Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Effective transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

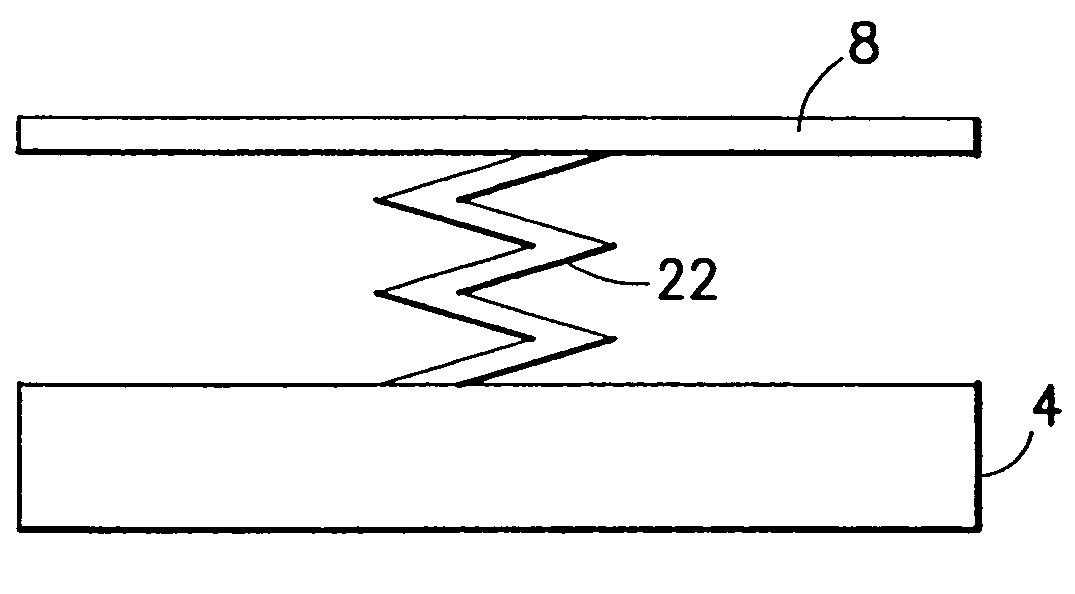

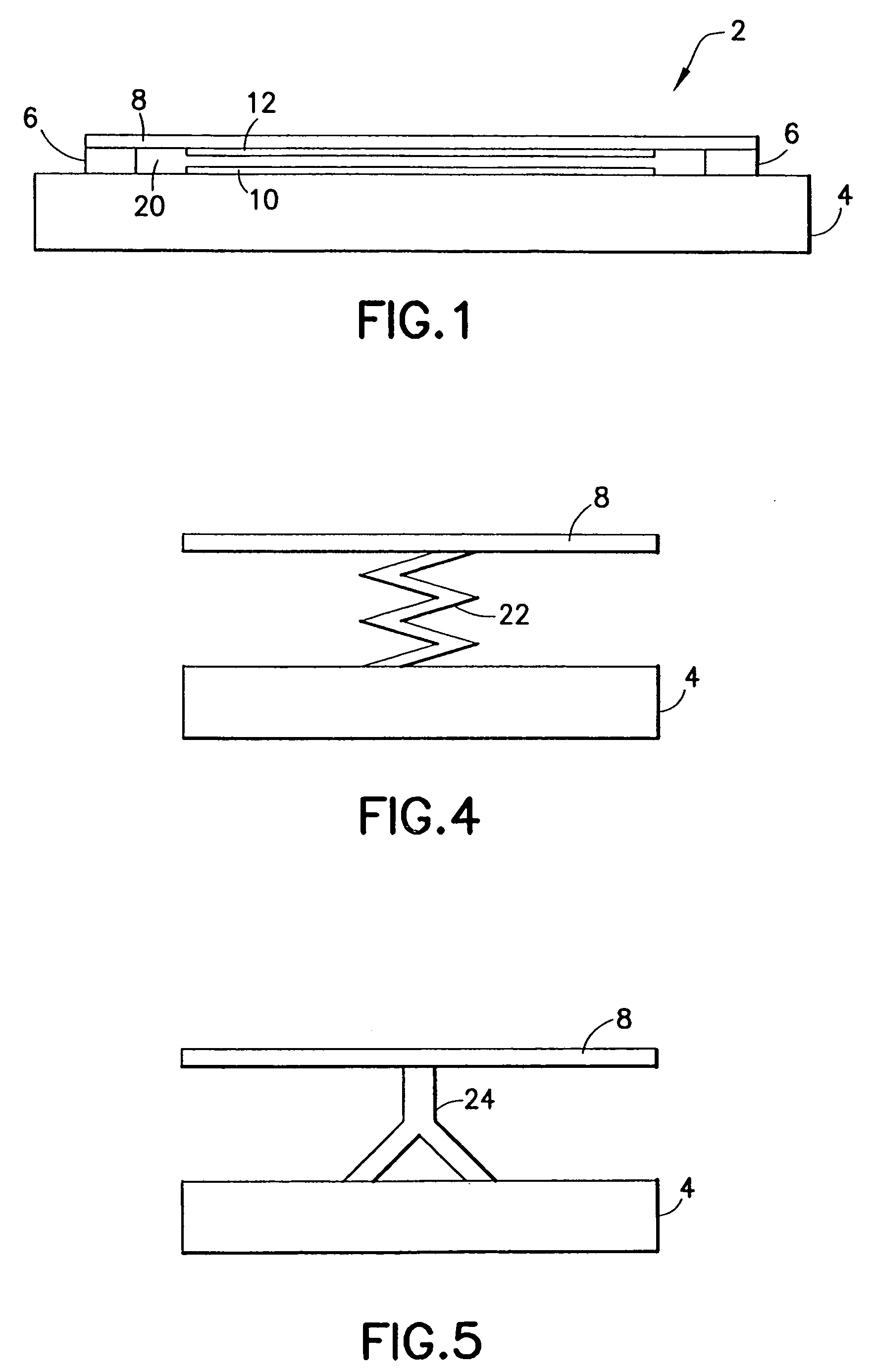

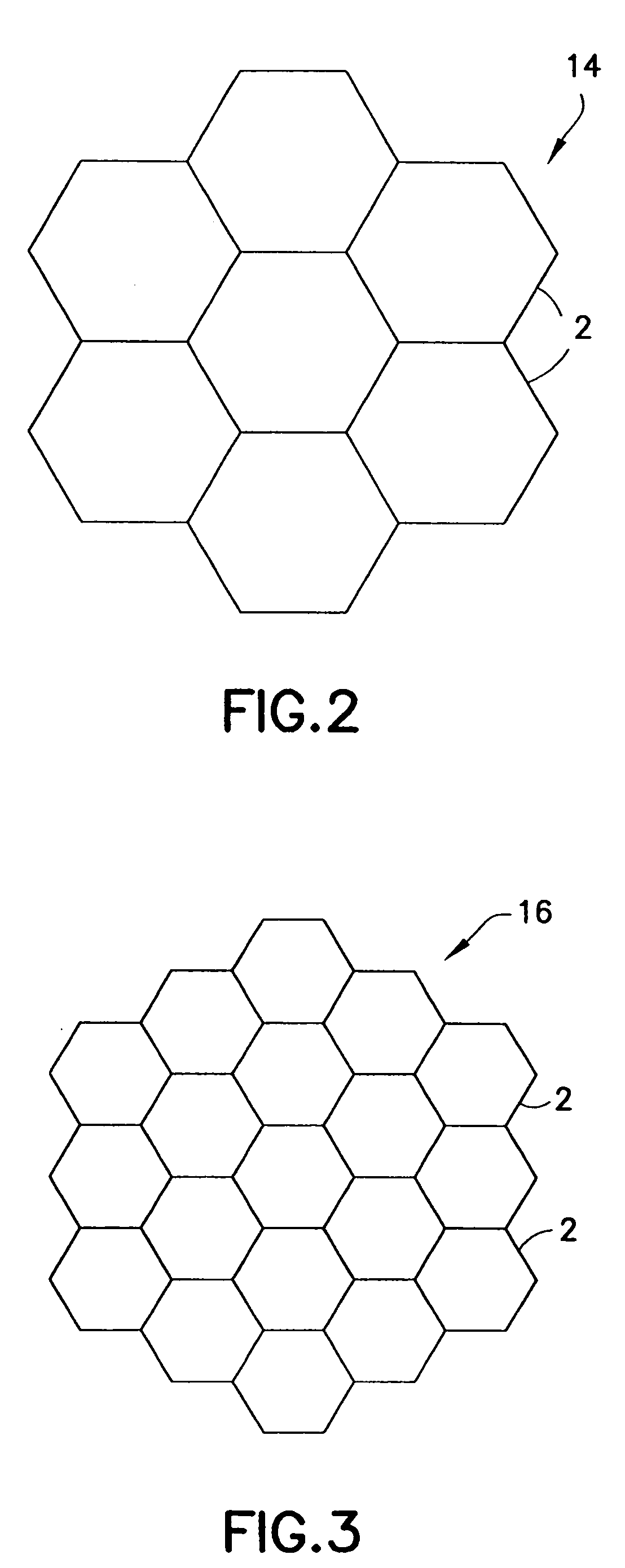

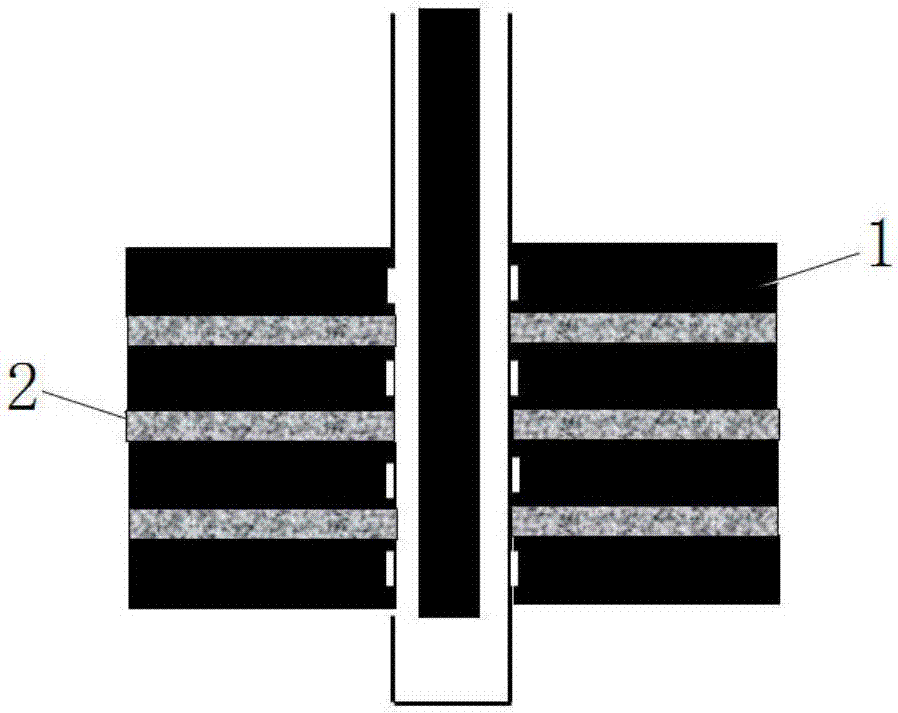

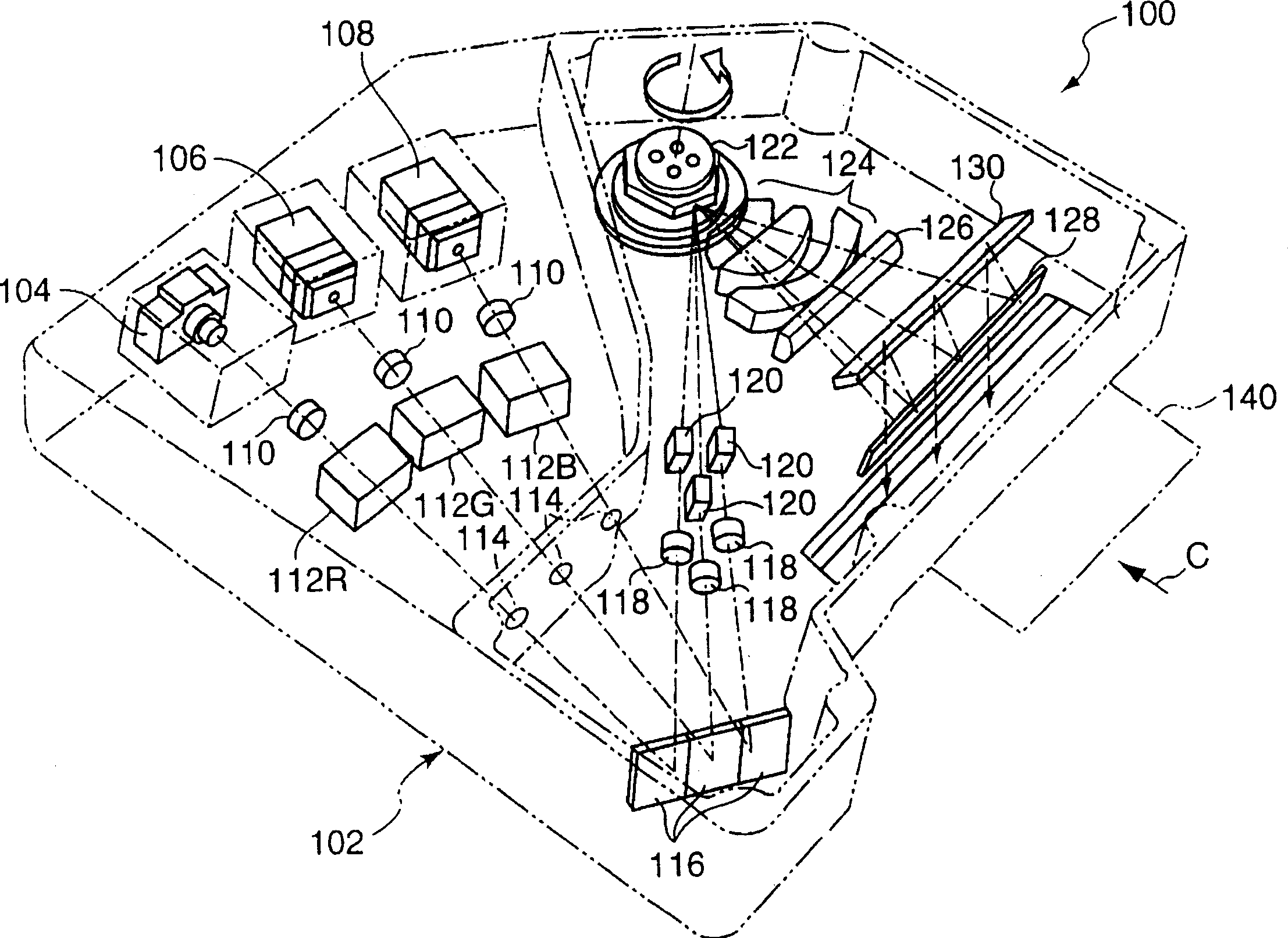

Micromachined ultrasonic transducer cells having compliant support structure

ActiveUS20050146240A1Effective transformationIncrease effective areaUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesPhysicsMembrane configuration

A micromachined ultrasonic transducer array comprising a multiplicity of cMUT cells built on a substrate. Each cMUT cell comprises a compliant support structure built on the substrate, a membrane supported over a cavity by the compliant support structure, a first electrode supported by the membrane, and a second electrode that forms a capacitor with the first electrode, the cavity being disposed between the first and second electrodes. The compliant support structure uncouples the non-membrane outer surface of each cMUT cell from the supporting substrate.

Owner:GENERAL ELECTRIC CO

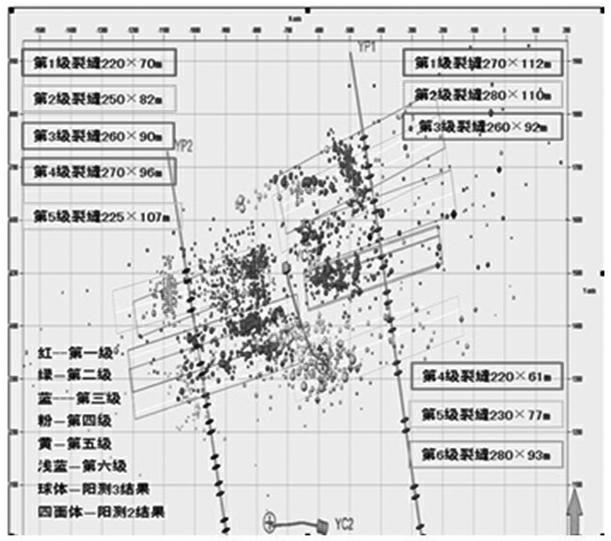

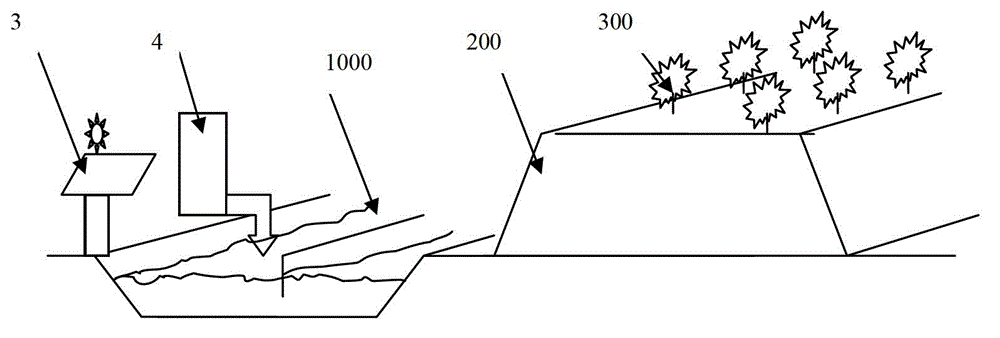

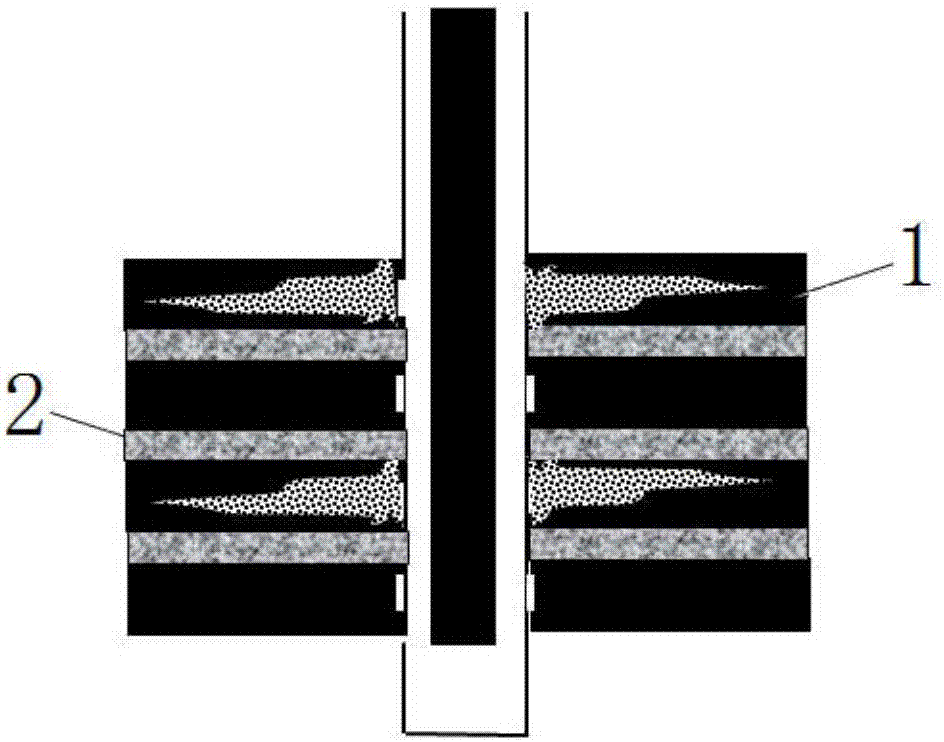

Method suitable for effective flow guide for fractures in fracturing of shale oil pool reservoir

ActiveCN106907137AImprove diversion capacityIncrease "retrofit volumeFluid removalMicro fractureFracturing fluid

The invention relates to the technical field of hydraulic fracturing capacity increasing revamping of oil and gas reservoirs, in particular to a method suitable for effective flow guide for fractures in fracturing of a shale oil pool reservoir. The method includes the following steps that A, the reservoir is pretreated through acid liquor; B, the main fracture is constructed through low-viscosity fracturing fluid; C, the micro fractures and the branch fractures are opened by injecting low-viscosity slickwater; D, slugging is conducted by injecting low-viscosity acid liquor and low-viscosity slickwater alternately; E, low-viscosity slickwater carrying a proppant and low-viscosity fracturing fluid carrying a proppant are injected in sequence so as to support a micro fracture system and a branch fracture system, and the first proppant is different from the second proppant; F, intermediate-viscosity fracturing fluid carrying proppants is injected so as to support a main fracture system; and G, the fourth proppant in a shaft is completely displaced to the openings of the fractures by means of the low-viscosity slickwater.

Owner:CHINA PETROLEUM & CHEM CORP +1

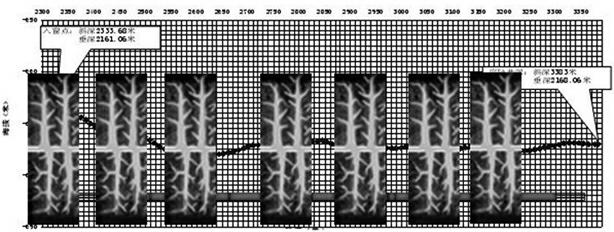

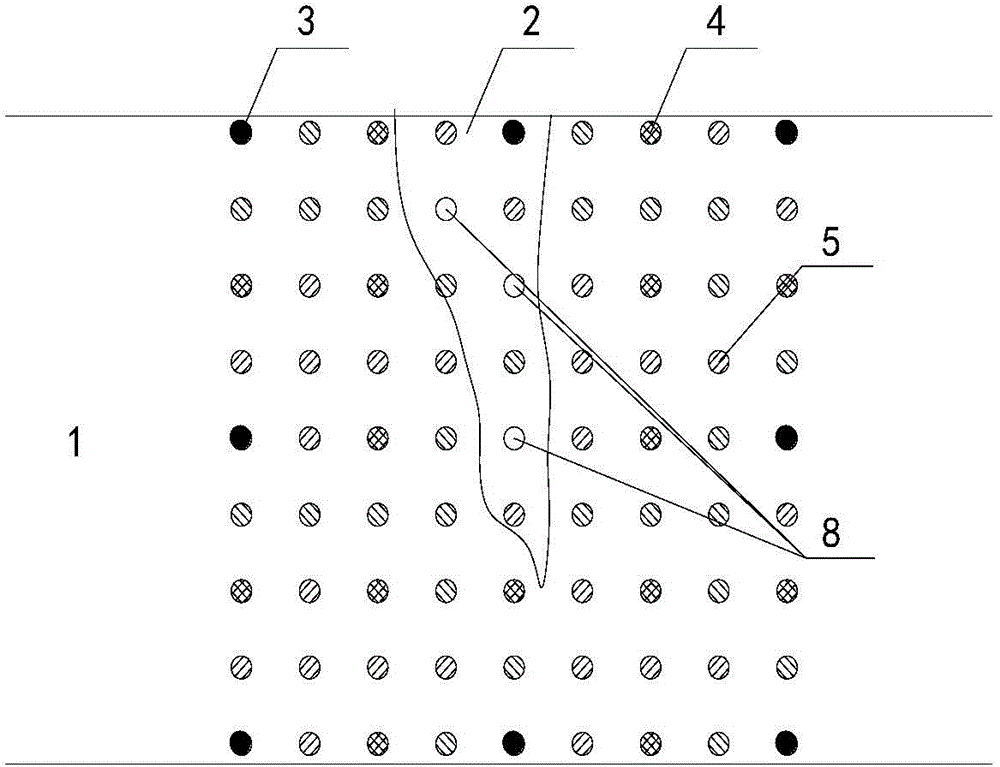

Sectioned multi-cluster synchronous volume fracturing technology for double horizontal wells

ActiveCN102606124AThe average air penetration rate is smallGood oilinessFluid removalMulti clusterHorizontal wells

The invention belongs to the field of oil and gas field exploration, discloses novel technology for volume fracturing of a compact oil reservoir, and particularly relates to a sectioned multi-cluster synchronous volume fracturing technology for double horizontal wells. The technology is characterized by including the steps of synchronous fracturing selection, synchronous fracturing well selection, multi-section and multi-cluster perforation position determination, synchronous fracturing construction and synchronous fracturing effect evaluation. In the technology, cracks are impelled to turn by means of interference among the cracks, thereby realizing complicated netted cracks and effectively modifying the compact oil reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Basic biomass synthetic resin and preparation method and application thereof

ActiveCN101629019AGood film formingIncrease stickinessProtein adhesivesGlue/gelatin preparationPolymer scienceAdhesive

The invention belongs to the material science field, in particular to a basic biomass synthetic resin and a preparation method and an application thereof. The basic biomass synthetic resin is prepared by the following steps: taking acidity regulator to prepare a water solution with pH value of 6.0-10.0, adding plant protein powder in the water solution under the stirring state; adding a molecular structure modifying agent under the stirring state, performing the modifying reaction for 15-240 min at 5-75 DEG C; sequentially adding modified starch and a resin assistant, performing the polymerization reaction for 15-240min at 5-90 DEG C, adding preservative in a reaction system within the last 5-20min of the polymerization reaction; adding or not adding packing after finishing the reaction, and stirring uniformly to obtain the basic biomass synthetic resin, wherein the part of the materials is taken by weight. The basic biomass synthetic resin has wide application range on the respect of preparing bonding adhesive or coating.

Owner:郑州佰沃科技发展有限公司

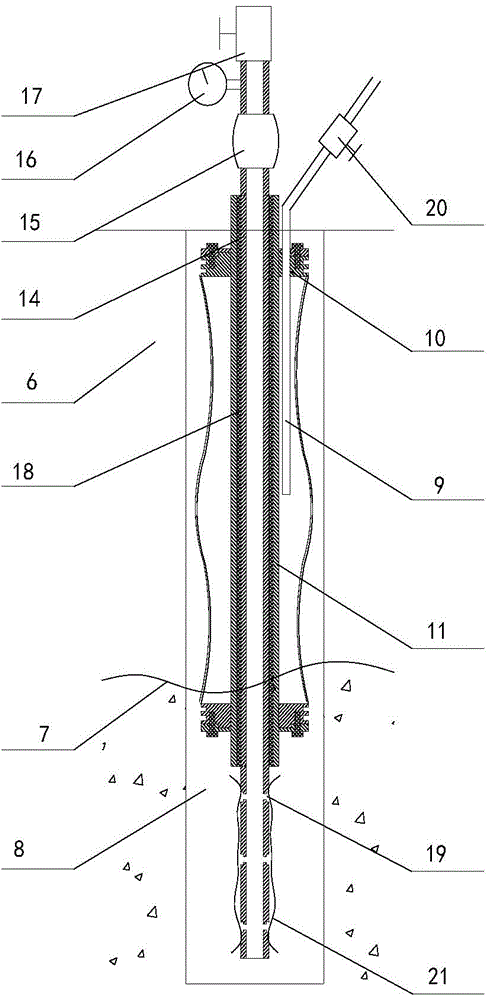

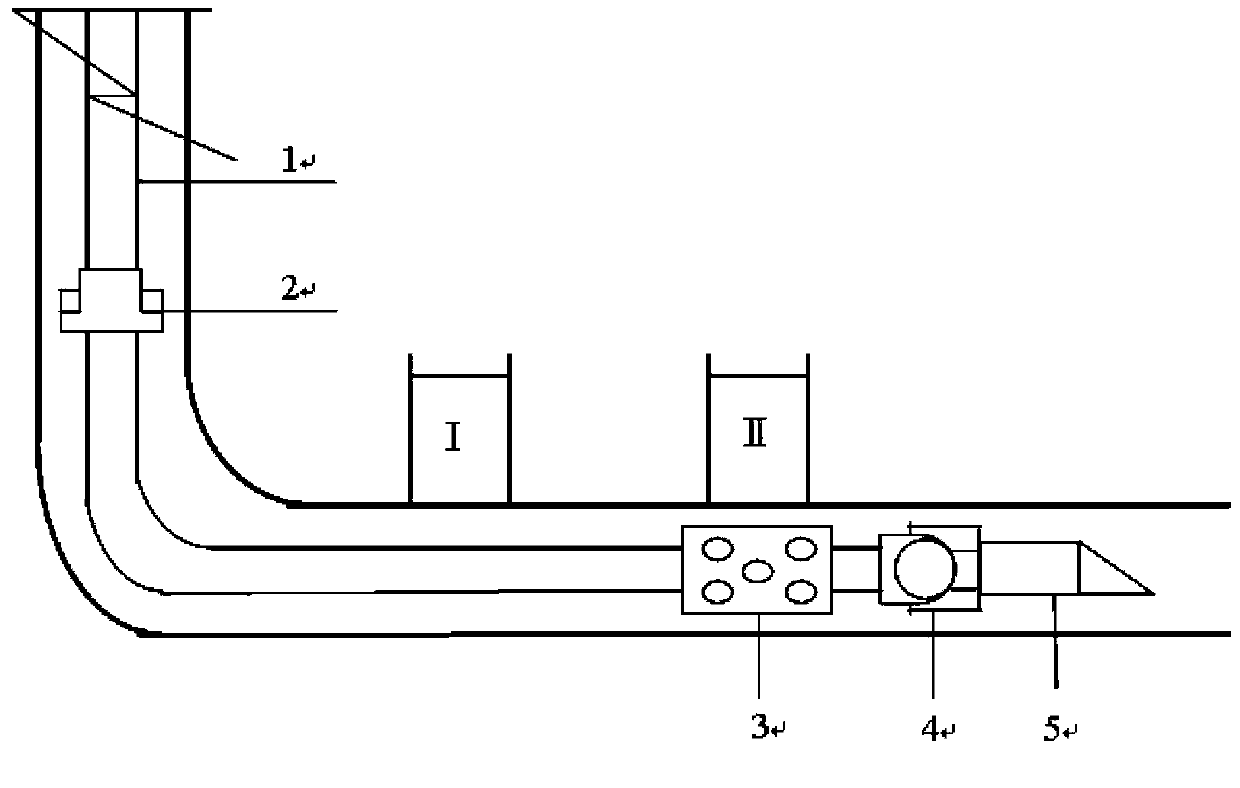

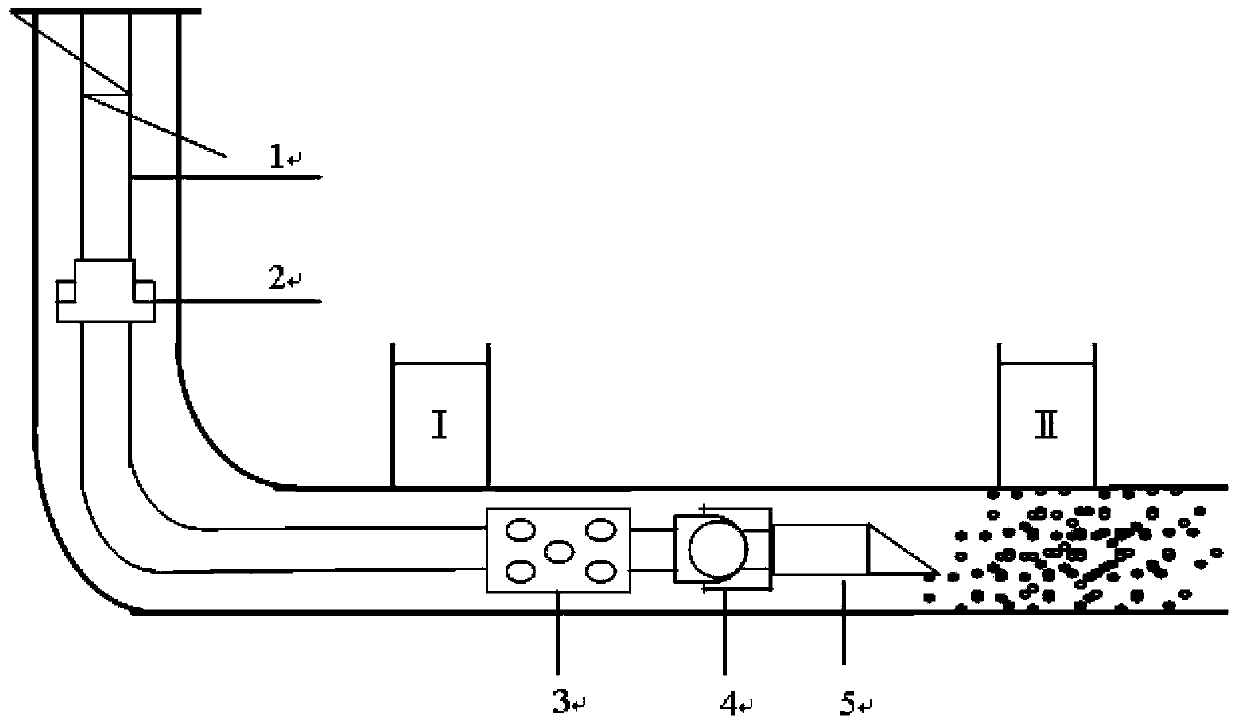

Packer packing multi-layer hydropower abrasive perforating and fracturing integrated technique

InactiveCN101270639AGuaranteed Design DisplacementEffective transformationFluid removalAbrasive blastingSurge tank

An integrative method for a packer to pack off a multi-layer hydraulic sand-spraying perforation and pressure fracture is used in the multi-layer perforation and the pressure fracture of a well of well completion of a petroleum casing. A pipe column comprises an oil pipe, a safety joint, a hydraulic ejector, a K34 or a Y34 packer, a uniflow valve, a sieve vessel and an end cap, wherein, the lower layer of a hydraulic ejector position requires perforation depth. With the completion of perforation, the hydraulic sand-spraying fractures the lower layer by actively circulating the lower layer of the hydraulic sand-spraying perforation. When the hydraulic sand-spraying pressure fracture for the lower layer is completed, a reverse circulation surge tank is processed and the pipe column is leveled up and dragged to the upper layer of perforation pressure fracture to continue to fracture the upper layer by hydraulic sand-spraying perforation. After completion, the pipe column is lifted to be put into the well-completion pipe column to discharge liquid and finish production. The perforation is not required by each layer because only an oil pipe needs to be dragged to finish the multiple fracturing of multiple layers of the well. The integrative method integrating the perforation, the fracture and the packing-off together is new stimulation treatment technology. In addition, the fracture is reliable, construction is easy and convenient and period is short.

Owner:PETROCHINA CO LTD

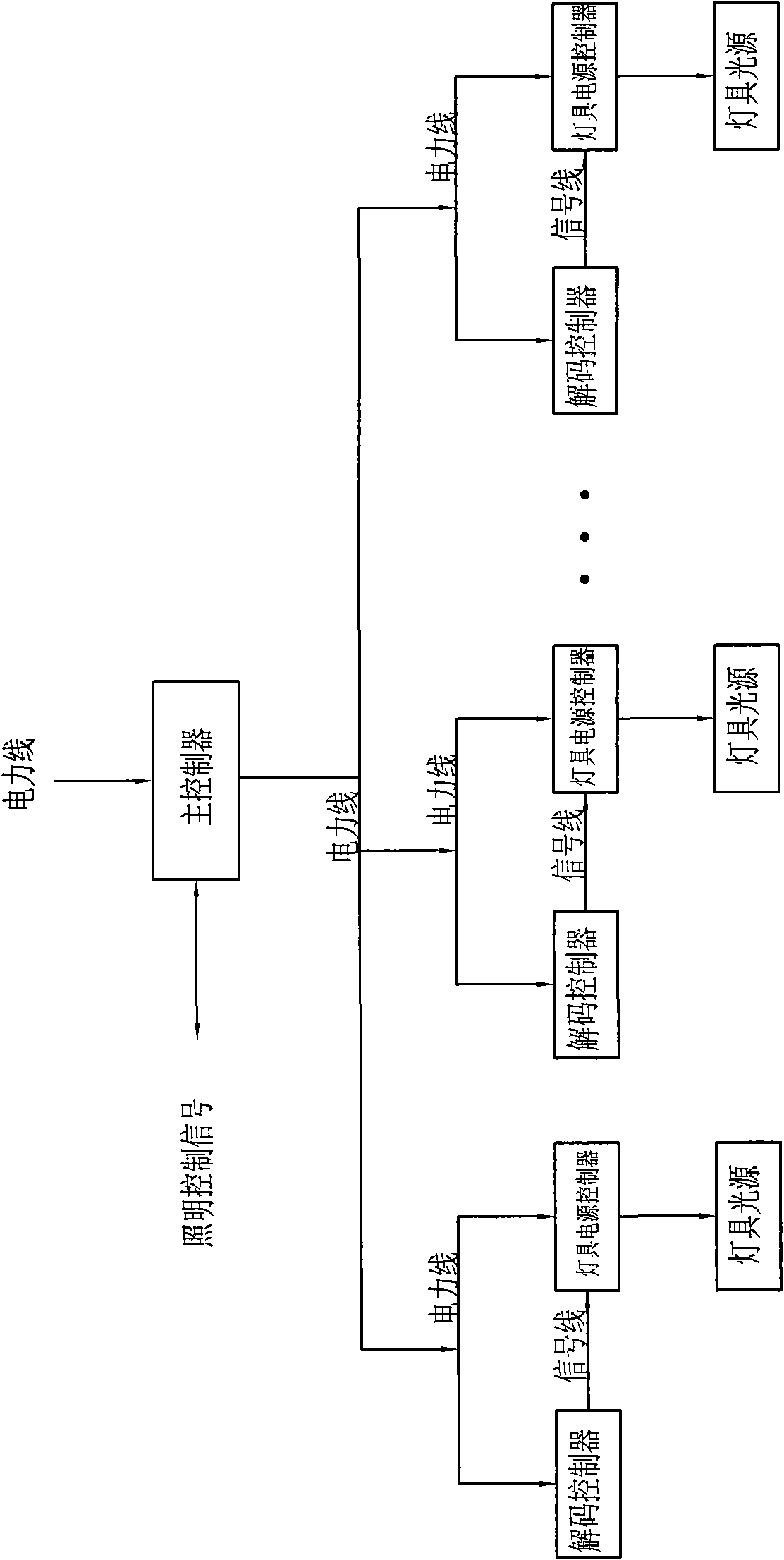

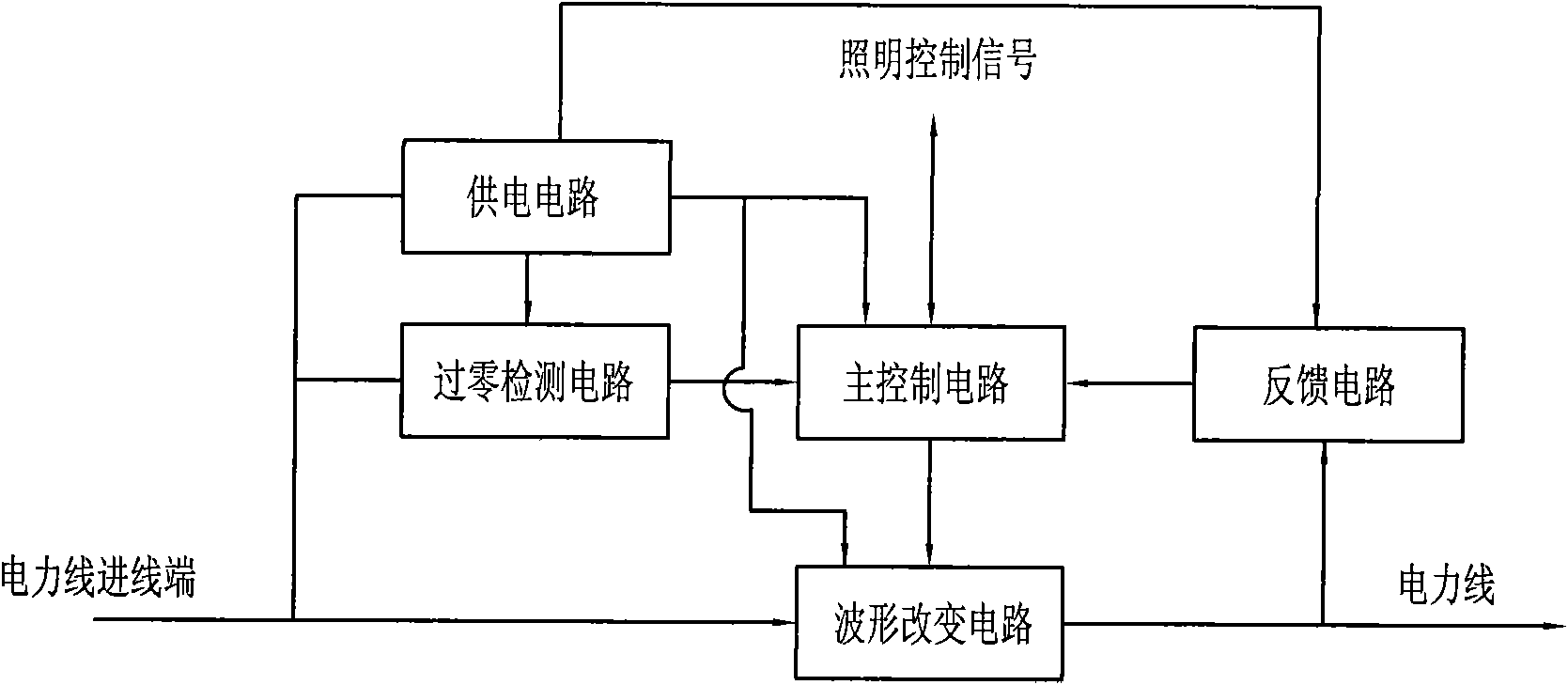

A lighting control method and its system

ActiveCN101553066AReliable Lighting ControlImprove anti-interference abilityTransmission systemsElectric light circuit arrangementLight energyElectric power system

A lighting control method is completed by a main controller and a decoding controller, wherein, the main controller encodes the lighting control signal into a transmission data signal composed of '0' or '1', and then converts the transmission data signal into a waveform data group that can be transmitted by the electric power line to transmit to the decoding controller, the decoding controller analyzes the lighting control data of the corresponding lamp from the received waveform data group, and then performs lighting control to the lamp. A lighting control system made up by the method, principally includes a main controller, a plurality of decoding controllers and lamps connected to the decoders. The invention has strong anti-interference capability and high reliability, does not has anyrestrictions to the transmission distance, and has little effect on the power grid factor; the invention only uses the existing electric power line network, can effectively perform reconstruction of lighting energy-saving engineering without increasing any cable, has very low manufacturing and installation costs, and can construct intelligent lighting system with different functions by combining different lighting control software.

Owner:重庆恒又源科技发展有限公司

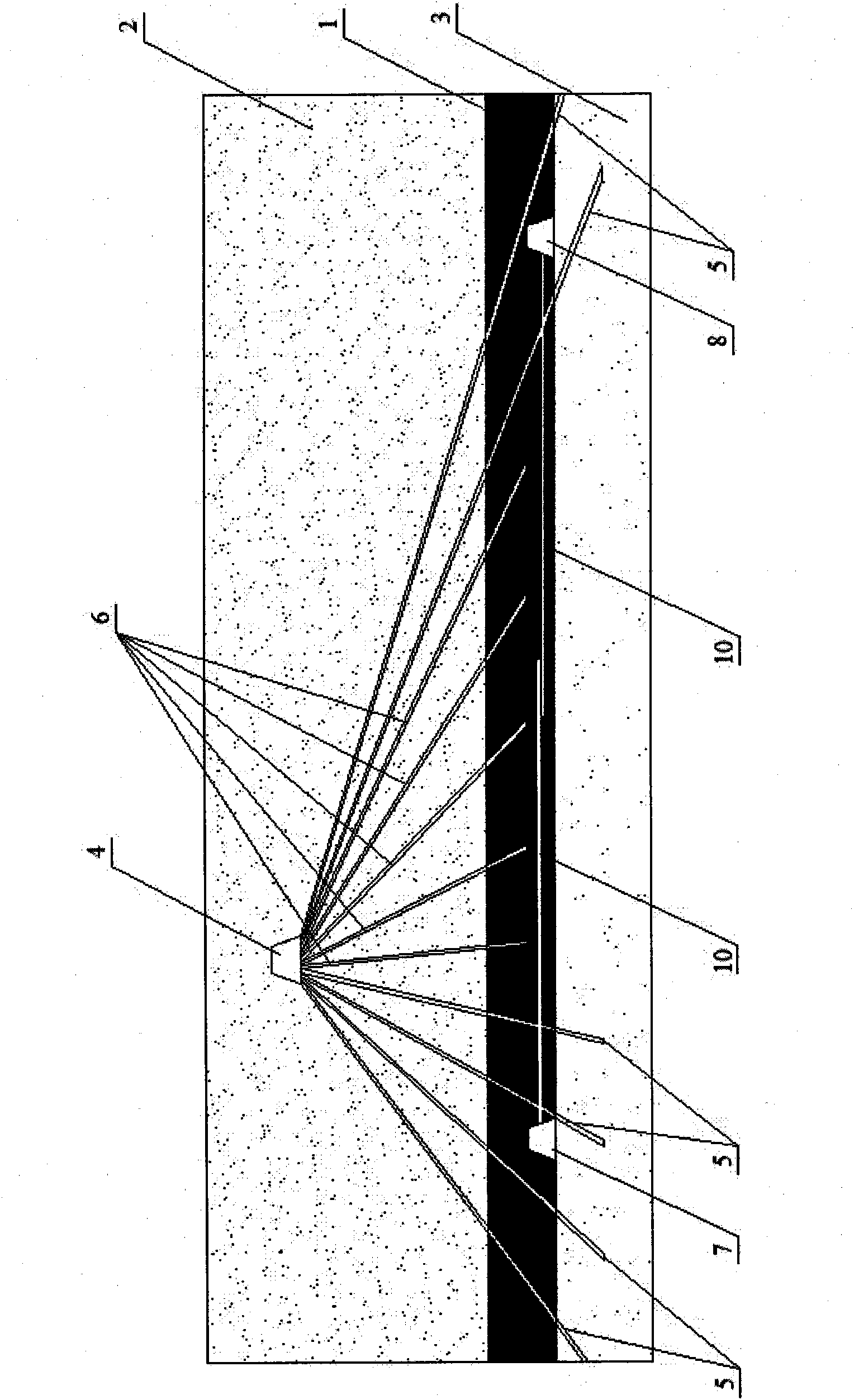

Regional forced gas extraction method for single low-permeability outburst thick coal seam

ActiveCN104100292AEliminate the problem of blank bands in extractionImprove extraction efficiencyGas removalHigh pressure waterHigh pressure

The invention provides a regional forced gas extraction method for a single low-permeability outburst thick coal seam. The regional forced gas extraction method comprises the steps of (a) excavating a rock gangway in a rock fissure zone and drilling a lower-position seam through hole downwards, (b) drilling a high-position seam through hole downwards in the rock gangway, (c) starting a high-pressure water-injection pump station, performing hole expanding operation on the coal seam through sections of the drilled holes under the conditions of the water pressure of 10-20MPa, the flow rate of 8m<3> / h and the single-hole coal output greater than 5t, (d) sealing the drilled holes and carrying out drainage strip networking extraction operation after the hole expanding operation is finished, (e) after the extraction is up to the standard, carrying out tunneling operation of an air return way and a transportation roadway, and meanwhile, drilling a bedding pre-extraction hole in the working face and carrying out the hole sealing and networking extraction operations, and (f) continuously extracting the gas of the goaf in the rock gangway during the recovery of the working face. The regional forced gas extraction method is capable of converting a high-gas outburst coal seam into a low-gas outburst risk-free coal seam, comprehensively guaranteeing safe production of the working face, and meanwhile, obviously increasing the coal roadway tunneling speed.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

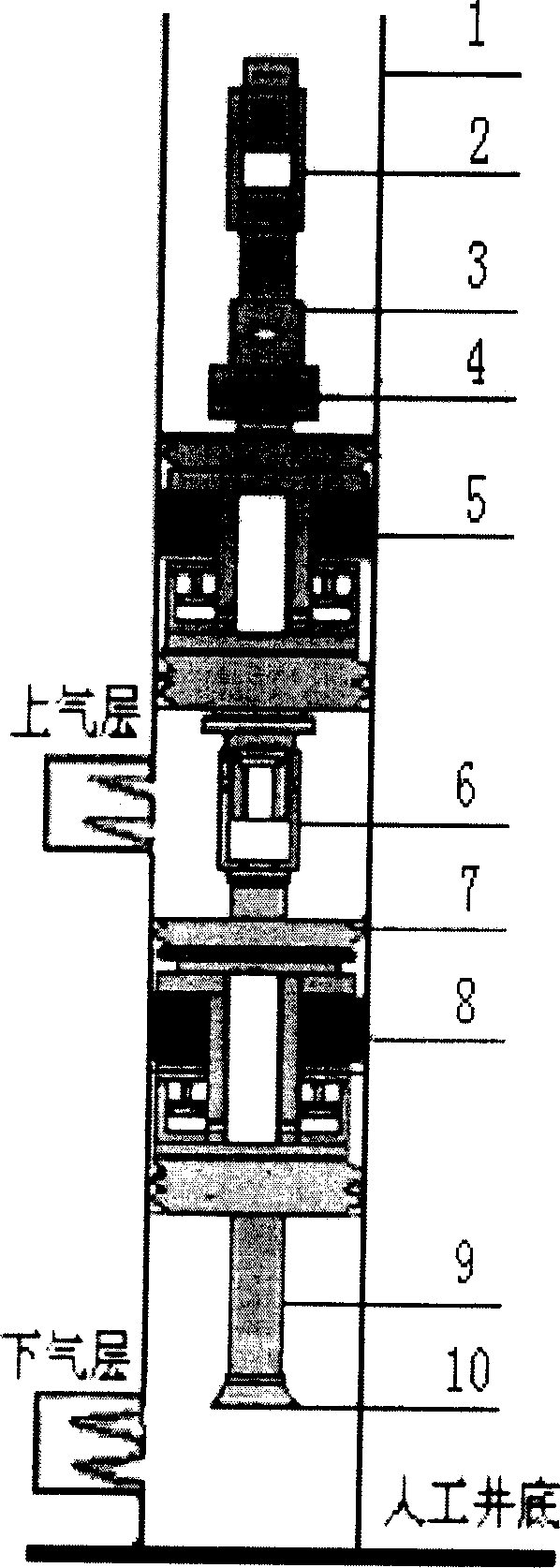

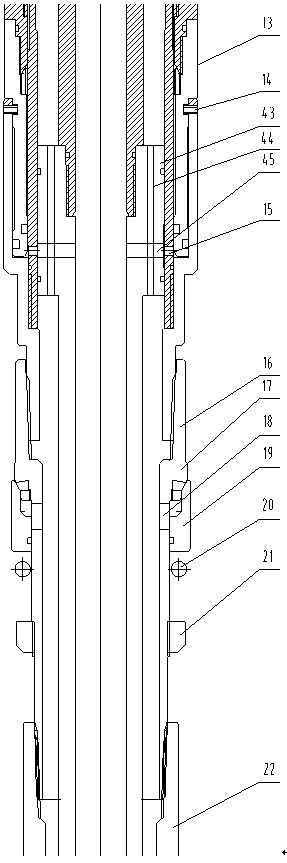

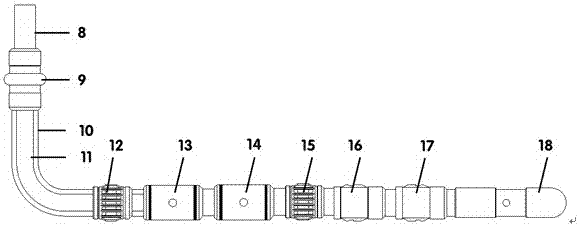

Gas well separate layer fracturing and producing integrated well completing pipe string and technique

InactiveCN1752404AEffective transformationSmall volumeDrilling rodsFluid removalMaterial PerforationPetroleum engineering

The present invention adopts separate layer fracturing layers-combined exploitation integrated well completion pipe string made up by combining oil pipe, pipe string extending compensator, well-flushing switch, safety connector, upper well-washable packer with hydraulic anchor, sandblasting sliding sleeve, lower well-washable packer with hydraulic anchor and ballseat from top to bottom, and adopts hydraulic setting upstrain unplugging working mode, and has repeated setting function so as to implement one-step perforation, two-layer fracturing and combined exploitation technical requirements under the condition of non-moving pipe string.

Owner:西安益友石油科技有限公司

Sand treatment vertisols fertilizer

InactiveCN101239855AImprove water absorptionImprove water retentionBio-organic fraction processingOrganic fertiliser preparationLitterSludge

A sand-controlling modified oil fertilizer is composed of the components with the following weight content: sewage sludge 5-20%, stalk 20-60%, feces 10-40%, bagasse 5-10%, hogwash 5-10%, and water-loss reducer 5-40%; the oil fertilizer is obtained by preparing the lime sludge, stalk, feces, bagasse and hogwash with the above content to prepare compost and finally adding the water-loss reducer. The sand-controlling modified oil fertilizer provided by the invention can effectively treat the household rubbish to facilitate the rubbish become a fertilizer which can control the desert excellently and improve the desert oil quantity, at the same time an approach for effectively settling the garbage is provided and a virtuous circle is formed.

Owner:长沙湘耀高新技术开发有限公司

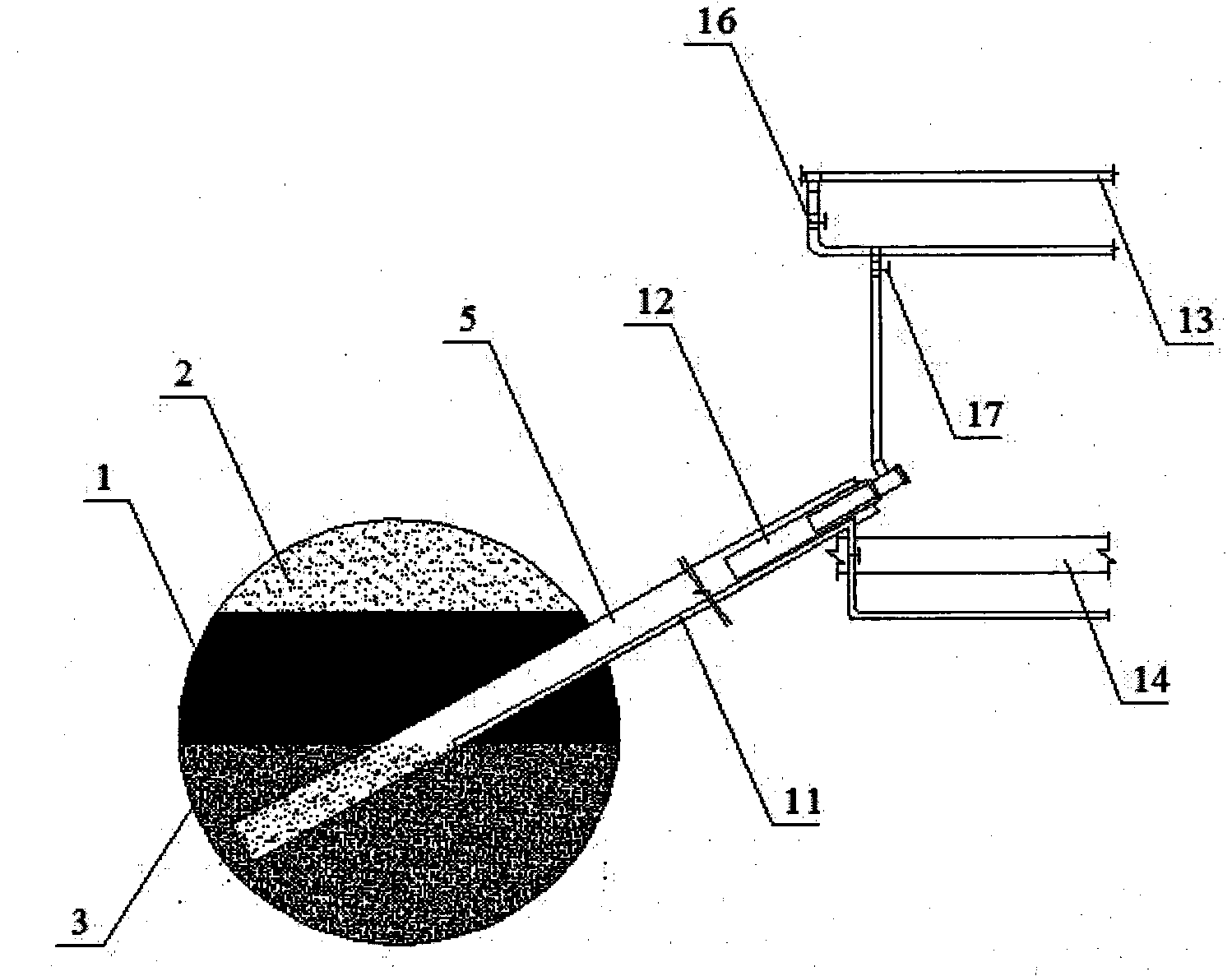

Method and system for desalting soil of coastal saline and alkaline land

ActiveCN102939806AEffective transformationClimate change adaptationCultivating equipmentsAlkali soilSalt Tolerant Plants

The invention provides a method and a system for desalting soil of coastal saline and alkaline land. The method for desalting the soil of the coastal saline and alkaline land includes the following steps of performing soil excavating and blocking up to the coastal saline and alkaline land to be desalted to form a platform field and bottom land; constructing a microalgae cultivating device in the bottom land and planting salt-tolerant plants on the platform field; subjecting the platform field to salt leaching by using underground salt water or natural rainfall to obtain salt-leached drained water with the salt content of 0.3-10 wt.%; and leading the salt-leached drained water in the microalgae cultivating device for microalgae cultivation. By means of the method and the system, the soil of the coastal saline and alkaline land can be effectively desalted, and simultaneously, the salt-leached drained water can be effectively used for cultivating microalgae.

Owner:TSINGHUA UNIV

Method for controlling water-rich fractured rock mass comprehensive grouting under effective sealing batholite shortage condition

ActiveCN104453943AEffective transformationAvoid pulpingUnderground chambersSealing/packingSocial benefitsWater source

The invention discloses a method for controlling water-rich fractured rock mass comprehensive grouting under the effective sealing batholite shortage condition. The method includes the steps of comprehensively detecting a hazard-formation water source and a water guide channel, designing a sealing batholite refitting scheme and a grouting treatment scheme, refitting sealing batholite, controlling the grouting process and the safety, conducting draining, pressure relieving, drilling and blocking, comprehensively detecting the grouting effect, compensating a weak zone for slip casting and the like. After construction is conducted through the method, by refitting the sealing batholite, the problems that due to the shortage of the effective sealing batholite, sap loss and grout leakage occur in the grouting process and the grouting effect is not good are solved, the grouting efficiency is improved, and good social benefits and economic benefits are created.

Owner:SHANDONG UNIV OF SCI & TECH

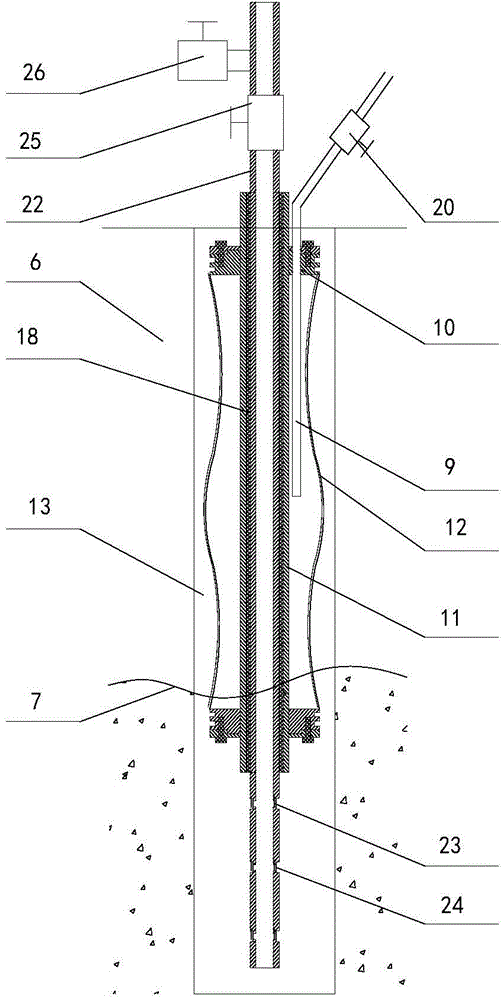

Hydraulic sand jet perforation, fracture and sand filling integrated technological method

ActiveCN104213895AAvoid damageImprove the transformation effectFluid removalFlushingSand blastingEngineering

The invention discloses a hydraulic sand jet perforation, fracture and sand filling integrated technological method which is designed for meeting the requirement for hydraulic sand jet perforation and fracture integrated work and ensuring the construction capacity of a pipe column under the large discharge capacity condition. The method of fracturing the lower layer through hydraulic jet, filling the lower layer with sand, sealing the lower layer and then conducting upper layer section hydraulic jet fracture construction is adopted, and therefore it is ensured that the lower layer is effectively refitted, a pipe column packer is prevented from being damaged, dragging and fracture of multiple sections of a horizontal well of an oil field can be executed, large-discharge-volume fracture refitting, with the high anisotropism, the large physical difference and the dense oil deposit, between reservoirs can be achieved, the refitting effect of the horizontal well with the dense oil deposit is improved, and the aim of increasing the yield is achieved. By means of a hydraulic safe connector on the technological pipe column, the pipe column above the connector can be conveniently jacked up when the pipe column is stuck.

Owner:PETROCHINA CO LTD

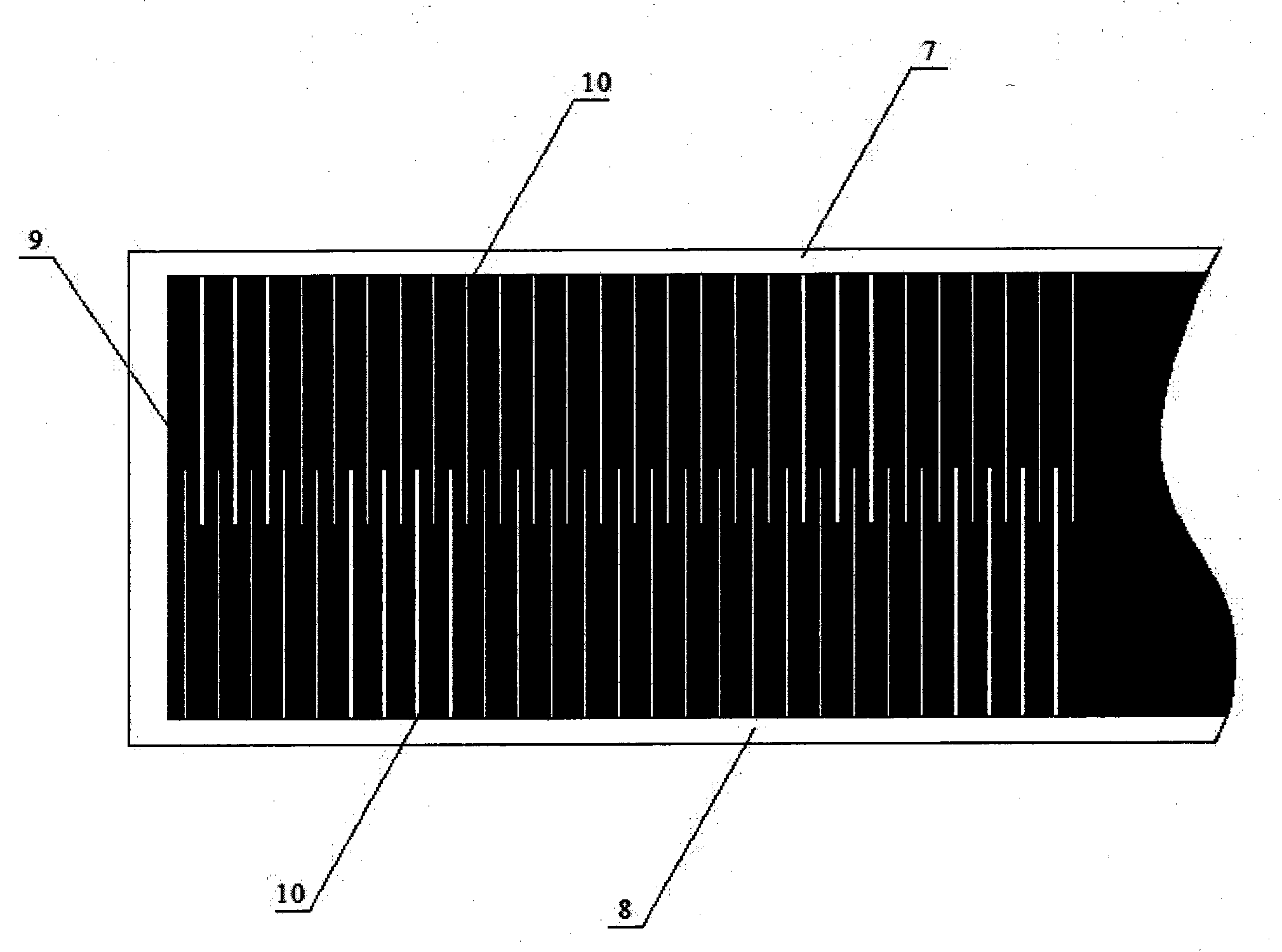

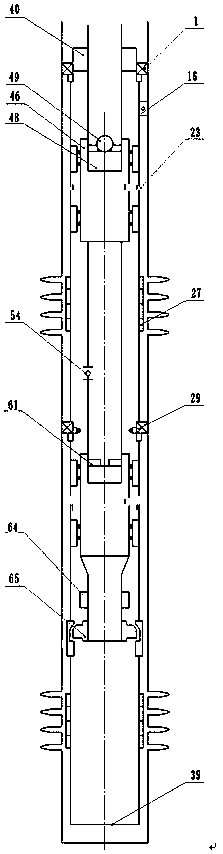

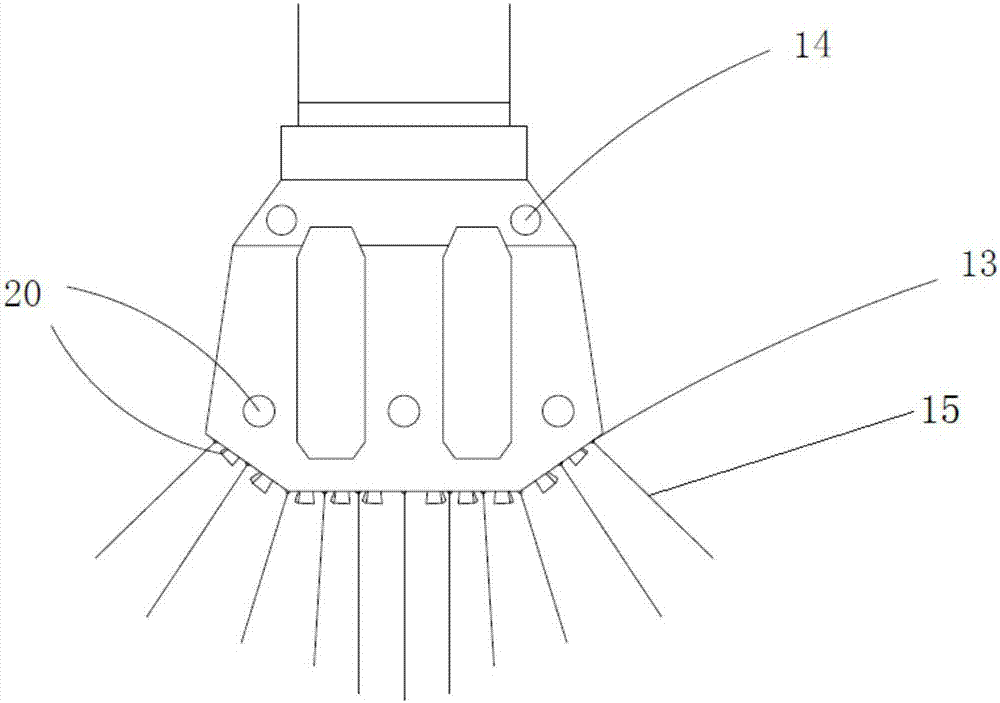

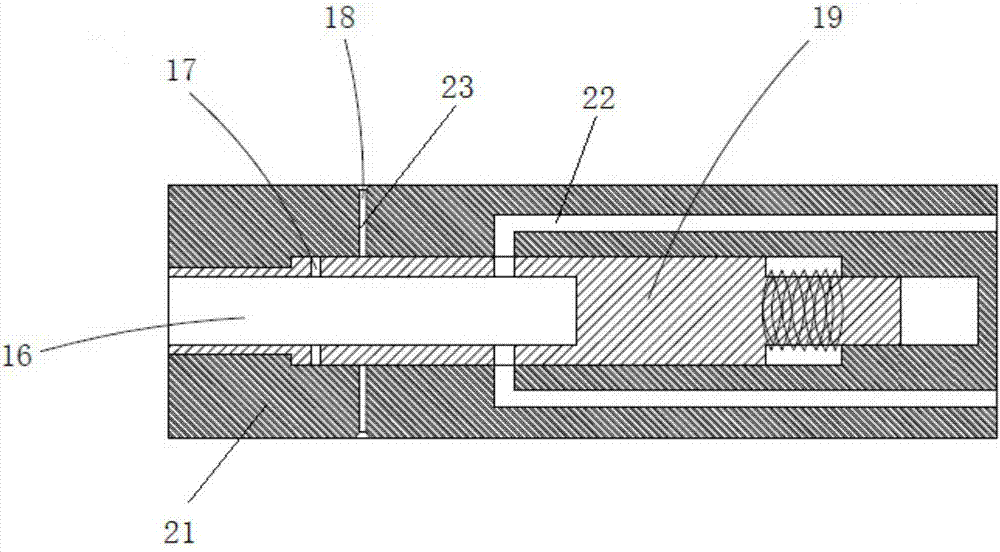

Ball-throwing type layered sand control process pipe column and method thereof

ActiveCN108625830AEfficient use ofEffective transformationGeothermal energy generationFluid removalProduction effectEngineering

The invention discloses a ball-throwing type layered sand control process pipe column and a method thereof. The pipe column comprises a sand control outer pipe and a sand control inner pipe placed inside the sand control outer pipe, wherein the sand control outer pipe comprises a top suspension setting mechanism, a reverse well-flushing device, external filling devices, screen tubes and a pipe plug from top to bottom, and the top suspension setting mechanism, the reverse well-flushing device, the external filling devices, the screen tubes and the pipe plug are connected in sequence. The sand control inner tube includes a releasing mechanism, inner filling devices, a switch mechanism and a bottom positioning device from top to bottom, wherein the releasing mechanism, the inner filling devices, the switch mechanism and the bottom positioning device are connected in sequence. The number of the inner filling devices is consistent with that of the external filling devices in each oil reservoir, and the inner filling devices and the external filling devices correspond to each other in the radial direction. Internal well-flushing valves are installed between every two inner filling devices. The ball-throwing type layered sand control process pipe column and the method thereof can realize completion of layered sand control construction of a multiple zone by one-trip pipe column, ensureindependence between layers, and give full play to the productivity of each small layer to achieve the best sand control production effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

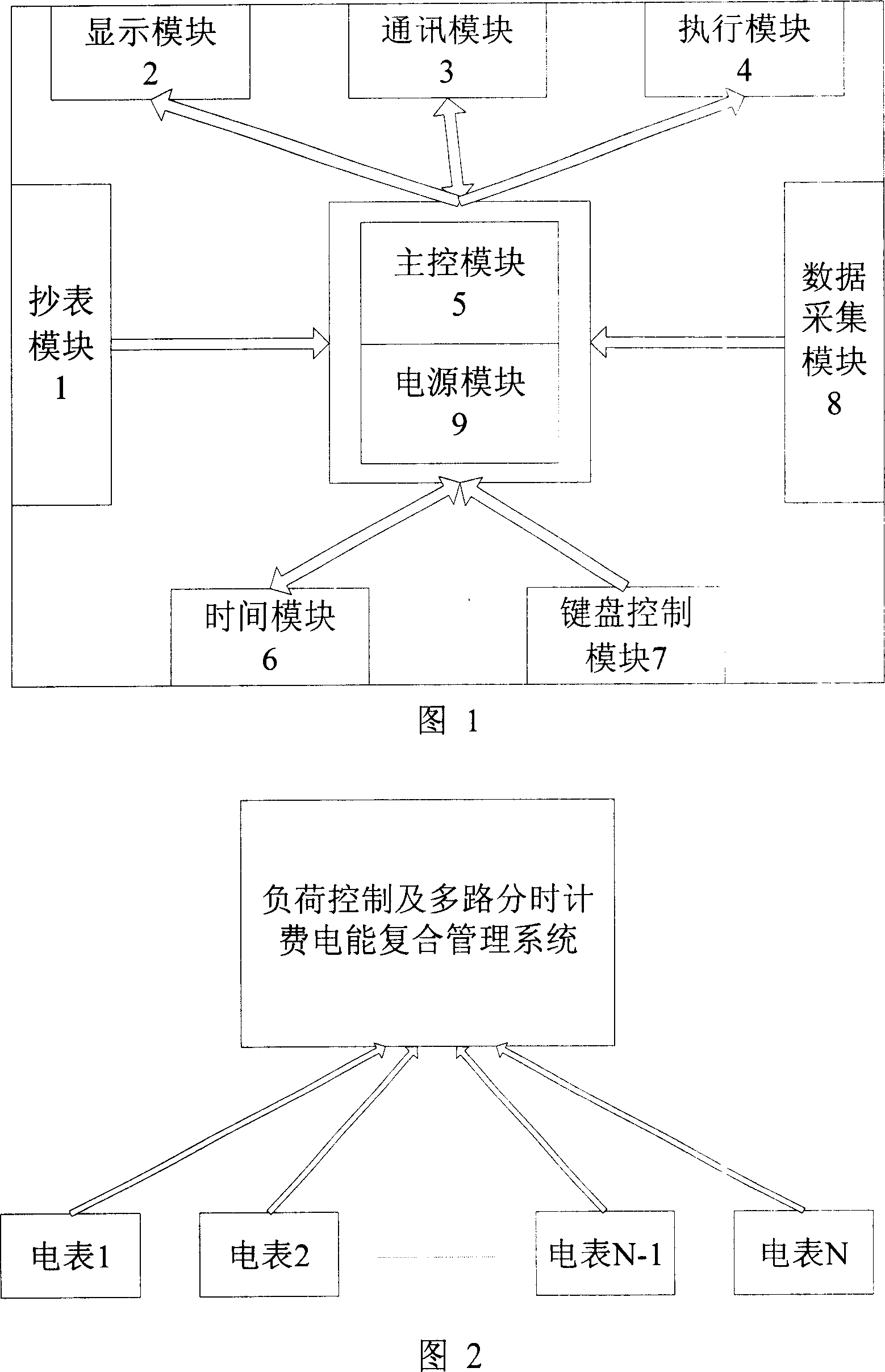

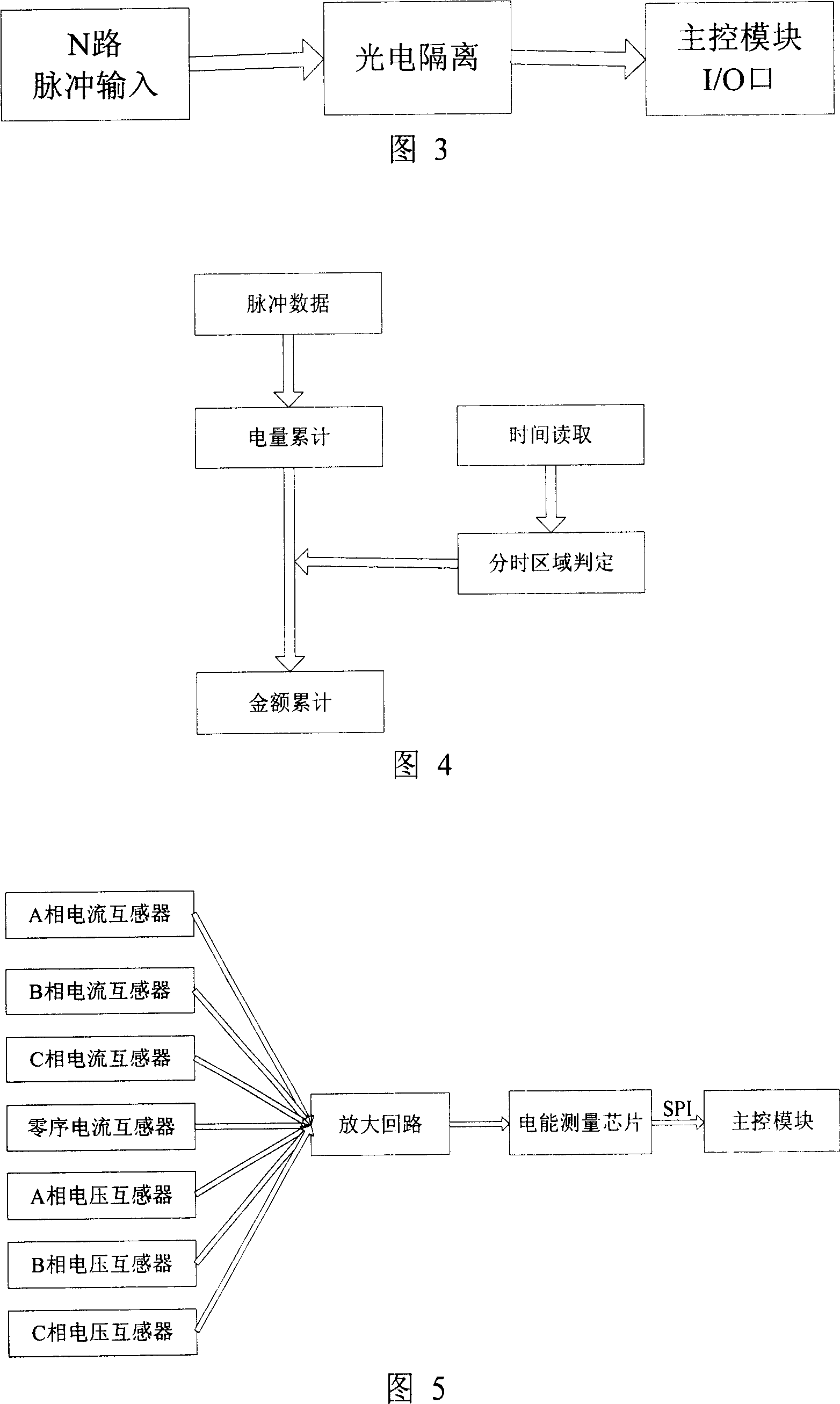

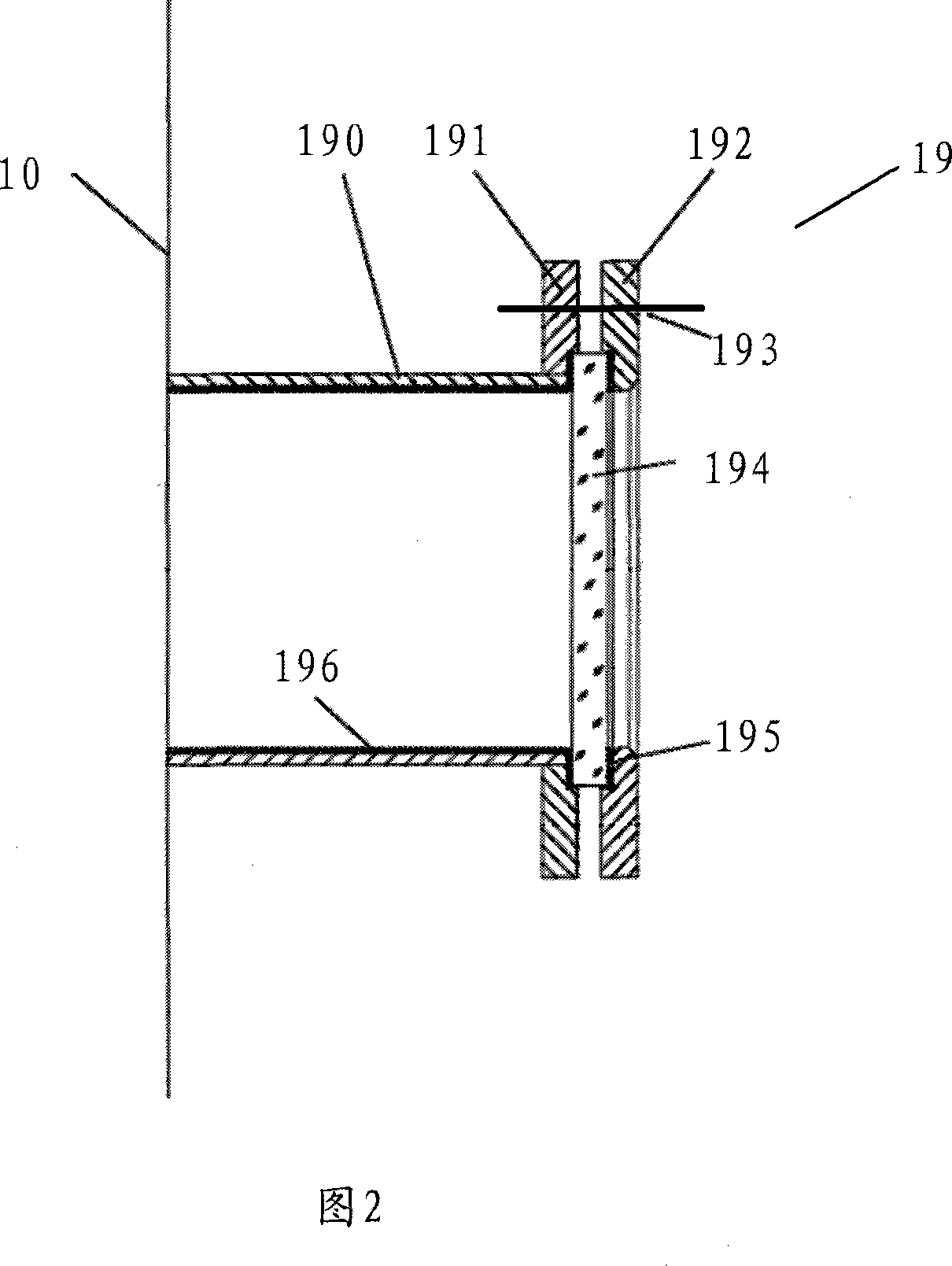

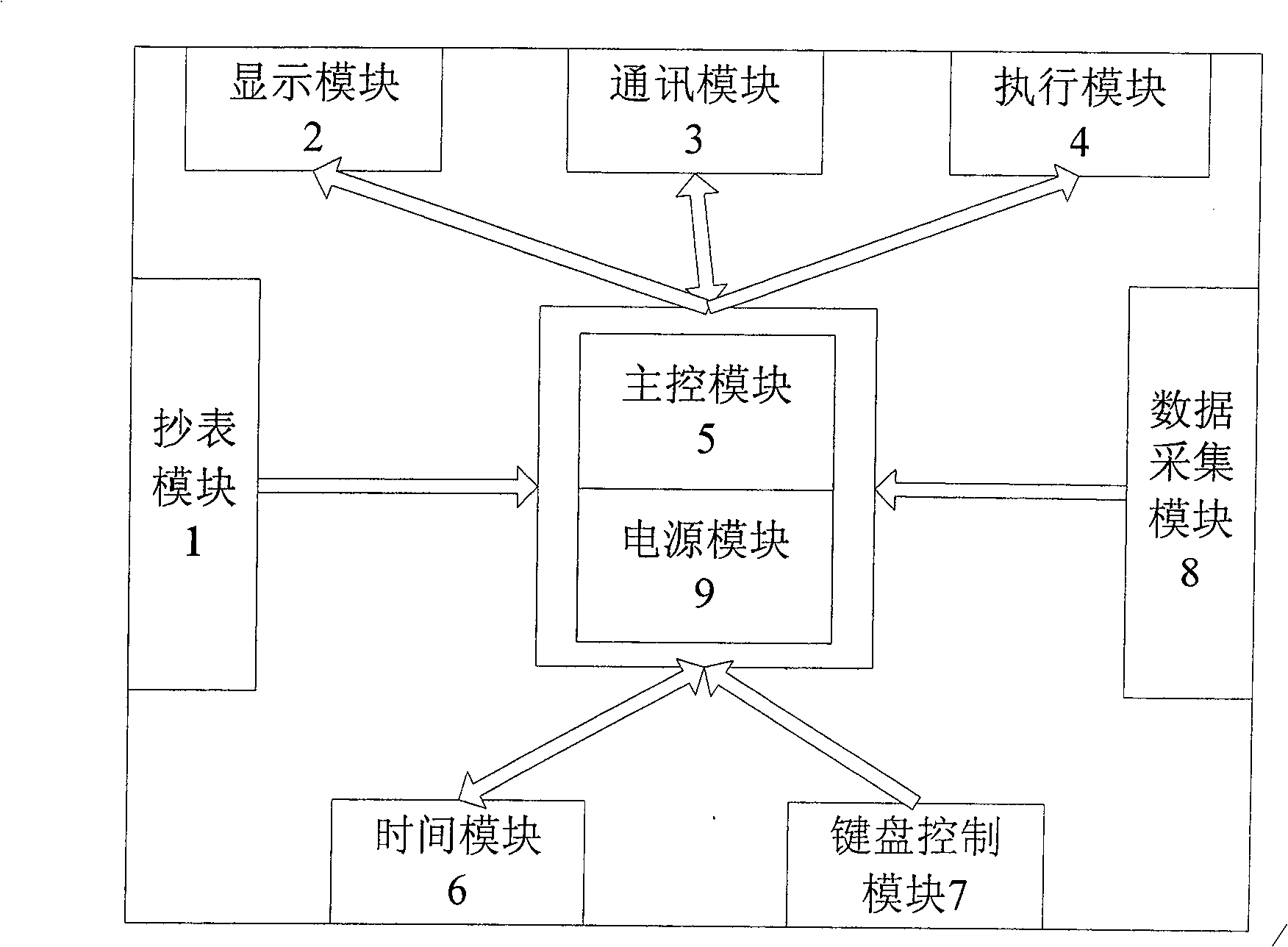

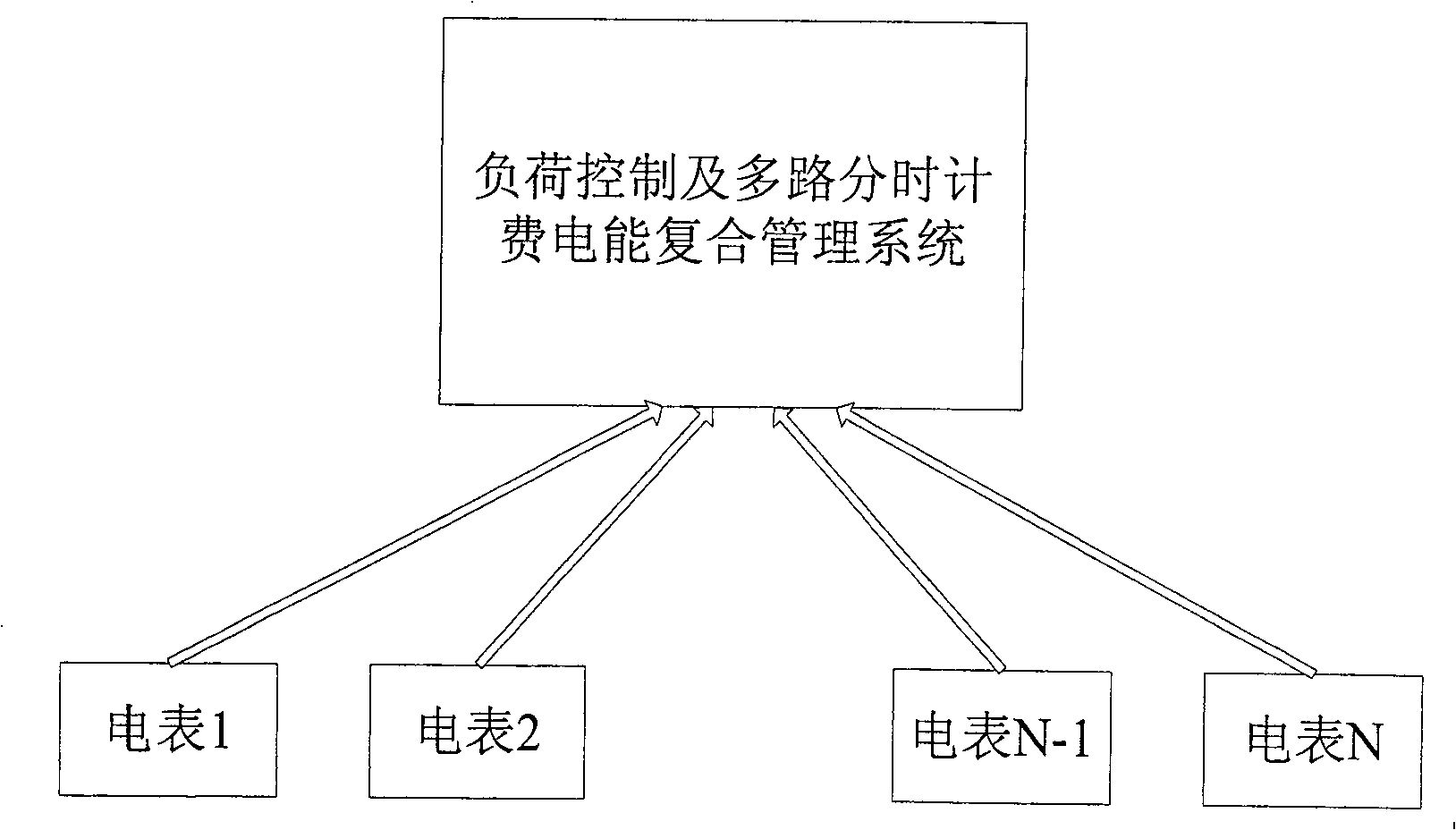

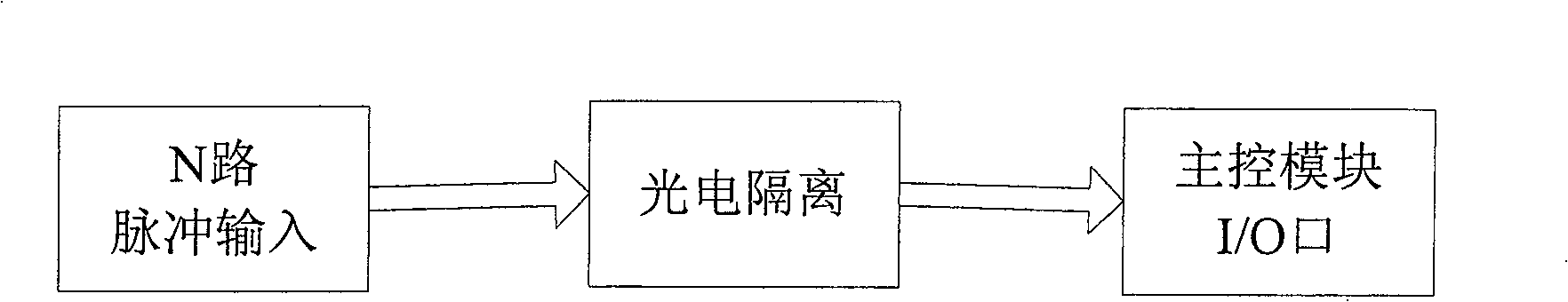

Loading control and multi-channel time-shared charge electric energy combined management system and its implementing method

InactiveCN101000710AEffective transformationLow costElectric signal transmission systemsEngineeringData acquisition module

An electric energy management system with load control and multi-path time-division charging function is prepared as connecting data collection module, time module, meter-copying module, execution module, display module, communication module and keyboard control module to master control module and power supply module; and connecting said meter-copying module to each electric meter in electric network. Its managing method is also disclosed.

Owner:GUANGZHOU ZHIGUANG ELECTRIC CO LTD

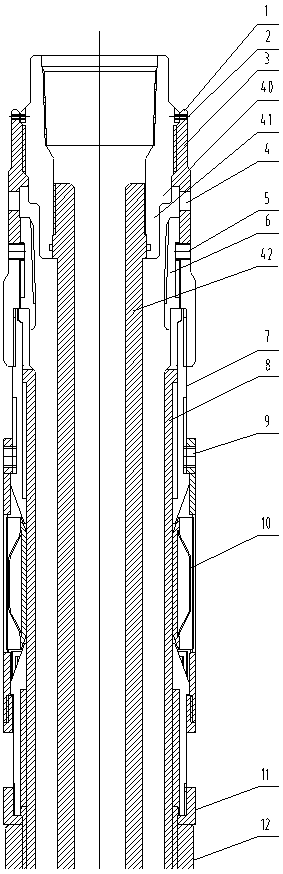

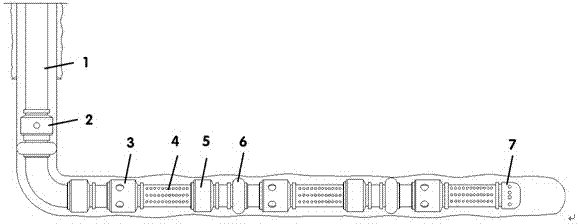

Horizontal well one-time multi-section open-hole gravel pack sand-proof well completion pipe string and method

The invention discloses a horizontal well one-time multi-section open-hole gravel pack sand-proof well completion pipe string and a method. The horizontal well one-time multi-section open-hole gravel pack sand-proof well completion pipe string comprises a well completion pipe string body and a pack sand-proof service pipe string body, wherein the pack sand-proof service pipe string body is arranged in the well completion pipe string body; the pack sand-proof service pipe string body comprises a drilling-free plug stage collar, a packing sliding sleeve assembly and sand filtering tubes, and the drilling-free plug stage collar, the packing sliding sleeve assembly and the sand filtering tubes are sequentially connected from front to back; the pack sand-proof service pipe string body comprises a liquid separation sealing device, a double-layer pipe, an upper positioning device, a packing assembly, a circulation assembly, a lower positioning device, a closing tool and an opening tool which are sequentially connected from the front to the back. At least two sand filtering tubes are arranged, and a heat-sensitive compensator and an open-hole packer are connected between every two sand filtering tubes. The tail end of the well completion pipe string is connected with a well washing valve. One-time multi-section packing can be achieved, infinite series packing can be achieved, segmented packing is achieved outside a pipe in a real sense for the first time, and the packing effect is improved. Horizontal section segmentation is completed, and requirements of post-selective production, segmented steam injection and other measures can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fracturing method for realizing effective partial pressure of dense heterogeneous reservoir stratum

ActiveCN107420081ASolve underutilized issuesOvercoming Inability to Retrofit AdequatelyFluid removalFiberFracturing fluid

A fracturing method for realizing the effective partial pressure of a dense heterogeneous reservoir stratum includes the steps of cutting to an artificial well bottom through a gauge cutter, conducting a pressure test on a shaft after well flushing till the test is qualified, selecting the point with the best physical property of the stratum as a perforation section or spot, conducting heat power perforation or heat power sandblast perforation, putting in a fracture drill tool to conduct first-grade fracturing construction, implementing general fracturing through fracturing liquid, replacing with sand-carrying fluid to enter the stratum, closing a well till a fracturing seam is closed, adding degradable fiber and a water-soluble temporarily plugging agent for blocking a fractured layer section, starting second-grade fracturing construction, repeatedly executing the steps of adding the degradable fiber and the water-soluble temporarily plugging agent and conducting fracturing construction according to the perforation hole number till all perforation sections are sufficiently refitted, and finally conducting well closing, well opening for gushing, production volume finding and well completing. Through the combination of multi-section fixed point perforation and the fiber and the water-soluble temporarily plugging agent, the opened fracturing seam is selectively blocked, an unused stratus is forced to be fractured and a new seam is created, and the aim of effective fracturing and sufficient refitting of all oil reservoirs can be achieved.

Owner:PETROCHINA CO LTD

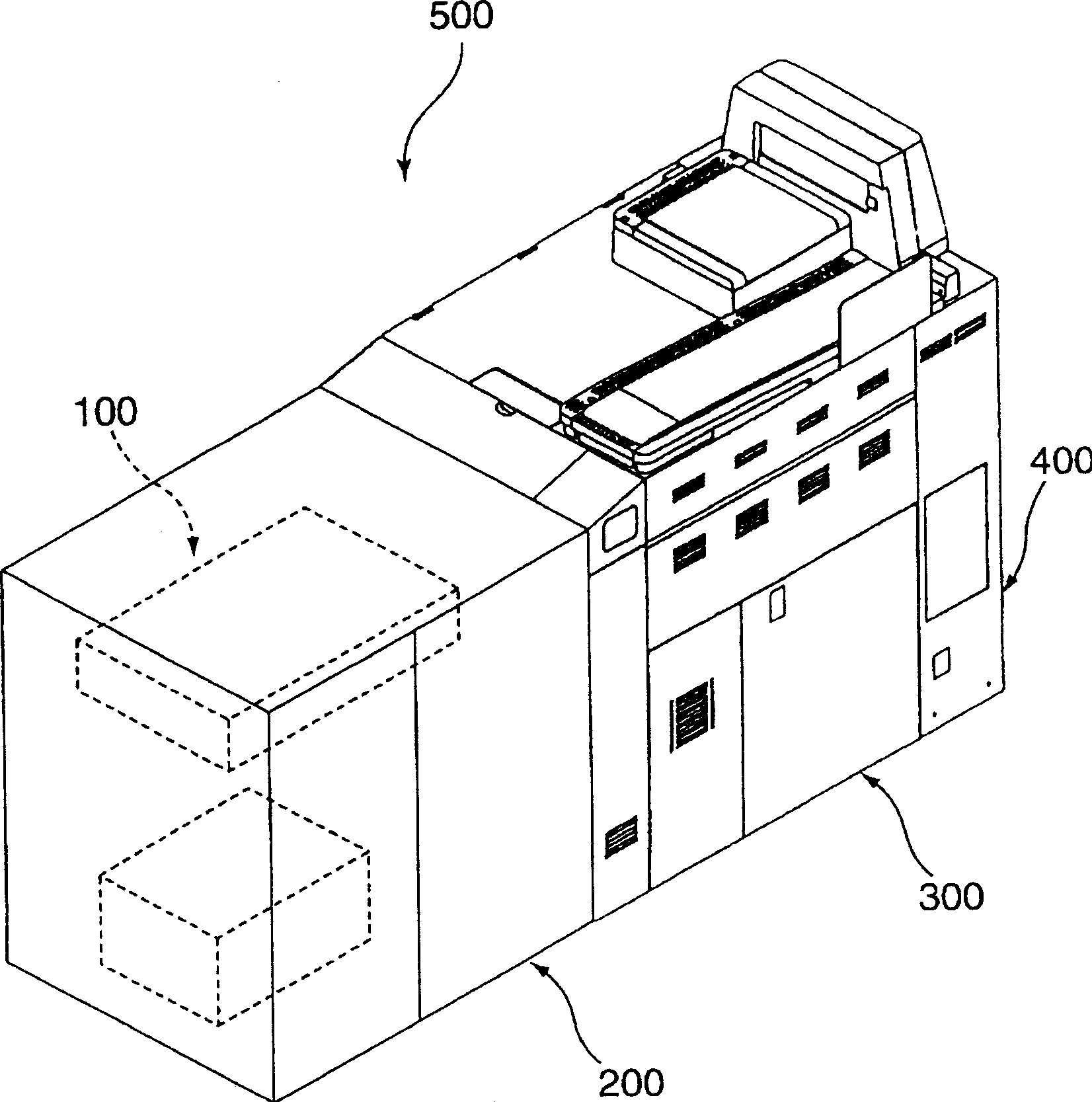

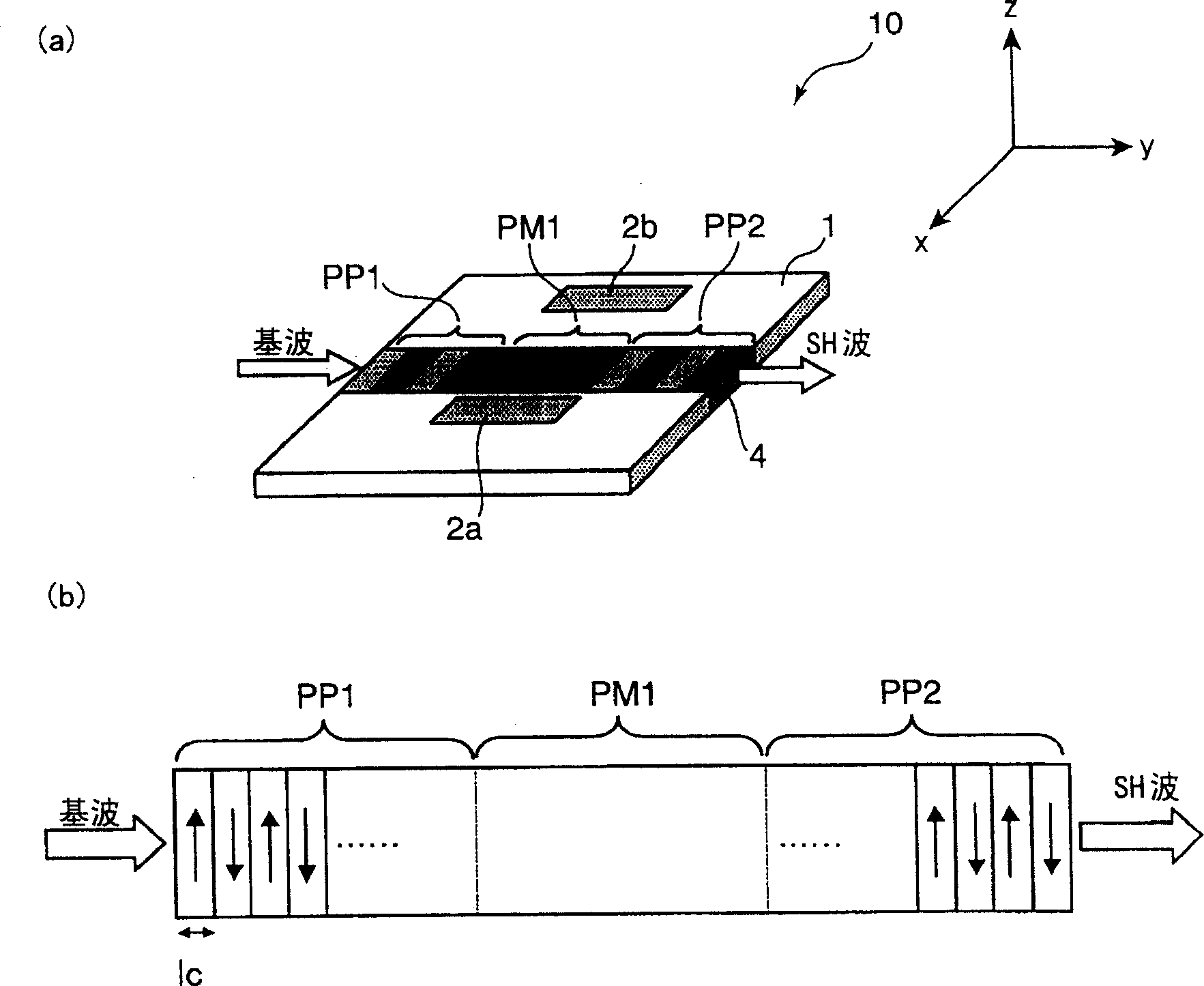

Light intensity modulation element, intensity-modulated-light generating device, laser exposure unit and photograph processing apparatus

InactiveCN1721984AReduced strengthEffective transformationPhotographic printingLight controlNonlinear optical crystalHarmonic

The invention aims at providing a miniature light strength modulation element with high efficiency which can implement the strength modulation of lights that are transformed into second higher harmonics. An optical guided wave road in certain direction is formed on the main surface of a substrate which is made form nonlinear optical crystal. In the optical guided wave road, a polarized structure in the thickness direction of the substrate is formed in the optical guided wave road direction in a way that the polarities periodically and interactively reverse. Thus, in the optical guided wave road, a first and a second wavelength transforming parts which respectively transform part of emitted infrared lights into the second higher harmonics are formed. In addition, a first phase adjustment part which is equipped with a pair of relatively configured electrodes for clamping the optical guided wave road is formed between the first and the second wavelength transforming part.

Owner:NORITZ CORP

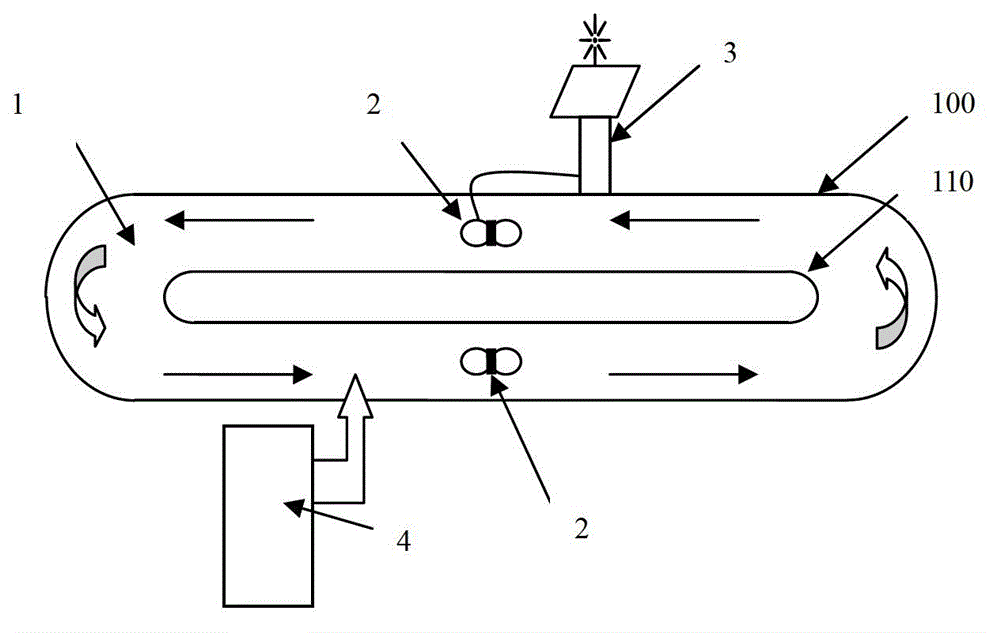

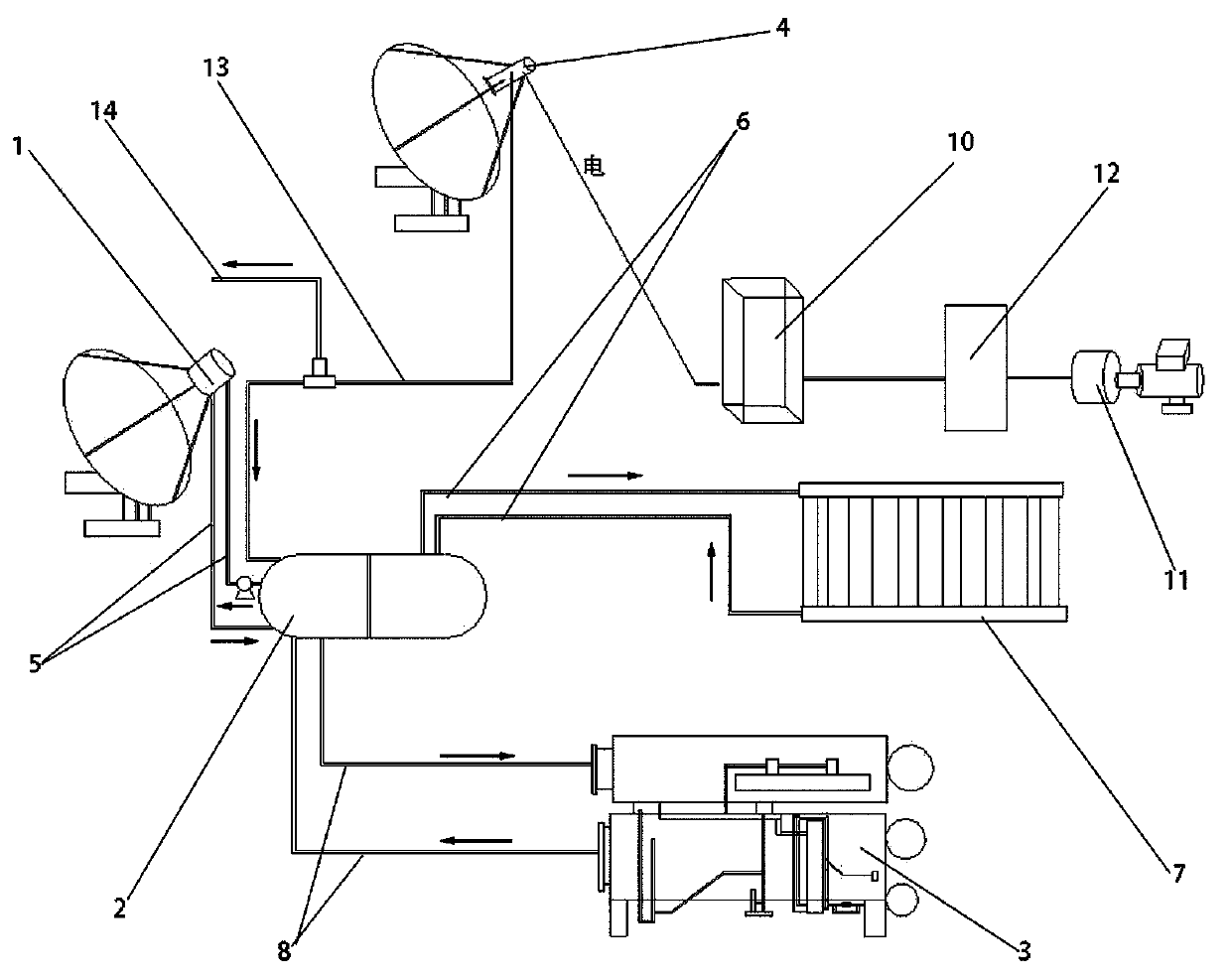

Disc type solar heating, refrigeration and power generation combined system

ActiveCN107905966ARealize power generationRealize heatingSolar heating energySolar heat collector detailsGeneration processHeat transmission

The invention belongs to the technical field of solar energy utilization, and particularly relates to a disc type solar heating, refrigeration and power generation combined system. The disc type solarheating, refrigeration and power generation combined system comprises a solar thermal collector, a water tank, an absorption refrigerator and a Stirling generator, wherein the solar thermal collectoris connected with the water tank through an oil pipe; a fluid in the oil pipe is heated through the solar thermal collector; the oil pipe heats water in the water tank through heat exchange; the water tank communicates with a radiator through a heat transmission pipe, and a cycle is formed; the absorption refrigerator communicates with the water tank through a heating medium pipe, and a cycle isformed; the Stirling generator communicates with the water tank; and hot water generated during the power generation process of the Stirling generator can flow into the water tank. According to the disc type solar heating, refrigeration and power generation combined system, integration of solar heating, refrigeration and power generation can be achieved.

Owner:山西三晋之窗新能源科技有限公司

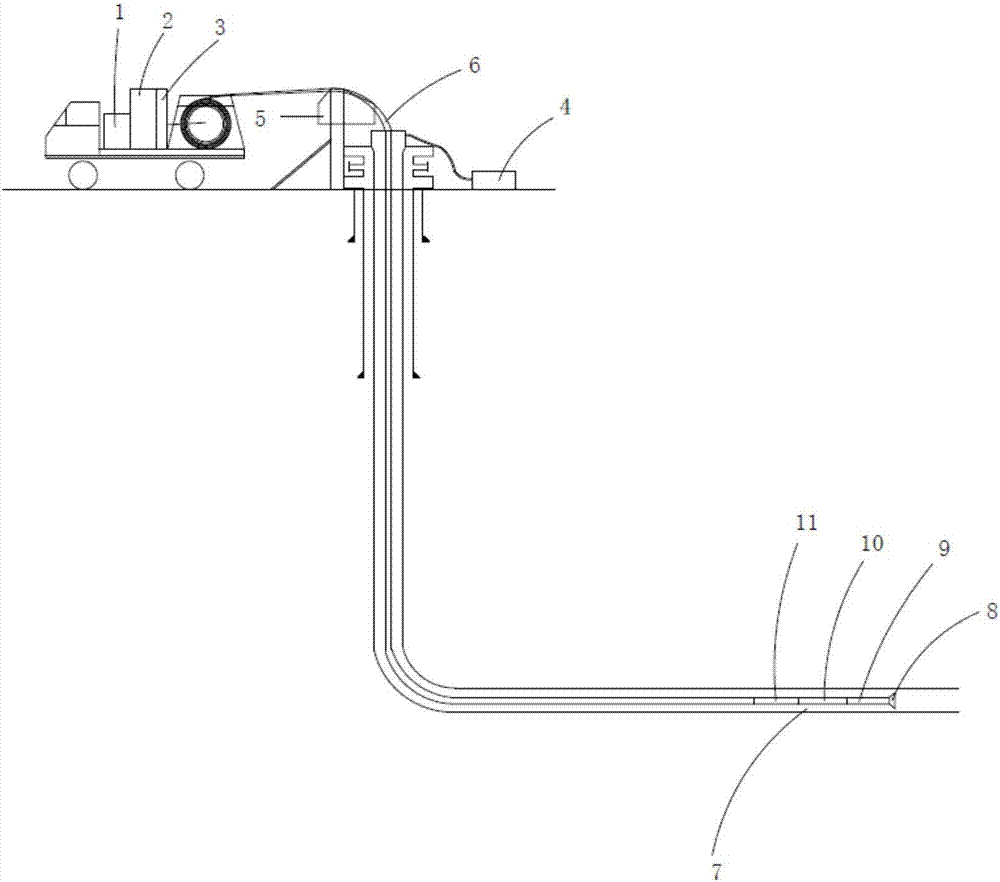

Oil-gas drilling production increasing combined operation device and method

ActiveCN107288540AImprove work efficiencyFast and efficient drillingDrill bitsLiquid/gas jet drillingEnvironment effectJet flow

The invention discloses an oil-gas drilling production increasing combined operation device and method. The device comprises a high-pressure pump, high-pressure coiled tubing and a downhole drilling tool combination, wherein the downhole drilling tool combination comprises a drill bit and a downhole cutting nipple; the drill bit is connected with the high-pressure coiled tubing, and a rock breaking nozzle and a thrust nozzle are formed in the front end and the rear end of the drill bit correspondingly; the downhole cutting nipple comprises a shell and a valve body; the valve body is provided with an axial hydraulic channel and a radial hydraulic channel; a jet flow channel is formed in the shell and provided with a radial jet flow nozzle; a drilling water channel is further formed in the shell; and the axial hydraulic channel communicates with the rock breaking nozzle of the drill bit. When the valve body moves in the shell to enable the axial hydraulic channel to communicate with the drilling water channel, the radial hydraulic channel does not communicate with the jet flow channel; and when the radial hydraulic channel communicates with the jet flow channel, the axial hydraulic channel do not communicate with the drilling water channel. Compared with an existing oil-gas exploitation technology, the oil-gas drilling production increasing combined operation device and the method have the advantages that (1) operation efficiency is high; (2) the production increasing effect is good; (3) reservoir adaptability is wide; and (4) the environmental influence is less.

Owner:CHINA PETROLEUM & CHEM CORP +1

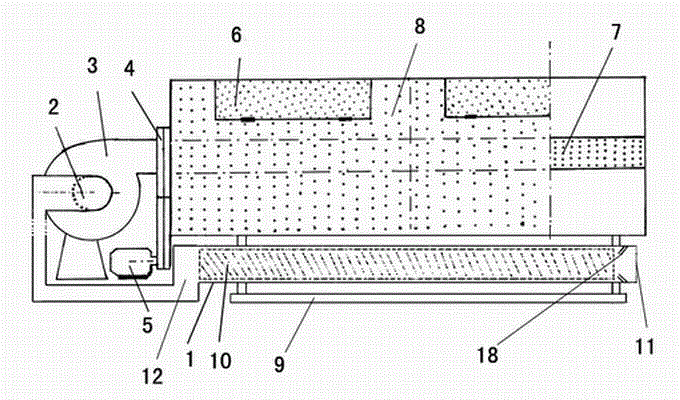

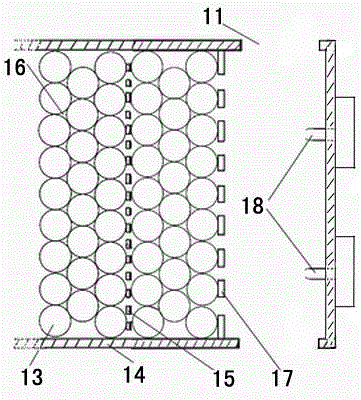

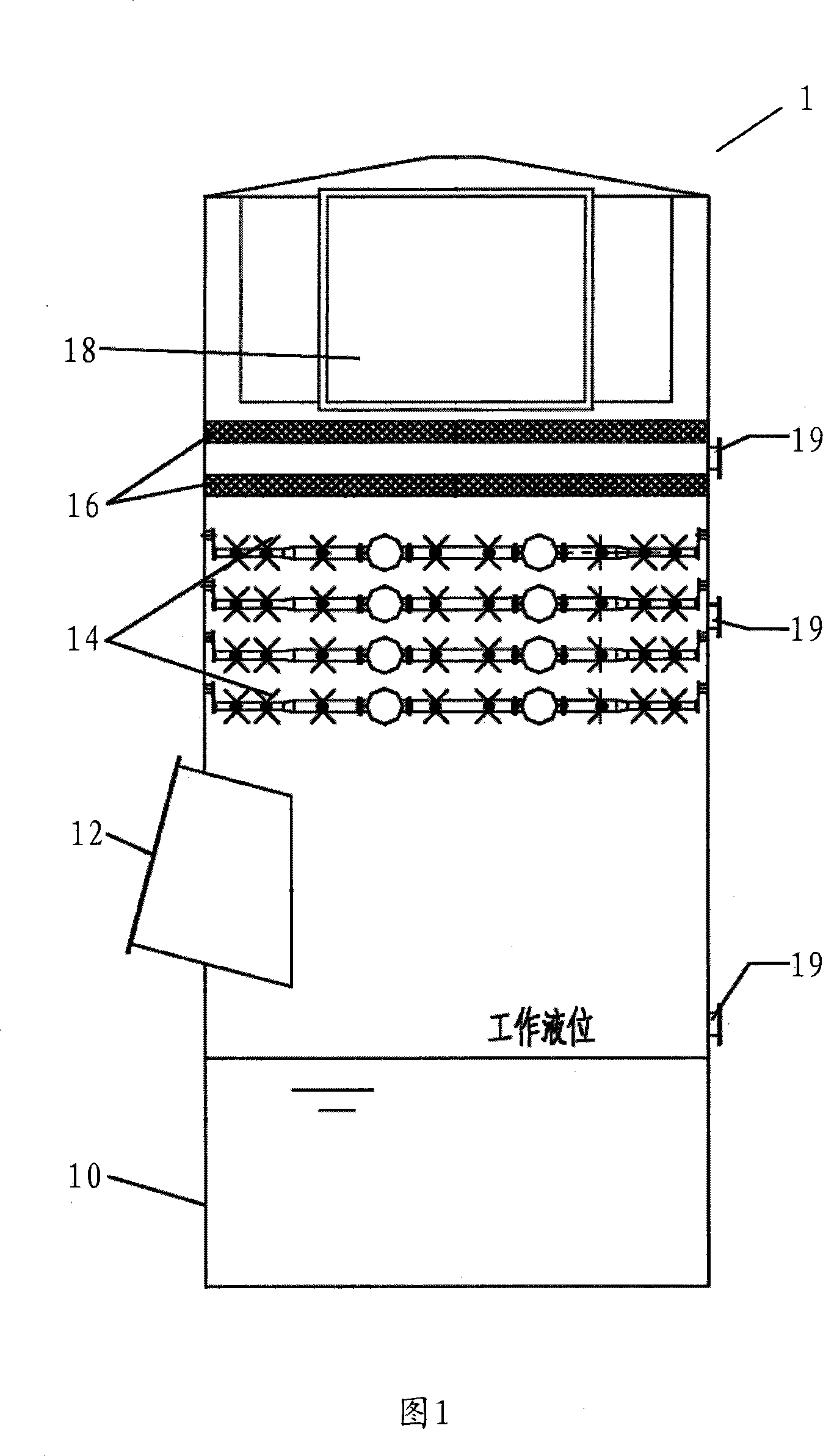

Integrated machine using clean energy and used for tea withering, fixing and green-making

InactiveCN103330009AWith explosive heat output functionNot easy to burnPre-extraction tea treatmentStorage heatersFirewoodProcess engineering

The invention discloses an integrated machine using clean energy and used for tea withering, fixing and green-making. The integrated machine comprises a drum-type green-making machine, and a heat storage device (1) used for providing heat for the drum-type green-making machine. The integrated machine is characterized in that the heat storage device (1) is a heat storage device having a function of explosive-type heat outputting. According to the technical scheme, a problem of an oversize electrical heating power peak value of the drum-type green-making machine is solved, the heating power peak value can be reduced by 50% to 85%. The technical scheme is the only practical technological method to change carbon burning into electrical heating for comprehensive green-making machines. The technical scheme has advantages of reduced investments and saved consumption over a method of directly changing into electrical heating for the comprehensive green-making machines. In addition, according to the technical scheme, the original comprehensive green-making machines can have functions of a fixing machine at the same time, and therefore a firewood problem of present fixing machines can be solved, no fixing device is needed to be separately configured, and equipment investments can be saved.

Owner:武夷山岩中韵茶业有限责任公司

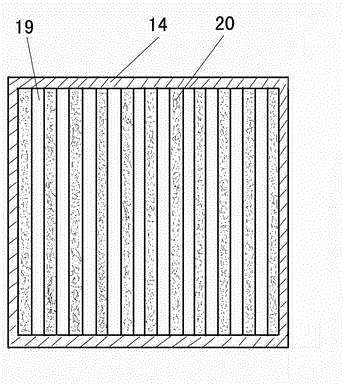

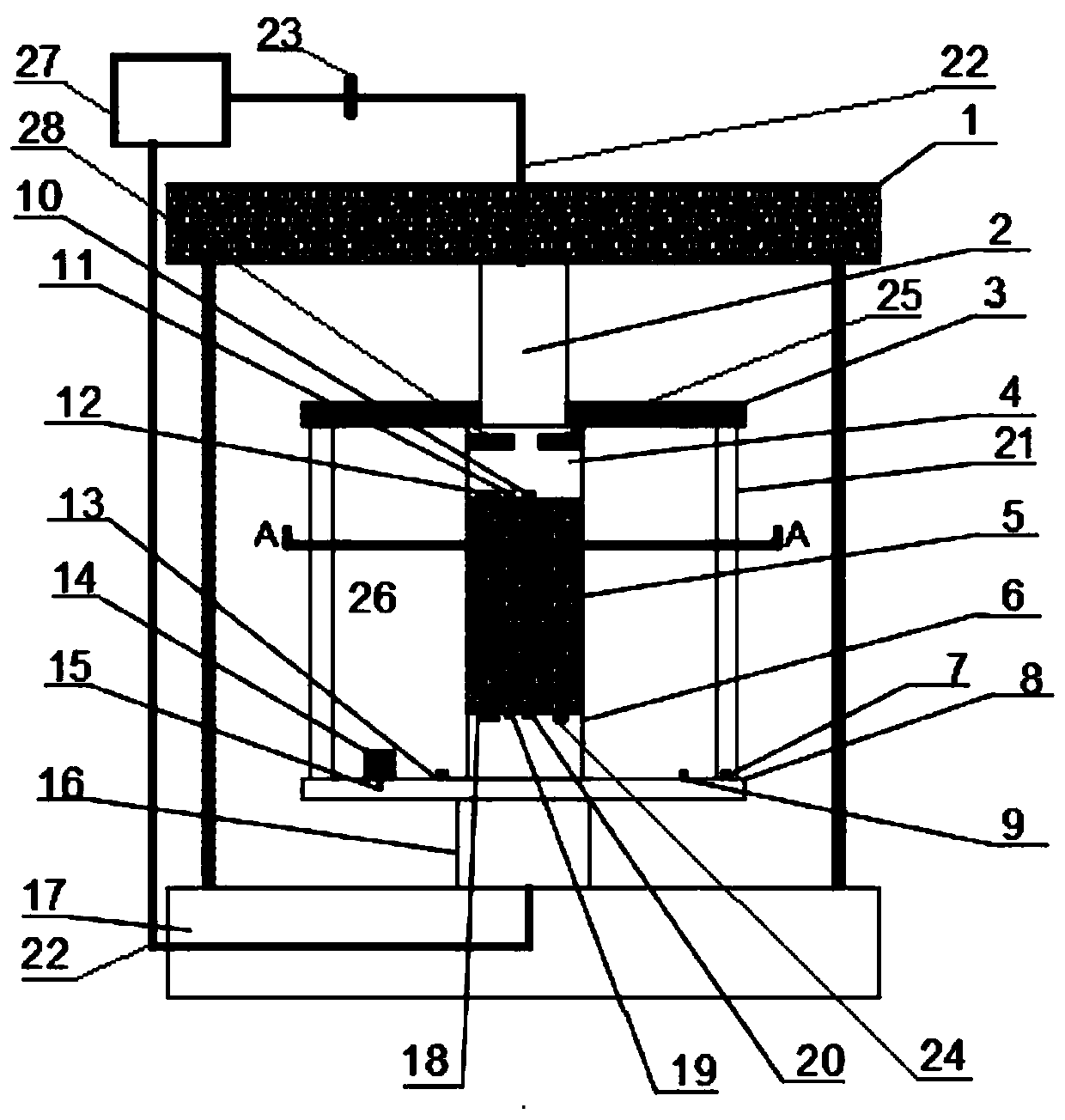

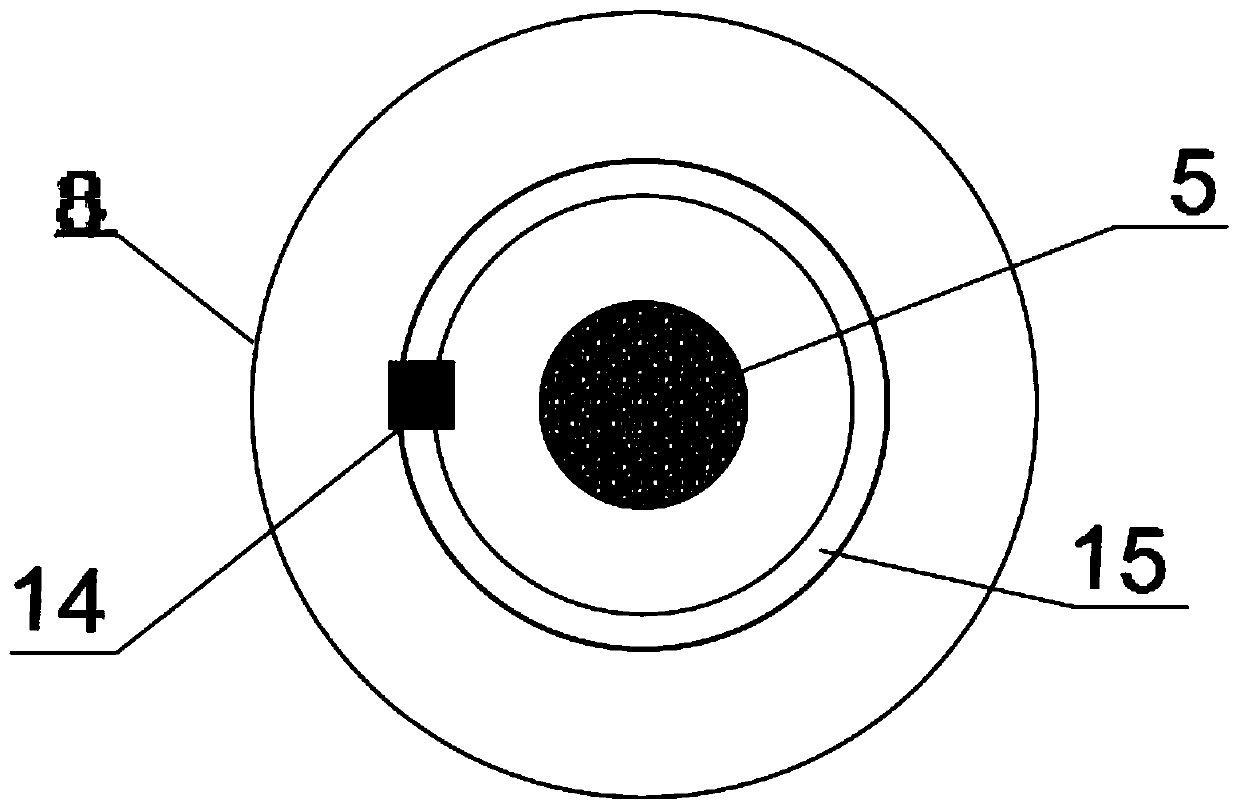

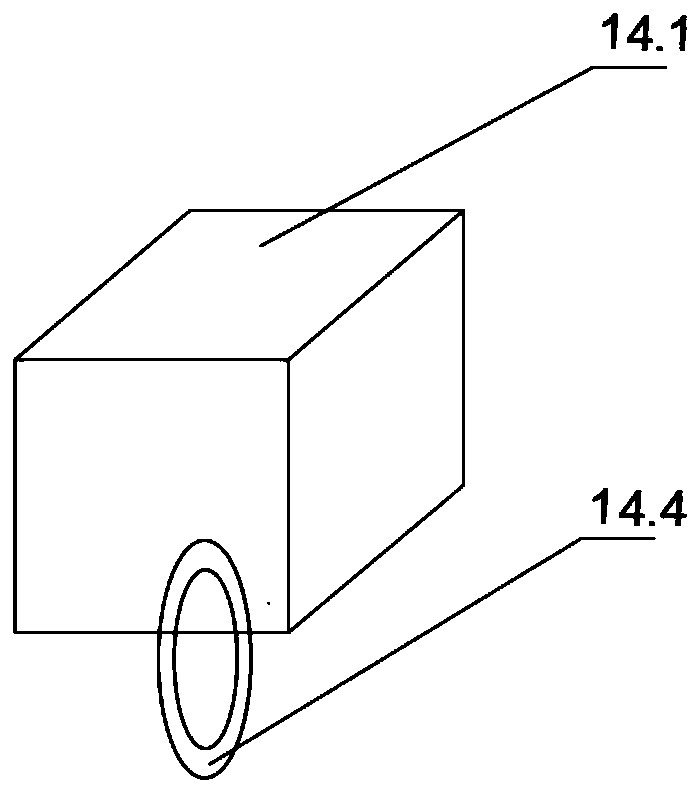

Dynamic tri-axial experiment device with ultrasonic scanning function for hydrate deposit of natural gas and method

PendingCN109752257ARapid positioningReal and effective simulationMaterial strength using tensile/compressive forcesWater resource assessmentAxial pressureHydraulic pump

The invention discloses a dynamic tri-axial experiment device with an ultrasonic scanning function for hydrate deposit of natural gas and a method. The device comprises a dynamic tri-axial pressure chamber, wherein the dynamic tri-axial pressure chamber comprises an upper end cover, a cylinder and a lower end cover, the cylinder is internally provided with a sample table for loading a sample, an upper press head and a lower press head are respectively arranged above and below the sample table, the upper press head is connected with a hydraulic pump station, the sample is dynamically loaded byusing the upper press head, the upper press head and the lower press head are respectively provided with a sound wave receiving device and a sound wave emitting device that are used for longitudinal and transverse wave tests on the sample, the lower press head is further provided with an electrode that is used for specific resistance tests on the sample, the lower end cover is provided with an ultrasonic wave scanning device and an annular rail, the ultrasonic wave scanning device moves around the sample table along the annular rail, so as to perform ultrasonic wave scanning on the sample. Thedynamic tri-axial experiment device has a simple structure, is convenient to operate, has high reliability, has an ultrasonic scanning function, and can rapidly record and position a crack of the sample and damage morphology of the sample in mechanical tests.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

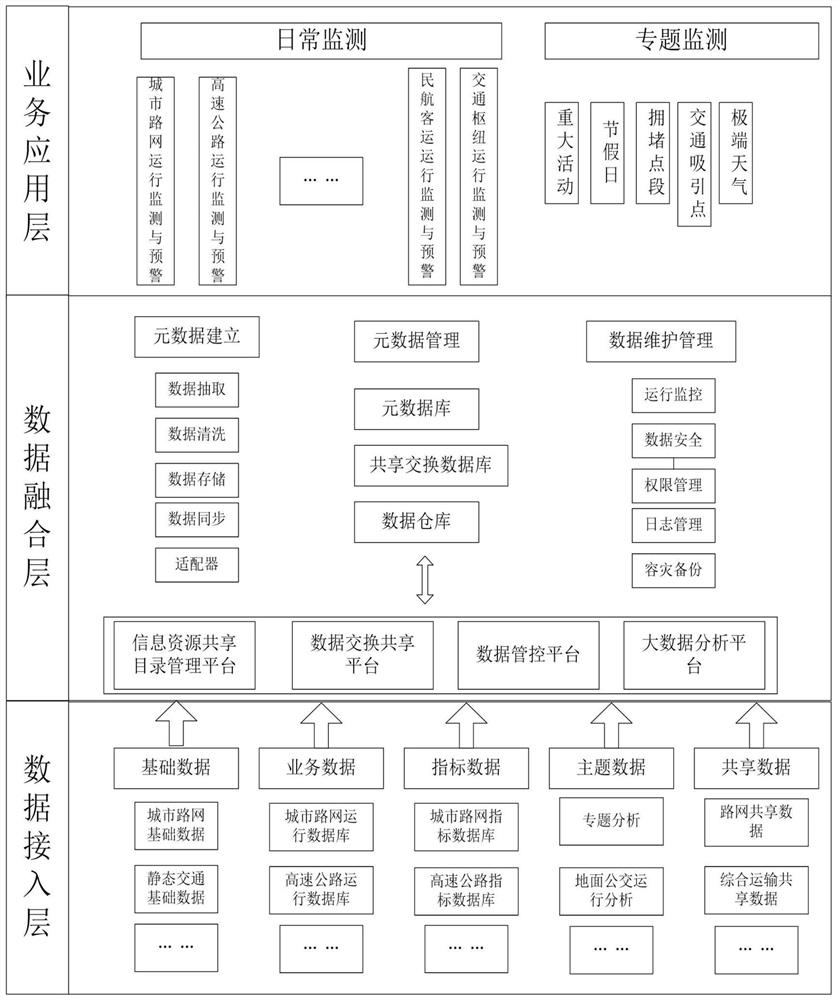

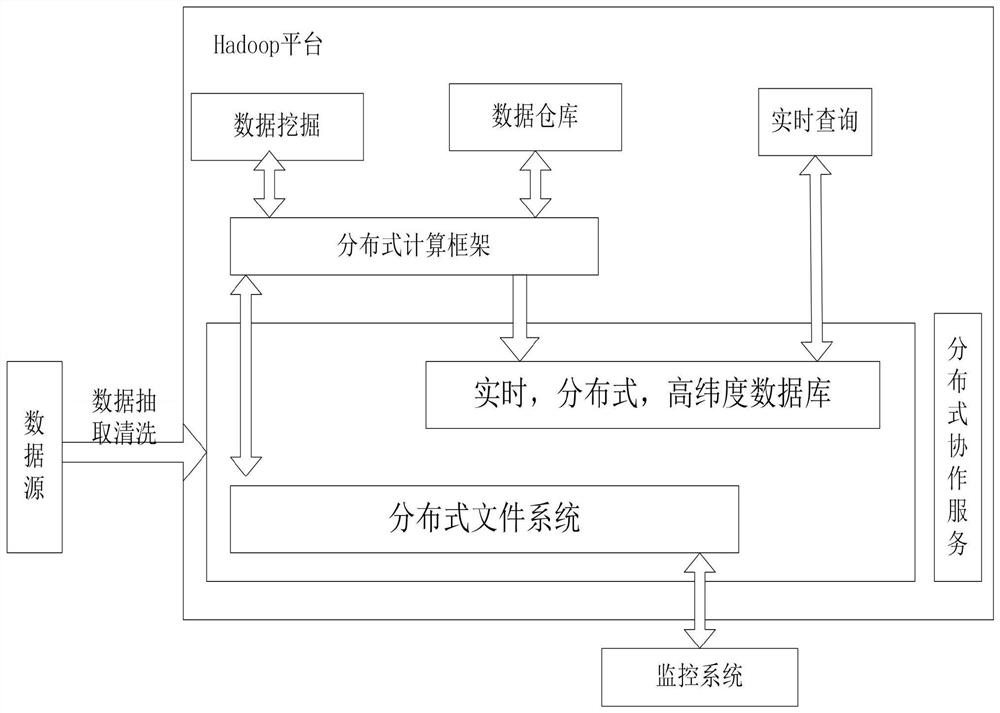

Comprehensive traffic monitoring system and method based on data fusion

PendingCN112668841AGuaranteed accuracyEffective transformationResourcesMetadata managementInformation resource

The invention is suitable for the technical field of traffic, and provides a comprehensive traffic monitoring system and method based on data fusion, and the system comprises: a data access layer which comprises a comprehensive database and is used for collecting different types of data, accessing real-time monitoring data of traffic operation, and transmitting the real-time monitoring data to the comprehensive database; a data fusion layer which comprises a data sharing exchange platform, wherein metadata management and data maintenance management guarantee the accuracy of data and the stability of operation; and a business application layer which comprises an index monitoring system, an index monitoring system and early warning management. Therefore, a basic information resource system capable of supporting whole-industry shared application can be formed, whole-road-network, multi-mode, integrated and all-around monitoring and service are provided for the industry, the cooperation strength among government enterprises, the industry and ministry provinces is improved, data standards are unified, and effective conversion, application and enabling of data are achieved.

Owner:北京华录高诚科技有限公司

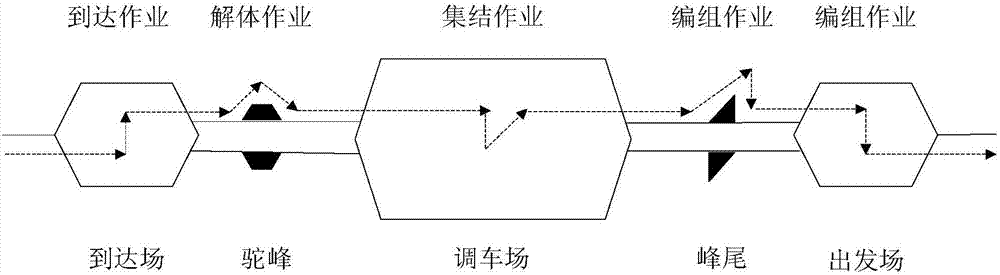

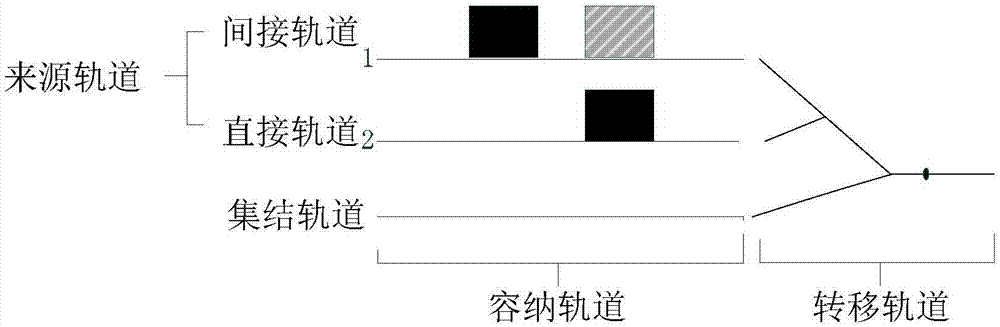

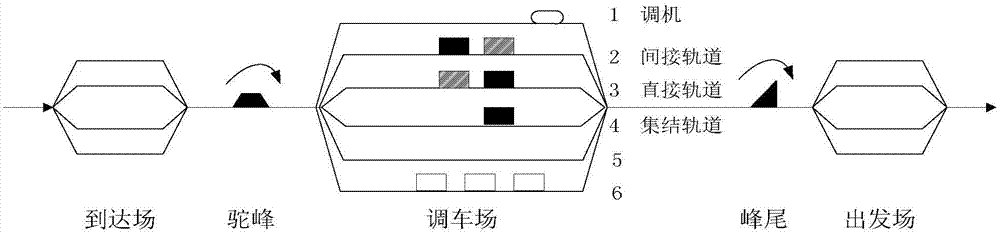

Shunting locomotive route planning method based on answer set program

ActiveCN107067114AEffective transformationFast operationForecastingKnowledge representationTyping ClassificationTheoretical computer science

The invention discloses a shunting locomotive route planning method based on an answer set program. In view of route moving arrangement of a single marshalling shunting locomotive, a method of combining the answer set program with a random generator is given. Firstly, type classification is carried out on tracks of a shunting yard in a typical marshalling station; then, positions of parked cars in an instance graph are converted to a network graph according to track types, the network graph is then converted to a rule set and a route planning scheme is obtained through various constraint conditions meeting artificial experience, the random generator is then used for randomly generating a rule set corresponding to the number of the tracks in the shunting yard, and thus, the continuously-increasing number of tracks in the shunting yard in a real scene can be handled. In combination of the theory and modeling language, the moving route of the shunting locomotive is planned, the random generator is used for generating program codes corresponding to the track number, and a planning result is finally generated automatically.

Owner:GUILIN UNIV OF ELECTRONIC TECH

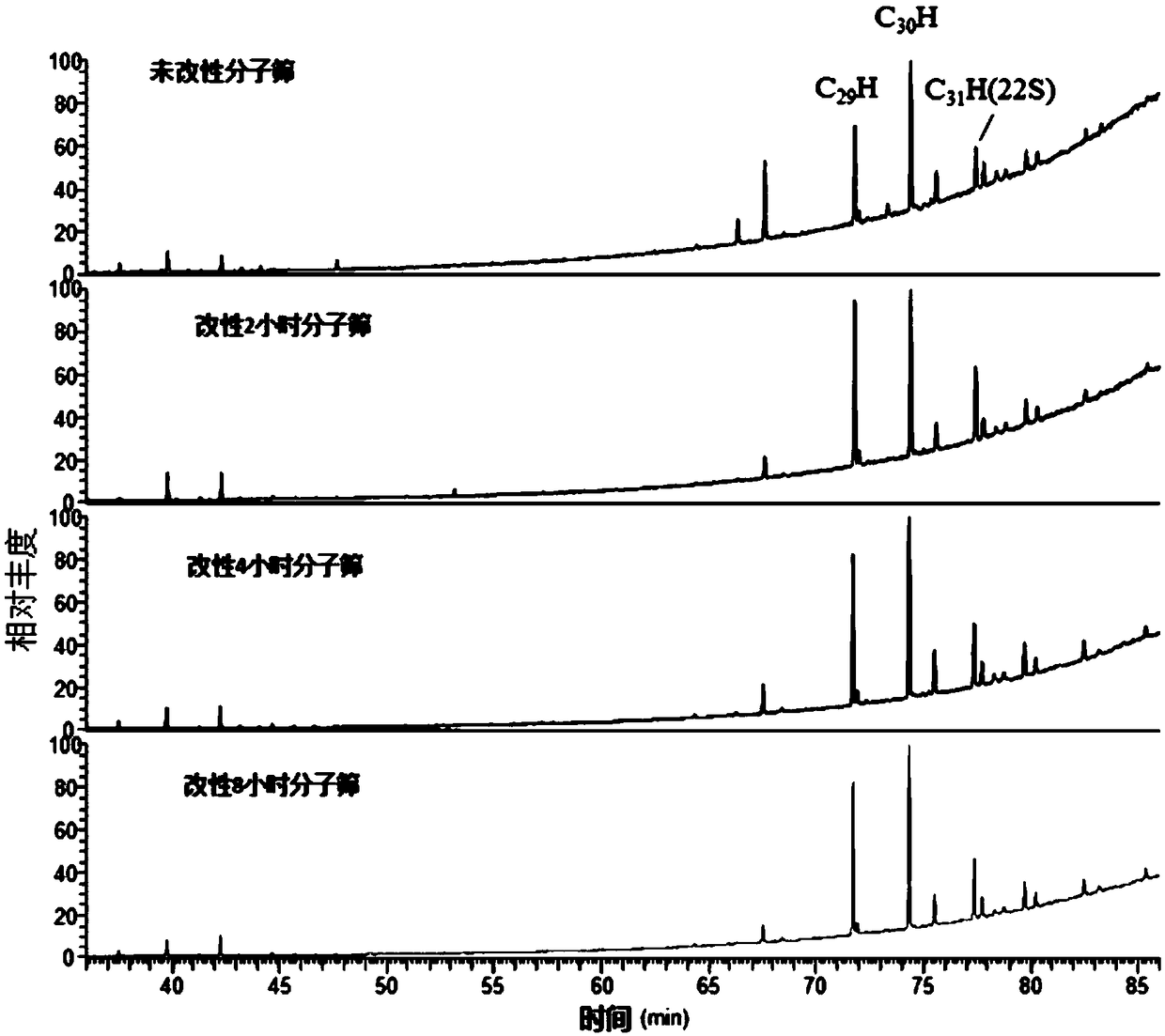

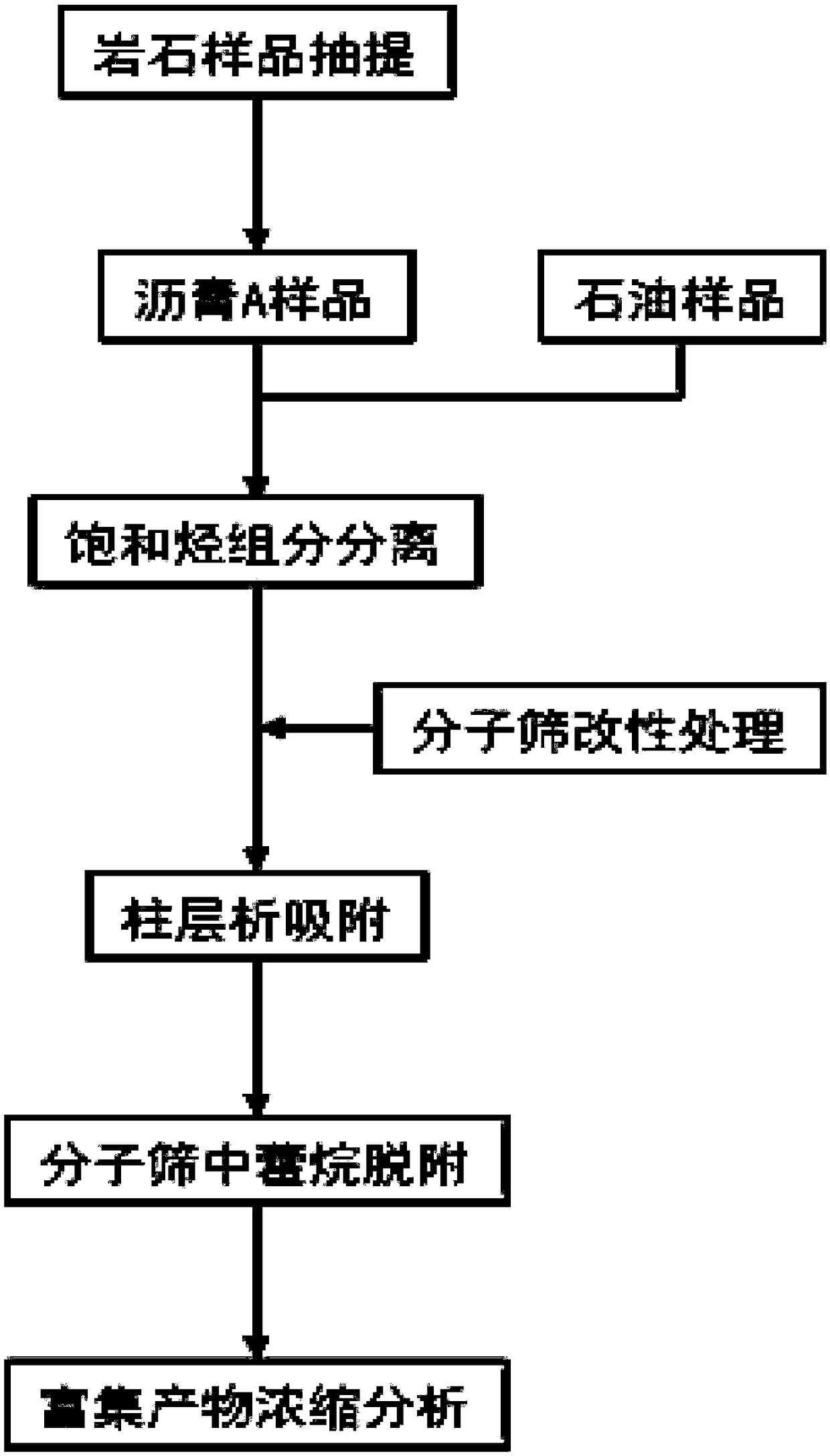

Modified zeolite molecular sieve as well as preparation method and application thereof

ActiveCN109317092APreserve structural featuresEffective transformationIon-exchange process apparatusOther chemical processesMolecular sieveOrganic acid

The invention provides a modified zeolite molecular sieve as well as a preparation method and application thereof. The modified zeolite molecular sieve is obtained through modification treatment on anX type molecular sieve, wherein the modification treatment refers to the modification on the X type molecular sieve in an organic acid alcoholic solution. The zeolite molecular sieve provided by theinvention can be used as an adsorption agent for hopance in a geological sample, and is used for enriching the hopance in the geological sample. The zeolite molecular sieve can be subjected to effective and controllable modification according to requirements.

Owner:PETROCHINA CO LTD

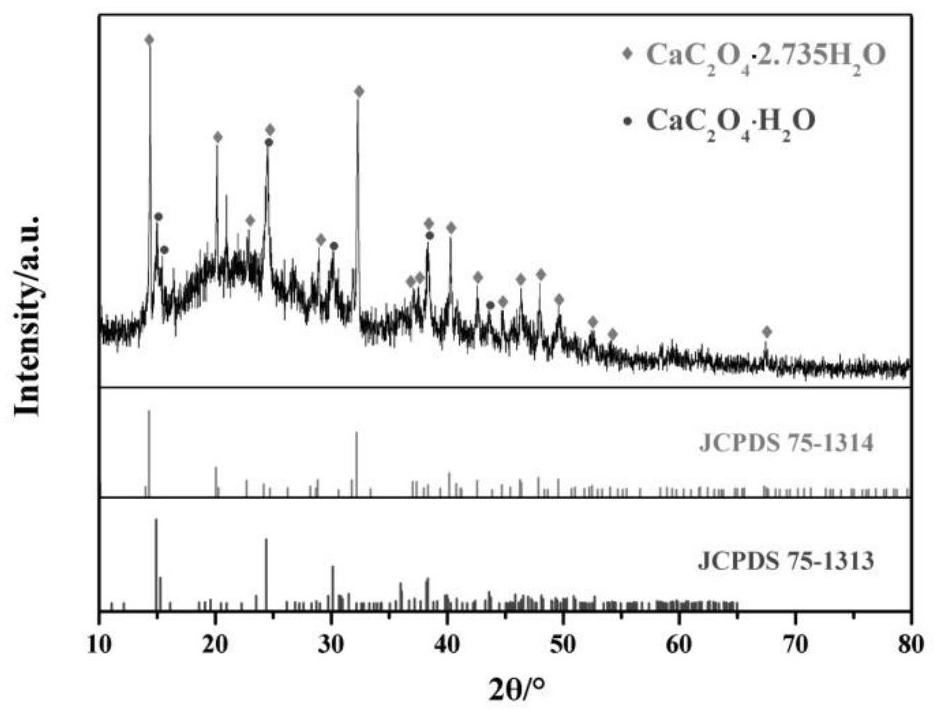

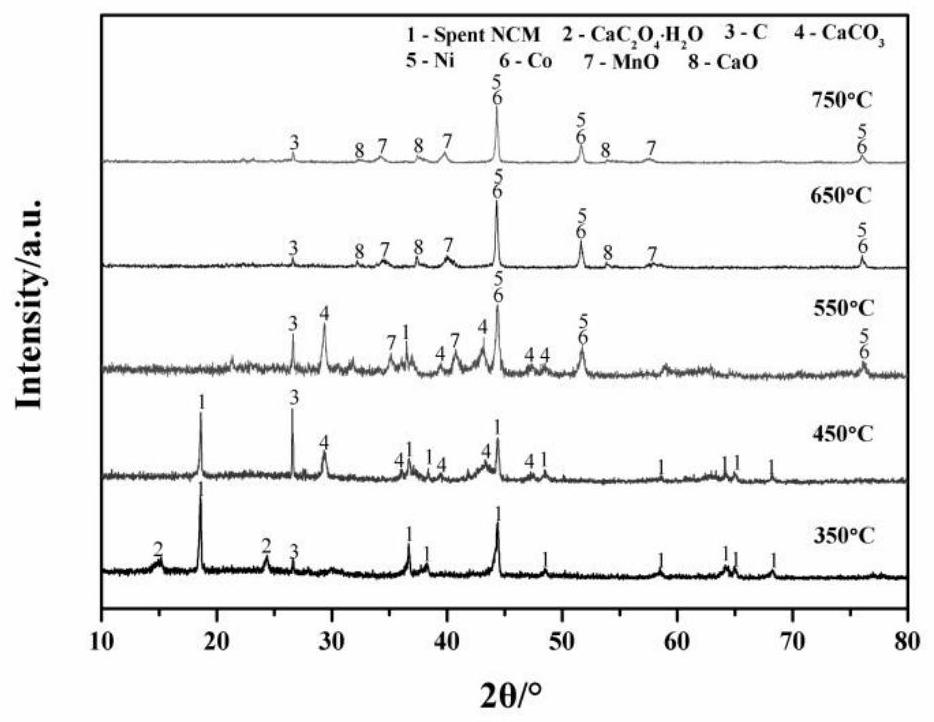

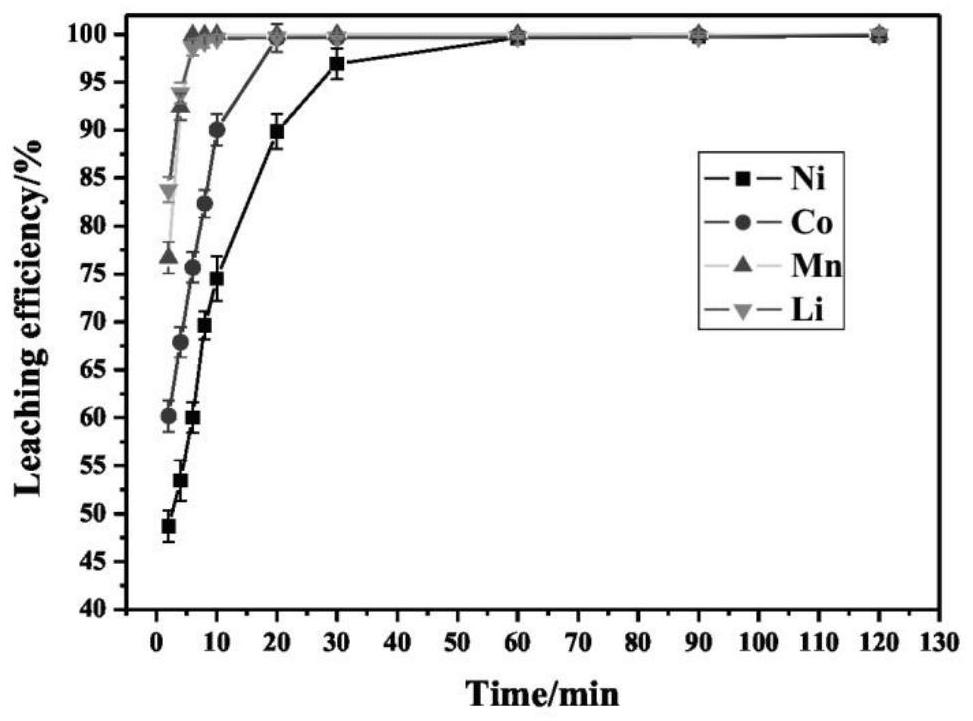

Method for recycling waste power lithium battery positive electrode material through antibiotic mushroom dreg auxiliary heat treatment

ActiveCN113215408AEffective transformationGood leaching effectWaste accumulators reclaimingCarbon preparation/purificationElectrical batteryLithium electrode

The invention belongs to the field of waste lithium ion battery recycling, and particularly discloses a method for recycling a waste power lithium battery positive electrode material through antibiotic mushroom dreg auxiliary heat treatment, the method comprises the following steps that auxiliary roasting treatment is conducted on antibiotic mushroom dregs and waste positive electrode powder in a protective atmosphere at the temperature of 550-850 DEG C to obtain roasted dregs; the roasted dregs are placed in an inorganic strong acid solution to be subjected to acid leaching, solid-liquid separation is conducted, and leaching slag and leaching liquid enriched with positive electrode material elements are obtained; and the leaching slag is washed to be neutral to obtain a carbon material. On the basis of coupling treatment of the antibiotic mushroom dregs and the waste positive electrode material and further cooperation of process conditions, the recycling effect of the positive electrode material can be effectively improved, moreover, the high-quality carbon material can be co-produced, research finds that the recycling rate of the positive electrode material can be close to 100%, and the carbon material obtained through co-production has the reversible capacity of 170.0 mAhg <-1 > or above under the large current of 2.0 Ag <-1 >.

Owner:CENT SOUTH UNIV

A method for changing the crystal form of lithium-containing aluminum electrolyte

ActiveCN107587167BIncrease productionReduce energy consumptionAluminium fluoridesLithium halidesAluminum fluorideLithium

The invention discloses a method for changing the crystal form of a lithium-containing aluminum electrolyte, and relates to the technical field of aluminum electrolyte extraction and recovery. It includes the following steps: S1, pulverizing the aluminum electrolyte containing lithium; S2, mixing the additive with the aluminum electrolyte powder, and mixing uniformly to obtain a mixed material, wherein the additive includes an alkali metal oxide other than lithium, and is baked at a high temperature One or more of the alkali metal oxo acid salts other than lithium that can be converted into alkali metal oxides, the alkali metal fluorides and additives contained in the aluminum electrolyte in the mixed material can be converted into The molar ratio of the sum of alkali metal fluorides to aluminum fluoride is greater than 3; S3, roasting the mixed material at high temperature. The invention can convert the insoluble lithium salt in the aluminum electrolyte into a soluble lithium salt, improves the leaching rate of the lithium salt, improves the purity of the aluminum electrolyte, and reduces the energy consumption of electrolytic aluminum production.

Owner:NORTHEASTERN UNIV LIAONING

Desulfurizing adsorption tower

InactiveCN101164668AEffective transformationTimely adjustmentDispersed particle separationAbsorption columnFlue gas

The present invention relates to a desulfurization absorption column. Said desulfurization absorption column includes an absorption column self-body, raw flue gas inlet set in the middle-lower portion of said absorption column self-body, slurry spraying layer set over the raw flue gas inlet in the middle-upper portion of absorption column self-body, demister set over the spraying layer, cleaned flue gas outlet set in the top portion of the described absorption column self-body and observation window which is communicated and connected with the portion above conventional working level of the described absorption column self-body.

Owner:CHINA SHENHUA ENERGY CO LTD +1

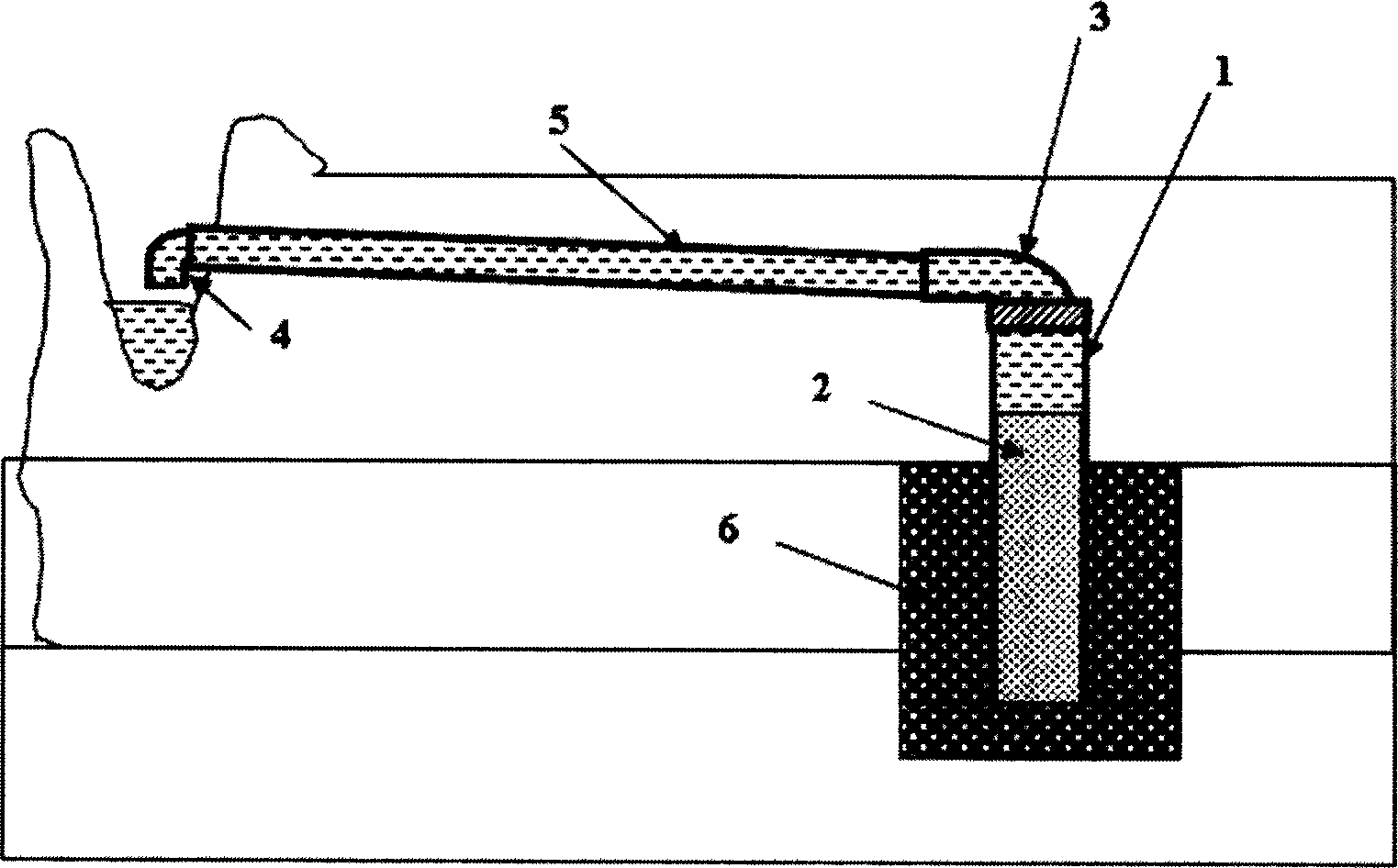

Installation for isolating and venting spring water

InactiveCN1726763AIncrease productionSimple structureWatering devicesCultivating equipmentsAgricultural irrigationWater filter

An isolated spring water draining apparatus for agricultural irrigation is composed of an isolated pilot pipe, a spring water filter arranged in said pilot pipe, the first and the second elbow pipes, a water draining pipe between said two elbow pipes, and the cobbles surrounding the lower end of said isolated pilot pipe.

Owner:SHANGHAI JIAO TONG UNIV

Loading control and multi-channel time-shared charge electric energy combined management system and its implementing method

InactiveCN100535951CLow costEasy to transformElectric signal transmission systemsData acquisitionData acquisition module

Owner:GUANGZHOU ZHIGUANG ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com