Method for preparing silicon dioxide aerogel with low density and large specific surface area at ordinary pressure

A large specific surface area, silica technology, applied in the direction of silica, silica, etc., can solve the problems of large modifier dose, high airgel density, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

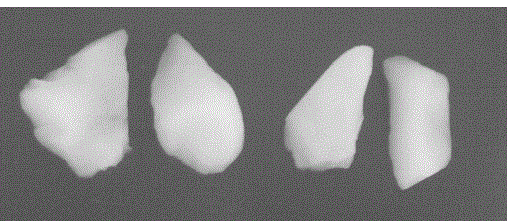

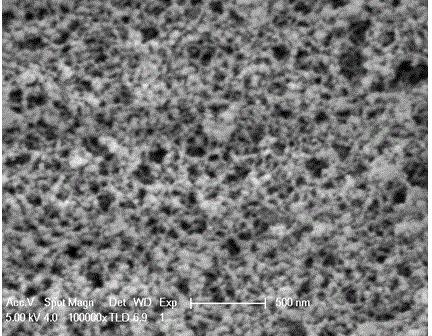

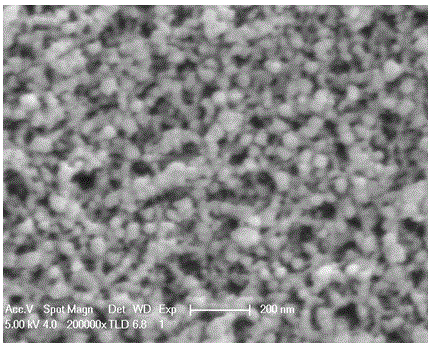

Image

Examples

Embodiment 1

[0028] (1) Mix 5ml of 34% industrial water glass with a modulus of 3.3 and 15ml of deionized water in a beaker, and stir for 5 minutes;

[0029] (2) Pass through the 732 strong acidic ion exchange resin. Before passing through the column, pass through the column with 80°C deionized water to fully expand the resin particles, and then pass the water glass solution heated to 45°C through the column to obtain a pH of 3. Silica sol, stir on a stirrer at room temperature, add 0.5mol / L ammonia solution to adjust the pH of the solution to 5~6, then add 0.5ml N,N dimethylformamide, stir for 2min, after about 15min it will completely gel, In a sealed container, heat in a water bath at 50°C for 12 hours;

[0030] (3) Cut the gel into pieces, add ethanol to the gel for solvent exchange, and perform solvent exchange in a water bath at 50°C, each exchange for 8 hours, a total of 3 times. The exchanged solution is recovered and can be recycled;

Embodiment 2

[0035] (1) Mix 5ml of industrial water glass with a modulus of 3.5 and a mass concentration of 32% and 15ml of deionized water in a beaker, and stir for 5 minutes;

[0036] (2) Pass through the 732 strong acidic ion exchange resin. Before passing through the column, pass through the column with 80°C deionized water to fully expand the resin particles, and then pass the water glass solution heated to 45°C through the column to obtain a pH of 3. Silica sol, stir on a stirrer at room temperature, add 0.5mol / L ammonia solution, adjust the pH of the solution to 5~6, add 1ml of glycerol, stir for 2min, and gel completely after about 2h, seal the container, and put it in a water bath at 50°C Heating for 12 hours;

[0037] (3) Cut the gel into pieces, add acetone to the gel for solvent exchange, and perform solvent exchange in a water bath at 50°C, each exchange for 8 hours, a total of 3 times. The exchanged solution is recovered and can be recycled;

[0038](4) Exchange acetone wit...

Embodiment 3

[0042] (1) Mix 5ml of industrial water glass with a modulus of 3.5 and a mass concentration of 32% and 15ml of deionized water in a beaker, and stir for 5 minutes;

[0043] (2) Pass 732 strong acidic ion exchange resin. Before passing through the column, pass through the column with 80°C deionized water to fully expand the resin particles. Then pass the water glass solution at room temperature through the column to obtain a silica sol with a pH of 3. Stir on a stirrer at room temperature, add 0.5mol / L ammonia solution during the period, adjust the pH of the solution to 6-7, then add 1.5ml of N,N dimethylformamide, stir for 2min, after about 2h it will completely gel, seal the container, Heating in a water bath at 50°C for 12 hours;

[0044] (3) Cut the gel into pieces, add acetone to the gel for solvent exchange, and perform solvent exchange in a water bath at 50°C, each exchange for 8 hours, a total of 3 times. The exchanged solution is recovered and can be recycled;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com