Automatic stringer

An automatic threading and skewering machine technology, which is applied in the fields of skewering meat on skewers, slaughtering, food science, etc. It can solve the problems of being unsuitable for medium and large-scale production, low efficiency of stamping, low degree of automation, etc., and achieves accurate The effects of rapid meat positioning, improved production efficiency, and reduced consumption of manpower, material and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

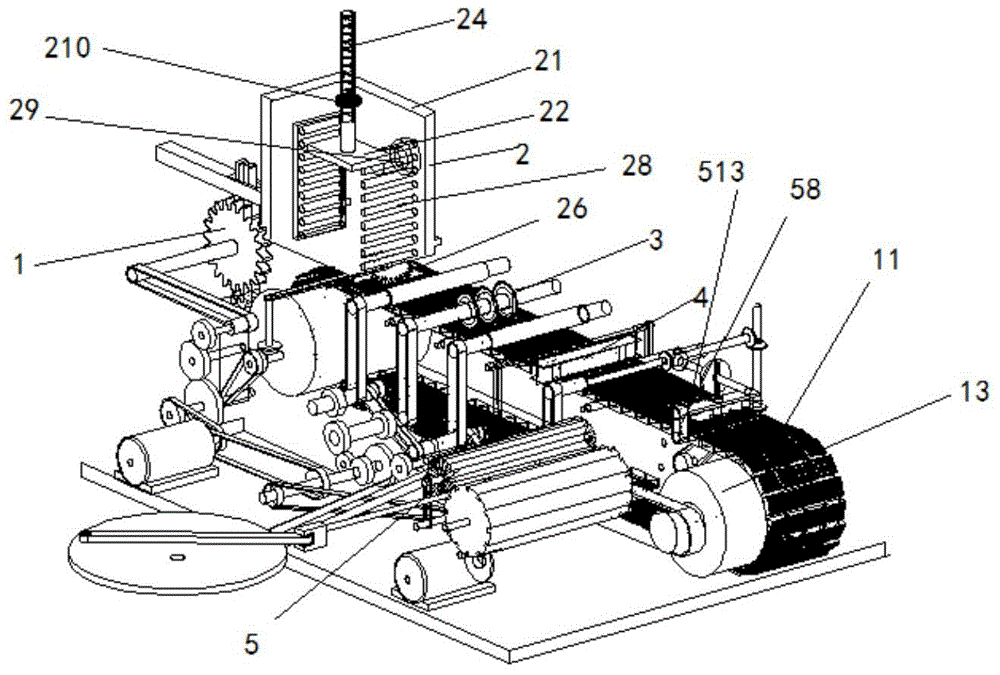

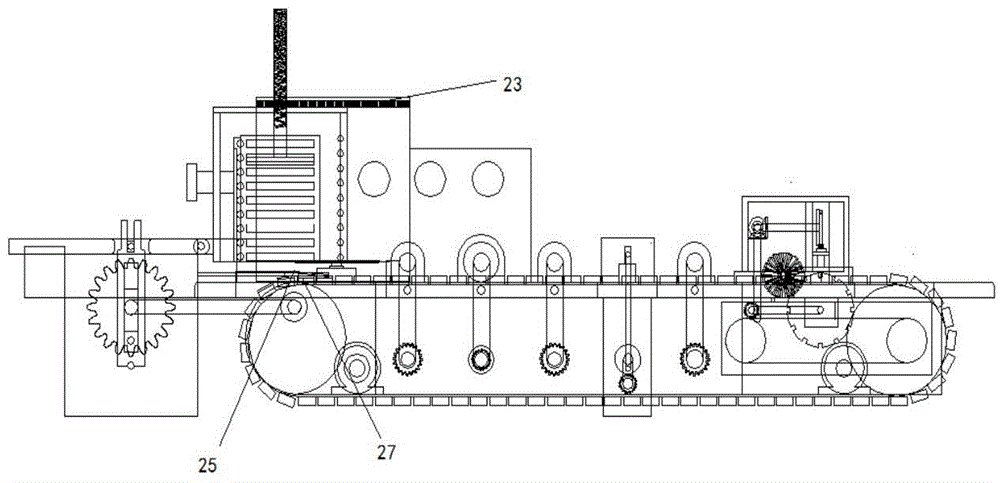

[0025] see figure 1 , an automatic skewering machine, including a power transmission device 1, an automatic meat slicer 2 with a push-type automatic lock meat box, a hob meat cutting device 3, a shearing and distributing device 4, and an automatic punching device 5.

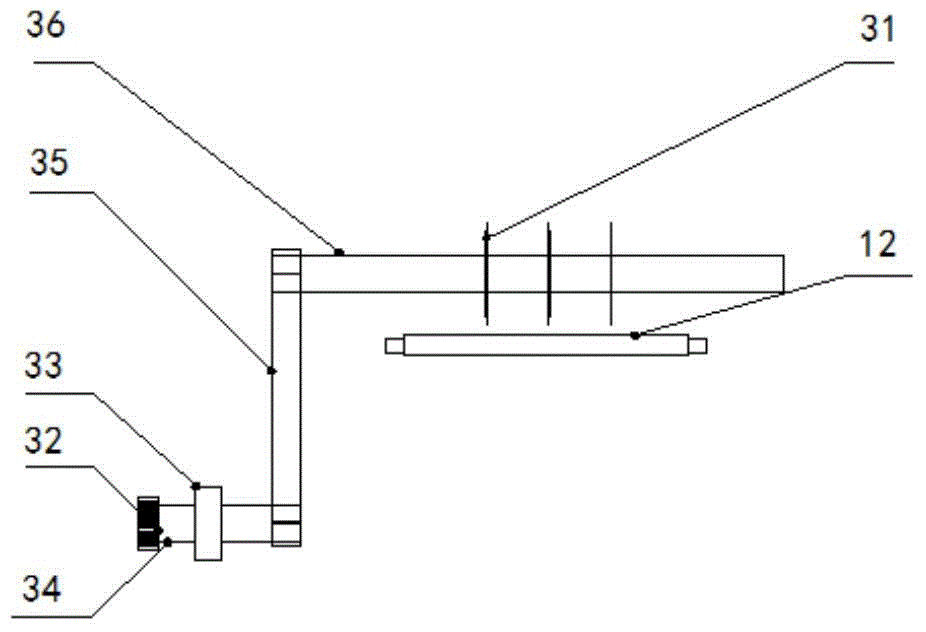

[0026] see further figure 1 , 3, the power transmission device 1 includes a crawler belt 11, a crawler top shaft 12, and a power sprocket 13, the crawler belt 11 is set on the power sprocket 13, and the crawler top shaft 12 is installed on the hob in the hob meat cutting device Below the knife 31 and the guillotine 41 in the cutting and distributing device 4;

[0027] see further Figure 1-2 , which also shows an automatic meat slicer 2 with a push-type automatic meat lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com