Method for preparing large-scale two-dimensional nanomaterial graphite

A two-dimensional nanomaterial, large-scale technology, applied in the preparation of two-dimensional nanomaterial graphene, using carbon element injection to prepare large-scale graphene, achieving large size, saving development and equipment costs, and large size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

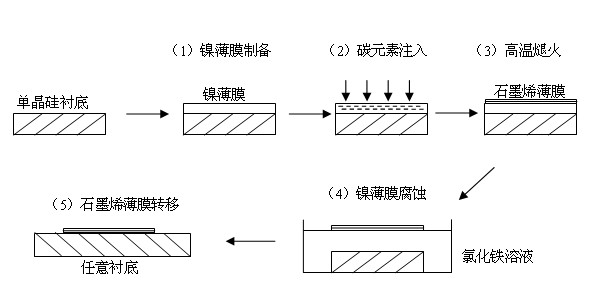

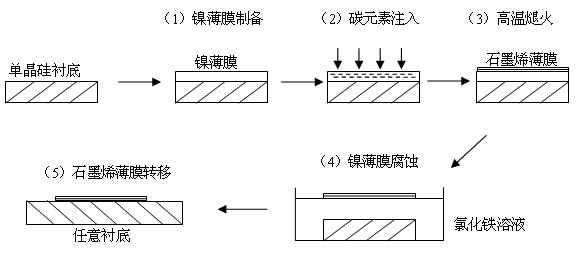

[0024] Embodiment 1: implement according to the following five steps

[0025] 1. Nickel thin film preparation: use sputtering method (Sputtering) to coat a uniform nickel thin film on the surface of a single crystal silicon wafer (0.7mm thick), with a thickness of 300nm.

[0026] 2. Carbon element implantation: The carbon element is implanted into the nickel film by means of ion implantation. The ion implantation energy is 600eV, and the dose is 5x10 15 cm -2 ,

[0027] 3. High-temperature annealing: put the sample injected with carbon into a high-temperature furnace for annealing, and the annealing temperature is 900 o C, the annealing time is 30 minutes, the vacuum degree is 10 -5 Pa. And after cooling down to room temperature. At this point, a layer of graphene film will grow on the surface of the nickel film,

[0028] 4. Corrosion of nickel film: put the substrate with graphene film on the surface into ferric chloride solution for corrosion, the solution concentrat...

Embodiment 2

[0031] Embodiment 2: one, nickel thin film preparation: utilize sputtering method (Sputtering) to coat uniform nickel thin film on the surface of monocrystalline silicon chip (0.7 mm thick), thickness is 300nm,

[0032] 2. Carbon element implantation: The carbon element is implanted into the nickel film by means of ion implantation. The ion implantation energy is 1000 eV, and the metering is 10 16 cm -2 ,

[0033] 3. High-temperature annealing: put the sample injected with carbon into a high-temperature furnace for annealing, and the annealing temperature is 800 o C, the annealing time is 45 minutes, and the vacuum degree is 1Pa. And after cooling down to room temperature. At this point, a layer of graphene film will grow on the surface of the nickel film,

[0034] 4. Corrosion of nickel film: put the substrate with graphene film on the surface into ferric chloride solution for corrosion, the solution concentration is 1 mol / liter, and the corrosion time is 10 hours. At ...

Embodiment 3

[0037] 1. Nickel thin film preparation: use sputtering method (Sputtering) to coat a uniform nickel thin film on the surface of a single crystal silicon wafer (0.7 mm thick), with a thickness of 200nm.

[0038] 2. Carbon element implantation: The carbon element is implanted into the nickel film by means of ion implantation. The energy of ion implantation is 600eV, and the metering is 5x10 15 cm -2 ,

[0039] 3. High-temperature annealing: put the sample injected with carbon into a high-temperature furnace for annealing, and the annealing temperature is 1000o C, the annealing time is 15 minutes, the vacuum degree is 10 -5 Pa. And after cooling down to room temperature. At this point, a layer of graphene film will grow on the surface of the nickel film,

[0040] 4. Corrosion of nickel film: put the substrate with graphene film on the surface into ferric chloride solution for corrosion, the solution concentration is 0.5 mol / liter, and the corrosion time is 24 hours. At thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com