Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

341 results about "Ti oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

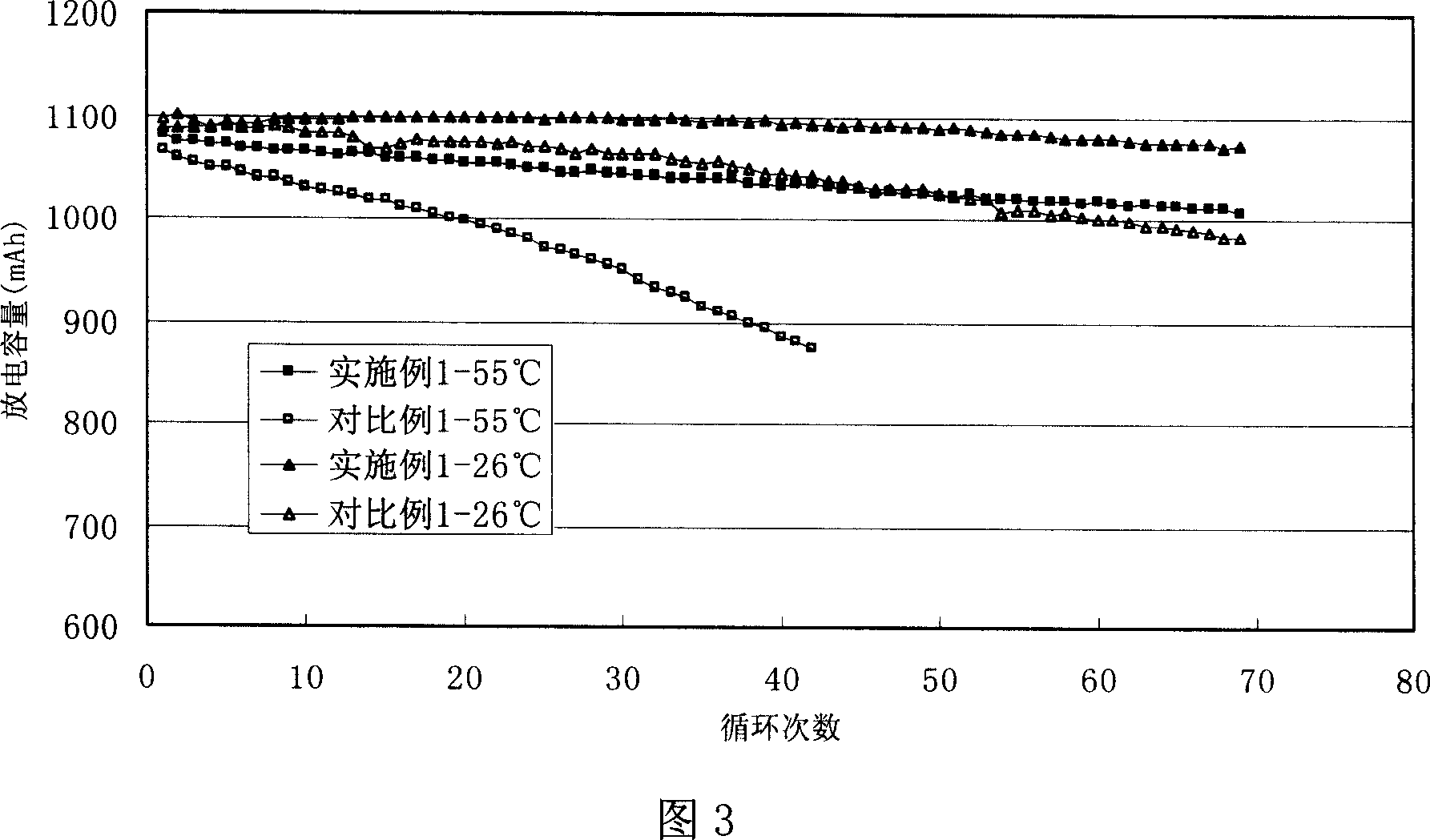

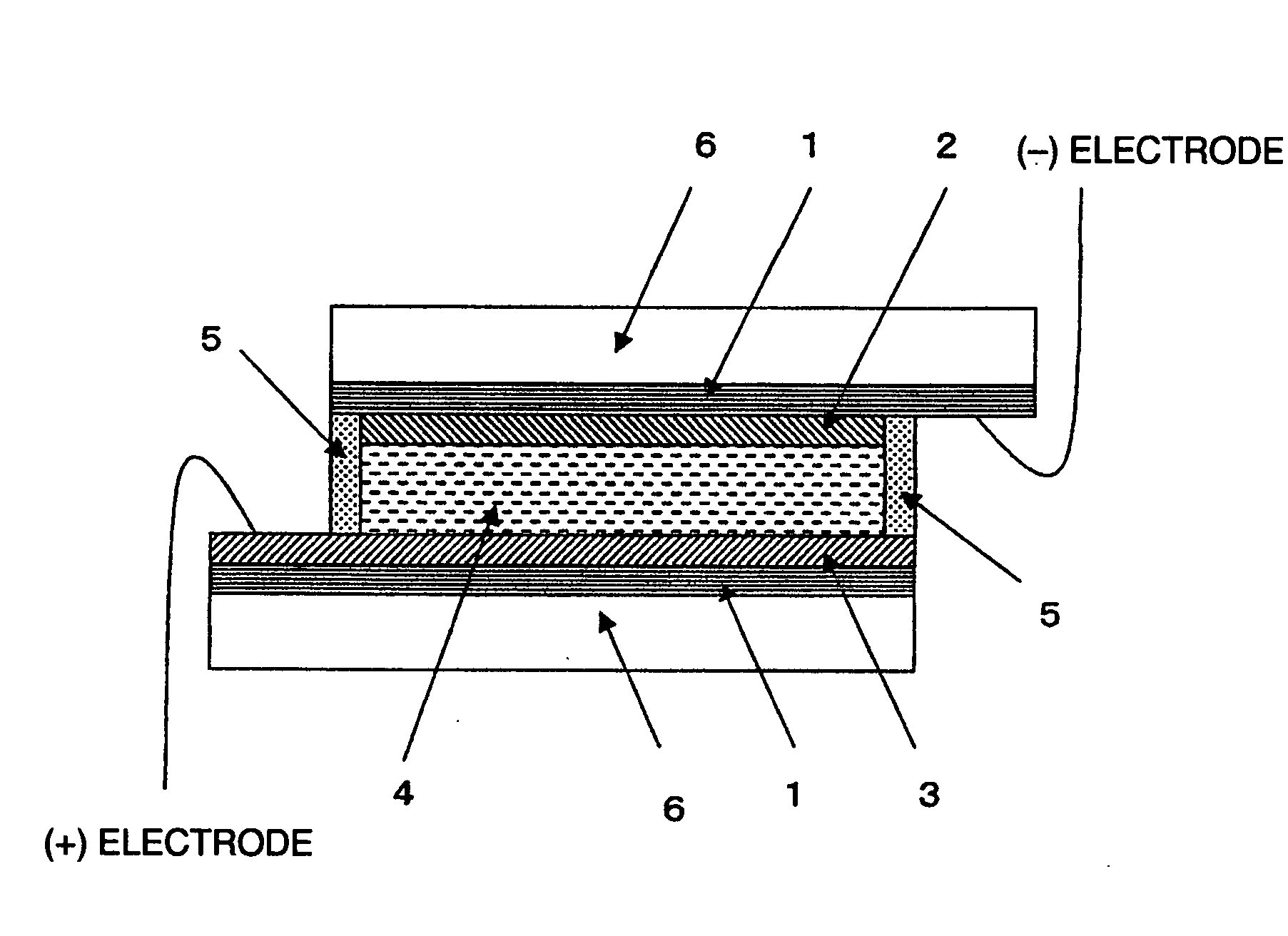

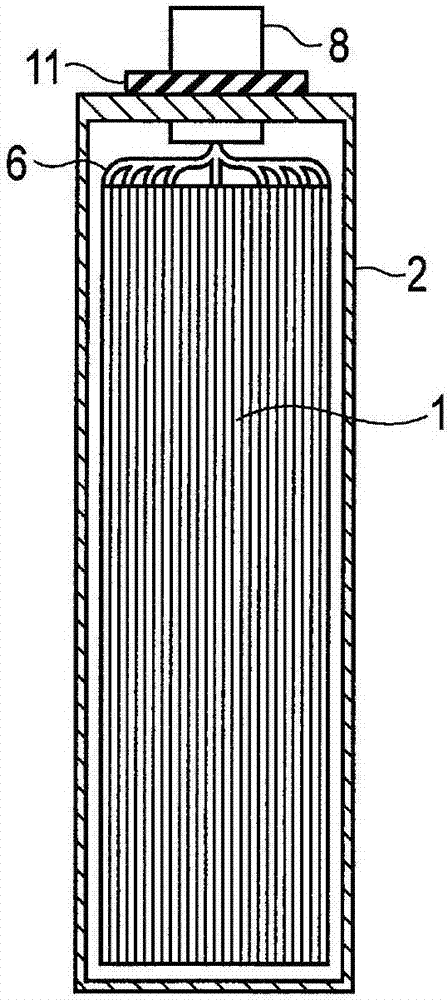

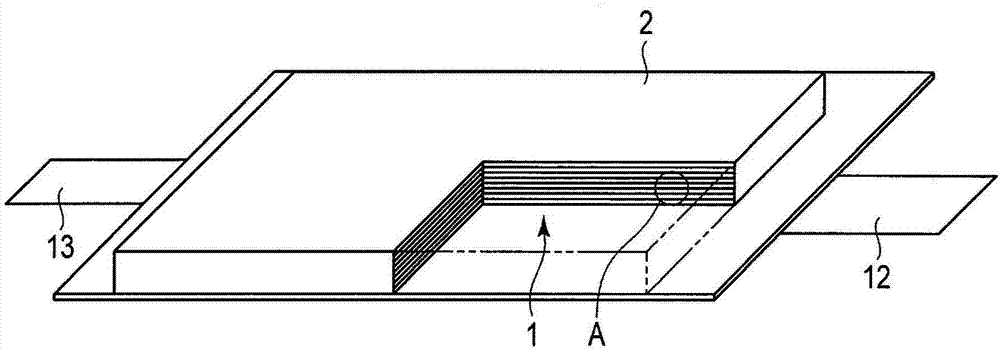

Non-aqueous electrolyte secondary battery and method of manufacturing the same

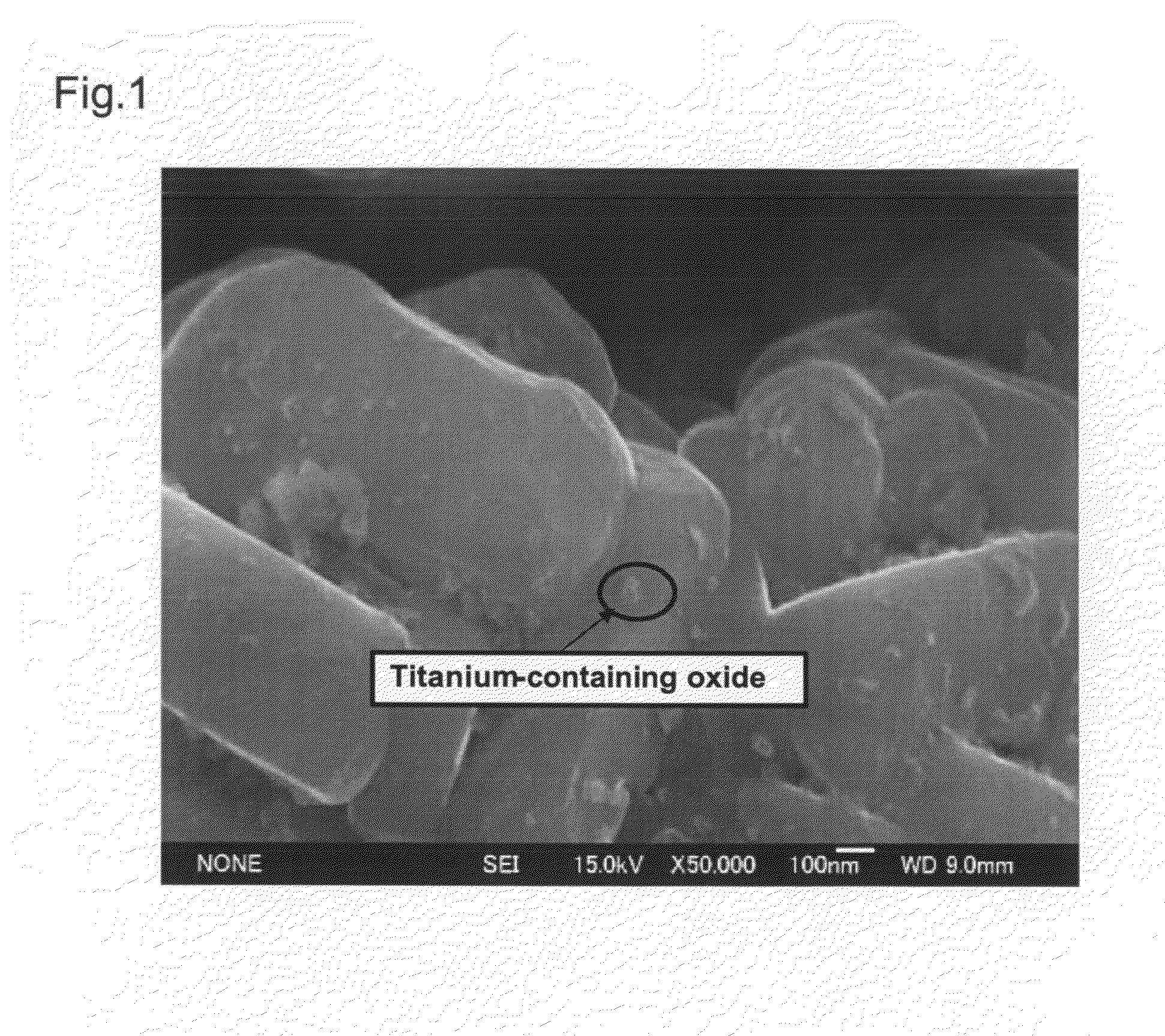

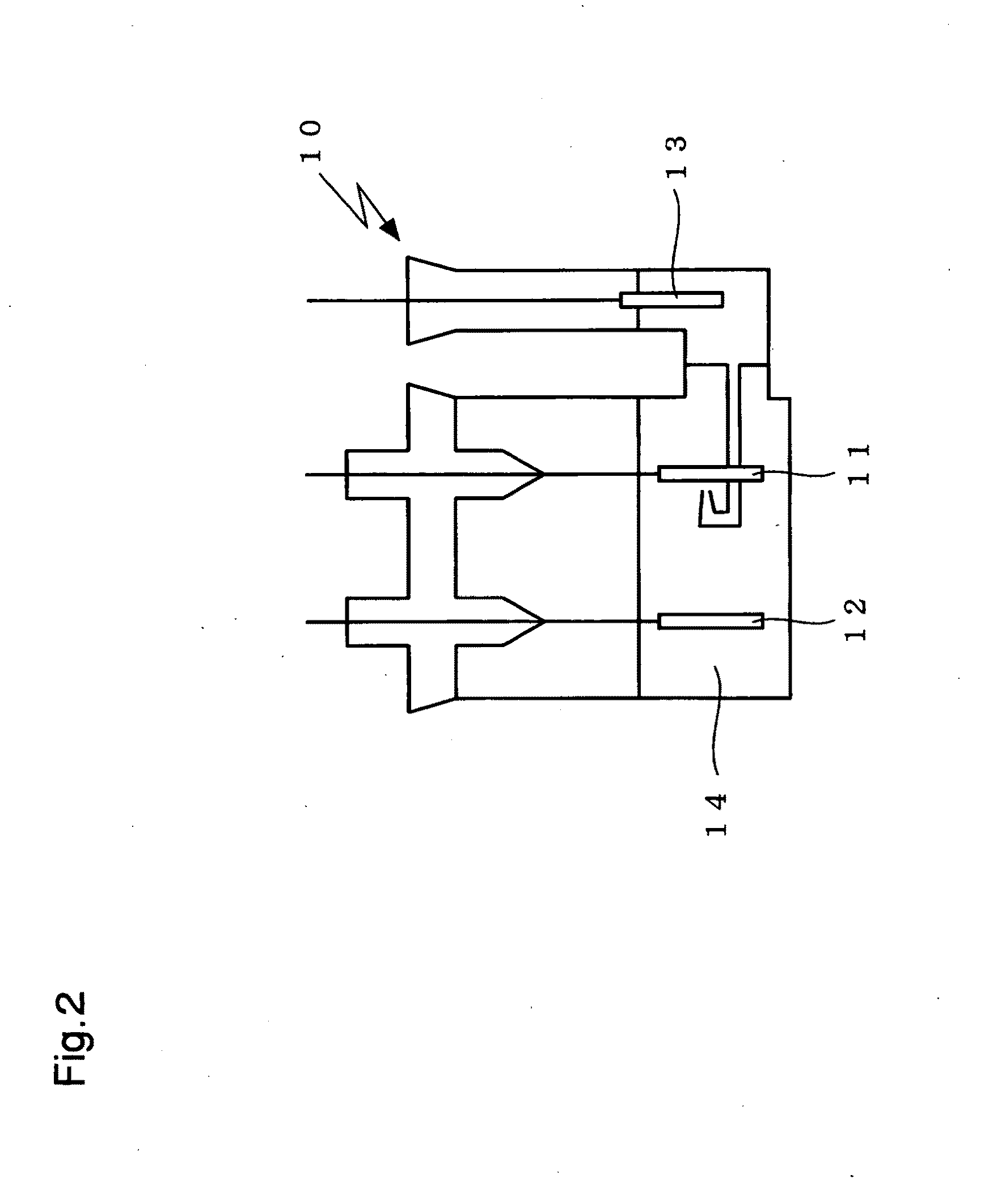

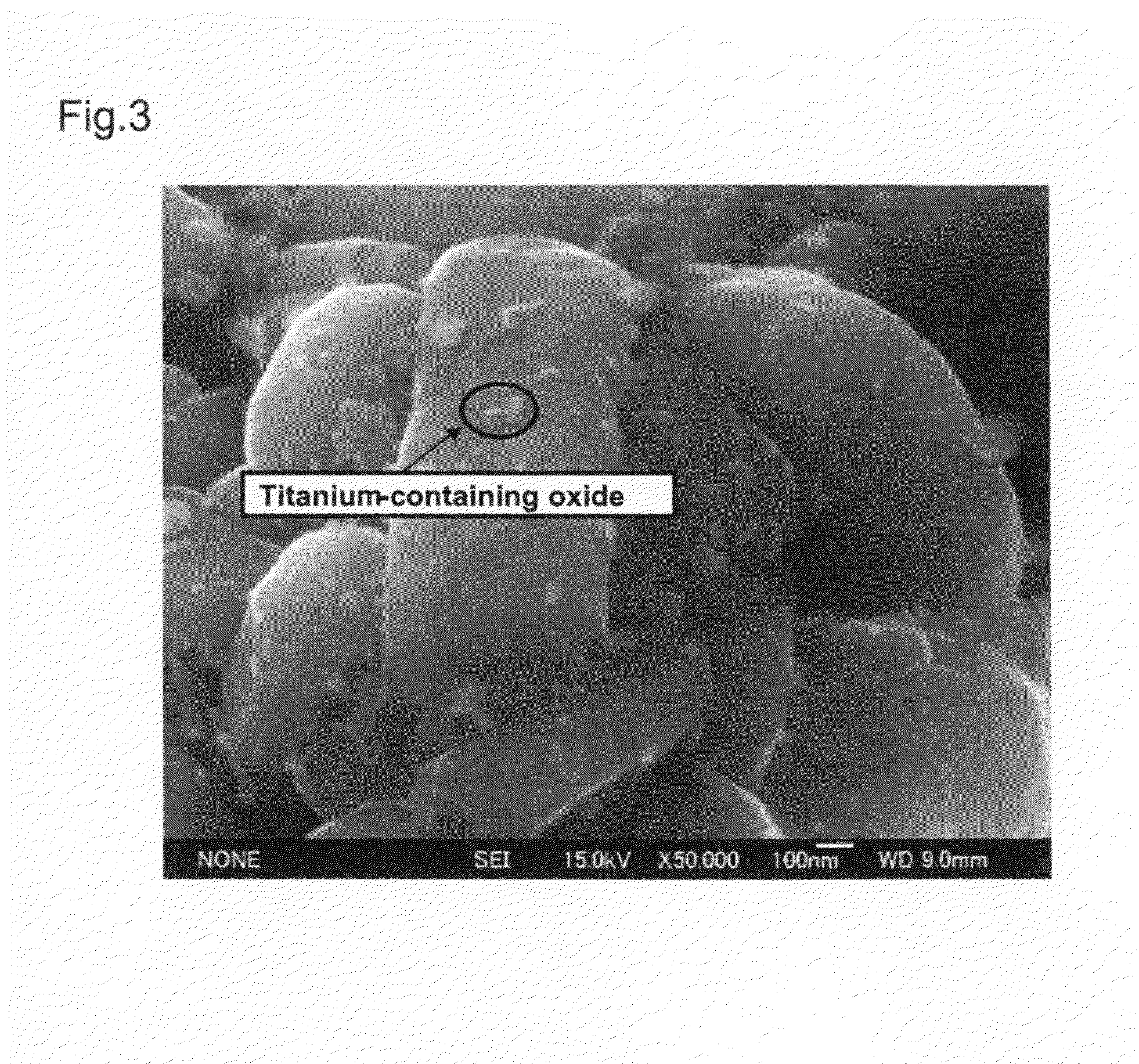

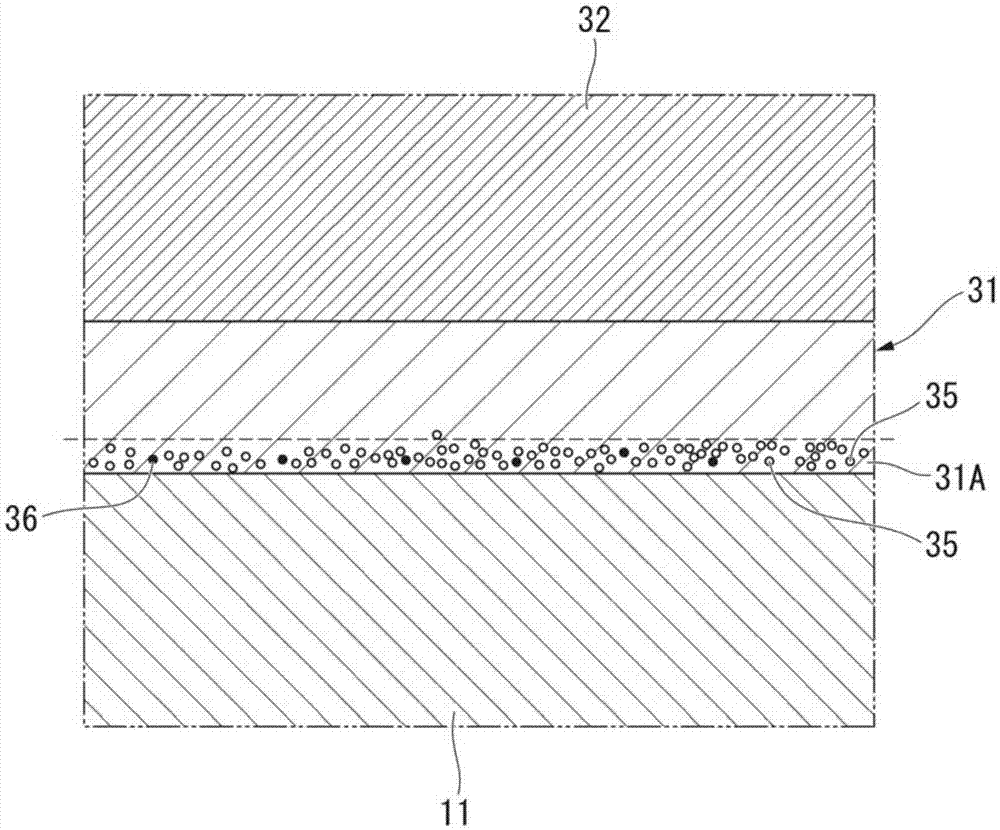

InactiveUS20090305136A1Stable crystal structureImproving high-rate charge-discharge capabilityMaterial nanotechnologyElectrode thermal treatmentPhysical chemistryTitanium

A non-aqueous electrolyte secondary battery has a positive electrode (11) containing a positive electrode active material, a negative electrode (12) containing a negative electrode active material, and a non-aqueous electrolyte solution (14) in which a solute is dissolved in a non-aqueous solvent. The positive electrode active material is obtained by sintering a titanium-containing oxide on a surface of a layered lithium-containing transition metal oxide represented by the general formula Li1+xNiaMnbCocO2+d, where x, a, b, c, and d satisfy the conditions x+a+b+c=1, 0.7≦a+b, 0≦x≦0.1, 0≦c / (a+b)<0.35, 0.7≦a / b≦2.0, and −0.1≦d≦0.1.

Owner:SANYO ELECTRIC CO LTD

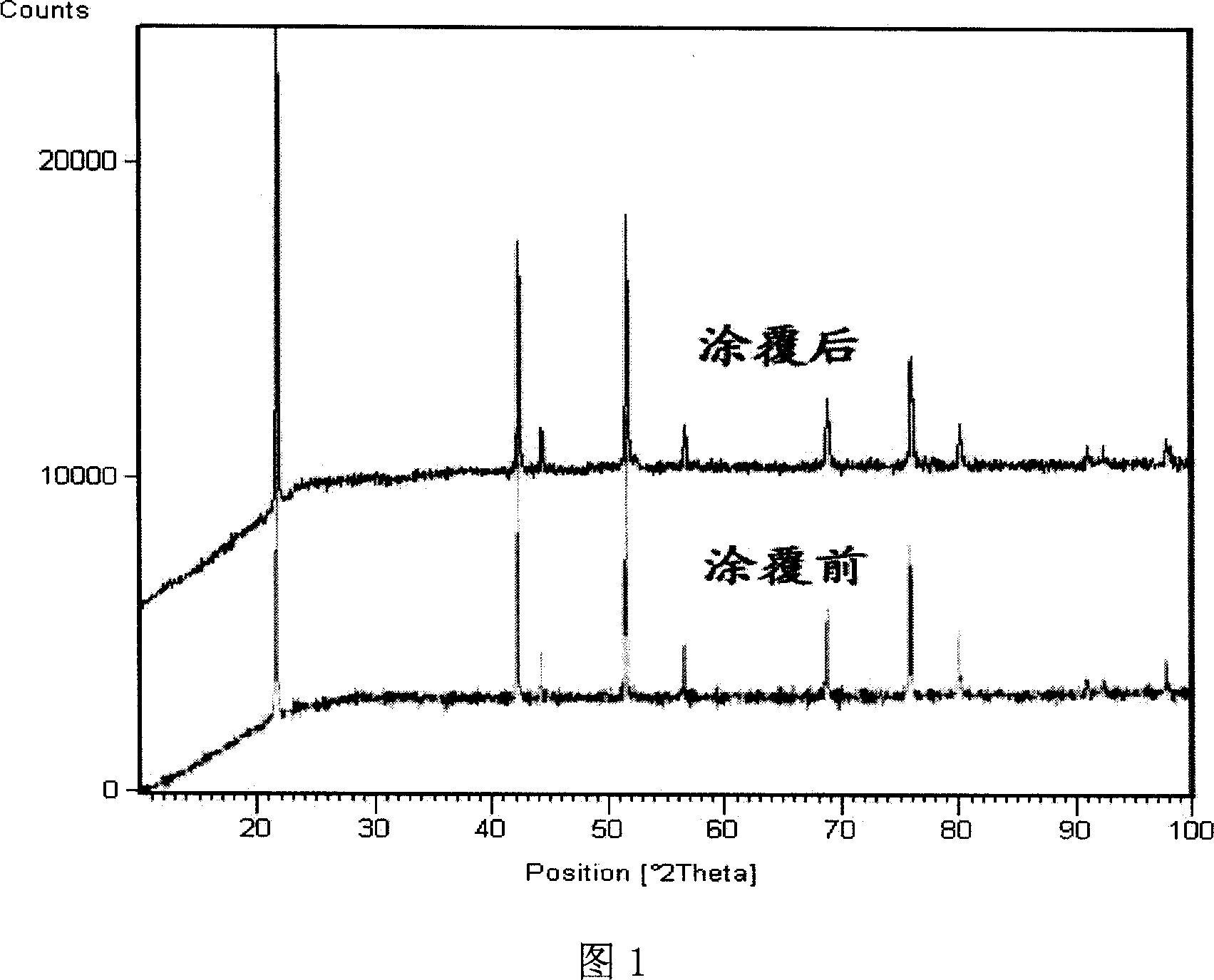

Complex Li-Mn-oxide, manufacture method and battery made of this material

ActiveCN101060173AImprove rate charge and discharge performanceEasy to prepareElectrode manufacturing processesSecondary cellsPhosphateComposite oxide

The disclosed Li-Mn composite oxide for positive of secondary Li cell comprises the core LiaMn2-bXbO4 and a coating layer, wherein 0. 97<=a<=1. 06, 0 <=b<=0. 5, X for other metal (except Li and Mn) or Si; the coating layer comprises one of more of Li-B composite oxide, Li-Co oxide, Li-V oxide, Al oxide, Al phosphate, Ti oxide, Cr. Oxide, Mg oxide, and Ca oxide This invention improves material performance, special the circulation performance at high temperature.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

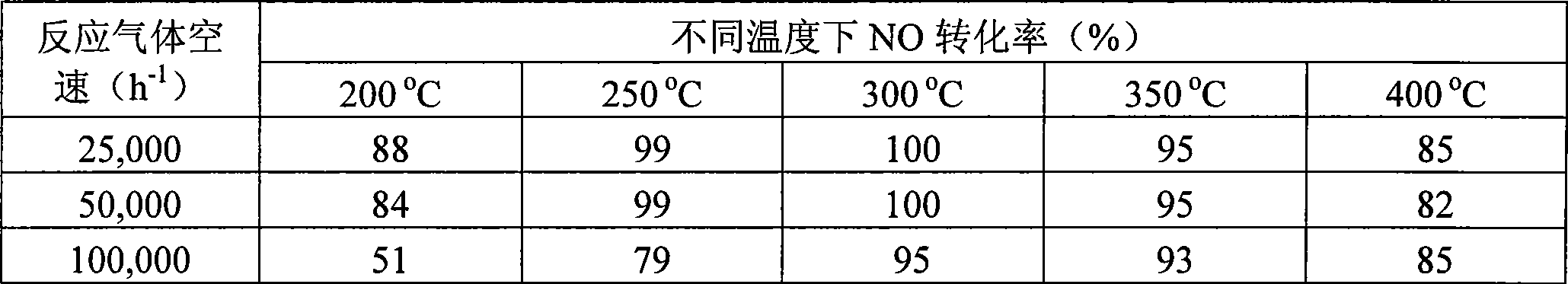

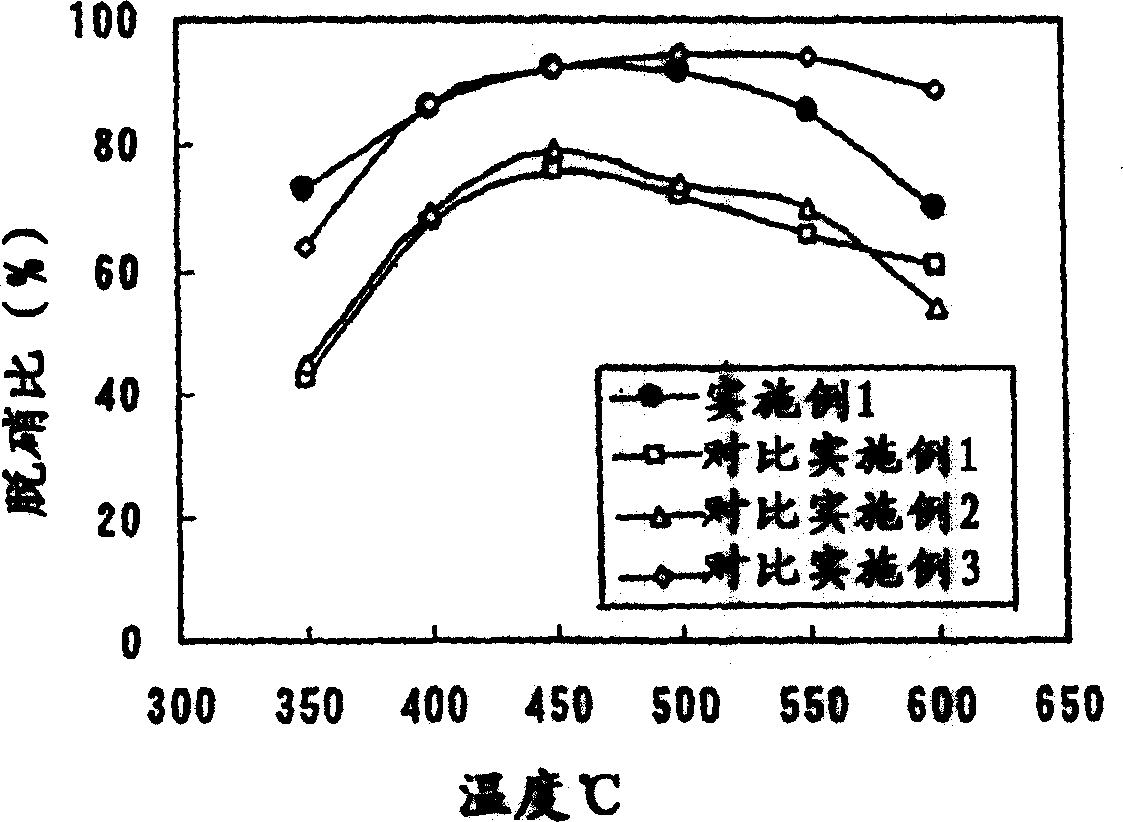

Ferrotitanium composite oxides catalyst for ammonia selective reduction nitric oxides

ActiveCN101380578ALow priceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideHigh activity

The invention relates to a catalyst of selective reduction of nitrogen oxide by ammonia, which mainly solves the existing problems that the commonly used NH3-SCR catalyst system is toxic to environment and human body, the anti-SO2 poisoning ability of the catalyst system is poor in the reference and the catalyst system can not adapt to the conditions of high space velocity. The invention adopts cheap and non-toxic raw materials to prepare a Fe-Ti oxide catalyst with high activity, selectivity, stability and anti-S2 poisoning ability by the simple and practicable co-precipitation method, which can better solve the existing technical problems. If the catalyst is loaded on honeycomb ceramics after being made into pulp, the catalyst is hopeful to be put into practical application of flue gas denitrification of coal-fired power plants.

Owner:江西中科鸿虔新材料有限公司

Method for preparing composite Ag-Ti oxide antibacterial film by magnetron sputtering

InactiveCN101717920AImprove uniformityStrong adhesionVacuum evaporation coatingSputtering coatingIntermediate frequencyOxide composite

The invention discloses a method for preparing a composite Ag-Ti oxide antibacterial film by magnetron sputtering, mainly comprising the steps of: 1) carrying out pretreatment on the surface of film carrier base material, sequentially washing by more than two organic solvents and deionized water under the condition of ultrasonic wave, the washing time by using the organic solvents and the deionized water being 5-15min, and finally, drying at 15-85 DEG C for 0.5-3h under the vacuum condition; 2) arranging a metal Ti target and a metal Ag target on a magnetron sputtering device, taking argon as working gas, filling reaction gas containing oxygen into a vacuum chamber of the magnetron sputtering device, sputtering the metal Ti by an intermediate frequency magnetron sputtering power supply of the magnetron sputtering device, sputtering the Ag by the magnetron sputtering power supply, and obtaining Ag-Ti metal oxide composite coating film. The method is simple and efficient, and the obtained film has high uniformity, good dispersibility and strong adhesive force, so as to be taken as antibacterial material which has the advantages of broad spectrum, high efficiency, permanent antibacterial performance, safety and environmental protection.

Owner:ZHEJIANG UNIV

Manufacture method of lithium lanthanum titanium oxide

ActiveCN1970455AImprove electrical performanceThe experiment process is simpleCell electrodesLithium compoundsAlcoholLithium-ion battery

The invention discloses a making method of Li-La-Ti oxide in the lithium ion battery domain, which comprises the following steps: adopting lithium nitrate, lanthanum nitrate and butyl titanate as raw material with molecular formula as Li3xLa2 / 3-xTiO3 (0<x<0.16); setting the molar rate of Li, La and Ti at 1: 1: 2; adopting alcohol or ethylene glycol monomethyl ether as solvent; or adjusting pH value under 1 through water and acetate; drying solution; sintering under 800-900 deg.c for 2h; obtaining pure LLTO. the invention shortens experimental period and synthesizing temperature with grain size about 200nm, which possesses excellent compact and electric property.

Owner:TSINGHUA UNIV

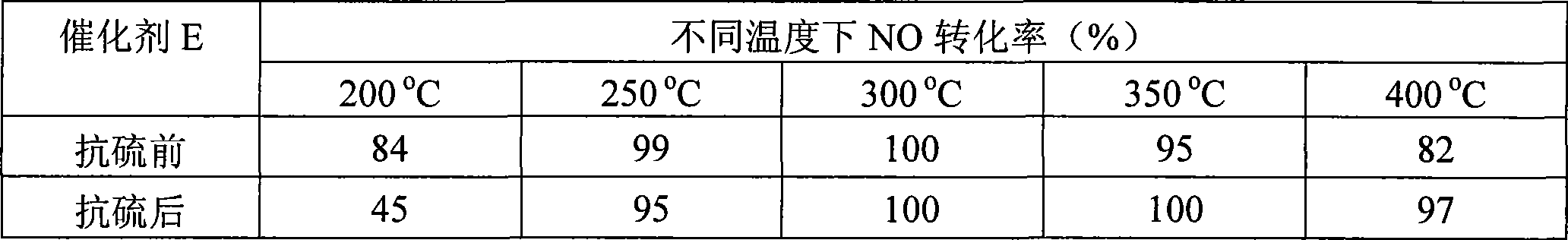

Fuel oil deep-adsorption desulfurizationn catalyst, preparation method and application thereof

ActiveCN104056632ALarge specific surface areaReduce hydrogen consumptionOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSorbent

The invention discloses a fuel oil deep-adsorption desulfurizationn catalyst. The desulfurizationn catalyst is characterized by consisting of an active component, a sulfur adsorbent and an adhesion agent, wherein the active component refers to one or more of Ni, Co, Cu, W and Mo oxides; the sulfur adsorbent refers to at least one of Mg, Ca, Zn, Ce, Fe, Mn and Ti oxides; the mass percent content of the active component is 2wt%-50wt%, the mass percent content of the sulfur adsorbent is 20wt%-90wt%, and the mass percent content of the rest components is the adhesion agent. The adhesion agent is one or a mixture of more than one of aluminium oxide, pseudo-boehmite, kaolin, imvite, bentonite, Yunmeng soil, kieselguhr, silica sol, silica gel and expanded perlite. The catalyst has the advantages of high specific surface area, moderate reaction, high intensity and low hydrogen consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Titanium oxide nano wire film on metallic titanium surface and manufacture method thereof

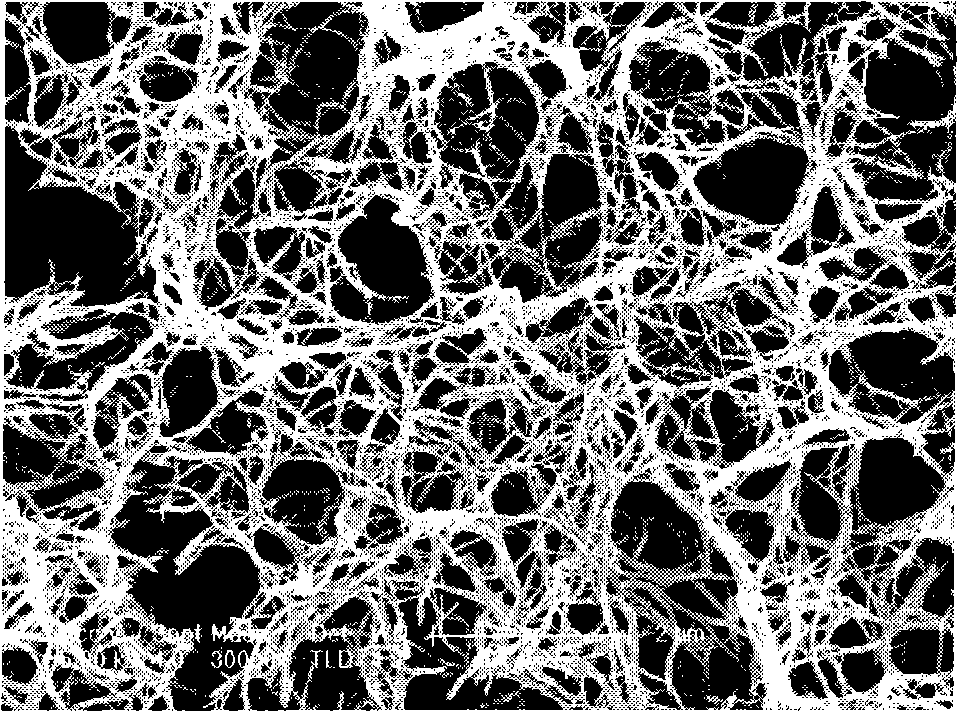

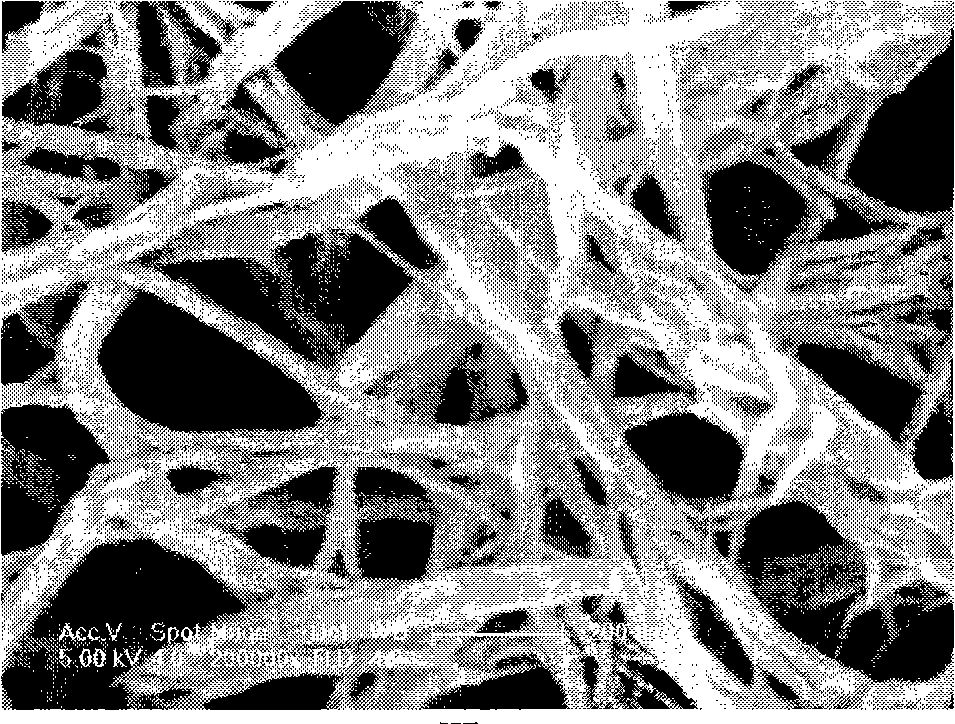

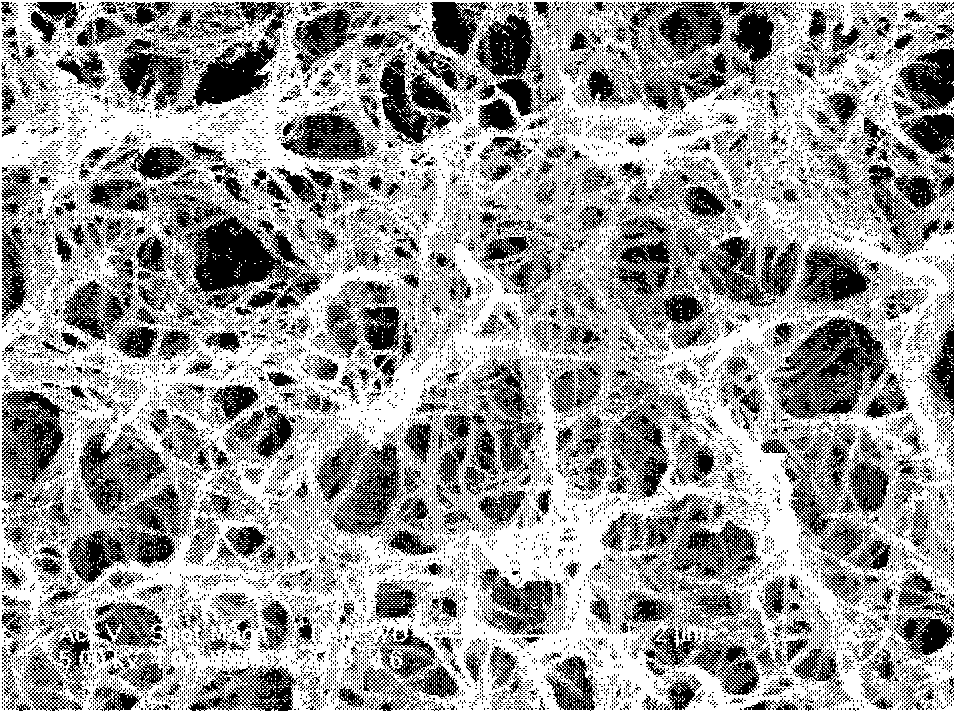

InactiveCN101343746ALarge specific surface areaImprove bindingMetallic material coating processesTitanium surfaceNanowire

The invention relates to a metal titanium surface titanium oxide nanowire film and the preparation method. The component of the prepared film can be titanate, titanic acid or titanium dioxide, the diameter of the nanowire is between 10nm to 100nm, the nanowires are interlaced and winded to form a great amount of large holes and mesopore networks, and the pore space is between 20nm to 500nm. The main procedures of the preparation method are: firstly, pickling cleaning of the metal titanium surface; secondly, mixed oxidizing solution of strong alkali and oxydol is used to oxidize the metal titanium surface and to form the titanate nanowire film; thirdly, acid soaking is adopted to exchange alkaline metal ions to form the titanic acid nanowire film; fourthly, the titanium dioxide nanowire film is formed through high temperature torrefying. The preparation method of the metal titanium surface titanium oxide nanowire film of the invention is simple, the cost is low, the method is suitable for large-scale industrial production, and the prepared titanium oxide has the application prospect in photochemical catalysis related field and the electrochemistry sensing related field.

Owner:SHANGHAI JIAO TONG UNIV

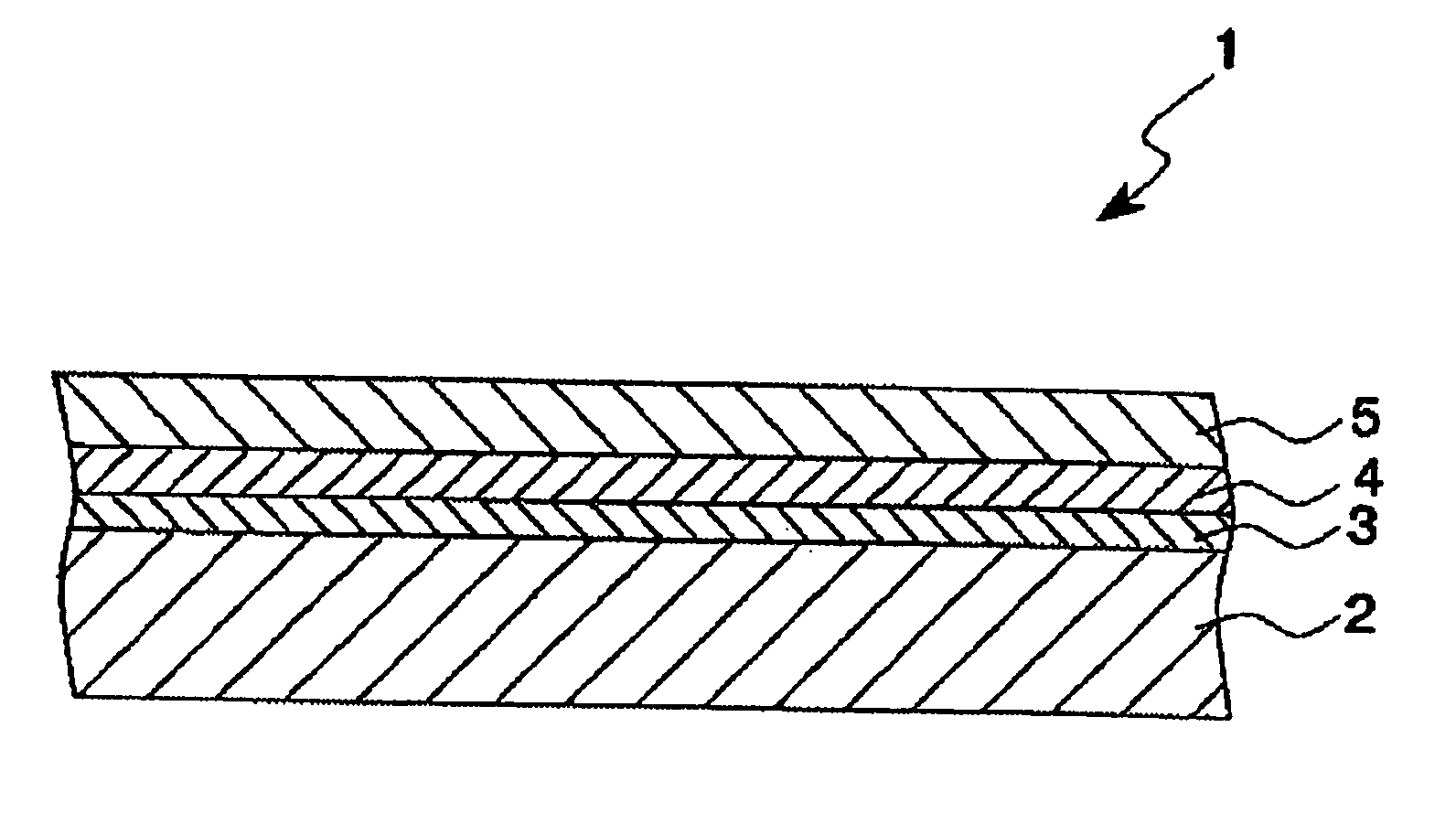

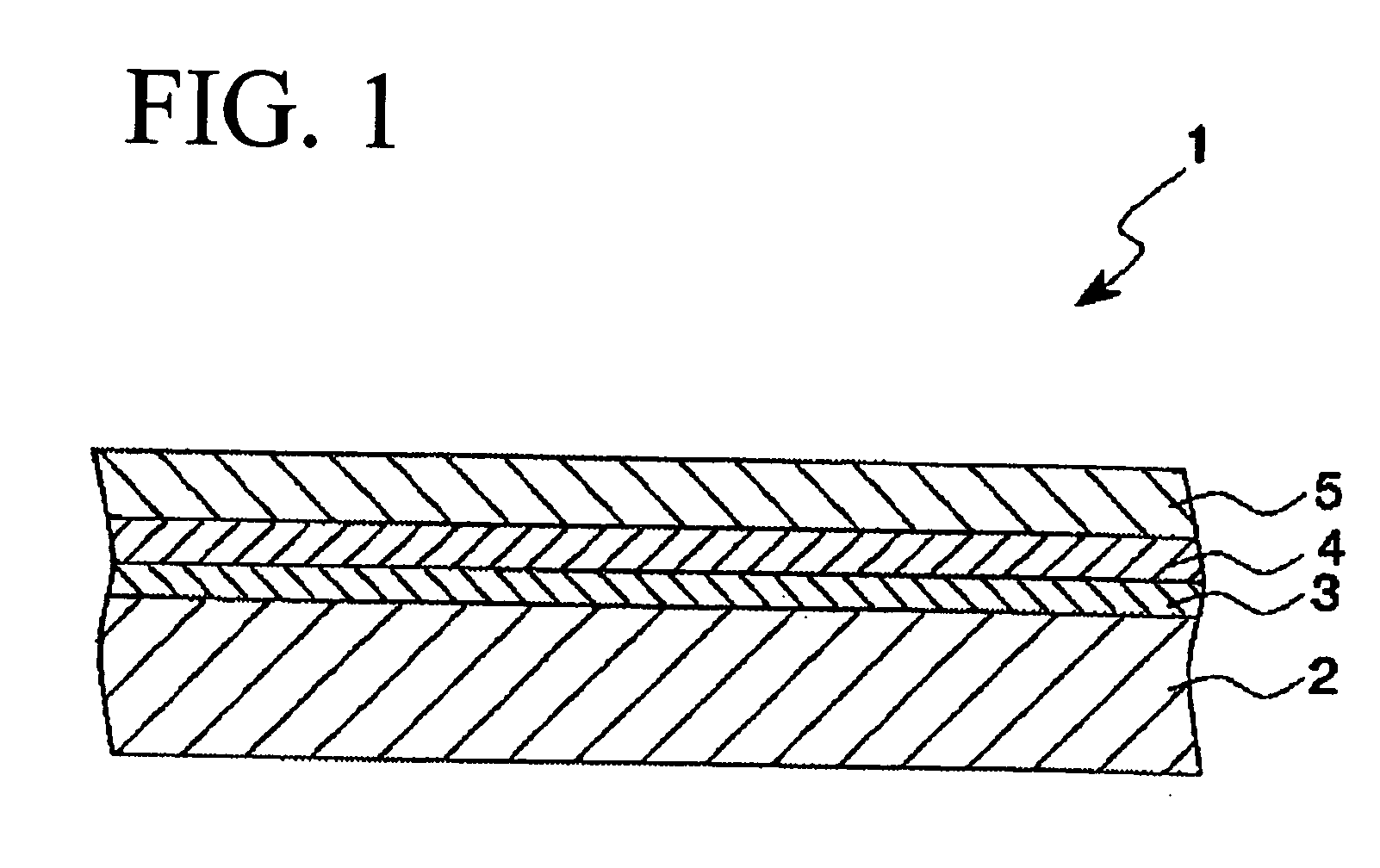

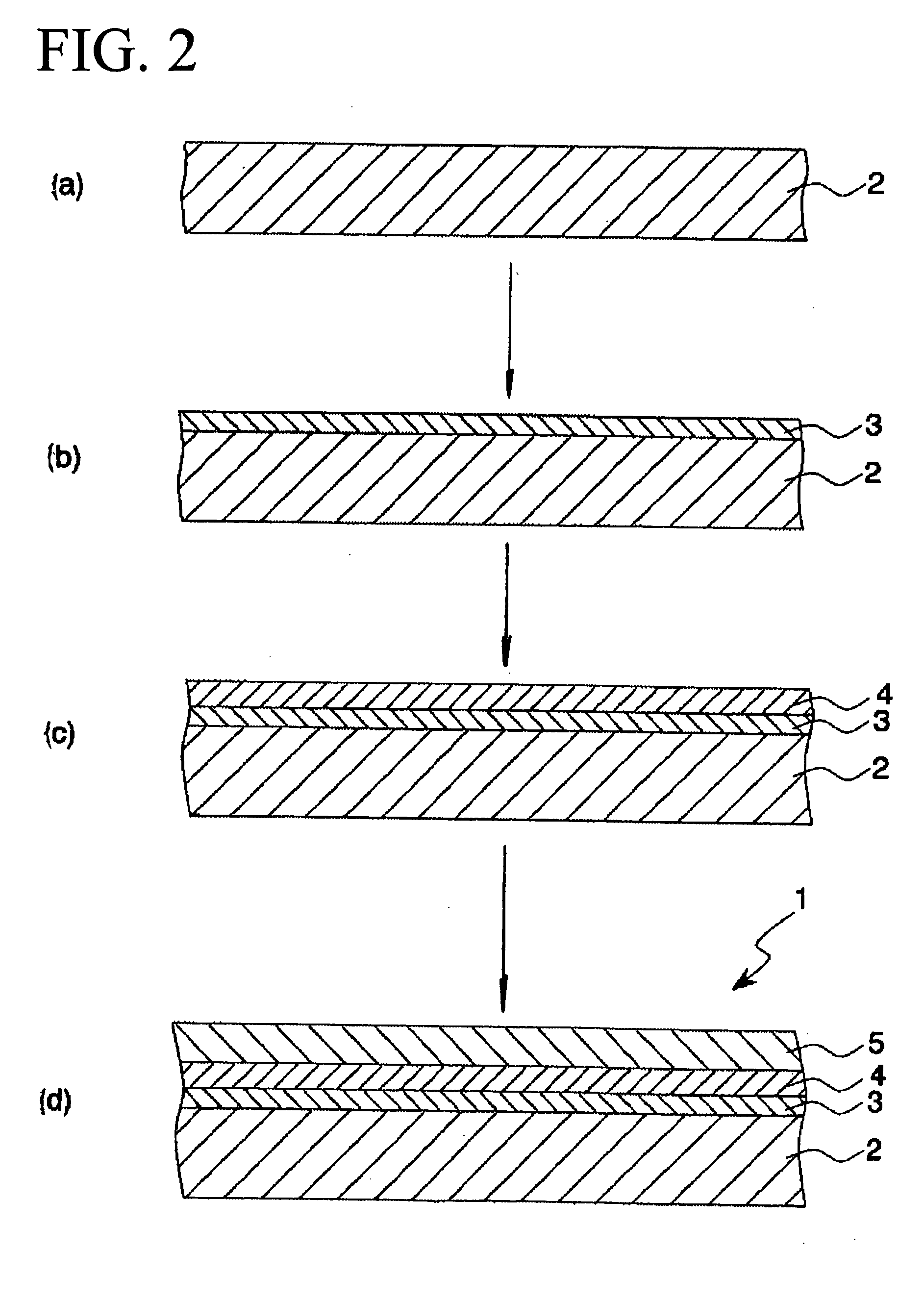

Decorative article, method of manufacturing same, and timepiece

InactiveUS20050185518A1Improve aesthetic appearanceIncreased durabilityVisual indicationVacuum evaporation coatingMicrometerPlastic materials

An ornamental article 1 has: a plastic material substrate 2; a first film 3 on the substrate 2 and made of a made of a material containing at least one substance selected from the group made of Cr, Ti, compounds of Cr, and compounds of Ti; and a second film provided adjacent to the surface of the first film that is on the opposite side of the side that faces the substrate and made of a material containing at least one metal selected from the group made of Ag and Al. It is preferred that the first film 3 contain at least one substance selected from the group made of Cr, Ti oxide, and Cr oxide. It is also preferred that the sum of the average thicknesses of the first film 3 and second film 4 be from 0.02 to 2.5 micrometers.

Owner:SEIKO EPSON CORP

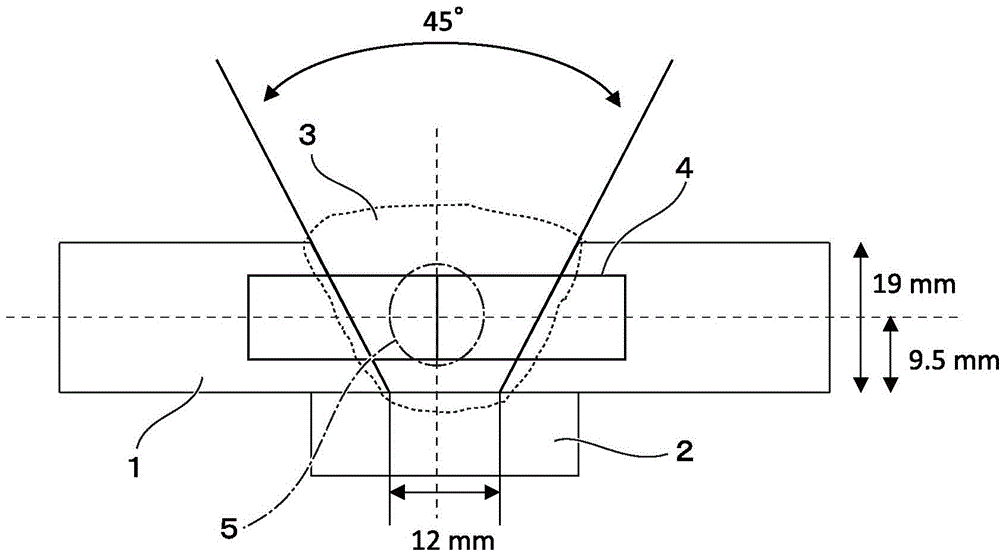

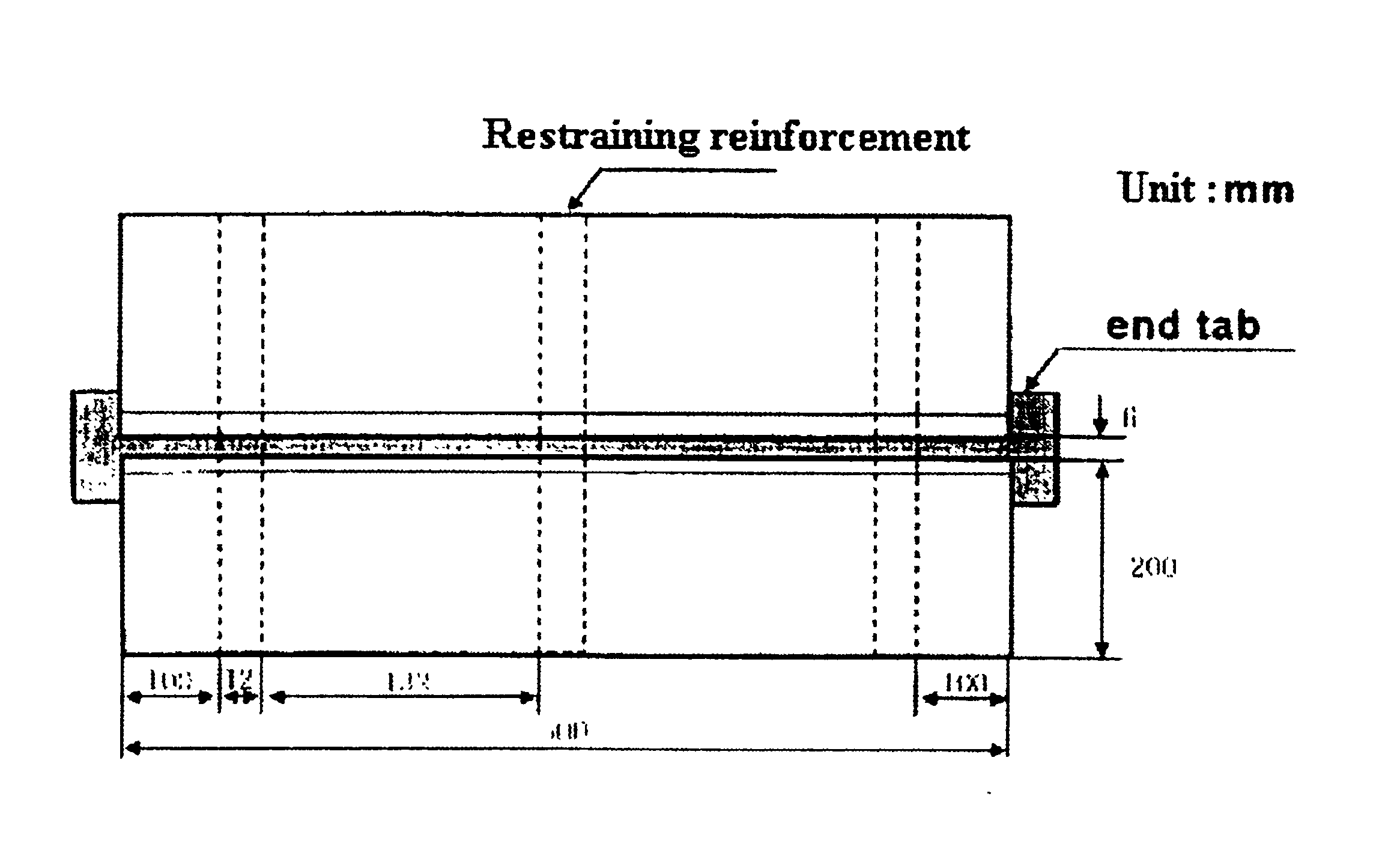

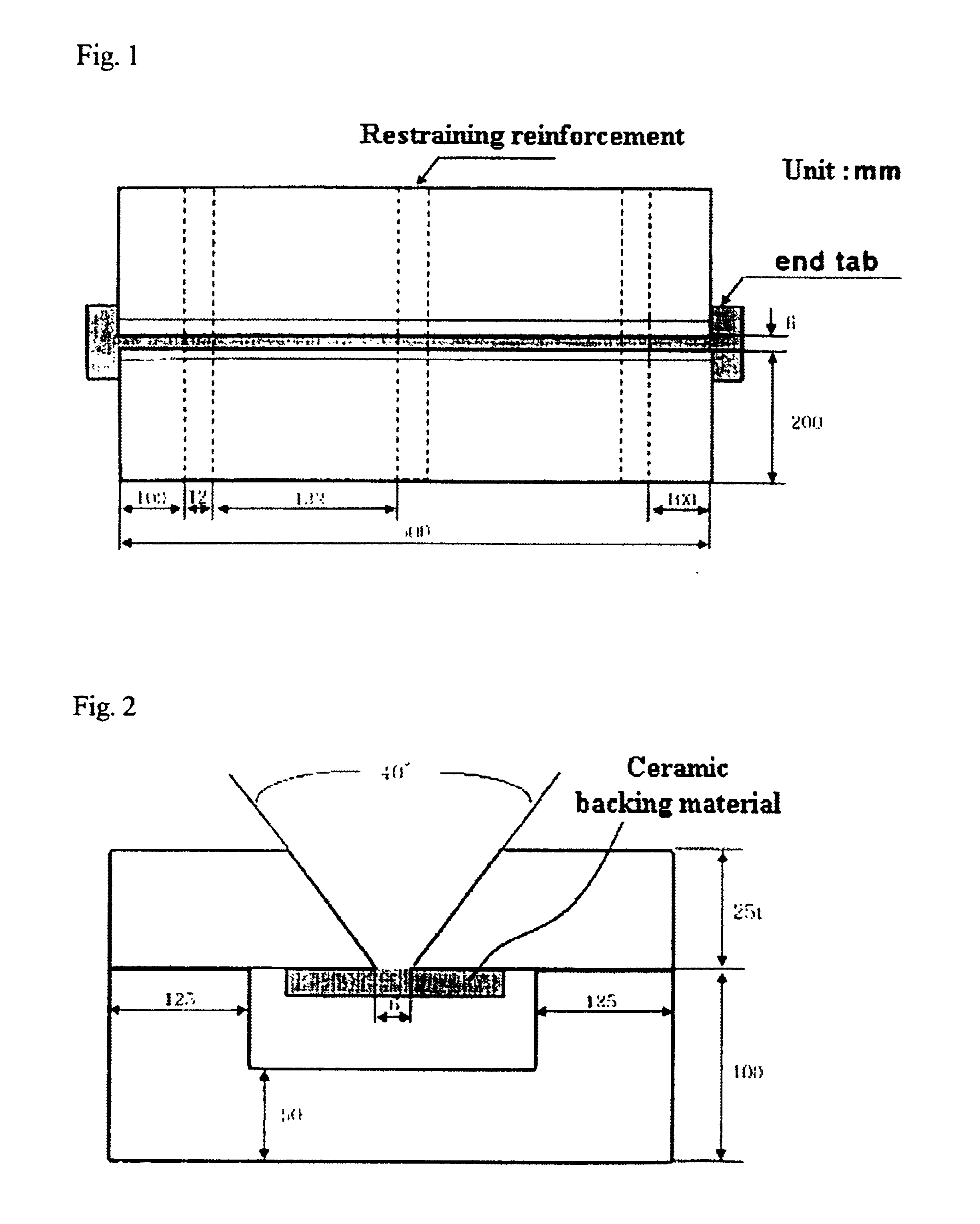

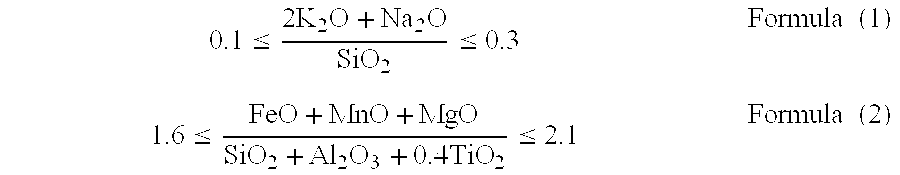

Flux cored wire, welding method using flux cored wire, method for producing welded joint using flux cored wire, and welded joint

ActiveCN104955610AImprove toughnessArc welding apparatusWelding/cutting media/materialsIron powderFlux-cored arc welding

This flux cored wire contains CaF2 and the like with the total content α of CaF2 and the like being 3.3-6.0% by mass relative to the total mass of the flux cored wire; contains Ti oxide and the like with the total content β of Ti oxide and the like being 0.4-1.2% by mass relative to the total mass of the flux cored wire; and contains CaCO3 and the like with the total content of CaCO3 and the like being 0.1-0.5% by mass relative to the total mass of the flux cored wire. The content of iron powder in the flux is less than 10% by mass relative to the total mass of the flux cored wire.

Owner:NIPPON STEEL CORP

Method for preparing spherical titanium oxide niobate anode material in large scale by utilizing spray drying method and application thereof to lithium ion battery

InactiveCN105502499AImprove electrochemical performanceLow costCell electrodesSecondary cellsAir atmosphereHigh rate

The invention discloses a method for preparing a spherical titanium oxide niobate anode material in a large scale by utilizing a spray drying method and application thereof to a lithium ion battery. The method comprises: 1, dispersing and dissolving a titanium source and a niobium source in an equal molar ratio in a solvent system, and sufficiently stirring to enable the titanium source and the niobium source to be uniformly dispersed; 2, spraying out the mixed solution in a spray dyer according to a certain flow, and drying obtained powder in an oven to obtain a precursor; 3, calcining the precursor in a high-temperature furnace in the air atmosphere at a temperature of 800 to 1,400 DEG C so as to obtain the spherical TiNb2O7 anode material. The spherical titanium-niobium composite oxide TiNb2O7 prepared by the method has excellent electrochemical performance, and has high coulombic efficiency and reversible capacity and excellent high-rate charge / discharge performance and safety performance when being used as a lithium ion battery anode material. The spherical titanium oxide niobate anode material is low in raw material cost, is non-toxic and harmless, and has a very wide application prospect.

Owner:HARBIN INST OF TECH

Basic flux cored wire with excellent weldability

InactiveUS6713723B2Improve crack resistanceLow toughnessWelding/cutting media/materialsSoldering mediaCrack resistanceShielding gas

Disclosed is a basic flux cored wire having a mild steel or an alloy steel sheath filled with flux, characterized in that the flux essentially consists of, with respect to the total weight of the wire: 0.3 to 3.0% Ti and Ti oxide (TiO2-converted value); 1.0 to 2.5% Si and Si oxide (SiO2-converted value); 0.1 to 1.5% Mg and Mg oxide (MgO-converted value); 1.5 to 4.0% Mn and Mn oxide (MnO-converted value); 0.2 to 1.5% Al and Al oxide (Al2O3-converted value); 0.1 to 1.0% Zr and Zr oxide (ZrO2-converted value); 0.2 to 3.5% CaF2; and 0.01 to 0.5% K2O, with the proviso that the components satisfy the basicity of 0.5 to 4.5 in the basicity equation (1) defined as B=(CaF2+MgO+MnO+K2O) / (TiO2+SiO2+Al2O3+ZrO2). The basic flux cored wire of the present invention is excellent in crack resistance and low temperature toughness, and exhibits excellent welding workability in all welding positions, ensuring an improvement in the efficiency of welding work. Furthermore, the basic flux cored wire according to the present invention exhibits excellent welding workability even under a shield gas of 100% CO2.

Owner:KISWEL LTD

High-energy welded high-toughness steel for resisting corrosion of molten zinc and its preparing process

A high-toughness steel welded with high linear energy (More than 50 KJ / cm) and resisting molten zinc corrosion is prepared through converter smelting at 1250-1320 deg.C, vacuum treating, and rolling at 1000-1180 deg.c or lower than 950 deg.C and cumulative drafts rate is greater than or aqual to 50%. It features that composite Ti oxide is used to resist high linear energy, the Nb, V, etc. and used for raising strength, and the Cu, Ni, B and RE are used to resist molten zinc corrosion. Its advantages are simple technology with high efficiency, low cost, and high performance of finished steel.

Owner:武钢集团有限公司

Ti oxide film having visible light-responsive photocatalytic activites and process for its production

InactiveUS20060225999A1High transparencyHydrophilicity and antifogging propertyDispersed particle separationVacuum evaporation coatingUltraviolet lightsLight responsive

To provide a visible light responsible Ti oxide film which has hydrophilicity and antifogging property and is excellent in transparency and which has an ability to decompose gas by UV radiation, and a process for its production, as well as a Ti oxide film-coated substrate. A Ti oxide film formed on a substrate, characterized in that when a voltage is applied to the Ti oxide film while the Ti oxide film is irradiated with light of a xenon lamp having a luminance of 100 mW / cm2 and having ultraviolet light of less than 400 nm cutoff, the electric current value is at least 1,000 times the electric current value when the same voltage as said voltage is applied to the Ti oxide film in a dark place.

Owner:ASAHI GLASS CO LTD

Production of coating anode for electrolysis

InactiveCN1680625AImprove conductivityCan control the thicknessSuperimposed coating processElectrodesPlatinumElectrolysis

A process of preparing coating positive pole for electrolyzation. The coating positive pole bases Ti. Middle layer is oxide Ti. Outside layer is Pt or Pt-Ru oxidate. The coat can be obtained by way of electrochemical oxidation or heat decomposition.

Owner:SHANGHAI UNIV +1

High-activity nano-grade flue gas denitrification catalyst and low-temperature liquid-phase preparation method thereof

ActiveCN103127930AImprove composite propertiesGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitric oxide

The invention provides a high-activity nano-grade flue gas denitrification catalyst for removing nitric oxides in fuel gas under a low temperature condition, and a low-temperature liquid-phase preparation method of the high-activity nano-grade flue gas denitrification catalyst. The method does not relate to high-temperature roasting; and the prepared catalyst exists in a manner of a lot of amorphous state mixed oxides, and the activity is obviously improved. The high-activity nano-grade flue gas denitrification catalyst can be widely applied to selective catalytic reduction reaction of the fuel gas under an SO2-free or low-concentration SO2 environment of the fuel gas, so as to reduce the nitric oxides in the fuel gas into N2 and H2O. The catalyst takes a Ti oxide as a main component and is at least loaded with Mn-Ce-M-Ti-Ox of compound oxides of active components Mn and Ce, wherein M represents one or more elements of Fe, Co, Cu, Cr, Zr, Al and V; and the mol ratio of the elements is as follows: Ti: Mn: Ce: M is equal to 1: (0.005-1): (0.005-1): (0-0.3).

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

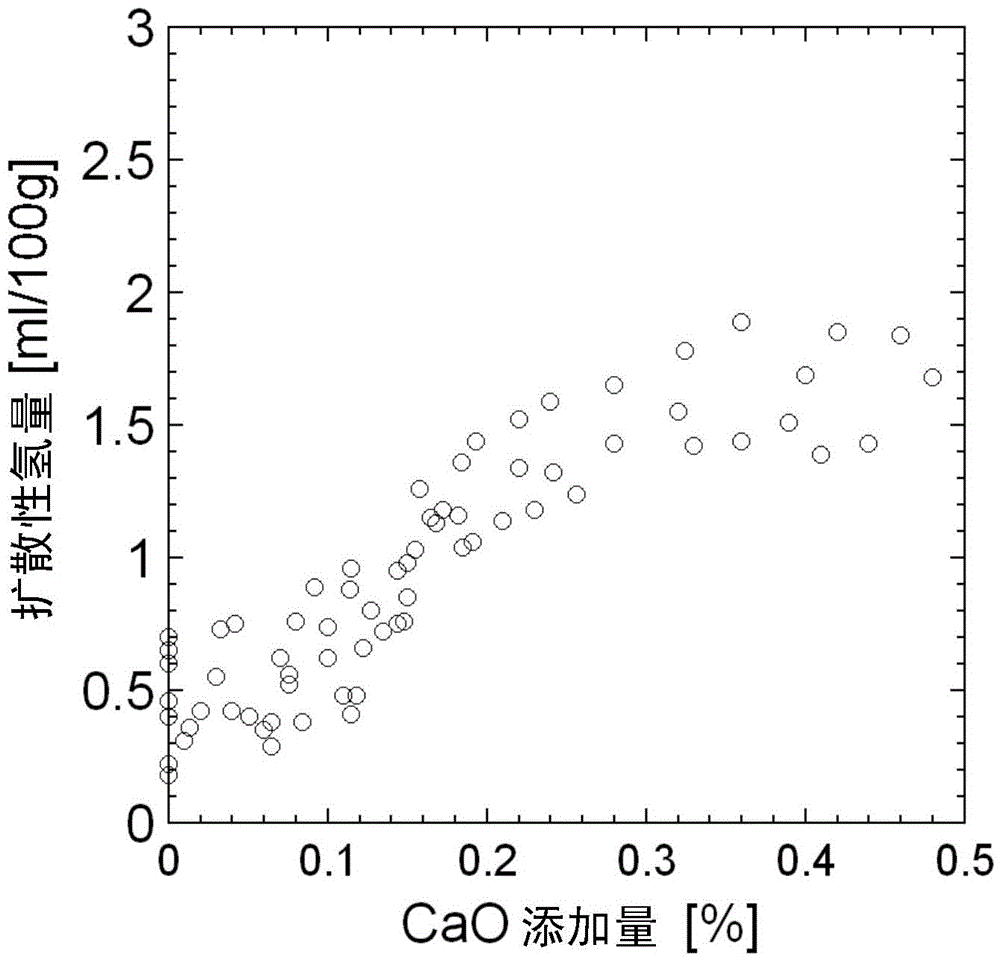

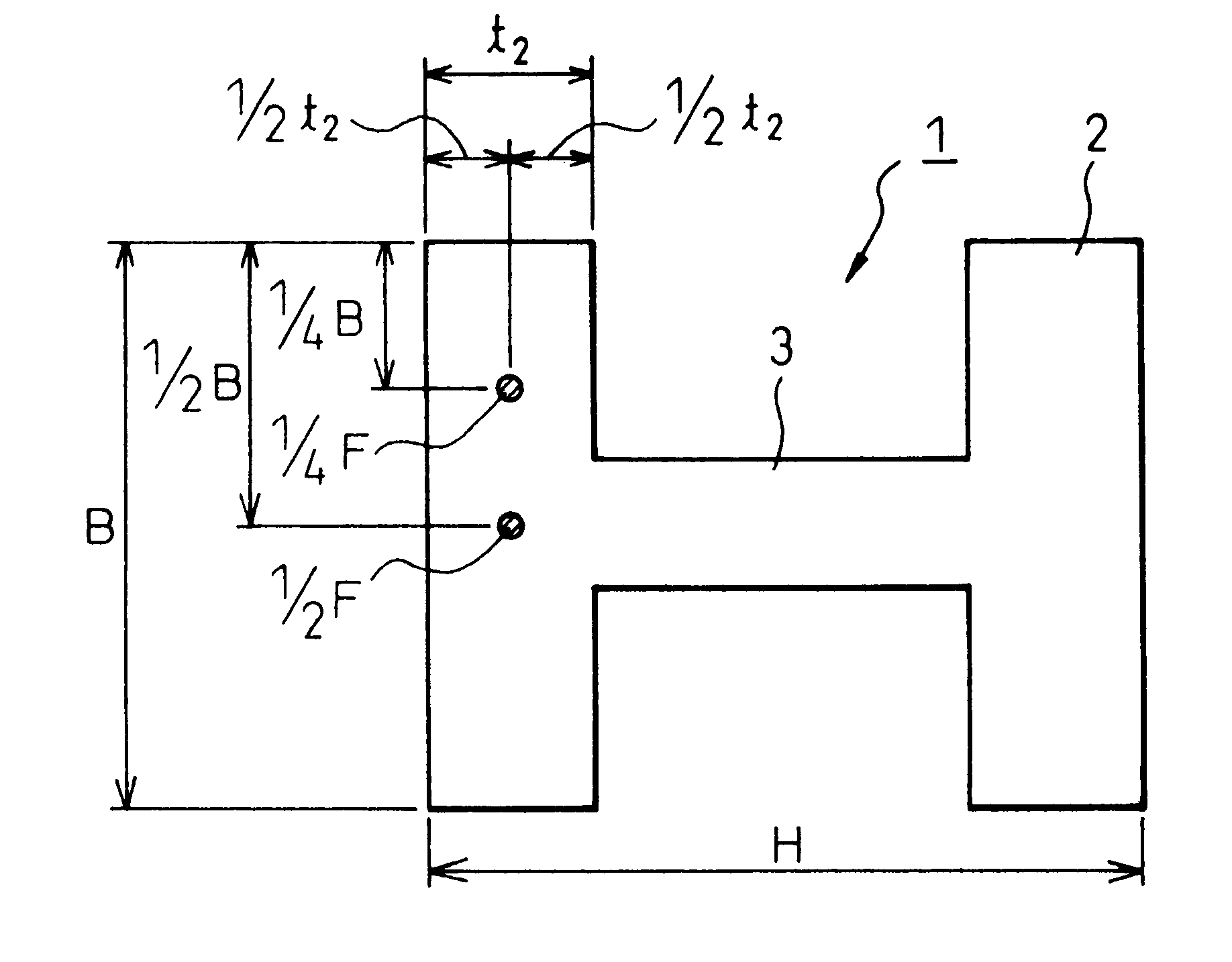

Steel with good cutting and cutting breaking performance for physical construction

Disclosed is a steel for machine structural use having good machinability and chip-breakability as well as a method of producing the steel. The steel consists essentially of, by wt.%, C: 0.05-0.8%, Si: 0.01-2.0%, Mn: 0.1-3.5%, S: 0.01-0.2%, Al: 0.001-0.020%, Ca: 0.0005-0.02%, O: 0.0005-0.01% and N: 0.001-0.04%, and further, one or both of Ti: 0.002-0.010% and Zr: 0.002-0.025%, the balance being Fe and inevitable impurities. At production of the steel controlled deoxidization is conducted by operation meeting certain conditions so that at least a certain amount of ''duplex inclusion'' having a specific chemical composition may be formed, and Ti and / or Zr is added to precipitate finely dispersed MnS inclusion particles with nuclei of Ti-oxide and / or Zr-oxide. The finely dispersed MnS inclusions must share a determined part of the total sulfide inclusions.

Owner:DAIDO STEEL CO LTD

Honeycomb manganese denitration catalyst and preparation method thereof

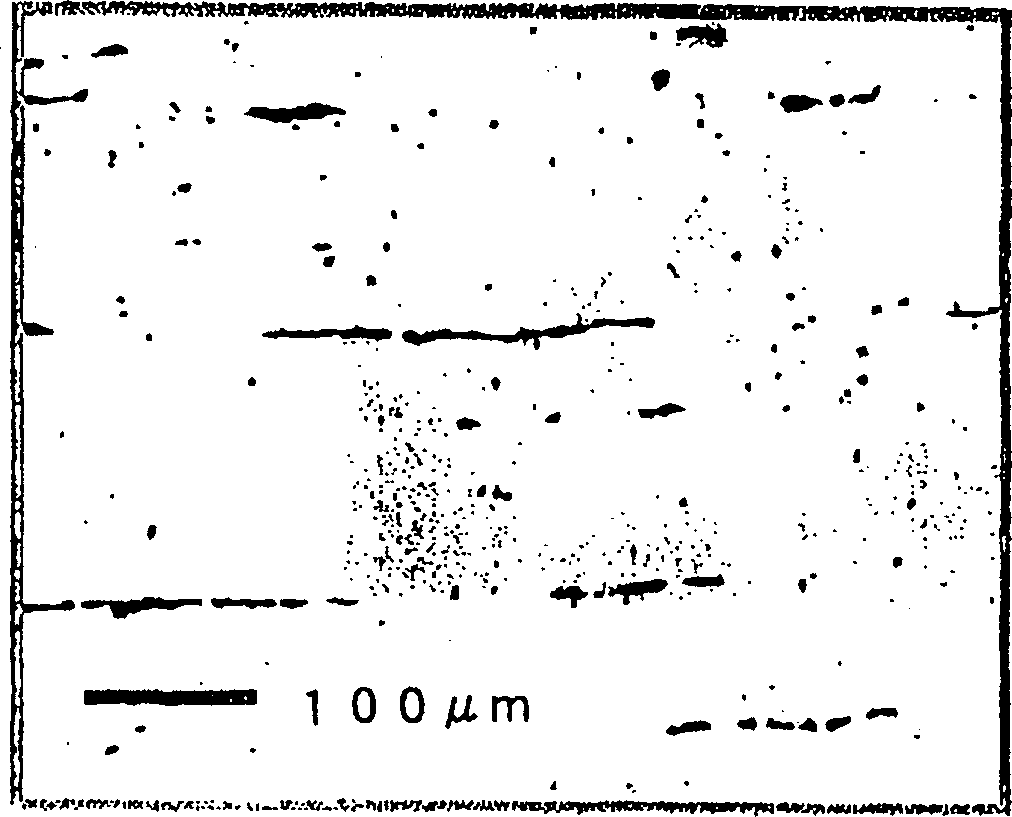

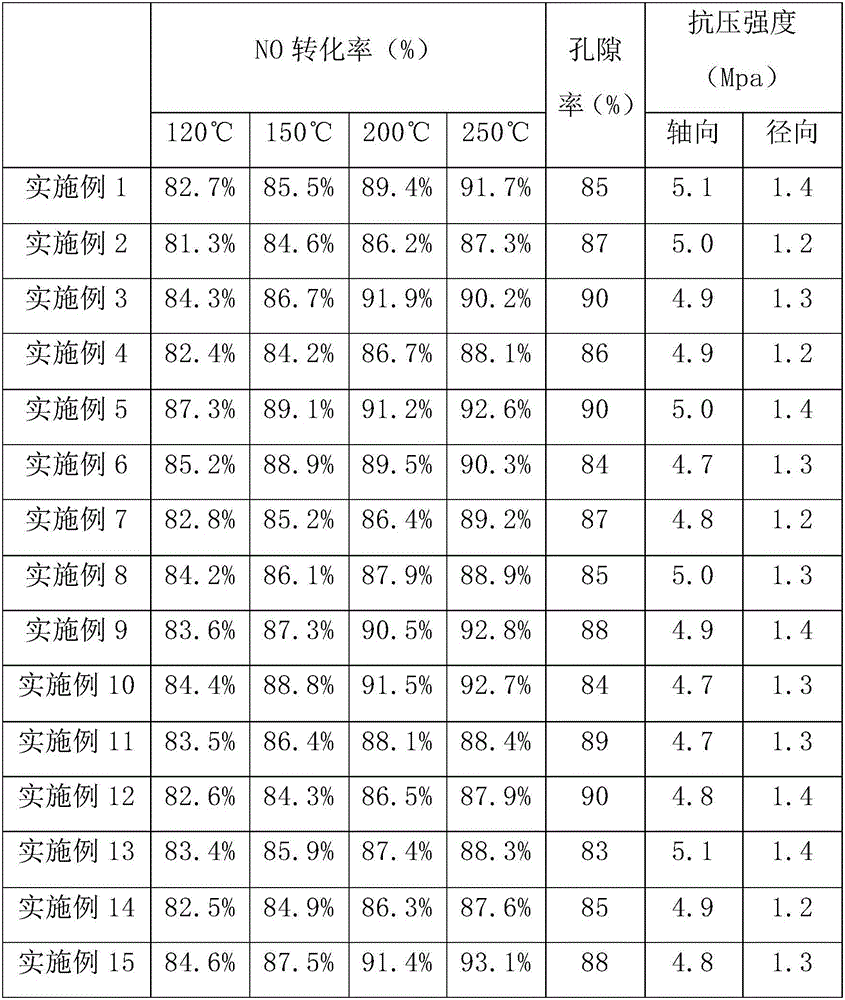

ActiveCN106423193AAvoid crackingNot easy to cause crackingGas treatmentHeterogenous catalyst chemical elementsPorosityDispersity

The invention relates to a honeycomb manganese denitration catalyst and a preparation method thereof. The method includes the following steps that manganese salt and a complexing agent are dissolved in water, titanium dioxide is added and stirred, ultrasonic dipping, drying and grinding are conducted, and Mn-Ti oxide solid particles are obtained, wherein the molar ratio of the manganese salt to the complexing agent is (65-187):1; metal salt and cerium salt are dissolved in water to obtain a mixed metal solution, wherein metal salt is at least one of ferric salt, cobalt salt, lanthanum salt, antimony salt and nickel salt; a pore-forming agent, an adhesive, an extrusion aid, a reinforcing agent, the Mn-Ti oxide solid particles and the mixed metal solution are mixed and formed into a honeycomb blank, and drying and forging are conducted. The catalyst is good in active component dispersity, is not easily sintered, good in pore structure, large in porosity and high in mechanical strength, the axial compressive strength of the catalyst is 4.7-5.1 MPa, and the radial compressive strength of the catalyst is 1.2-1.4 MPa. The porosity of the catalyst is 84-90%. The catalyst prepared through the method has relatively high denitration activity in the range of 120-250 DEG C and is suitable for low-temperature denitration.

Owner:CHINA BUILDING MATERIALS ACAD

Low-temperature catalyst and preparation method thereof

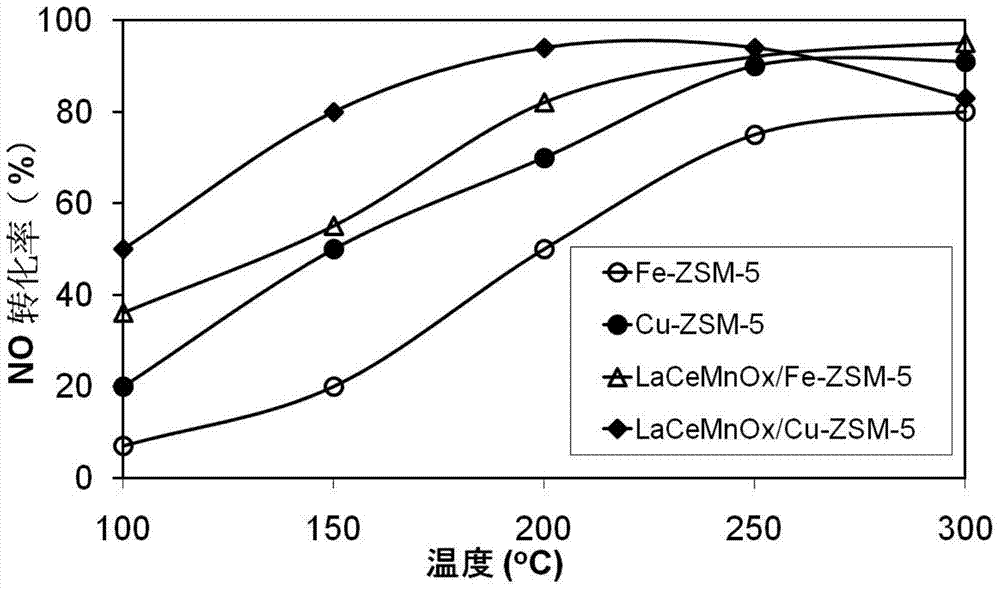

InactiveCN103566964AHigh reactivityMolecular sieve catalystsDispersed particle separationMolecular sievePhysical chemistry

The invention discloses a low-temperature catalyst. The low-temperature catalyst comprises one or more lanthanide series metal oxides and / or one or more transition metal oxides and / or one or more alkali or alkaline earth metal oxides, and also comprises copper and iron molecular sieve catalysts. The one or more lanthanide series metal oxides are selected from La, Ce, Zr and Nb oxides and have a use ratio of 1-50wt%. The one or more transition metal oxides are selected from Fe, Co, Ni, Cu, Mn, Zn, V, W, Mo and Ti oxides and have a use ratio of 1-50wt%. The one or more alkali or alkaline earth metal oxides are selected from Li, K, Cs, Ba, Sr and Ca oxides and have a use ratio of 1-30wt%. The copper and iron molecular sieve catalysts comprise aluminosilicate zeolite and / or aluminum phosphate molecular sieves. Through loading the one or more composite oxides on the copper and iron molecular sieve catalysts, the oxidizing agent for oxidizing NO into NO2 is obtained and reaction activity of whole SCR is improved.

Owner:无锡科立泰科技有限公司

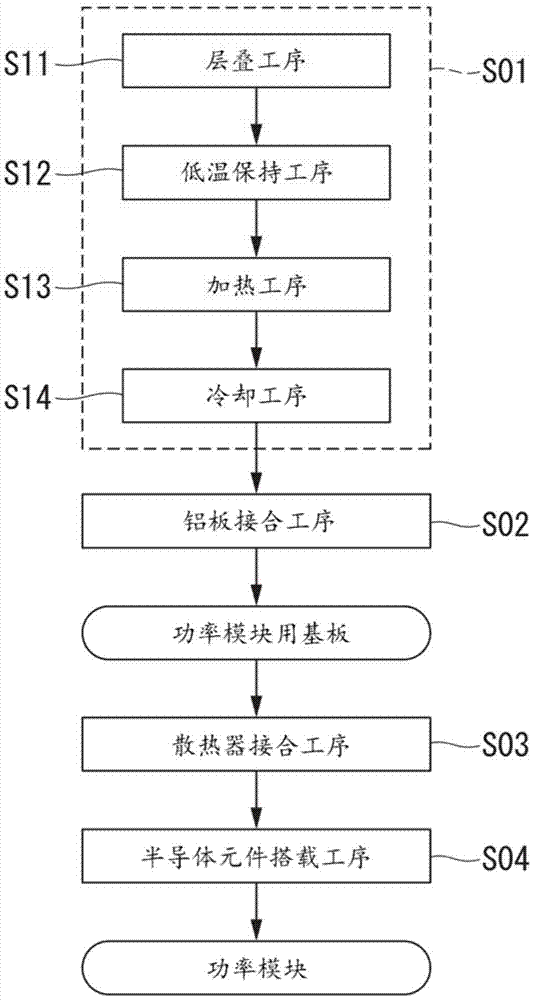

Cu/ceramic material joint, method for manufacturing Cu/ceramic material joint, and substrate for power module

ActiveCN105452195AReliable jointPromote generationSemiconductor/solid-state device detailsSolid-state devicesNitrideCopper alloy

A Cu / ceramic material joint according to the present invention is produced by joining a copper member comprising copper or a copper alloy to a ceramic member comprising AlN or Al2O3 using a joint material containing Ag and Ti, wherein a Ti compound layer comprising a Ti nitride or a Ti oxide is formed at the joint interface between the copper member and the ceramic member, and Ag particles are dispersed in the Ti compound layer.

Owner:MITSUBISHI MATERIALS CORP

Nonvolatile semiconductor memory and method of manufacturing the same

ActiveUS20080237697A1Increase storage capacityIncreasing threshold variation widthTransistorSemiconductor/solid-state device manufacturingNitrogenOptoelectronics

Owner:KIOXIA CORP

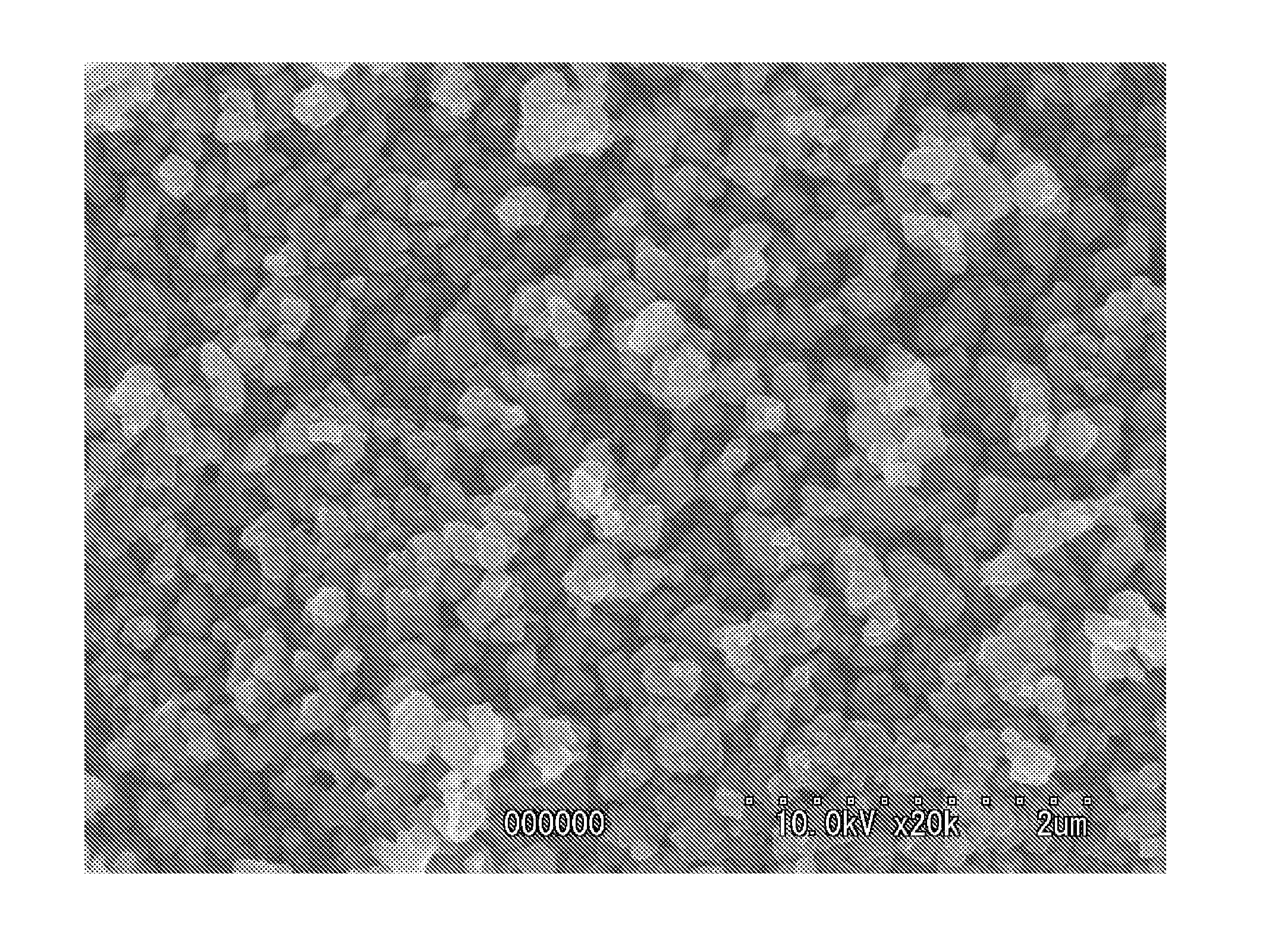

Lithium titanate particles and process for producing the lithium titante particles, MG-Containing lithium titanate particles and process for producing the MG-Containing lithium particles, negative electrode active substance particles for non-aqueous electrolyte secondary batteries, and non-aqeous electrolyte secondary battery

ActiveUS20130244114A1Well-balanced battery characteristicImprove output characteristicsAlkaline earth titanatesAlkali titanatesFiltrationLattice constant

According to the present invention, there are provided lithium titanate particles which exhibit an excellent initial discharge capacity and an enhanced high-efficiency discharge capacity retention rate as an active substance for non-aqueous electrolyte secondary batteries and a process for producing the lithium titanate particles, and Mg-containing lithium titanate particles. The present invention relates to lithium titanate particles with a spinel structure comprising TiO2 in an amount of not more than 1.5%, Li2TiO3 in an amount of not less than 1% and not more than 6%, and Li4Ti5O12 in an amount of not less than 94% and not more than 99% as determined according to Rietveld analysis when indexed with Fd-3m by XRD, and having a specific surface area of 7 to 15 m2 / g as measured by BET method, a process for producing lithium titanate particles comprising the steps of adding and mixing a water-soluble lithium solution into a water suspension of an oxide of titanium having a BET specific surface area of 40 to 400 m2 / g and a primary particle diameter of 5 to 50 nm and subjecting the resulting mixed suspension to aging reaction at a temperature of 50 to 100° C.; subjecting the resulting reaction product to filtration, drying and pulverization; and subjecting the obtained dry particles to heat-calcination treatment at a temperature of 550 to 800° C., and Mg-containing lithium titanate particles having a composition represented by the formula: LixMgyTizO4 wherein x, z>0; 0.01≦y≦0.20; 0.01≦y / z≦0.10; and 0.5≦(x+y) / z≦1.0, the Mg-containing lithium titanate particles having a BET specific surface area of 5 to 50 m2 / g, a spinel single phase as a crystal structure, and a lattice constant (a) represented by a value of 0.050y+8.3595<a≦0.080y+8.3595 (Å).

Owner:TODA IND

High-strength, high-toughness rolled shape steel and method of producing the same

InactiveUS6364967B1Enabling effective texture grain refinementImprove toughnessFurnace typesHeat treatment furnacesTemperature controlSheet steel

A 590 MPa-class rolled steel shape of high strength and excellent toughness for use as a building structural member and a method of producing the high-tensile rolled steel shape are provided. Strength optimization by an alloy that elevates hardenability, texture refinement obtained by fine dispersion of Ti oxides and TiN owing to Ti addition, precipitation strengthening by Cu addition, and formation of a fine bainite texture by temperature-controlled rolling, cooling control and the like enable a high-strength, high-toughness rolled steel shape of high-strength and excellent toughness having mechanical properties of a tensile strength of not less than 590 MPa, a yield strength or 0.2% proof strength of not less than 440 MPa and a Charpy impact absorption energy at 0° C. of not less than 47 J, and method of producing the same.

Owner:NIPPON STEEL CORP

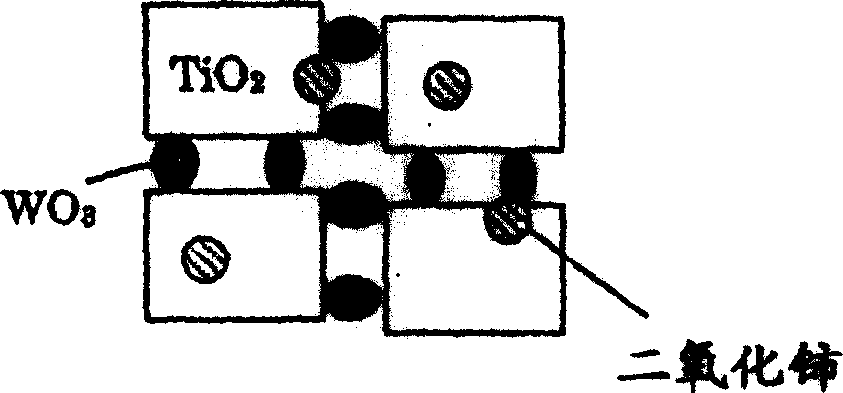

Catalyst for removing nitrogen oxides, method for production thereof and method for removing nitrogen oxides

InactiveCN1642636AHigh activityImprove heat resistanceExhaust apparatusDispersed particle separationCerium(IV) oxideIon exchange

Disclosed is a method for producing a catalyst for removing nitrogen oxides which comprises dispersing a hydrated titanium (Ti) oxide or dried material thereof, tungstic acid or a salt thereof, and cerium (Ce) dioxide in a dispersion medium to form a sol-like material, mixing the sol-like material with an aqueous medium to form a catalyst slurry or paste, supporting the catalyst slurry or paste on a catalyst carrier, and then calcinating the carrier; in which catalyst the Ce dioxide is prevented from being embedded in the Ti oxide to realize such a high degree of dispersion of the Ce dioxide on the surface of the Ti oxide as comparable with the case wherein cerium ions are dispersed in micro voids of a zeolite by ion exchange; and the catalyst is free from the occurrence of such phenomena as sintering of the Ti oxide, and deterioration of zeolite with steam when a zeolite is used as carrier.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

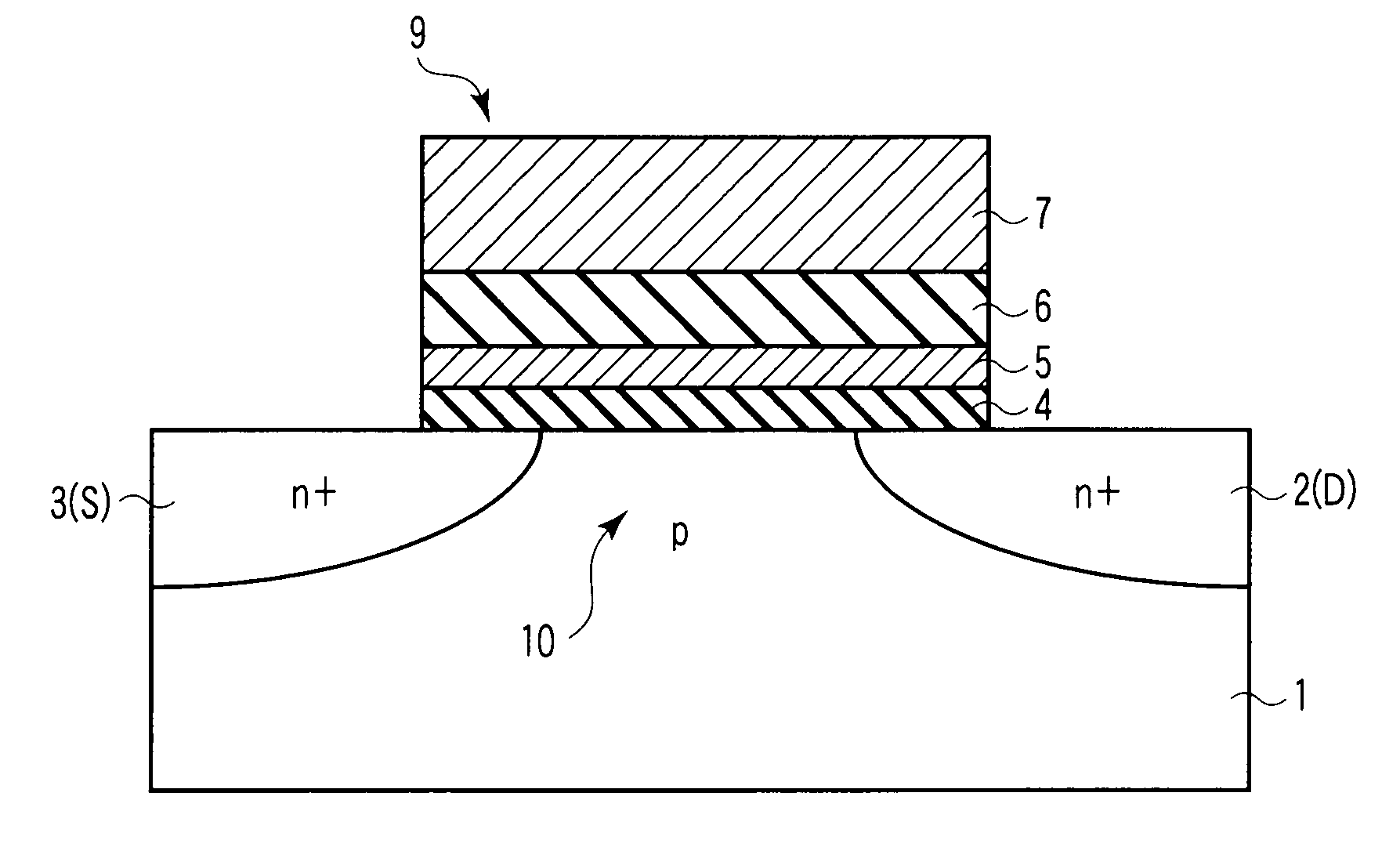

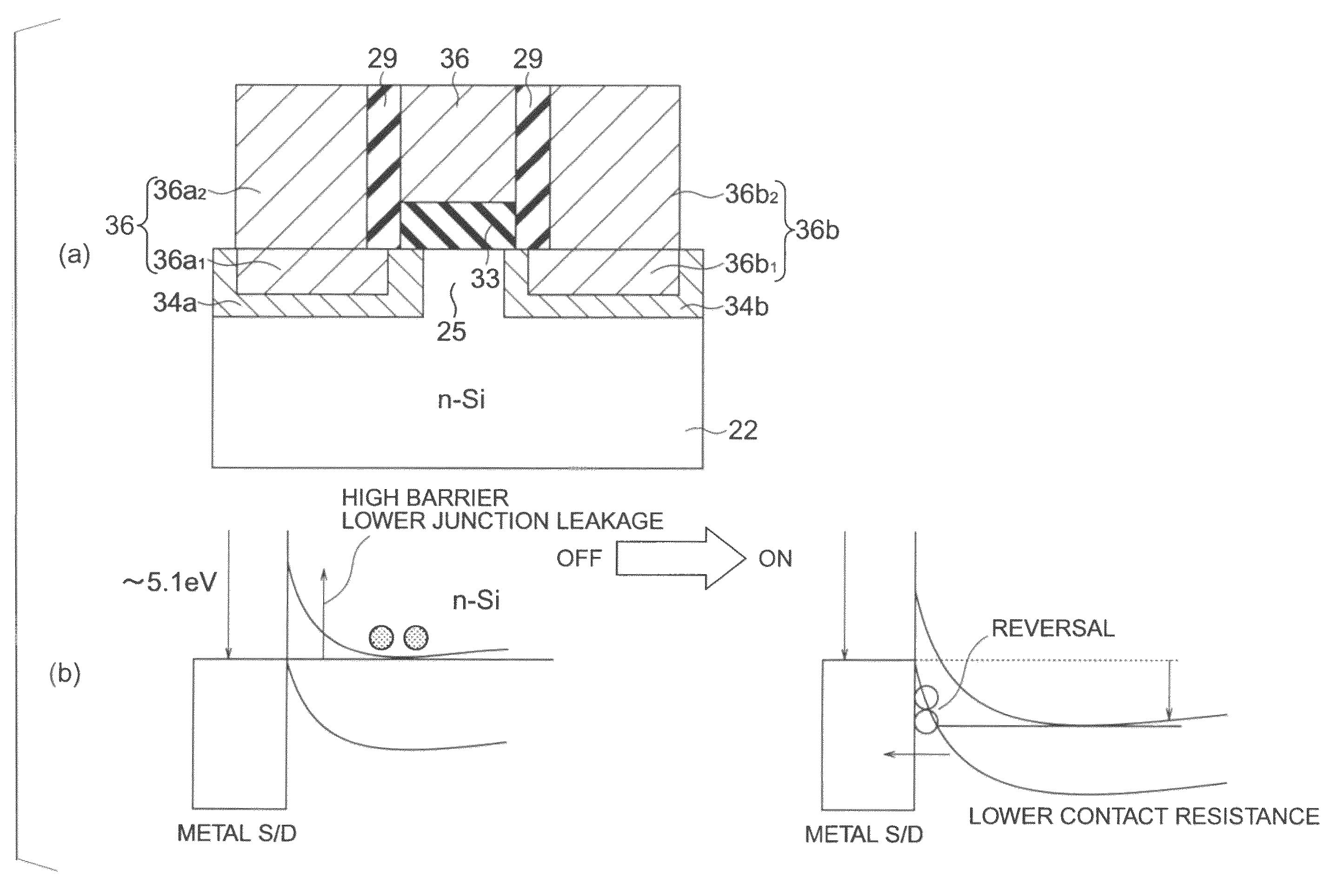

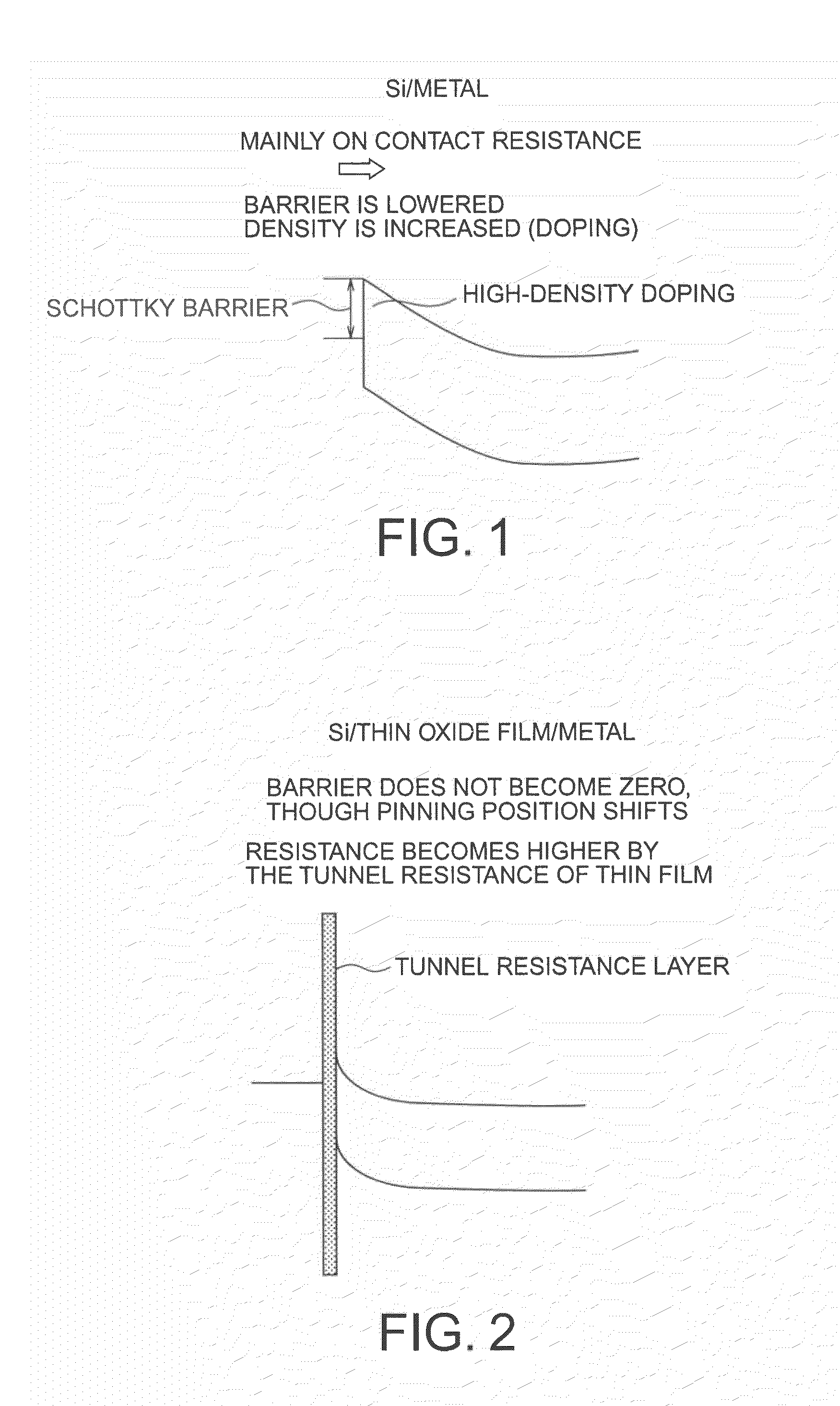

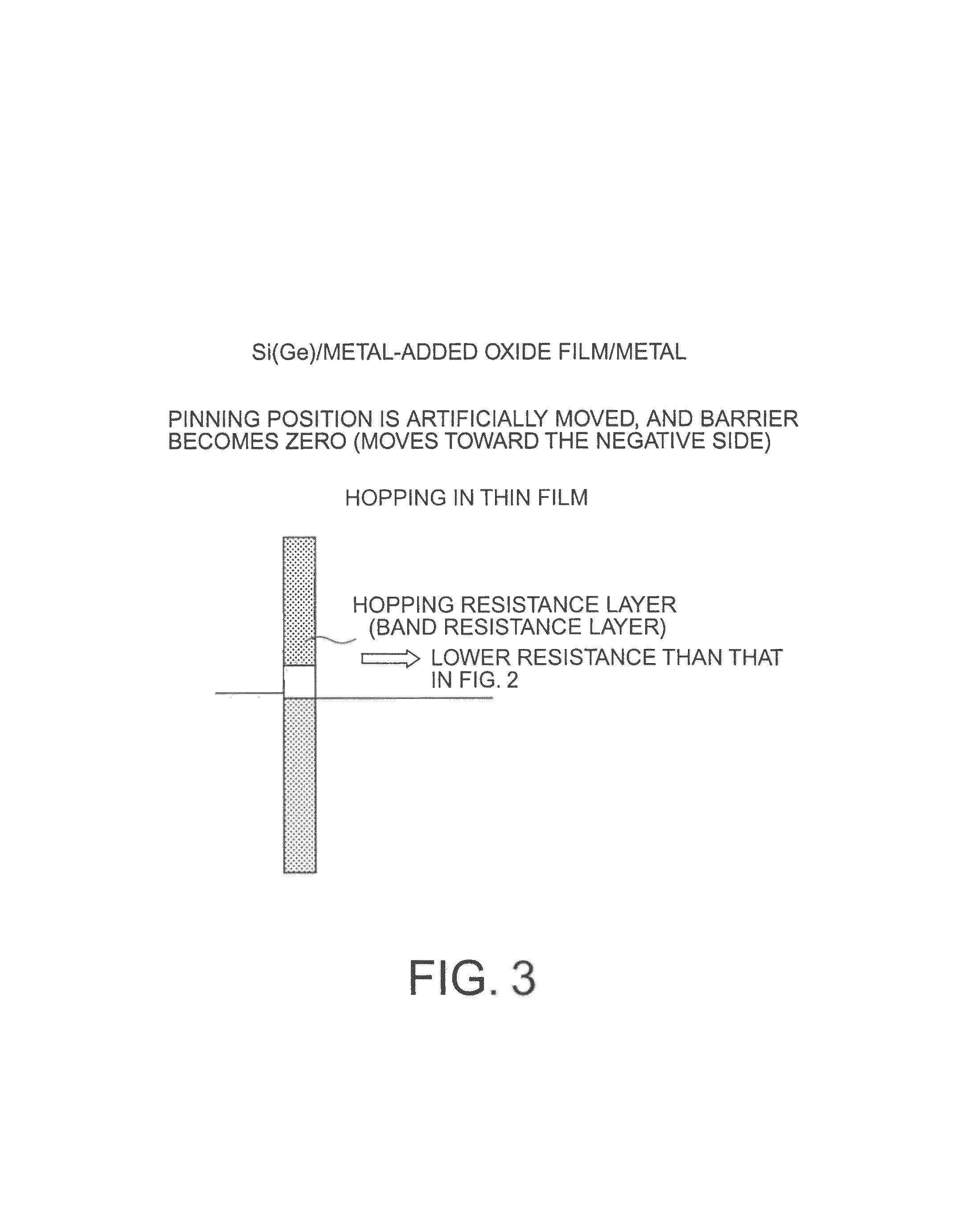

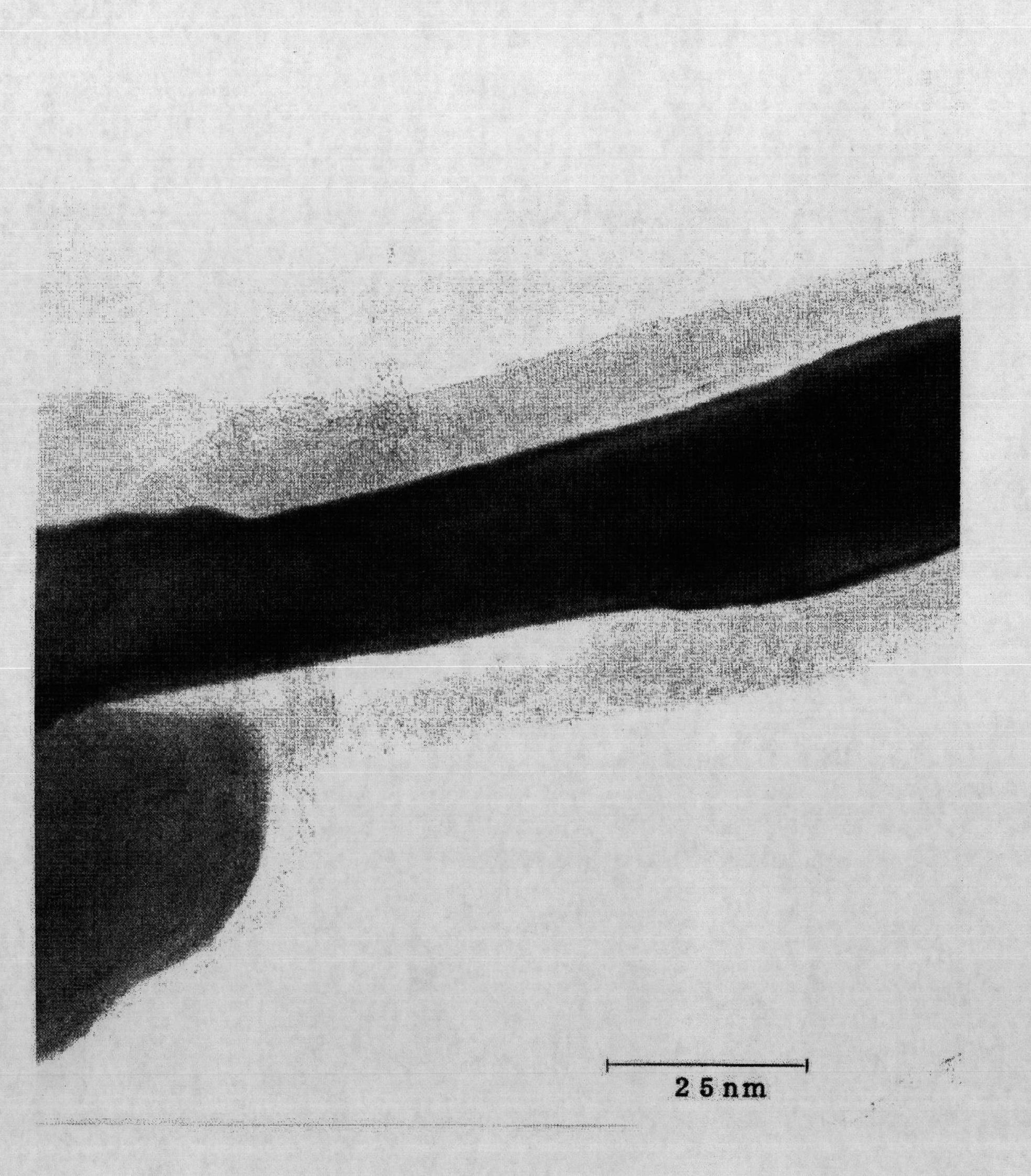

Semiconductor device

InactiveUS8299507B2Function optimizationInhibition resistanceTransistorSemiconductor/solid-state device detailsPower semiconductor deviceWork function

It is made possible to optimize the effective work function of the metal for a junction and suppress the resistance as far as possible at the interface between a semiconductor or a dielectric material and a metal. A semiconductor device includes: a semiconductor film; a Ti oxide film formed on the semiconductor film, and including at least one element selected from the group consisting of V, Cr, Mn, Fe, Co, Ni, Nb, Mo, Tc, Ru, Rh, Pd, Ta, W, Re, Os, Ir, and Pt; and a metal film formed on the Ti oxide film.

Owner:KK TOSHIBA

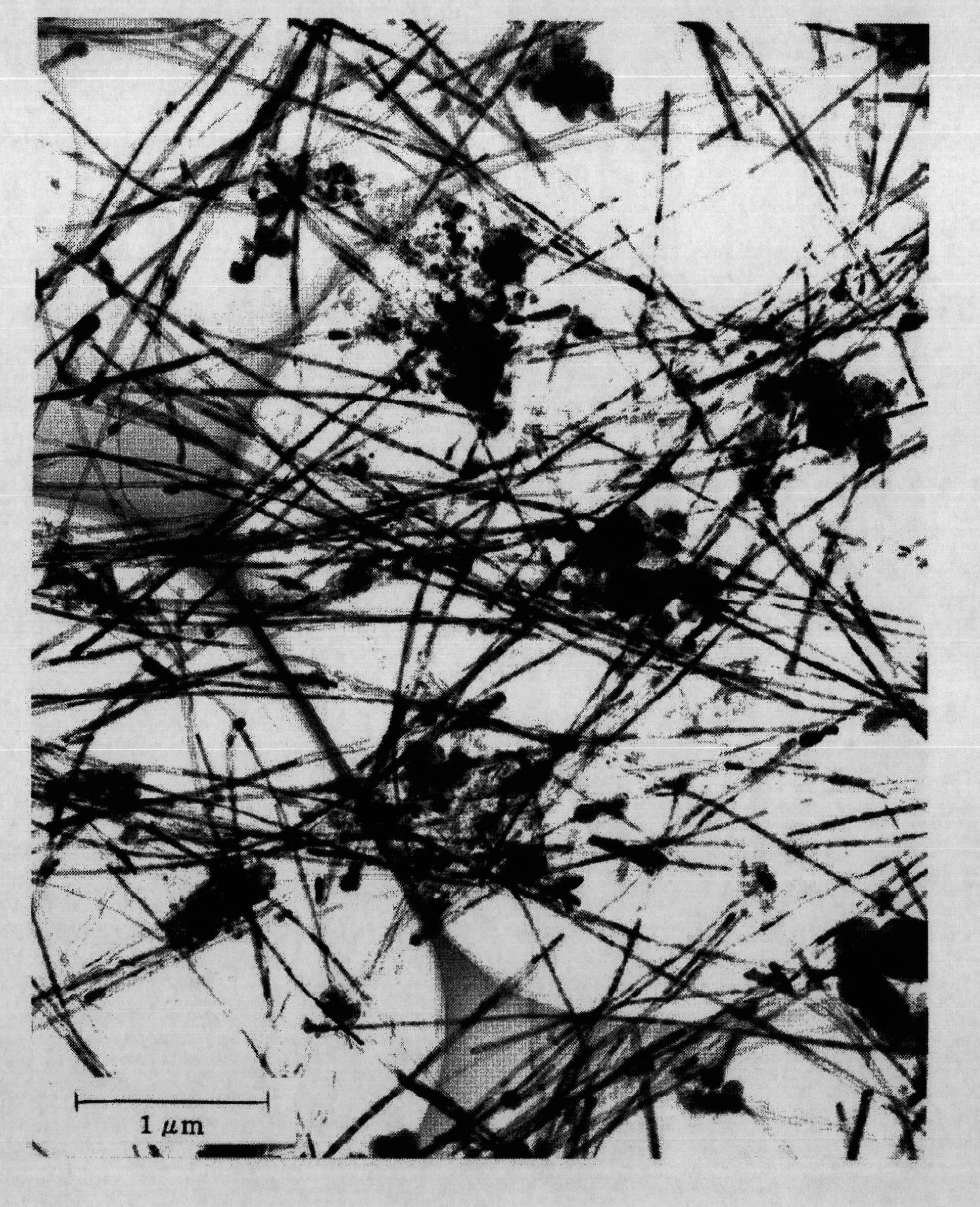

Titanium oxide coated carbon fiber and porous titanium oxide coated carbon material composition

InactiveCN102066243AEfficient migrationPigmenting treatmentMaterial nanotechnologyCarbon fibersElectrical battery

Owner:OSAKA GAS CO LTD

Flux-cored wire, welding method using flux-cored wire, method for manufacturing weld joint using flux-cored wire, and weld joint

ActiveUS20150360327A1Improve toughnessReduce warm-upArc welding apparatusWelding/cutting media/materialsIron powderTi oxides

In a flux-cored wire according to the present invention, CaF2 and the like are included and a total amount thereof α is 3.3 to 6.0% in terms of mass % with respect to a total mass, Ti oxide and the like are included and a total amount thereof β is 0.4 to 1.2% in terms of mass % with respect to the total mass, CaCO3 and the like are included and a total amount thereof is 0.1 to 0.5% in terms of mass % with respect to the total mass, and an amount of an iron powder in the flux is less than 10% in terms of mass % with respect to the total mass.

Owner:NIPPON STEEL CORP

Flux cored wire for gas-shielded arc welding

InactiveUS20020060212A1Improve abilitiesEasy to shapeArc welding apparatusWelding/cutting media/materialsAlloyArc welding

The flux cored wire comprises, with respect to the total weight of the wire, a Ti and a Ti oxide of 3.0 wt % to 8.0 wt % as calculated in terms of TiO2 content, a Si and a Si oxide of 0.5 wt % to 2.0 wt % as calculated in terms of SiO2 content, a metal Mn and an alloy of Mn of 1.5 wt % to 3.5 wt % as calculated in terms of Mn content, a carbon (C) of 0.02 wt % to 0.10 wt %, an Mg and an Mg oxide of 0.5 wt % to 1.5 wt % as calculated in terms of MgO content, a compound of Na2O and K2O of 0.2 wt % and less, a Zr and a Zr oxide of 0.1 wt % to 0.5 wt % as calculated in terms of ZrO2 content, and an Al and an Al oxide of 0.2 wt % to 0.8 wt % as calculated in terms of A12O3 content.

Owner:KISWEL LTD +1

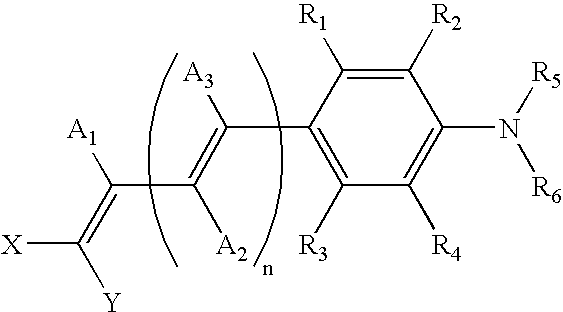

Modified Titanium Oxide Microparticle and Photoelectric Transducer Making Use of the Same

InactiveUS20080110497A1Increase the open circuit voltageHigh voltageElectrolytic capacitorsFinal product manufactureTransducerSilicon oxide

[PROBLEMS] To develop metal microparticles useful in dye-sensitized solar cell, etc. and to provide a photoelectric transducer capable of exhibiting enhanced release voltage in dye-sensitized solar cell.[MEANS FOR SOLVING PROBLEMS] There are provided modified titanium oxide microparticles comprised of titanium oxide and one or two or more types of nontitanic metal oxides (including silicon oxides) selected from the group consisting of periodic-table group IB oxides, group IIA oxides, group IIB oxides, group IIIA oxides, group IIIB oxides, group IVA oxides other than titanium oxides, group IVB oxides, group VIA oxides, group VIII oxides and vanadium oxides.Further, there is provided a photoelectric transducer making use of the modified titanium oxide microparticles.

Owner:NIPPON KAYAKU CO LTD

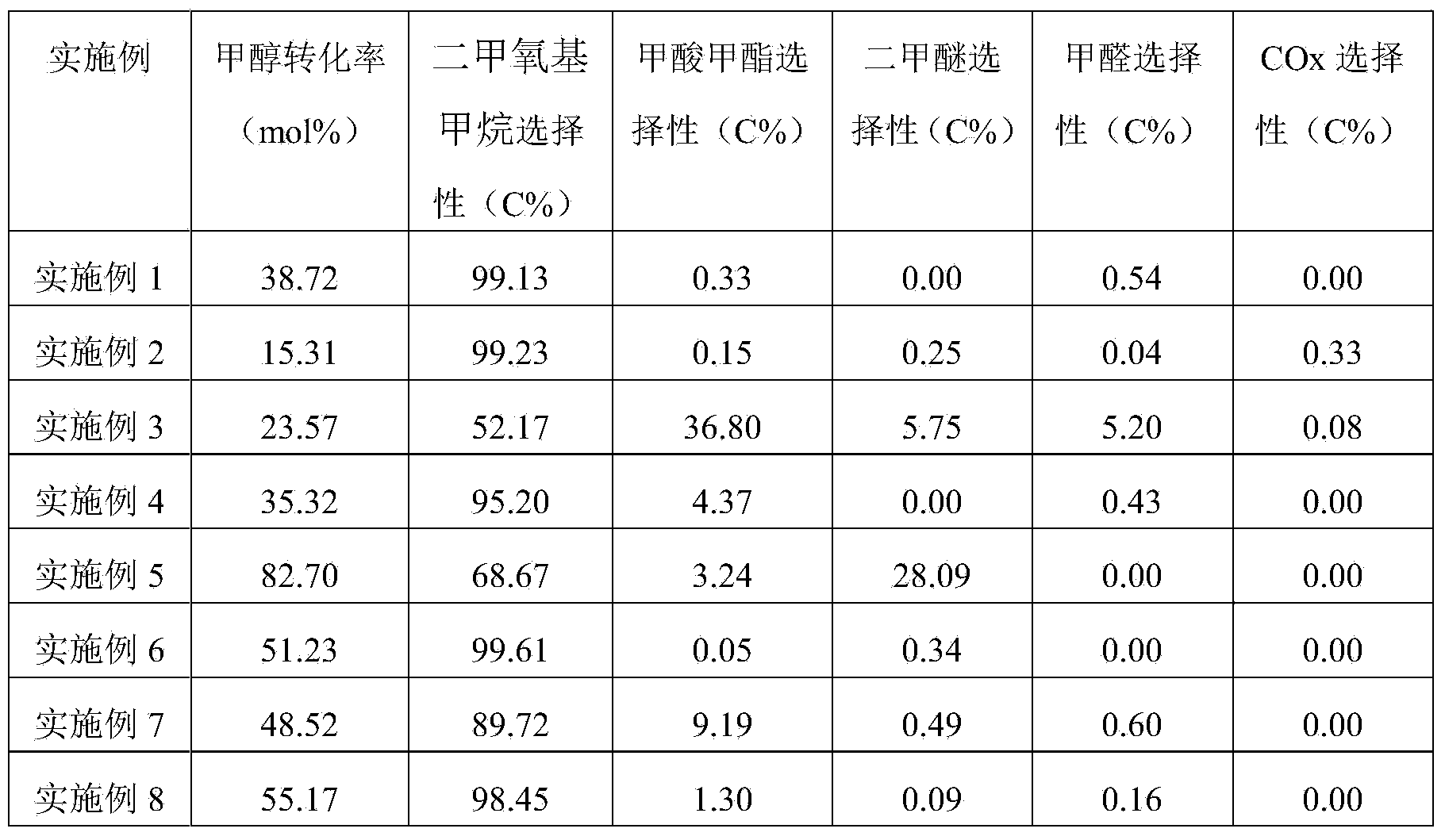

Catalyst for oxidizing and synthesizing dimethoxymethane by methyl alcohol as well as preparation method and application thereof

ActiveCN103933965AHigh yieldHigh selectivityOrganic chemistryOrganic compound preparationAlcoholActive component

The invention discloses a catalyst for oxidizing and synthesizing dimethoxymethane by methyl alcohol. The catalyst for oxidizing and synthesizing dimethoxymethane by methyl alcohol consists of vanadium oxide serving as a main catalytic active component, titanic oxide serving as an auxiliary catalytic active component and auxiliary metallic oxide with the composition in mass percentage: 6-60wt% of V2O5, 40-95wt% of TiO2 and 0-55wt% of auxiliary metallic oxide. The catalyst for oxidizing and synthesizing dimethoxymethane by methyl alcohol, which is provided by the invention, has the advantages of simple method, mild reaction condition, good stability, easiness in reproducibility, and high dimethoxymethane selectivity and methyl alcohol conversion rate.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Secondary battery, battery pack, and vehicle

ActiveCN107204468AImprove securityIncrease energy densityBatteries circuit arrangementsFinal product manufactureElectrolytic agentDischarge efficiency

According to one embodiment, a secondary battery is provided. The secondary battery includes a positive electrode, a negative electrode, and an electrolyte solution. The negative electrode includes a negative electrode current collector including elemental zinc, and a negative electrode layer disposed on the negative electrode current collector. The negative electrode layer includes a negative electrode active material including at least one compound selected from the group consisting of an oxide of titanium, a lithium-titanium oxide, and a lithium-titanium composite oxide. The electrolyte solution includes an aqueous solvent and an electrolyte.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com