Preparation method of phosphotungstic acid @MIL(Fe) photocatalyst

A photocatalyst, a certain amount of phosphotungstic acid technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve low quantum efficiency, separation recovery and recycling Difficult to use, high pH requirements of the reaction system, etc., to achieve the effects of no secondary pollution, easy centrifugal recovery, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

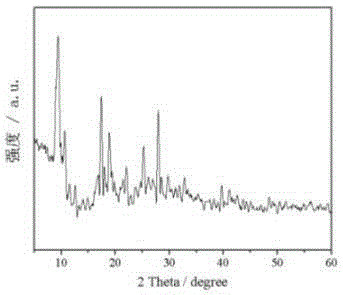

[0026] (1) Preparation of phosphotungstic acid@MIL-53(Fe) composite material

[0027] Ultrasonic disperse 0.498g of terephthalic acid in 15mL of DMF, then add 0.8109g of FeCl in sequence 3 ·6H 2 O and 0.162g phosphotungstic acid, stirred by magnetic force for 15min; in a Teflon-lined autoclave, reacted at 150°C for 5h; cooled to room temperature, centrifuged, washed with water and ethanol, and finally vacuum-dried at 60°C 24h; meanwhile, MIL-53(Fe) was prepared by this method.

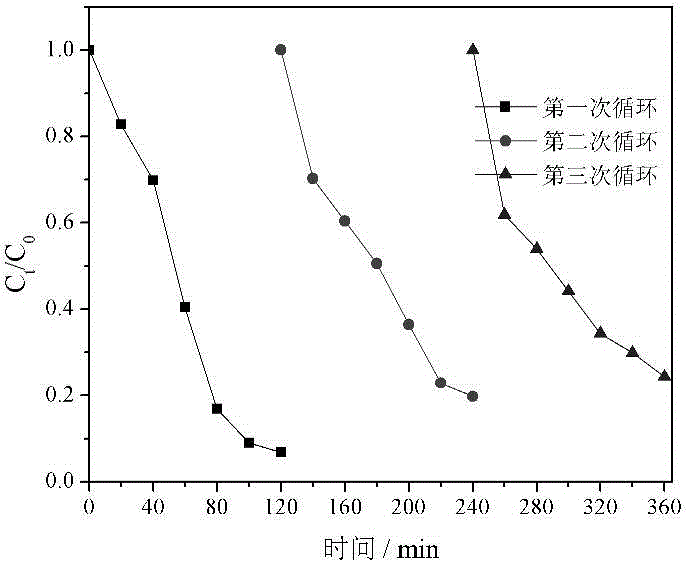

[0028] (2) Photocatalyst performance evaluation

[0029] The organic dye rhodamine B was selected as the probe molecule to study the performance of the prepared photocatalyst. Prepare 25mL of rhodamine B dye wastewater with a concentration of 20mg / L, add a certain amount of photocatalyst, stir magnetically at room temperature, and degrade the organic pollutants in the water under the irradiation of an LED lamp 10cm above the water surface with a power of 20W and a wavelength of 450nm; Sampling was ...

Embodiment 2

[0032] (1) Preparation of phosphotungstic acid@MIL-88B(Fe) photocatalyst

[0033] Ultrasonic disperse 0.348 g terephthalic acid in 15 mL DMF and 1.2 mL 2mol / L NaOH mixed solution, then add 1.212 g Fe(NO 3 ) 3 9H 2 O and 0.405g phosphotungstic acid, magnetically stirred for 15min; reacted in a polytetrafluoroethylene-lined autoclave at 100°C for 12h; cooled to room temperature, centrifuged, washed with water and ethanol, and finally vacuum-dried at 60°C 24h; meanwhile, MIL-88B(Fe) was prepared by this method.

[0034] (2) Photocatalyst performance evaluation

[0035] With embodiment 1.

[0036] Add 5mg of phosphotungstic acid@MIL-88B(Fe), phosphotungstic acid and MIL-88B(Fe) to Rhodamine B wastewater, and after 120min degradation reaction, the degradation rates of Rhodamine B are 82.32%, 5.64% and 57.20%, respectively. %.

Embodiment 3

[0038] (1) Preparation of phosphotungstic acid@MIL-100(Fe) photocatalyst

[0039] Ultrasonic dispersion of 0.4102g trimesic acid in 15mLH 2 O, and then sequentially added 0.605gFeCl3 ·6H 2 O and 0.605g phosphotungstic acid, magnetically stirred for 15min; reacted in a Teflon-lined autoclave at 150°C for 15h; cooled to room temperature, centrifuged, washed with water and ethanol, and finally vacuum-dried at 60°C 24h; meanwhile, MIL-100(Fe) was prepared by this method.

[0040] (2) Photocatalyst performance evaluation

[0041] With embodiment 1.

[0042] Add 5mg of phosphotungstic acid@MIL-100(Fe), phosphotungstic acid and MIL-100(Fe) to Rhodamine B wastewater, and after 120min degradation reaction, the degradation rates of Rhodamine B are 95.38%, 5.64% and 53.16%, respectively. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com