Method for preparing high-white ness nano calcium carbide

A technology of nano-calcium carbonate and high whiteness, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as limiting the production capacity of enterprises, failing to meet market demand, and long preparation process time, and achieve shortening Synthetic reaction time, no effect on drying performance, narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

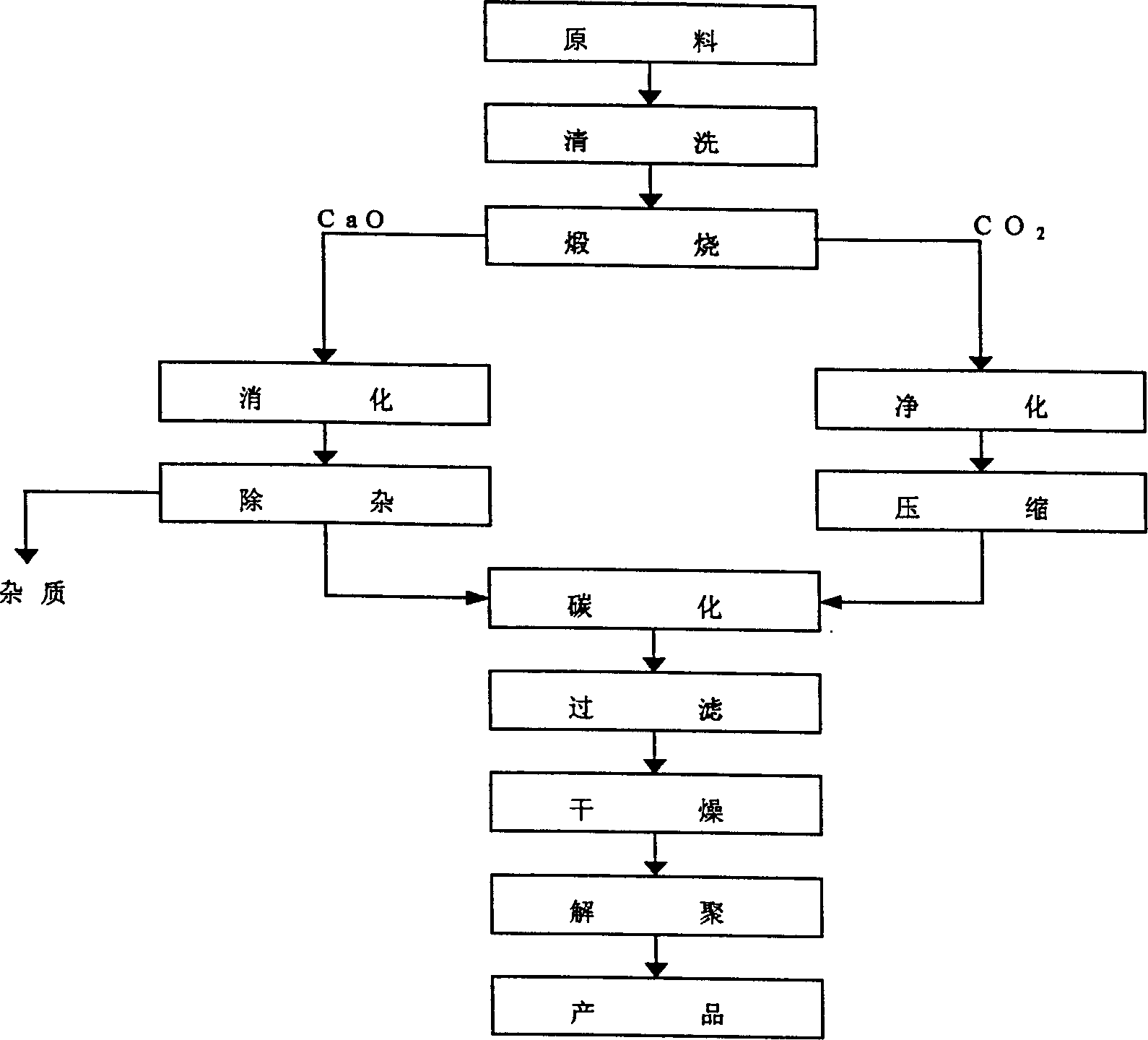

Method used

Image

Examples

example 1

[0055] The raw material is selected from the Chifeng area of Inner Mongolia. The limestone sample is delicate in appearance, and the whiteness of the -325 mesh product is as high as 95%. The calcium carbonate content in the limestone is 98.9%, and the main impurities are carbonates of magnesium, manganese, and iron. Limestone is calcined at a temperature of about 900°C to generate calcium oxide. Take 80 grams of calcium oxide and digest it with deionized water at a temperature of 40-80°C. After removing impurities and refining the lime milk solution, it is prepared into 6% calcium oxide Ca(OH)2 solution, put into synthetic reactor, open the high-shear particle size homogenizer, and start to stir, stirring speed is 400rpm, then pass into CO2 gas, gas flow is 9.6m3 / hkgCa(OH)2, reaction The initial temperature is 25°C, and the reaction process is monitored by a conductivity meter and a pH meter. When the pH of the solution is ≤7, the reaction ends, and the whole reaction time is...

example 2

[0057] Add crystal form control agent in embodiment 1, specific method is as follows: when reaction starts, add crystal form control agent sodium citrate earlier, its add-on is 0.6~1.8% of calcium hydroxide weight; Pass into CO then Gas starts reaction, When the solution conductivity dropped and recovered for the first time, add the crystal form control agent AlCl3, the add-on is 0.5~2% of calcium hydroxide weight, other conditions are the same as example 1, obtain 107 grams of products. The test results of the product show that the crystal form is chain nano-calcium carbonate, the average particle size of a single particle is 10-30nm, and the aspect ratio is 5-10; the product whiteness is 98.4.

example 3

[0059] Limestone is calcined at a temperature of about 900°C to generate calcium oxide. Take 20kg of calcium oxide, digest it with deionized water at a temperature of 80°C, and then remove impurities and refine the lime milk solution to prepare 8% Ca(OH )2 solution, put into the synthesis reactor, open the high-shear particle size homogenizer, and start stirring, the stirring speed is 400rpm, then pass into CO2 gas, the gas flow rate is 9.6m3 / hkgCa(OH)2, the initial reaction temperature is 20°C. At the beginning of the reaction, add the crystal form control agent sodium citrate first, and the addition amount is 0.6 to 1.8% of the weight of calcium hydroxide; then feed CO2 gas to start the reaction. The control agent AlCl3 is added in an amount of 0.5-2% of the weight of calcium hydroxide. The reaction process is monitored by a conductivity meter and a pH meter. When the pH of the solution is neutral, the reaction ends, and the whole reaction time is 40 minutes. Filter the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com