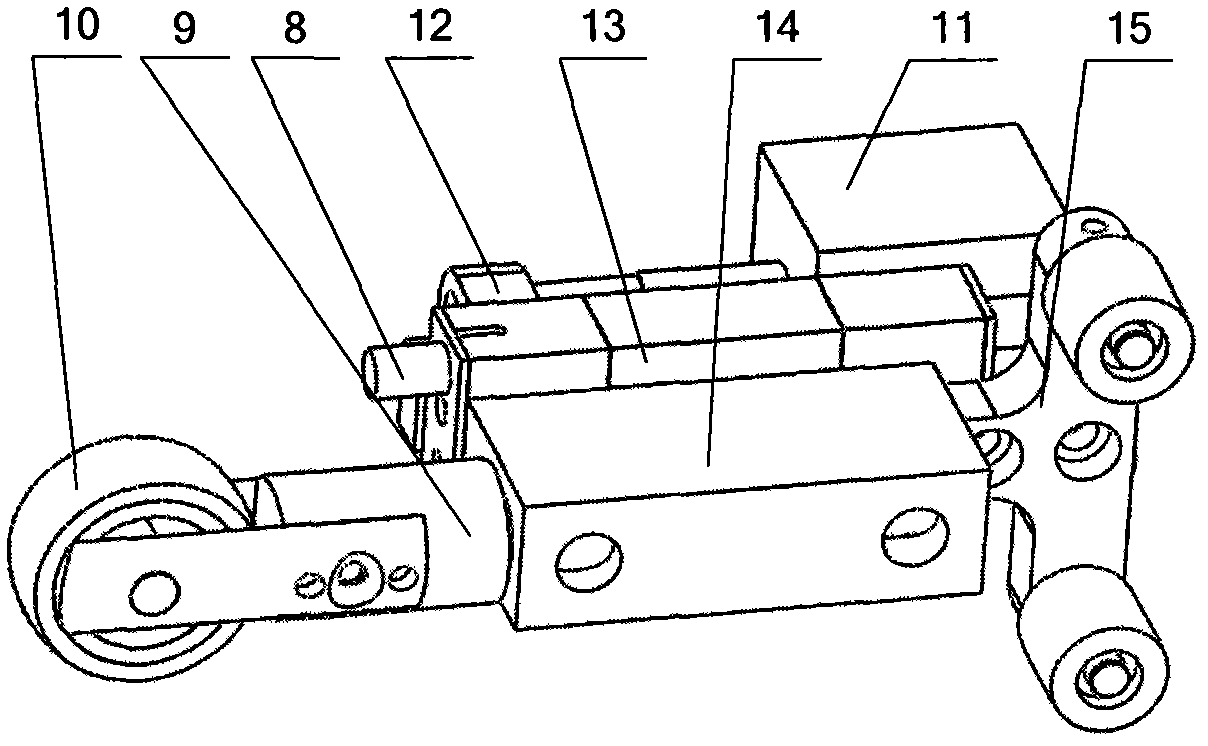

[0027] see figure 1 , figure 2 , the substrate 1 provides support for the entire abrasive belt flexible mechanism, and is used for the installation and fixation of the flexible mechanism 2, the roller 3, the deviation correction mechanism 4, the tensioning cylinder 5, the driving wheel 6, the mounting frame 7 and the flexible mechanism; the flexible mechanism 2 Make the polishing wheel 10 move along its fixed axis direction, make the polishing process flexible, and control the size of the polishing force to avoid rigid impact. The flexible mechanism 2 is installed on the substrate 1 through the guide rail 8; the roller 3 provides support for the abrasive belt , its inside is a bearing structure, which rotates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com