Titanium oxide nano tube and preparing method thereof

A titanium oxide, titanate nanotube technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of thick nanotube diameter, harsh condition control requirements, harsh condition control, etc., and achieve easy large-scale industrial production. , the speed environment is friendly, the conditions are easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation technique of the present invention mainly comprises following two aspects:

[0028] 1. Preparation of titanate nanotubes from industrially produced titanium dioxide

[0029] This method of preparing titanate nanotubes fully utilizes the pulverization effect of ultrasonic waves to fully pulverize large particle materials into fine particles, increases the contact area between materials, and reduces the mass transfer resistance of the reaction; at the same time, it uses ultrasonic cavitation to generate The instantaneous local ultra-high temperature and ultra-high pressure accelerate the reaction, and then use low-temperature hydrothermal crystallization to obtain titanate nanotubes. After post-treatment, titanate nanotubes are formed.

[0030] Process steps: mix 1-5 grams of industrially produced titanium dioxide with 40 ml of 5-20 mol / L NaOH solution, place in an ultrasonic generator, and perform ultrasonic chemical reaction at a temperature of 30-90°C and ...

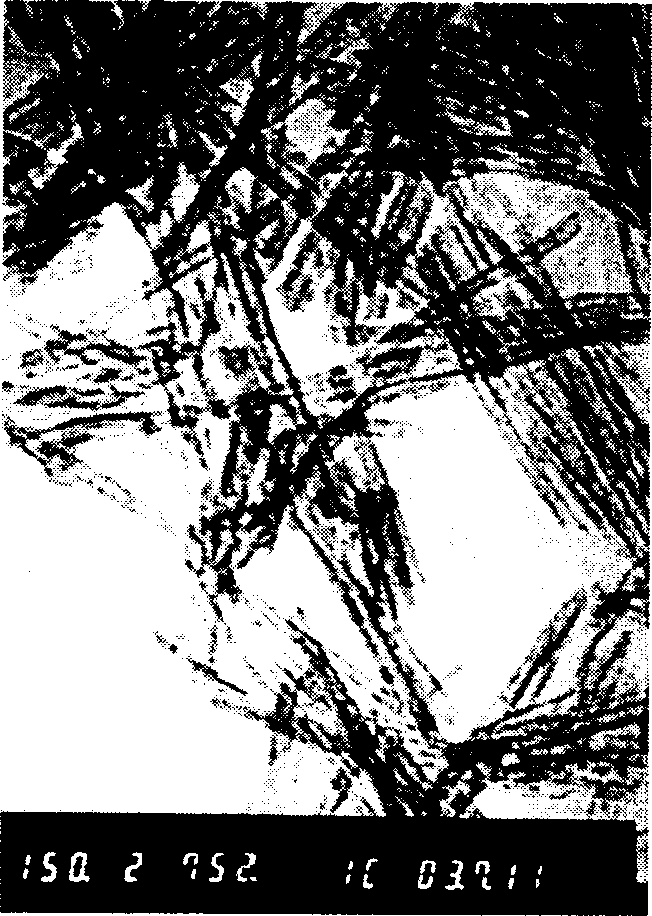

Embodiment 1

[0036] Preparation of titanate nanotubes

[0037] Weigh 1.0 g of industrially produced anatase crystal form titanium dioxide powder, put it into an Erlenmeyer flask, add 40 ml of 10 mol / L NaOH solution, put it into an ultrasonic generator, and the ultrasonic temperature is 35 ° C, with 0.2 W / cm 2The power of ultrasound for 5 hours. Then move it into a 50mL polytetrafluoroethylene-lined autoclave, conduct a hydrothermal reaction at 125°C for 20 hours, centrifuge the white product from excess alkali, and use 0.1 mol / L of HNO 3 Neutralize until the pH value is 2-6, age, rinse with deionized water, exchange with absolute ethanol three times, and dry to obtain titanate nanotubes. Its molecular formula is H 2 Ti 3 o 7 ·H2O.

[0038] Repeat the above operation steps, the ultrasonic temperature is 85°C, and the ultrasonic temperature is 0.2W / cm 2 Ultrasound with high power for 2 hours can obtain titanate nanotubes.

[0039] Repeat the above operation steps, the ultrasonic tempe...

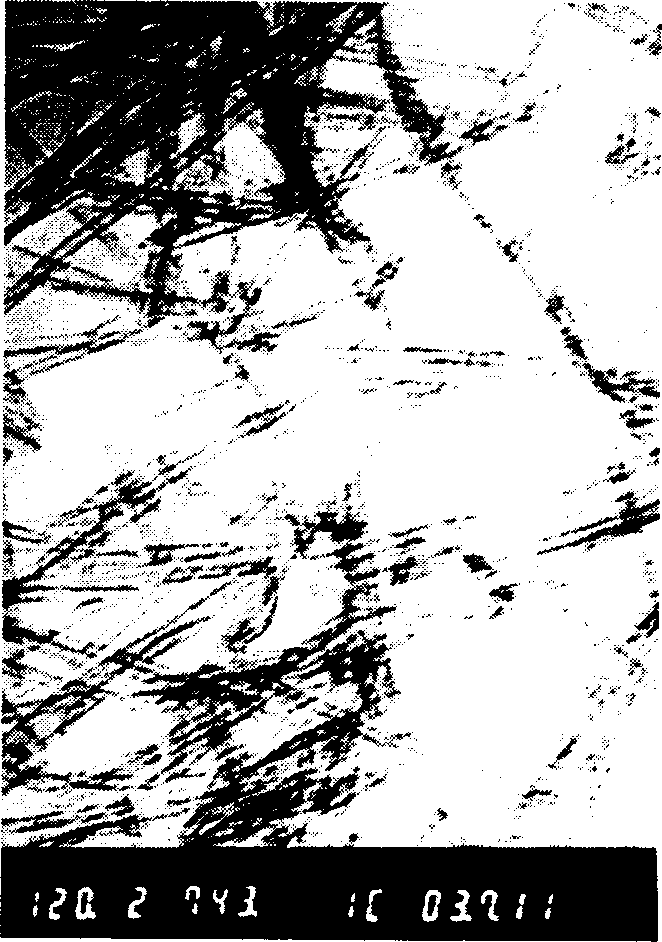

Embodiment 2

[0048] Weigh 1.0 g of industrially produced titanium dioxide powder of rutile crystal form, put it into an Erlenmeyer flask, add 40 milliliters of 10 mol / liter NaOH solution, put it into an ultrasonic generator, and use 0.2W / cm 2 Sonicate for 5 hours at a power of 85 °C. Then move it into a 50mL polytetrafluoroethylene-lined autoclave, conduct a hydrothermal reaction at 125°C for 30 hours, centrifuge the white product from excess alkali, and use 0.1 mol / L 3 Neutralize until the pH value is 2-6, age for 8 hours, rinse with deionized water, exchange with absolute ethanol three times, and dry to obtain titanate nanotubes. Its molecular formula is H 2 Ti 3 o 7 ·H2O.

[0049] Repeat the above operation steps, the ultrasonic temperature is 85°C, and the ultrasonic temperature is 0.2W / cm 2 Ultrasound with high power for 3 hours can obtain titanate nanotubes.

[0050] Repeat the above operation steps, the ultrasonic temperature is 35°C, and the ultrasonic temperature is 95W / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com