Apparatus and method for continuously composite plating metallic and nano particle on carbon fiber surface

A nano-particle and composite electroplating technology, applied in jewelry and other directions, can solve the problems of large consumption of drugs, expensive equipment, complex chemical plating process, etc., to achieve good uniformity and continuity, adjustable thickness, and solve the effect of black hearts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0077] The electroplating solution before adding nanoparticles is acidic nickel sulfate solution. The solution formula range is as follows:

[0078] Nickel sulfate 210g / L Sodium chloride 10g / L

[0079] h 3 BO 3 33g / L anhydrous sodium sulfate 25g / L

[0080] Magnesium sulfate 35g / L

[0081] pH 5-6

[0082] Temperature 25°C

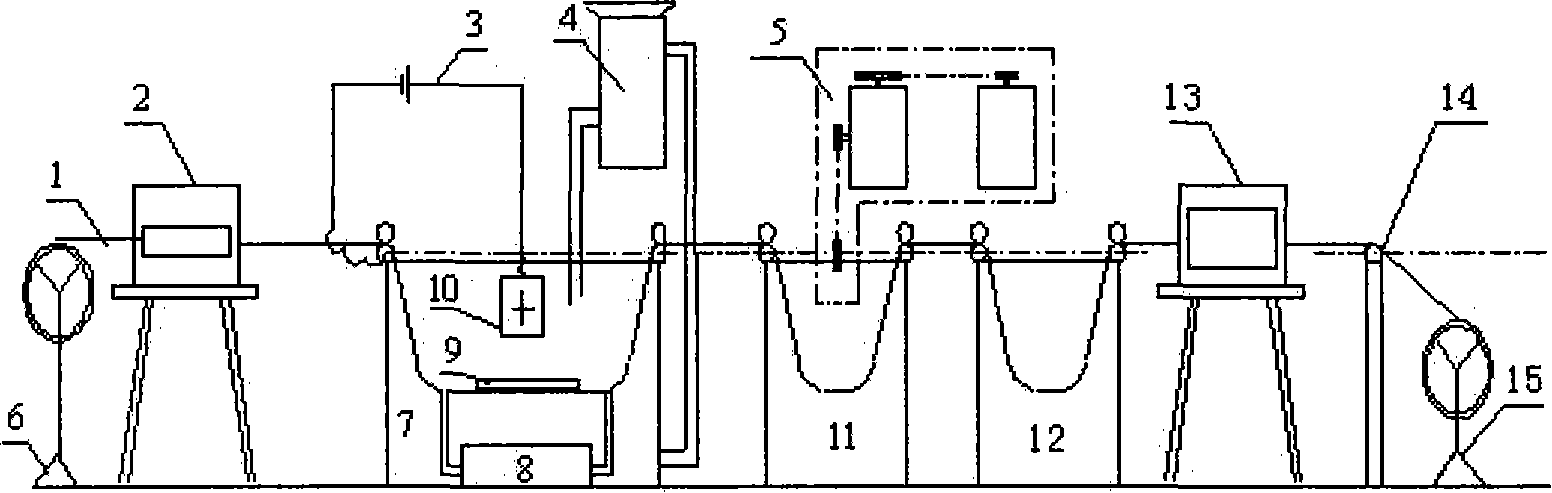

[0083] A 12K continuous long carbon fiber with a diameter of 7 μm was passed through a continuous nickel plating device ( figure 1 ), add dispersed 5g / L Fe in the acidic nickel plating solution 3 o 4 Nanoparticles (average particle size 100nm), and 3A current is passed through, and composite electroplating is realized by strong stirring, and the fiber advances in the plating tank at a speed of 0.1m / min. The long carbon fiber first passes through the tube furnace, and undergoes degumming treatment in it, and then enters the plating tank as an electrode under the action of the mechanical transmission device, wiring device, pay-off wheel, and take...

example 2

[0085] The electroplating solution before adding nanoparticles is an alkaline copper sulfate solution. The solution formula range is as follows:

[0086] Copper Sulfate Pentahydrate 40g / L Potassium Sodium Tartrate 12g / L

[0087] Sodium hydroxide 23g / L Anhydrous citric acid 30g / L

[0088] pH 9-10

[0089] Temperature 20°C

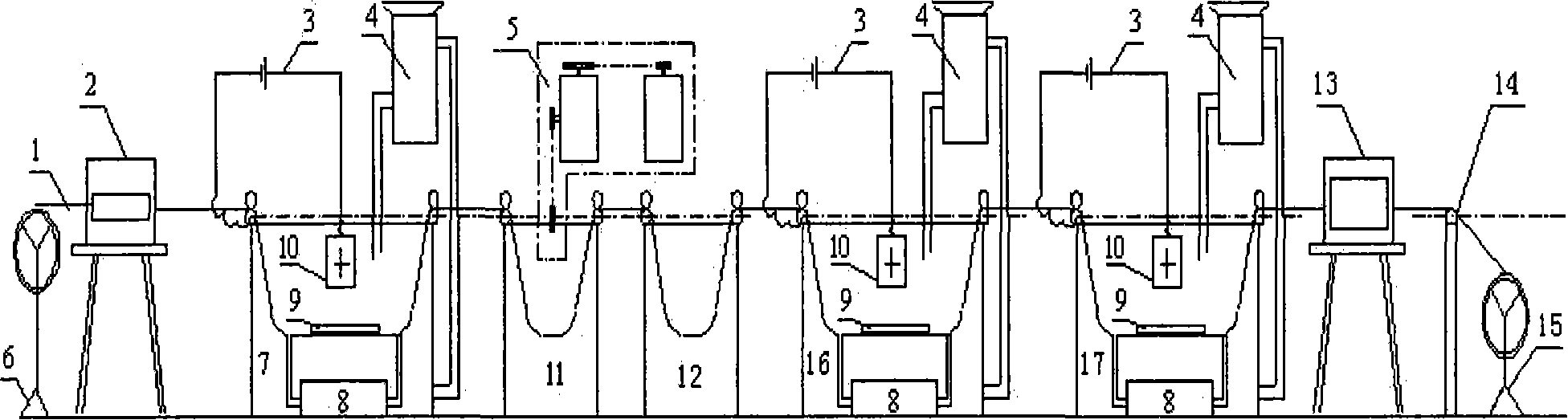

[0090] A 24K continuous long carbon fiber with a diameter of 7 μm was passed through a continuous copper plating device ( figure 2 ), add dispersed 0.5g / L carbon nanotubes (average diameter 50nm) in the alkaline copper plating solution, and pass through 4A electric current, realize composite electroplating by strong stirring, the advancing speed of fiber in plating tank is 0.1m / min . The long carbon fiber first passes through the tube furnace, and undergoes degumming treatment in it, and then enters the plating tank as an electrode under the action of the mechanical transmission device, wiring device, pay-off wheel, and take-up wheel. device to ensure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com