Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Reduce warm-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

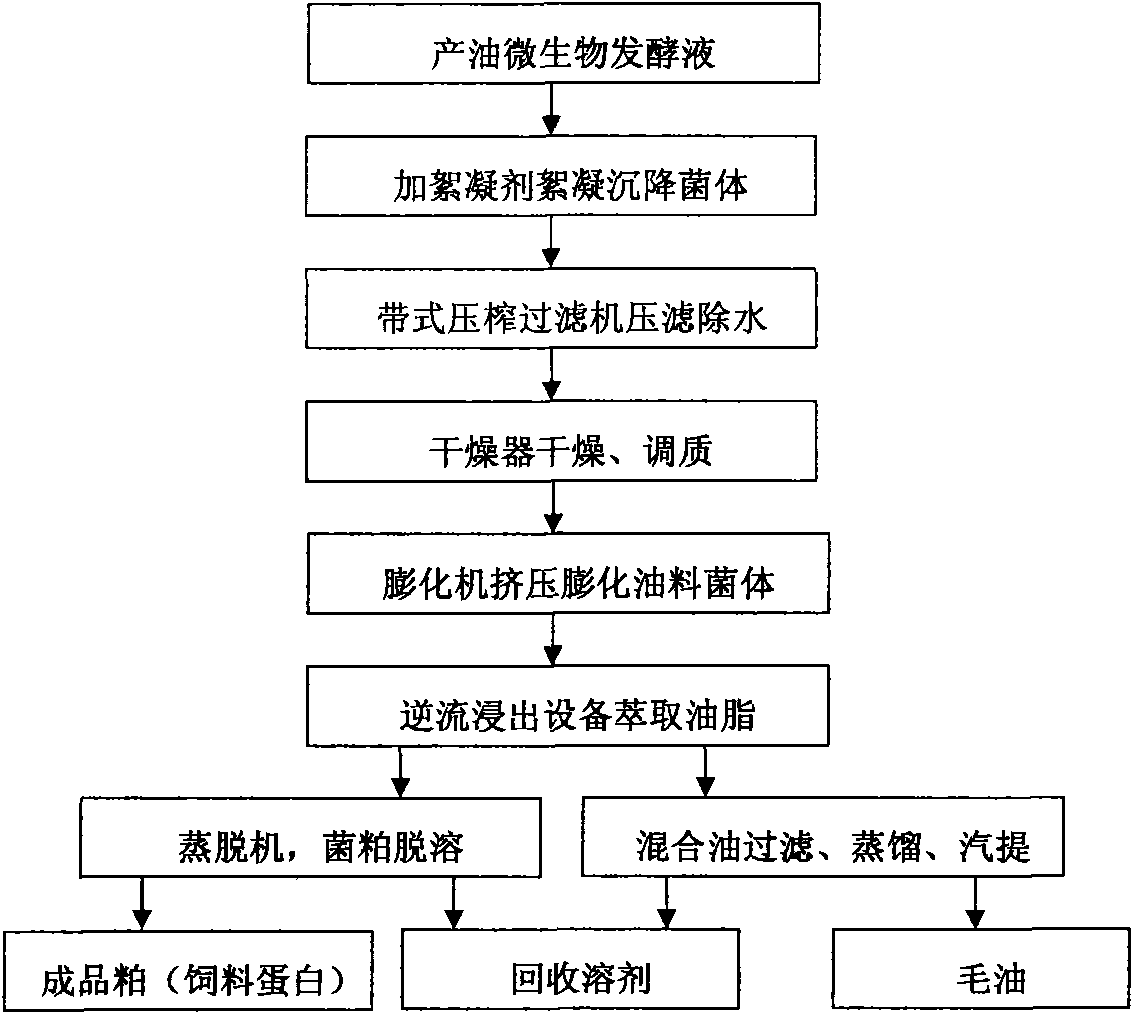

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

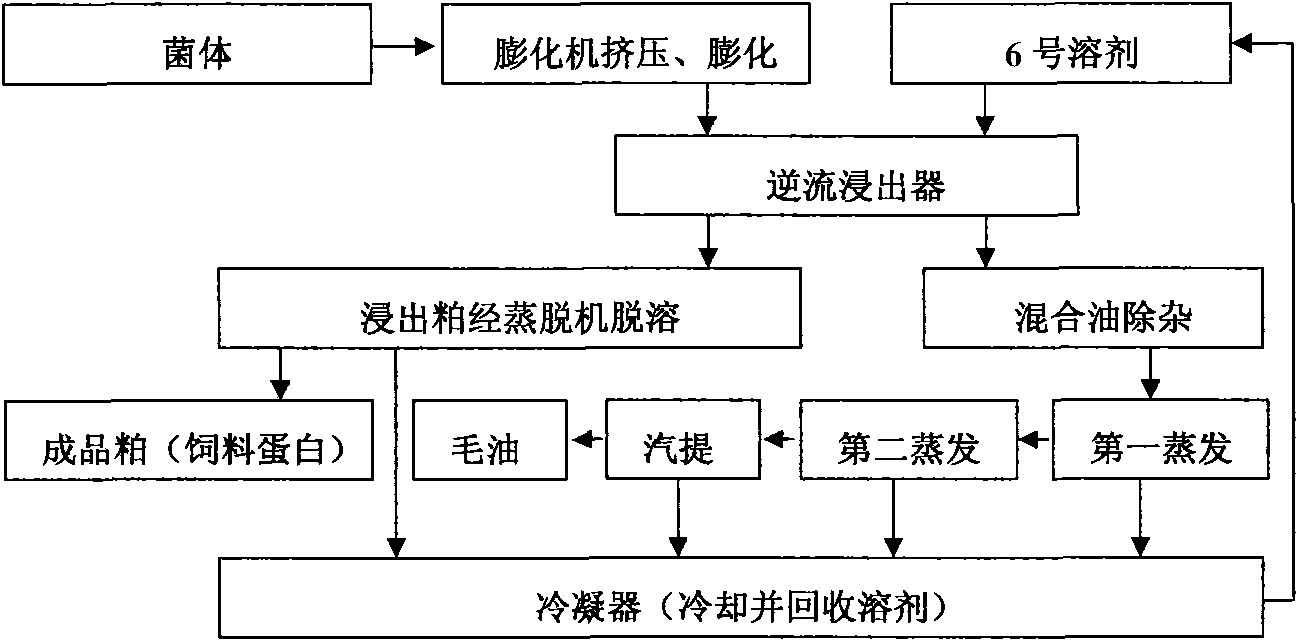

Aluminum alloy medium plate preparation method

The invention discloses an aluminum alloy medium plate preparation method. The aluminum alloy medium plate preparation method comprises the following steps of: smelting at 700-750 DEG C, degassing a melt by adopting a multistage degassing purification system, and filtering the melt by adopting a 300ppi-foamed ceramic filtration plate; casting the melt to obtain an aluminum alloy ingot blank, and carrying out stress-relieving treatment at 300-500 DEG C for more than or equal to 1 hour; controlling the temperature of a saw cutting aluminum alloy sheet at 350-500 DEG C, carrying out solution treatment for more than or equal to 0.5 hour, controlling the tensile deformation at 1%-4%, controlling the temperature of the aluminum alloy sheet at 50-300 DEG C, and carrying out aging treatment for 2-40 hours to obtain an aluminum alloy medium plate. Compared with the aluminum alloy medium plate prepared by a conventional hot-rolling method, the aluminum alloy medium plate prepared by the method has the advantages that the preparation working procedures are reduced, the production cycle is short, the cost is reduced, the plate has good quality and high strength and meets the market requirements, and the good economic benefits and social benefits are achieved.

Owner:广西南南铝加工有限公司

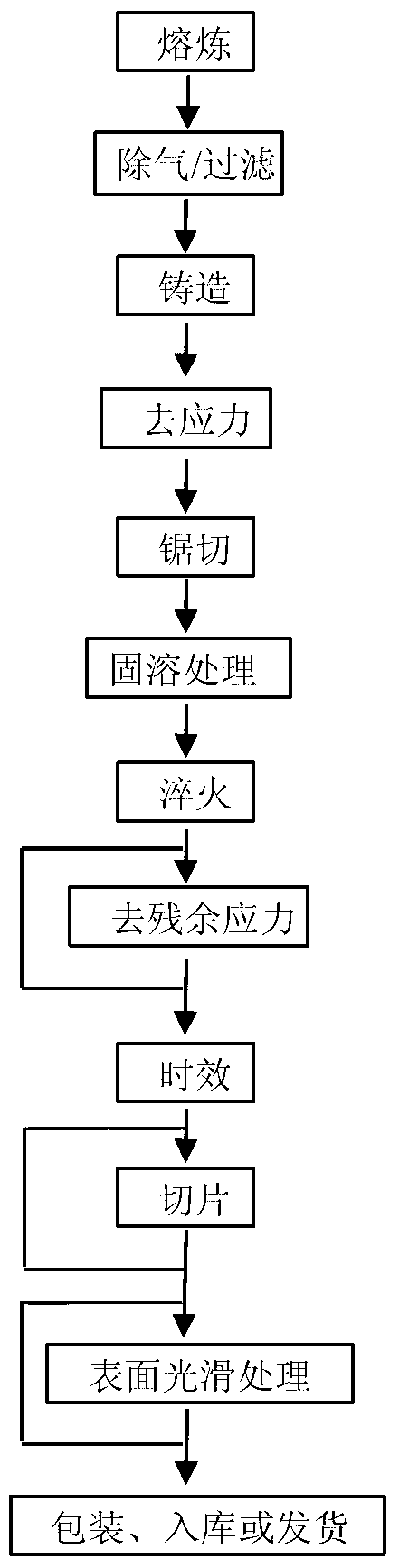

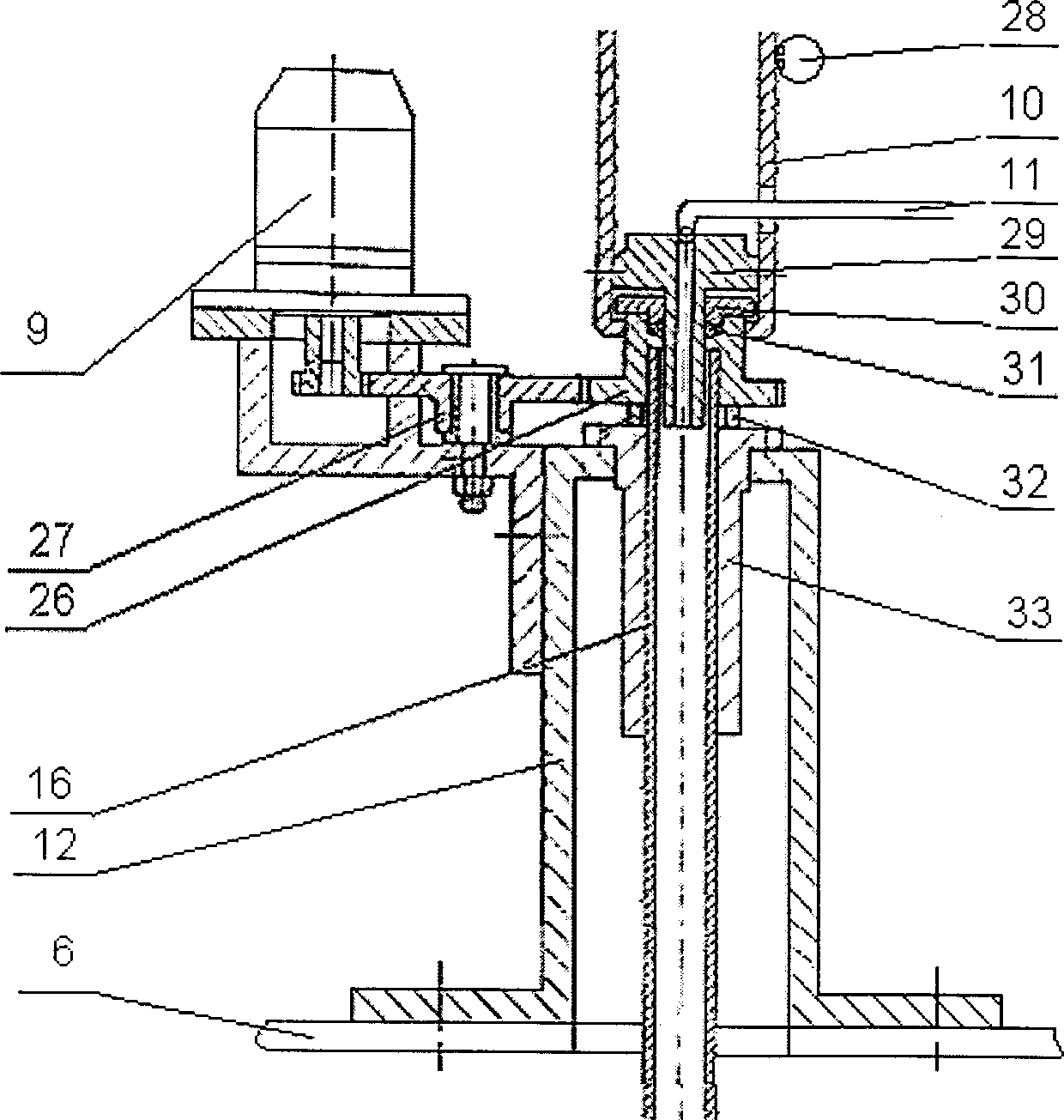

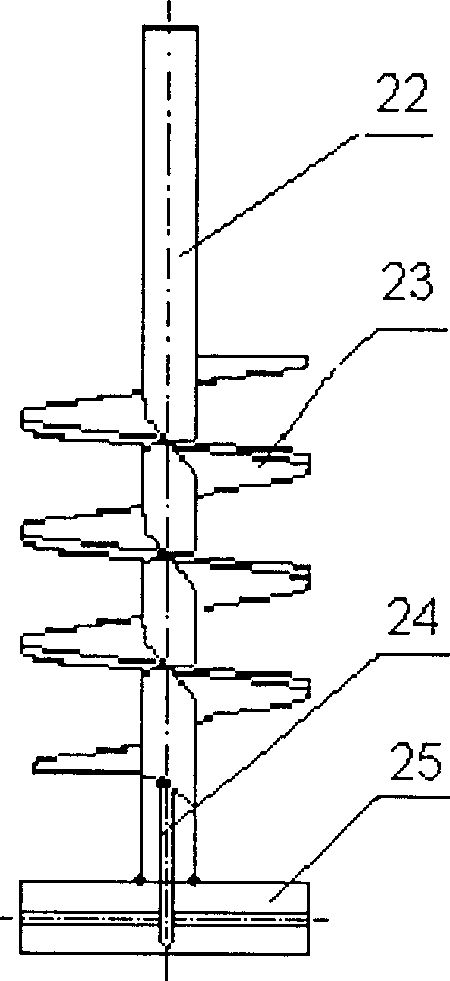

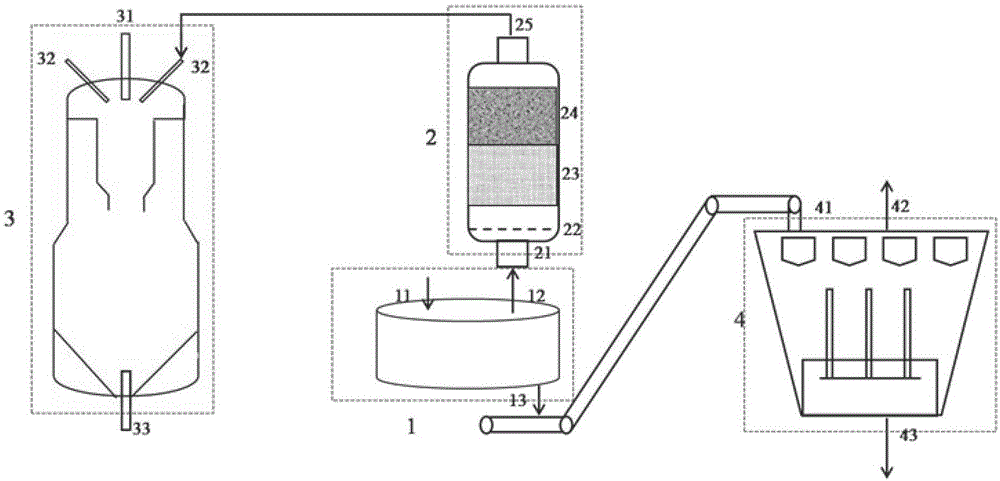

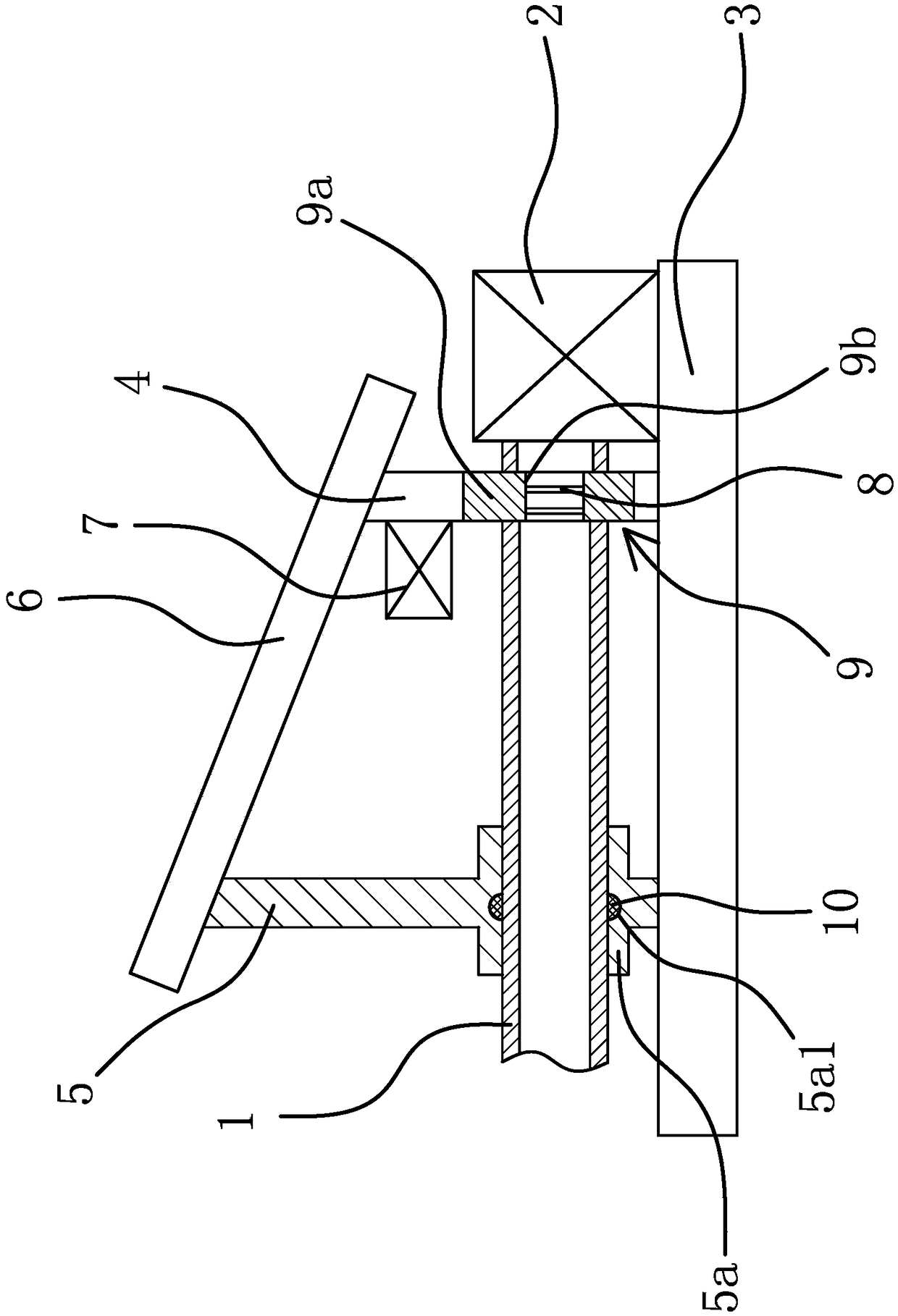

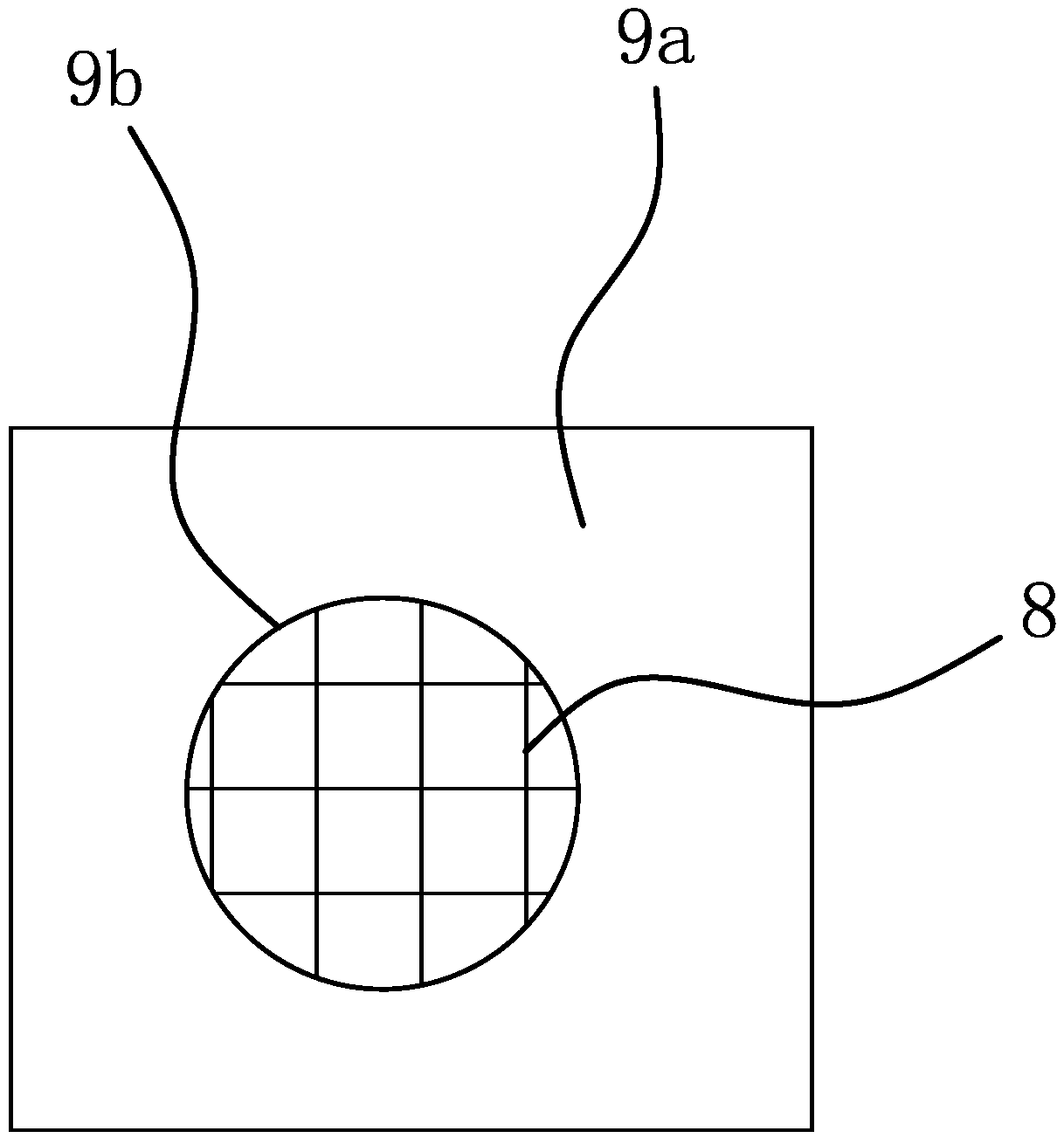

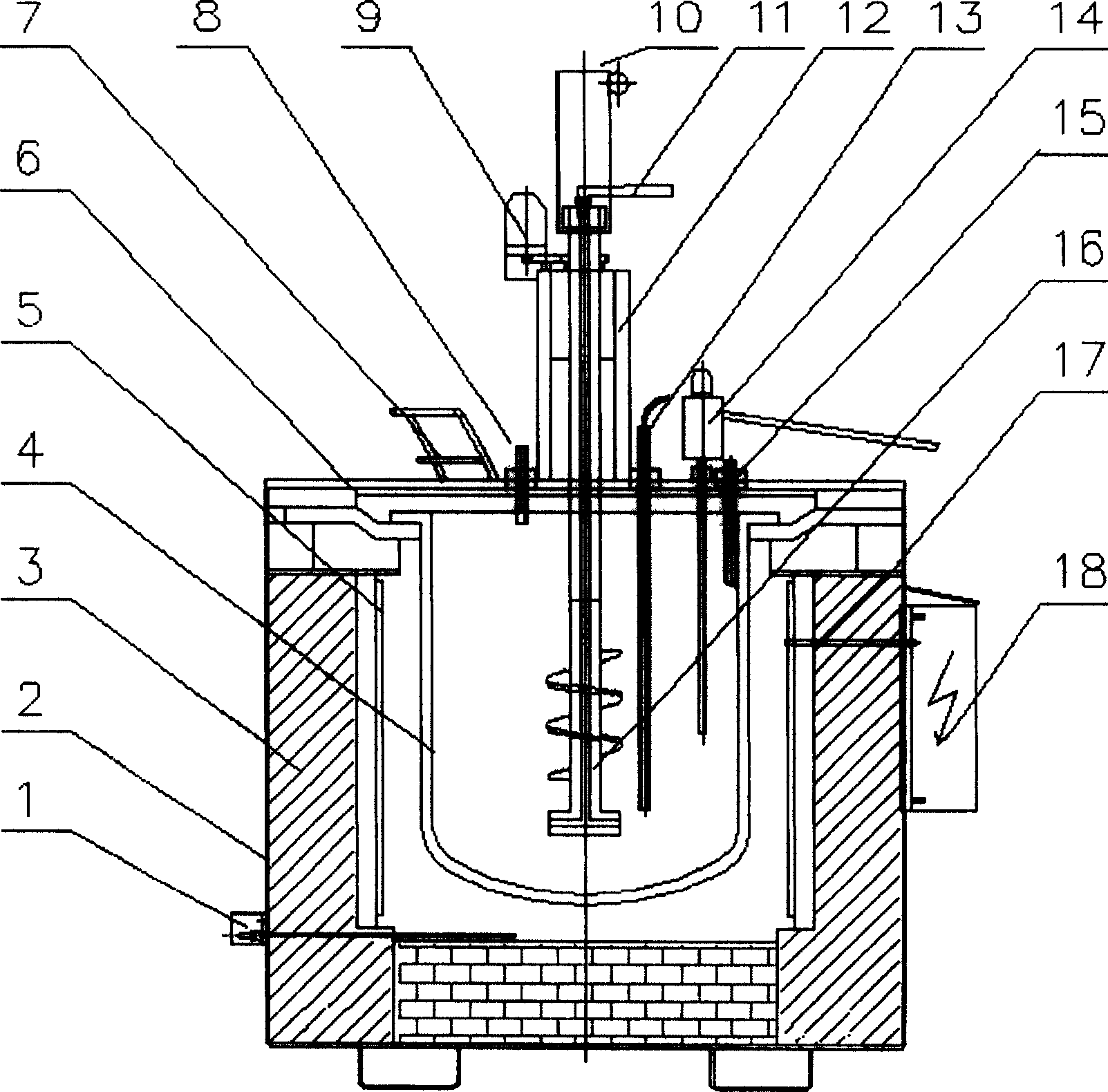

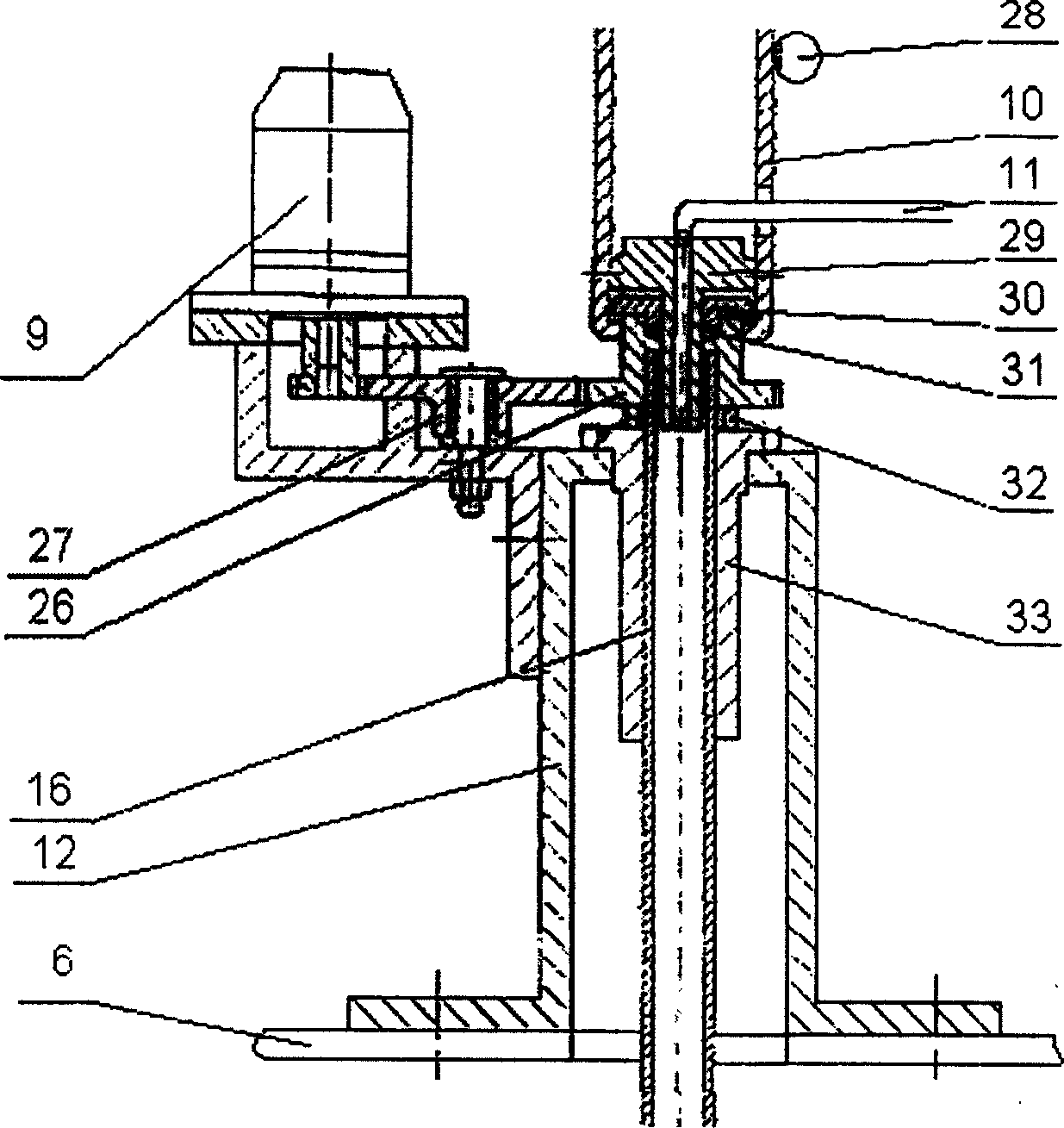

Magnesium alloy waste regenerator

InactiveCN1436865AReduce recycling costsImprove refining effectCrucible furnacesCombustionSpiral blade

The magnesium alloy waste regenerator consists of furnace body, feeding and discharge system and refining system. The apparatus has a stirrer comprising stirring rod with spiral blades and stirring head and these is a through hole in the stirring rod and the stirring head and connected to the refining gas passage via fixing flange. There are dynamic sealing structure in the upper part of the stirring rod and partitioned bin feeder comprising partitioned bin, rotary opened upper cover and withdrawable partition boards. The present invention can realize mechanical composite stirring of gas during refining and isolate magnesium alloy waste in smelting and refining from outside, and these results in less oxidation and combustion, saving in flux and protective gas, improved refining effect, regeneration quality and efficiency, low cost and less environmental pollution.

Owner:TSINGHUA UNIV

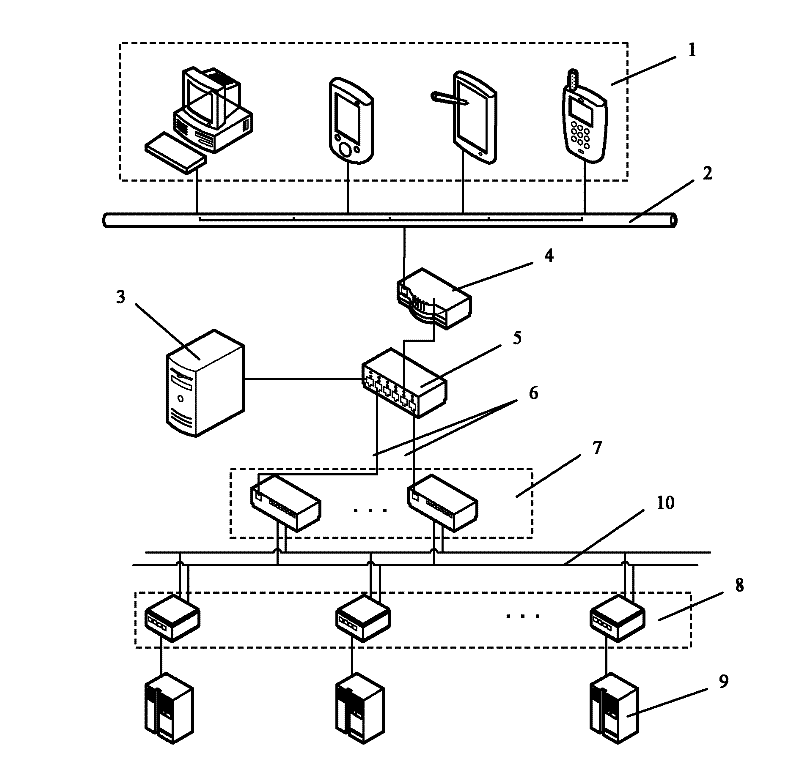

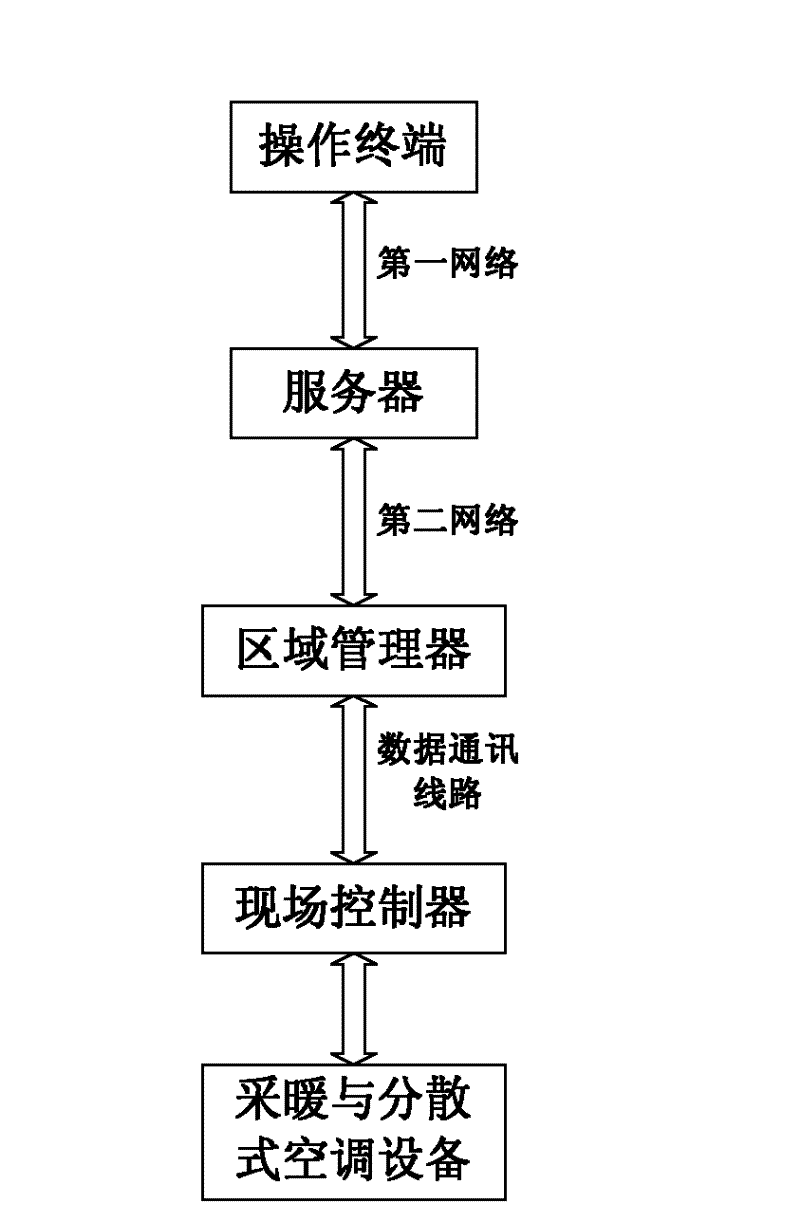

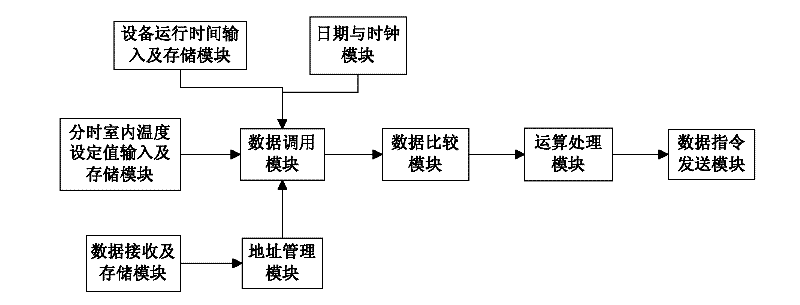

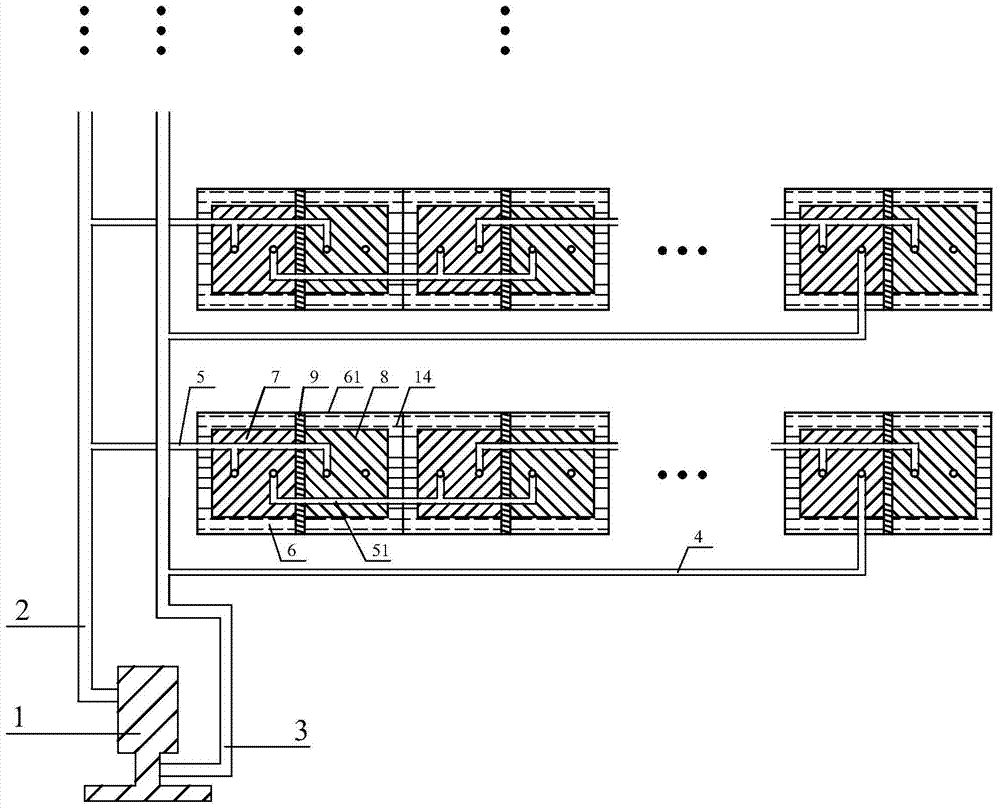

Heating and decentralized air-conditioning system for teaching or office building and control method

ActiveCN102411346ARealize fine controlAvoid wastingProgramme total factory controlRoom temperatureEngineering

The invention discloses a heating and decentralized air-conditioning system for a teaching or office building and a control method; in the system, an operation terminal is connected with a server through a first network; the server is connected with a regional manager group through a second network; all regional managers are connected with all on-site controllers in corresponding on-site controller groups through data communication lines; all the on-site controllers are arranged in all the rooms of the teaching or office building; all the on-site controllers are connected with radiators in the rooms; radiator electric two-way valves are arranged on hot water inlet pipes of the radiators; the method comprises the steps that: centralized control is realized by networking, so that heat supply, room temperature as well as heating and decentralized air-conditioning of all the rooms in the teaching or office building are controlled in real time, the heating or refrigeration speed is high, the automation of heating and decentralized air-conditioning of the teaching or office building can be effectively improved, the purpose of energy saving is achieved, and heating or refrigeration are truly realized.

Owner:GUANGZHOU YUANZHENG INTELLIGENCE TECH

Cutting method for digital controlled flame cutter

InactiveCN1928756AImprove appearance qualityIncrease profitTotal factory controlGas flame welding apparatusFlameoutEngineering

The disclosed cutting method with digital-control flame cutter comprises: a. designing pattern, which includes: according to product detail shape and target plate material, drawing the pattern figure with some closed ring figure element with same shape as the product; b. designing the cutting path and defining cutting processing codes; c. loading codes; d. cutting. During the procedure of startup, warm-up, perforating, cutting and flameout, this invention can process scores even hundreds details for one time.

Owner:陈晓坚

Tamping paste for aluminum electrolytic cell and use method of tamping paste

The invention discloses tamping paste for an aluminum electrolytic cell and a use method of the tamping paste. The tamping paste mainly comprises carbonaceous aggregate, a binder, metal powder, an expansion agent and a curing agent. Normal-temperature tamping connection is conducted through the high-expansion high-conductivity tamping paste, and assembly is completed through the working procedures of paste preparation, cleaning of a dovetail groove and a cathode steel bar, laying of the thin-layer tamping paste on the bottom face of the dovetail groove, placing of the cathode steel bar, filling and tamping of the tamping paste, normal-temperature curing and the like. Compared with existing tamping paste and a use method of the existing tamping paste, the tamping paste for the aluminum electrolytic cell and the use method of the tamping paste have the beneficial effects that operation under the normal temperature is easy, and expansion and conductivity are high; the property of conduction between the cathode steel bar and a carbon block and the conductive property of the steel bar paste are improved, the aluminum electrolytic cell cathode voltage drop is reduced, the aluminum electrolysis energy consumption is saved, and the service life of an aluminum electrolytic cathode is prolonged.

Owner:CENT SOUTH UNIV

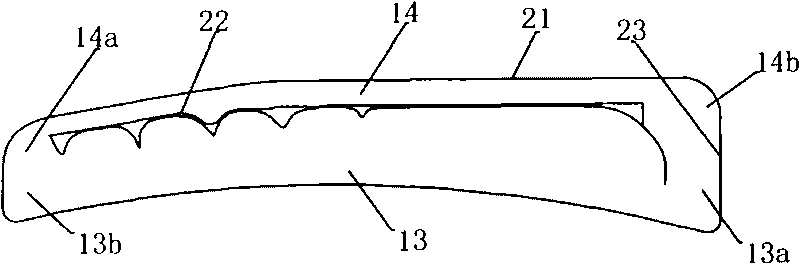

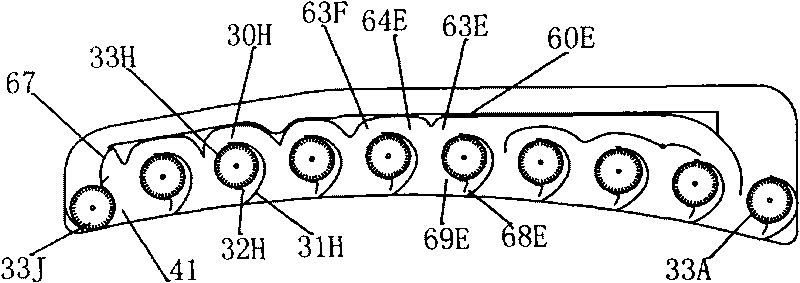

Energy-saving and environment-friendly printer

InactiveCN101700713AReduce consumptionThe effect of reducing consumption and realizing a closed loopPrinting press partsInlet channelMaterial consumption

The invention relates to an energy-saving and environment-friendly printer, comprising a printer body and a drying device (10). The energy-saving and environment-friendly printer is characterized in that the drying device (10) comprises an oven cap (20) and a base (50), and is provided with a printing product inlet (03) and a printing product outlet (04); the oven cap (20) is provided with a drying cavity (13) and a recovering cavity (14); an air supply unit (60), a heat pump condenser (88) and a refrigerating evaporator (96) are arranged in the oven cap (20); the air supply unit (60) comprises a fan (30) provided with an air inlet channel (63), an air exhaust channel (64) and an air outlet channel (68) to form an air blowing and circulating system; the heat pump condenser (88) is installed in the air supply unit (60), and the refrigerating evaporator (96) is installed in the recovering cavity (14). In the invention, drying equipment is firstly reformed, and an air channel with skillful interior is utilized to replace the original air channel with complicated structure and signal function, thereby the effects of compact structure, space saving and reduction of material consumption are achieved.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

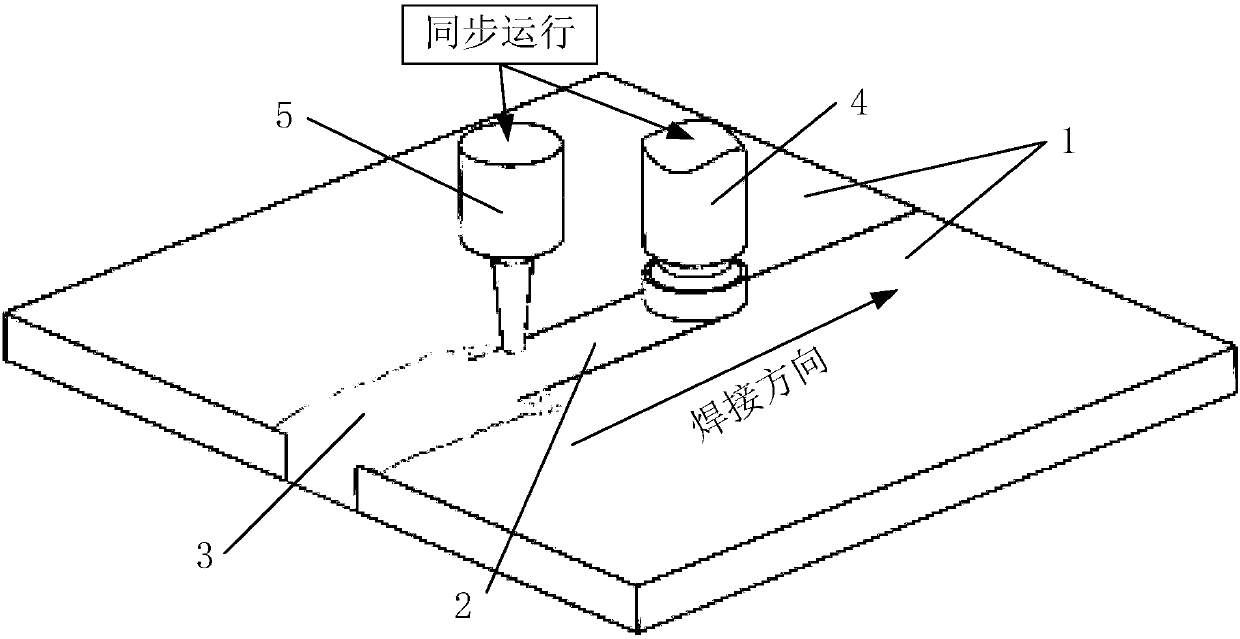

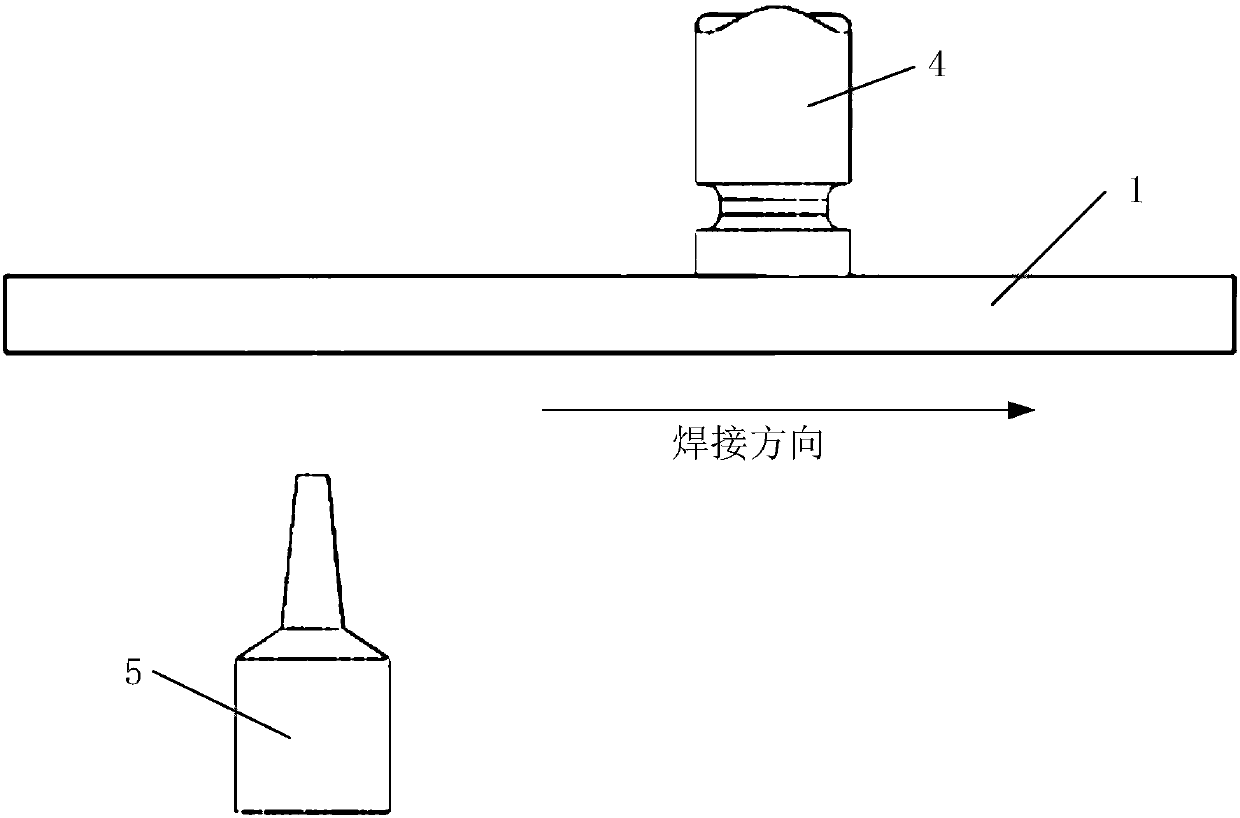

Method for friction stir welding of high-strength aluminum alloy

InactiveCN107717209AImprove stress corrosion resistanceImprove bindingWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingTherapeutic effect

The invention discloses a method for friction stir welding of high-strength aluminum alloy. A finished welding part is subjected to cold spraying treatment synchronously while a high-strength to-be-welded aluminum alloy part is subjected to friction stir welding, and thus a cold spraying layer is formed at the position of a high-strength aluminum alloy welding joint. The method for friction stir welding of the high-strength aluminum alloy not only can improve stress corrosion resistance of the friction stir welding joint conveniently and effectively and prolong service life of the friction stir welding joint, but also can reduce treatment process, improve treatment efficiency and save treatment time, and is stable and reliable in treatment effect, economical and practical.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Combustor capable of quickly realizing flameless combustion

The invention relates to a combustor capable of quickly realizing flameless combustion. The combustor comprises a center fuel gas spraying pipe, a loop fuel gas spraying pipe coaxially sealed outside the center fuel gas spraying pipe, two symmetric air spraying pipes symmetrically arranged at the two sides of the loop fuel gas spraying pipe in parallel, a loop air spraying pipe arranged outside the loop fuel gas spraying pipe and the symmetric air spraying pipe, and a flame stabilizing blunt body, wherein the loop air spraying pipe and the loop fuel gas spraying pipe are coaxially arranged; the flame stabilizing blunt body is detachably connected to the front ends of the center fuel gas spraying pipe and the loop fuel gas spraying pipe, and is provided with a center fuel gas nozzle communicated with the center fuel gas spraying pipe, more than two peripheral fuel gas nozzles positioned around the center fuel gas nozzle and communicated with the loop fuel gas spraying pipe and two air nozzles symmetrically arranged at the two sides of the center fuel gas nozzle; the two air nozzles are communicated with the two symmetric air spraying pipes; an annular projection is arranged at the front end of the flame stabilizing blunt body; the outer diameter of the annular projection is equal to the inner diameter of the loop air spraying pipe; and a distance is left between the annular projection and the front end of the loop air spraying pipe.

Owner:PEKING UNIV

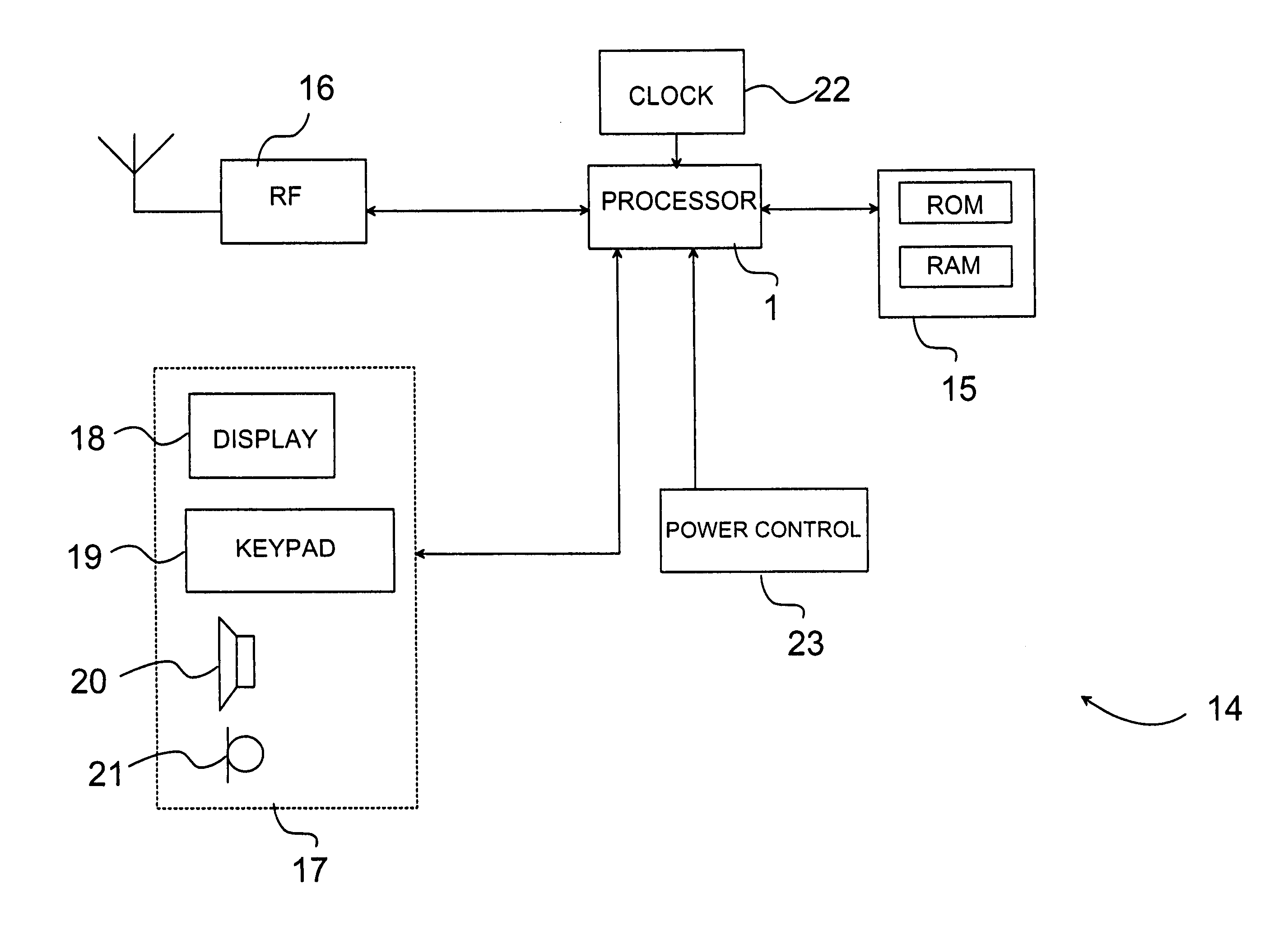

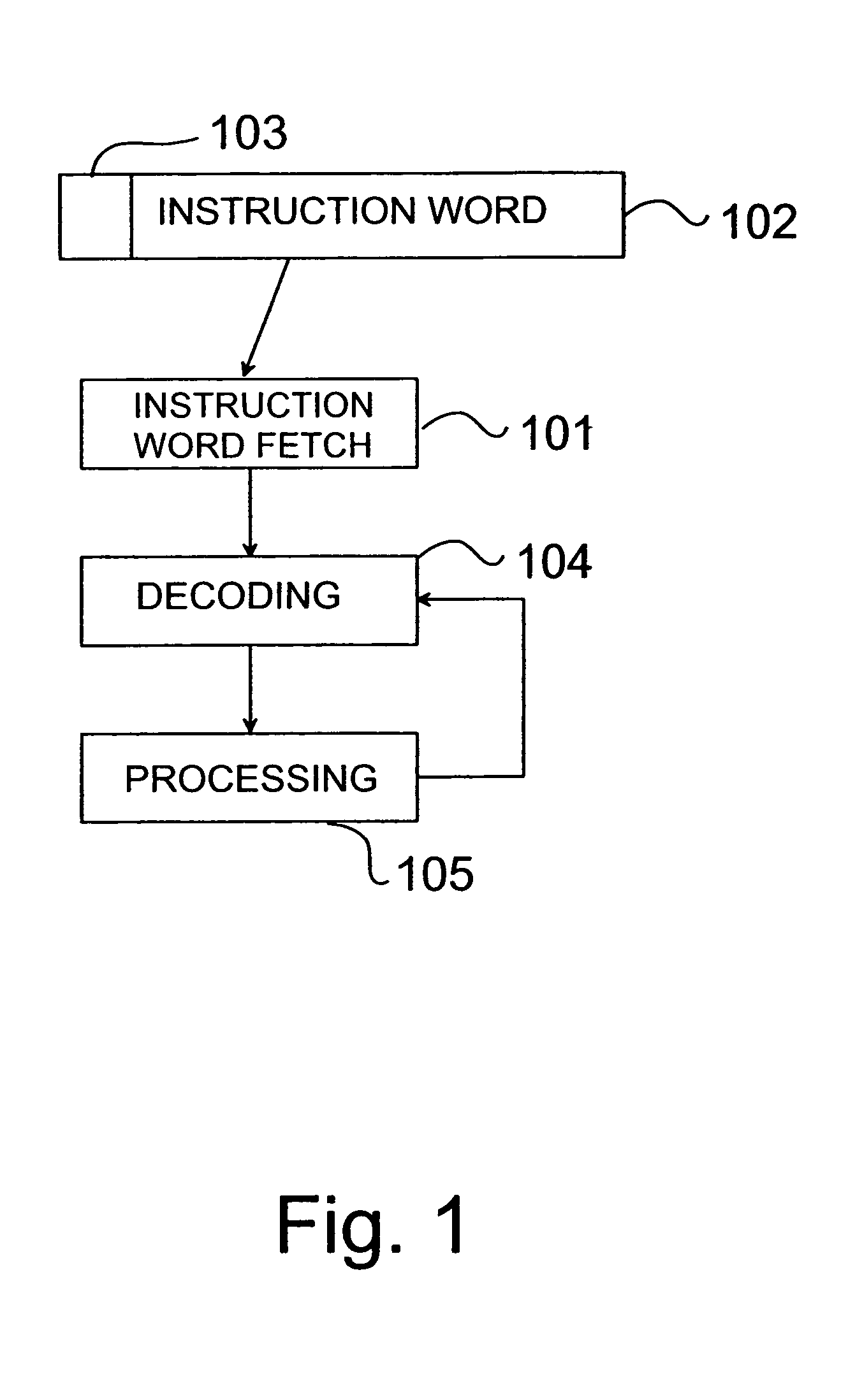

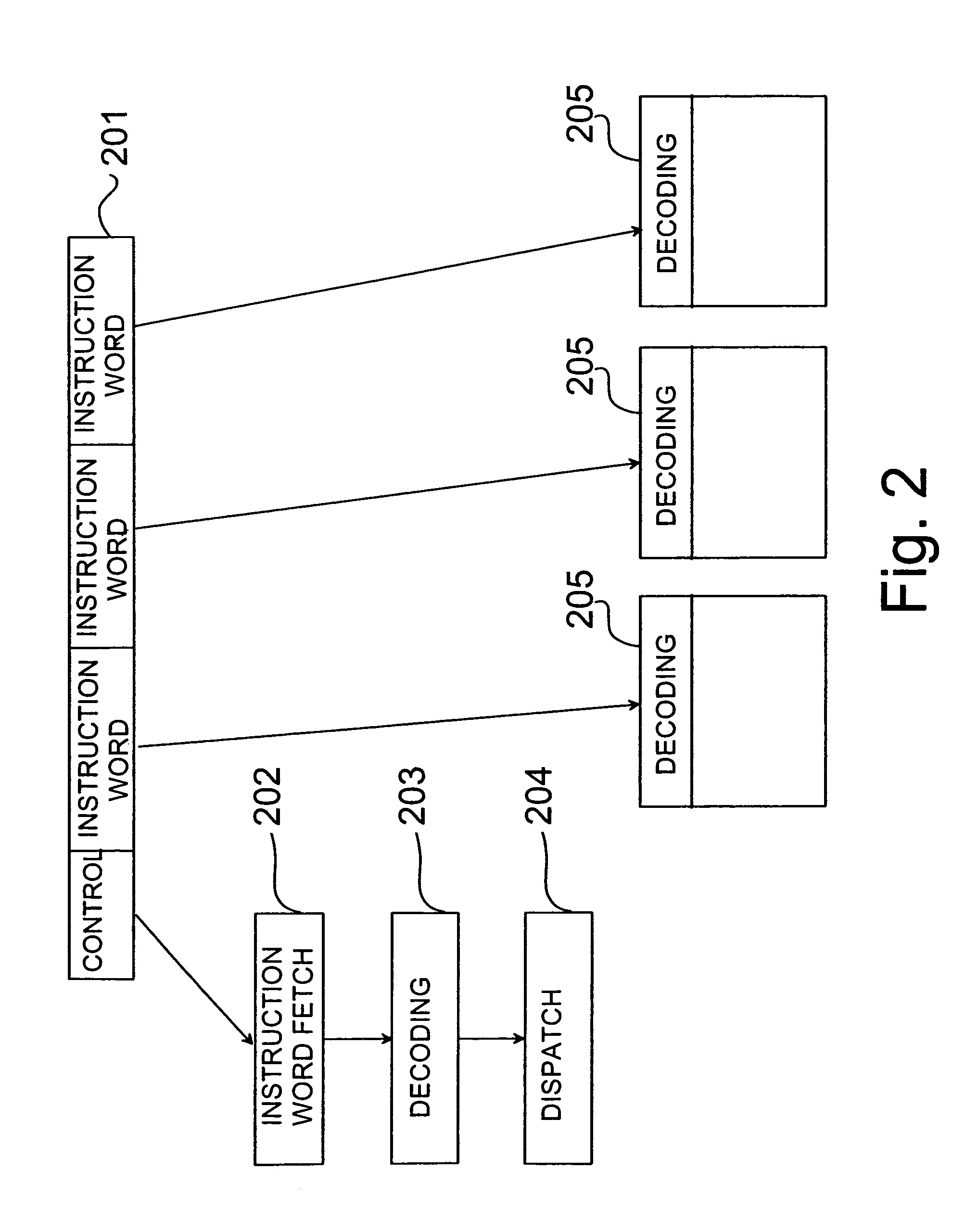

System for controlling operation of a processor based on information contained within instruction word

ActiveUS7114089B2Extended operating timeReduce warm-upEnergy efficient ICTVolume/mass flow measurementComputer architectureProgram code

An instruction word is used to transfer information about whether the instruction word pertains to mode setting of a functional block. Instruction words included in the program code are processed in at least a first decoding step and a second decoding step, wherein in the first decoding step, said information included in the instruction word is examined. On the basis of the examination, it is determined whether the mode of one or more functional blocks is to be set or whether the second decoding step is to be taken, in which the instruction word is decoded to be run by one or more of said functional blocks. The invention also relates to a processor and an electronic device, in which the method can be implemented. The invention further relates to a program, in which a program code is provided for implementing the method.

Owner:NOKIA TECHNOLOGLES OY

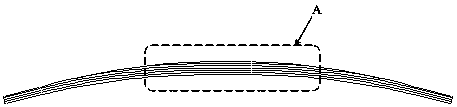

Process for high-efficiency molding of composite plate spring

ActiveCN108928012AIncrease productivityRealize automated mass productionDomestic articlesCompression moldingEngineering

The invention discloses a process for high-efficiency molding of a composite plate spring. The process comprises the following steps: (1) subjecting a plate spring to modeling and carrying out layeredmodeling on a plate spring model from bottom to top; (2) preparing a curved-surface workbench according to each single-layer model; (3) separately carrying out paving and pasting on each curved-surface workbench by using an automatic tape laying machine so as to form a whole piece of a blank material and cutting the whole piece of the blank material with a cutting machine so as to form a plurality of single blank materials with the same structure; and (4) piling up the plurality of single blank materials and carrying out compression molding so as to form the plate spring. With such a technical scheme, the process for high-efficiency molding of the composite plate spring greatly improves the production efficiency of the composite plate spring prepared through molding and can realize automatic batch production of the composite plate spring.

Owner:AVIC COMPOSITES

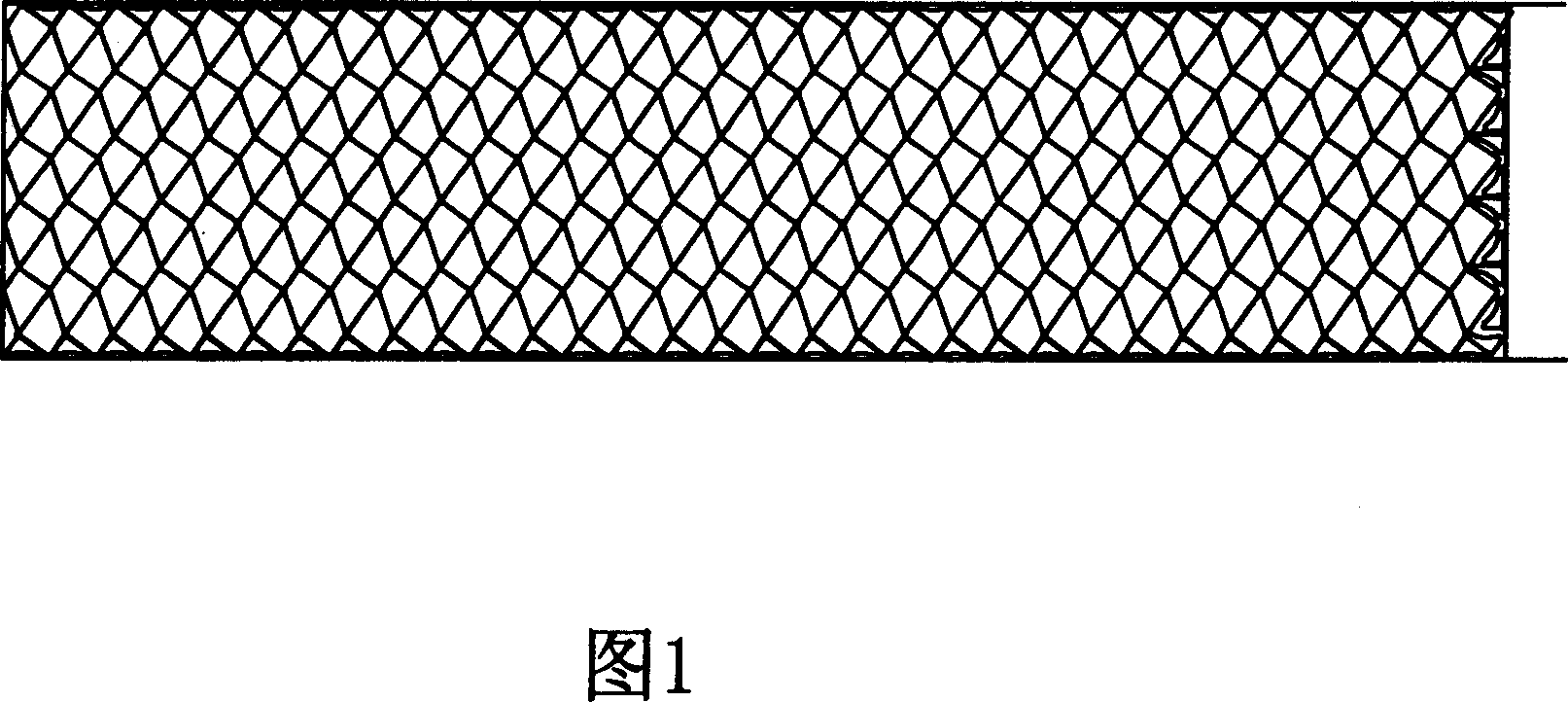

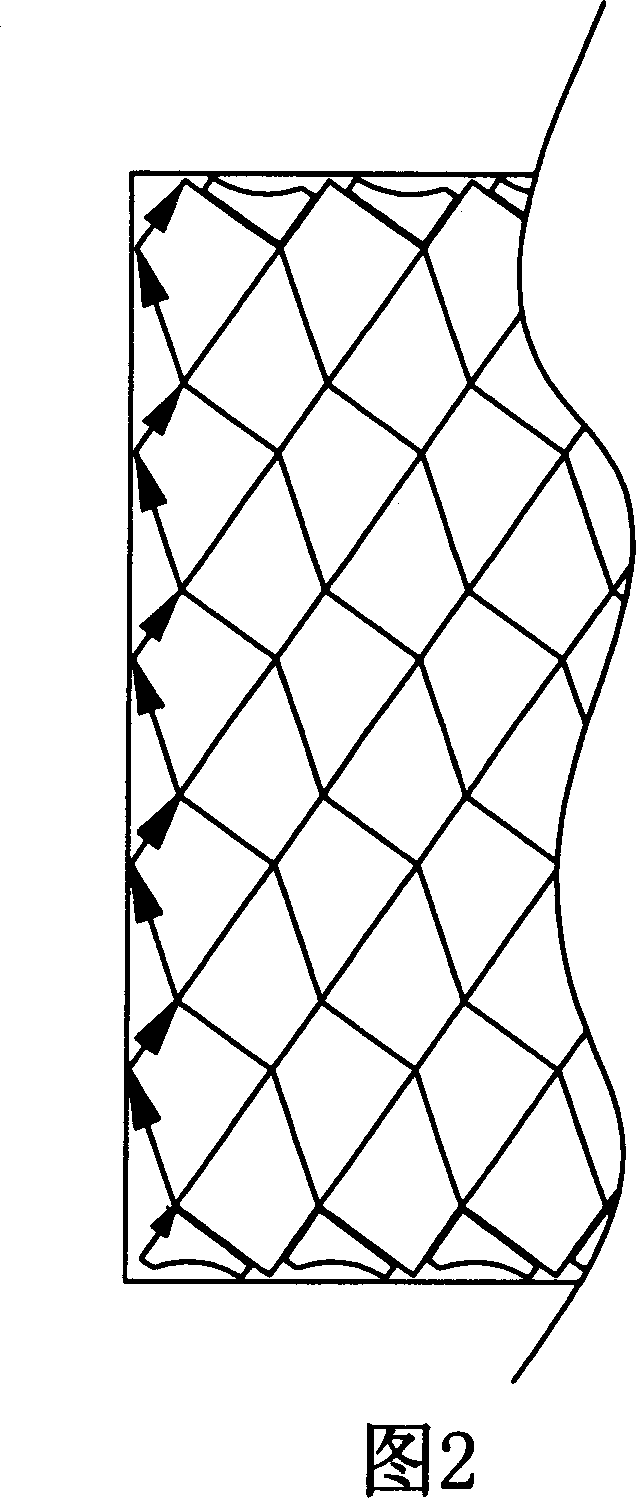

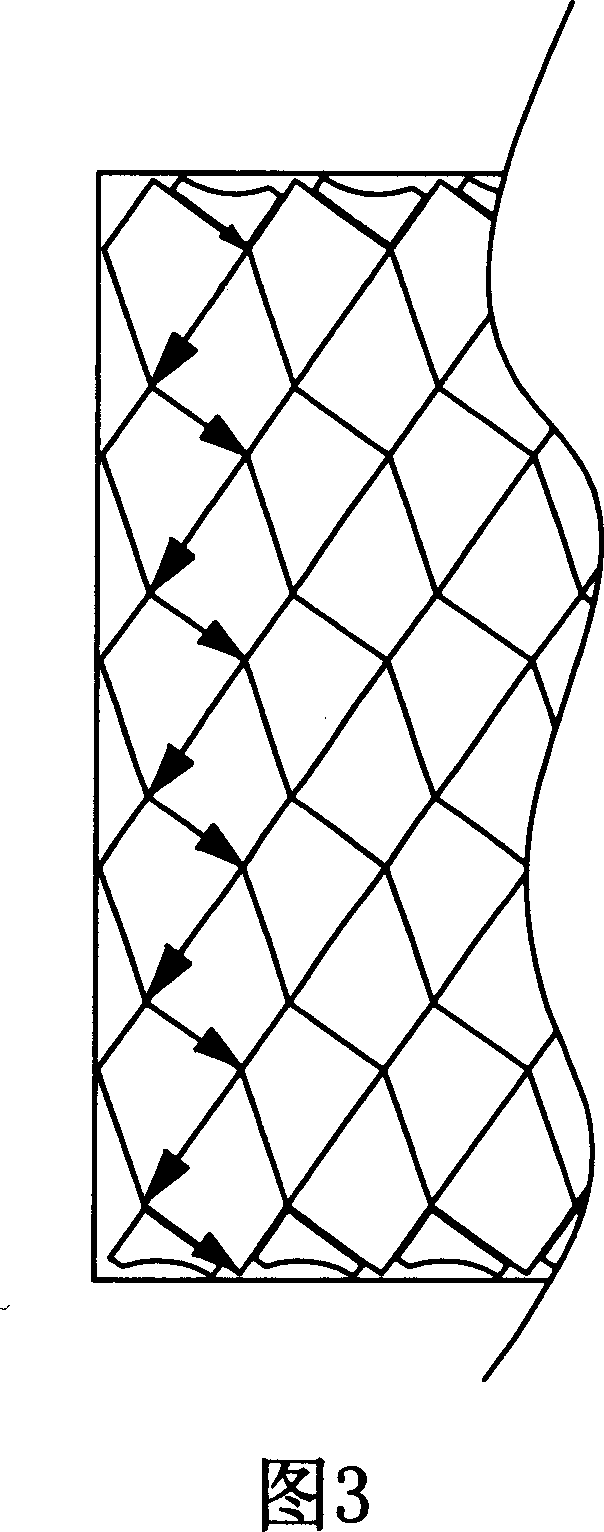

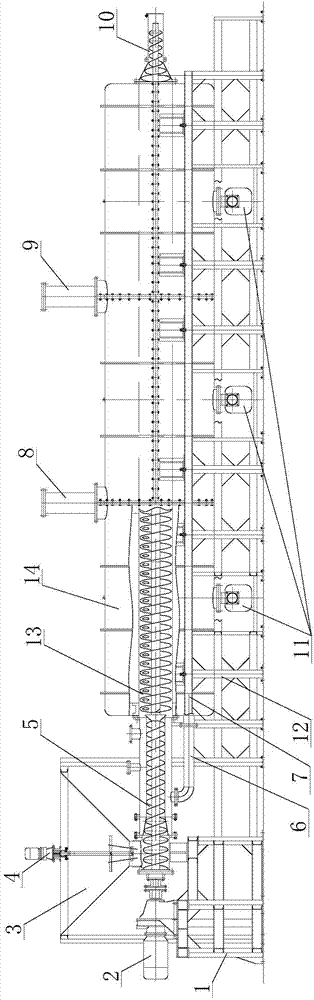

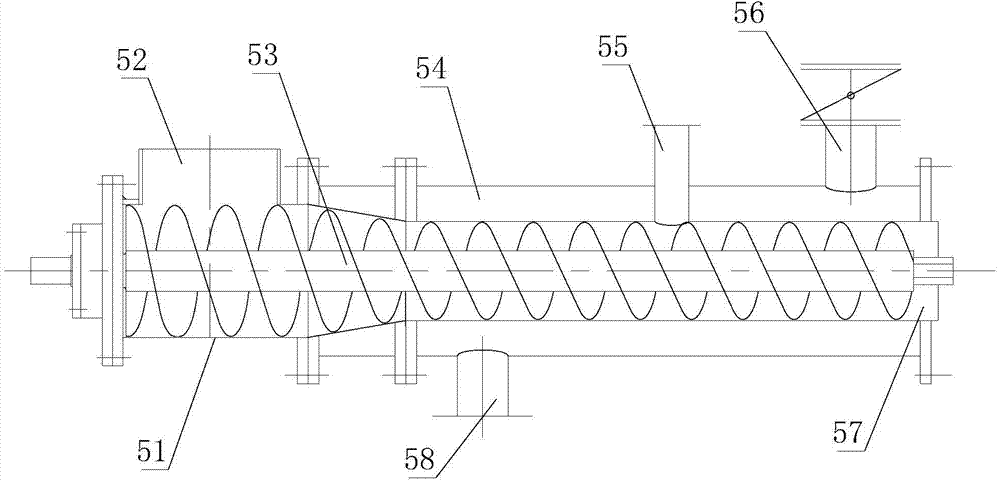

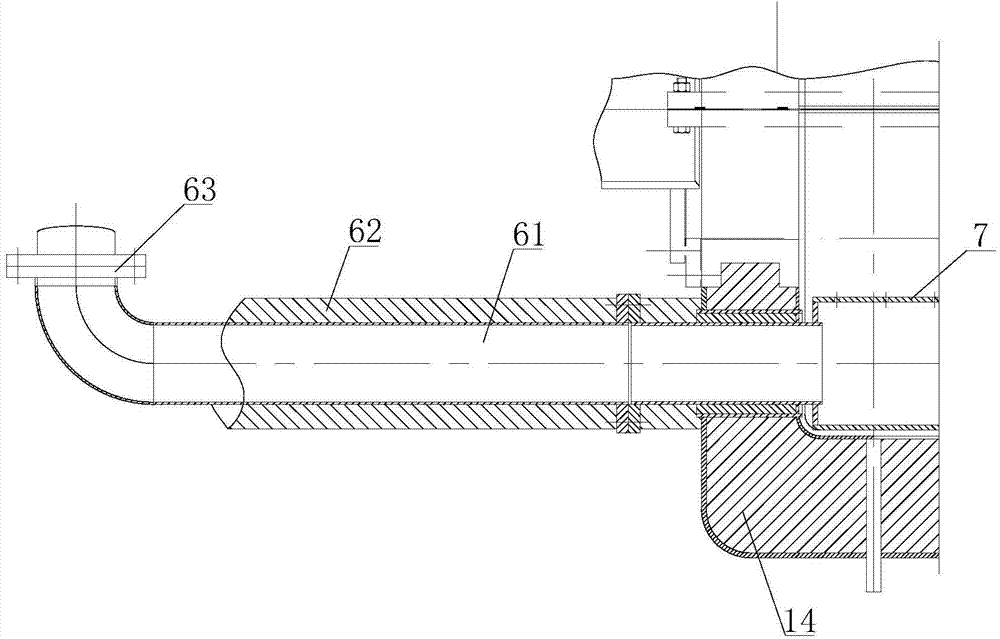

Energy-saving type grain microwave insect preventing and mould-proof method and special equipment

InactiveCN1813550AIncrease the venueIncrease Microwave TimeFood processingSeed preservation by irradiation/electric treatmentEngineeringMicrowave irradiation

The present invention relates to an energy-saving type pests-resisting mould-proofing treatment method for grains and its special-purpose equipment. Said invention includes the microwave irradiation-cooling treatment steps, and is characterized by that it includes the steps of preheating, microwave irradiation, cooling and heat exchange, in which the heat exchange is implemented in unit A for preheating and cooling and the microwave irradiation is implement in unit B, and between unit A and unit B ac closed channel is connected. Besides, said invention also provides its working principle and operation method.

Owner:HUAZHONG AGRI UNIV

Novel process for directly melting fiber reinforced thermoplastic composite material

A new process for directly melting fiber-reinforced thermoplastic composite material relates to a new technology for forming the fiber-reinforced thermoplastic composite material. The technical proposal of the invention combines the process of directly melting and dipping the fiber-reinforced thermoplastic composite material with a molding process, and directly melts the thermoplastic resin and accessories and adds the molten materials to a mould for one-step molding. The proportions of the raw materials are as follows: 50-65% of acrylic resin, 28-35% of glass fiber, 0.5-2.0% of silicane coupling agent particles, 0.5-1% of bismaleimide, 0.05-0.1% of ultraviolet absorbent, 1-2% of antioxidant and 5-8% of packing. The specific process comprises batching, heating for soaking, press molding and demolding to obtain the blank of the fiber-reinforced thermoplastic composite material. The process has the advantages of forming by only one single heating process with low energy consumption; reducing intermediate links of batching storage, transport, preheating and the like, reduced energy consumption and manpower, lower production cost, high degree of batching freedom and small fiber attrition, and the process can more easily realize reuse of the recycled wastes.

Owner:SHANDONG GRAD GROUP

Solar energy sea water desalination system

InactiveCN105439349AImprove permeabilitySpeed up condensationGeneral water supply conservationSeawater treatmentElectricityWater desalination

The invention relates to a solar energy sea water desalination system which comprises an evaporation-coagulation housing, a desalination mechanism adopting a sandwich structure, a solar panel and a scale inhibitor feeding device, wherein the evaporation-coagulation housing adopts an open box-packed structure; a transparent baffle is arranged at the open end of the evaporation-coagulation housing; a support rack is arranged in the evaporation-coagulation housing; the desalination mechanism is fixed on the support rack, and divides the interior of the evaporation-coagulation housing into an upper vapor cavity and a lower fresh water cavity. The solar energy sea water desalination system has the advantages that the structure is compact; sea water desalination can be realized without external power or electricity input; the design is simple; sea water can be supplied in a real-time manner via capillary force; a sunny side is adopted for evaporation to produce vapor, while the shadier side is adopted for coagulation to recover latent heat, that is, twice utilization of energy is realized, and fresh water yield is improved.

Owner:RUNHAI ENERGY TECH INC JIANGSU

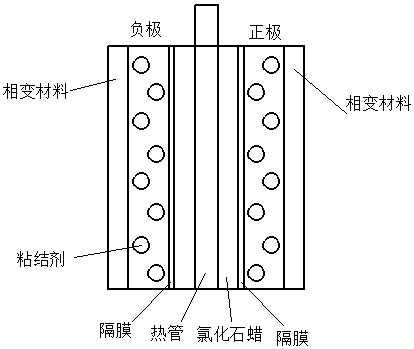

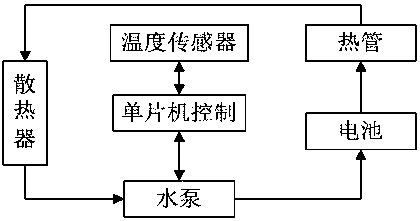

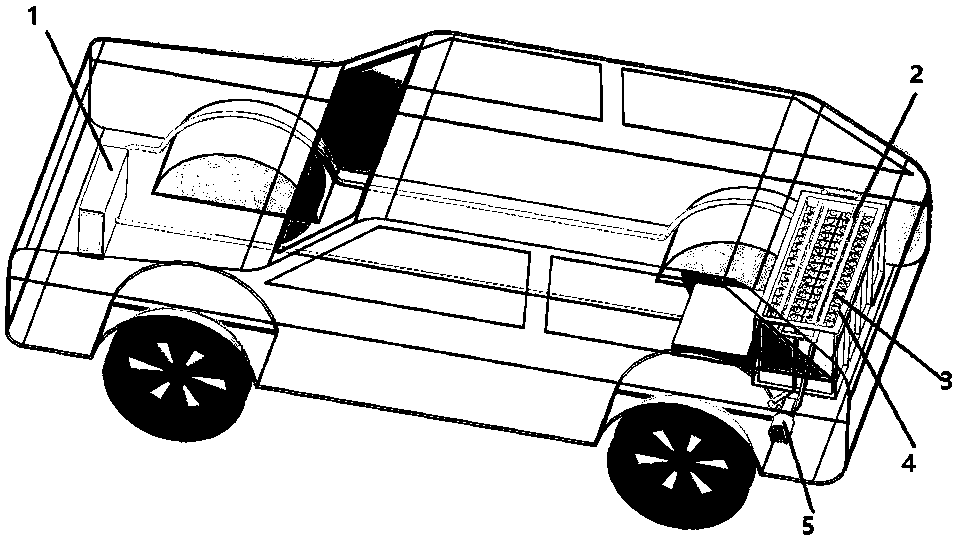

Cooling system of electric vehicle lithium battery

ActiveCN108199115AGuaranteed temperatureReduce warm-upSecondary cellsElectrical batteryParaffin oils

The invention relates to a cooling system of an electric vehicle lithium battery. The cooling system comprises a lithium battery pack and a water-cooling system, wherein the lithium battery pack comprises single lithium batteries, the water-cooling system is used for integrally cooling the lithium battery pack, the single lithium battery comprises a dual-separator layer, the dual-separator layer is used for isolating a positive electrode and a negative electrode of the single lithium battery, chlorinated paraffin is injected to the dual-separator layer, a hot pipe is inserted into a middle part of the dual-separator layer, a hot pipe of each single lithium battery extends out of one end of the single lithium battery and is connected to the water-cooling system, a phase changing material wraps the periphery of the single lithium battery so as to absorb heat discharged from the single lithium battery, the heat can be stored in a latent heat form, and meanwhile, a heat preservation effectunder a low-temperature environment achieved. By the cooling system, a hot heat region of the lithium battery is enabled to be cooled to the maximum extent, other regions are cooled to a normal extent, so that different regions of an electric vehicle lithium battery obtains different cooling capability effects, meanwhile, the single batteries are preserved, the working of the battery working a cold region is maintained, and the pre-heating link is reduced.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE +1

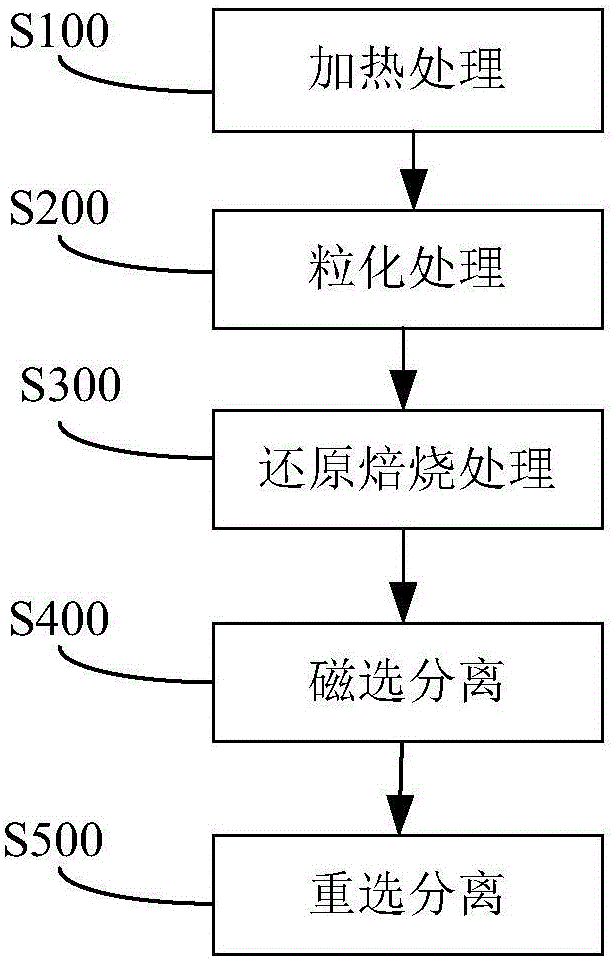

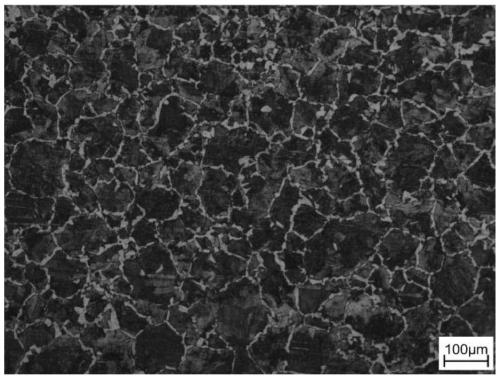

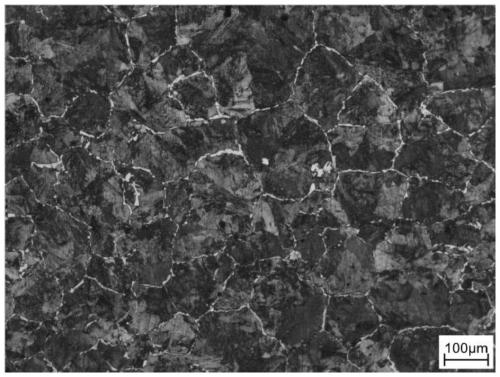

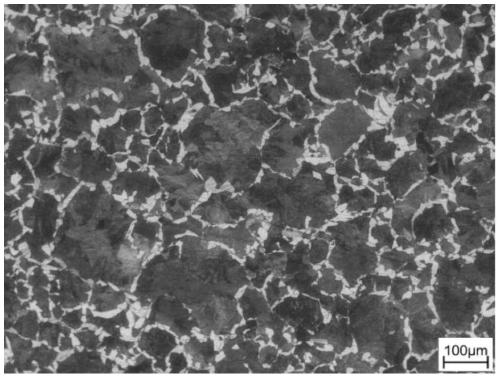

Granular iron preparation method and system

ActiveCN105838839ARaise the gradeEfficient use ofProcess efficiency improvementHearth type furnacesChemical compositionZinc

The invention discloses a granular iron preparation system and method. The granular iron preparation system comprises a slag melting device, a granulator, a reduction roasting device, a magnetic separation device and a gravity concentration device. By the system, melted copper slags are taken as raw materials, the problem that the traditional high-temperature copper slags only can be continued being treated after being cooled by water quenching or cooled slowly is solved, high-grade granular iron and zinc oxide dust can be prepared, and the heat utilization rate of the system is high. In addition, an additive inlet is formed in the slag melting device, an additive is added in the high-temperature melted copper slags before heating treatment, the melted copper slags can be homogenized after being stirred by a stirrer, the interior structures and chemical components of the copper slags are adjusted directly, the metallurgical performance of the copper slags is improved, then the copper slags are granulated at high temperature, so that granulated copper slag raw materials can be provided for direct reduction of a rotary hearth furnace, technologies such as pelletizing, drying and pellet preheating are omitted, the reduction time of the rotary hearth furnace is shortened, and the energy consumption of the rotary hearth furnace is reduced.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

A burner capable of rapidly realizing flameless combustion

The invention relates to a combustor capable of quickly realizing flameless combustion. The combustor comprises a center fuel gas spraying pipe, a loop fuel gas spraying pipe coaxially sealed outside the center fuel gas spraying pipe, two symmetric air spraying pipes symmetrically arranged at the two sides of the loop fuel gas spraying pipe in parallel, a loop air spraying pipe arranged outside the loop fuel gas spraying pipe and the symmetric air spraying pipe, and a flame stabilizing blunt body, wherein the loop air spraying pipe and the loop fuel gas spraying pipe are coaxially arranged; the flame stabilizing blunt body is detachably connected to the front ends of the center fuel gas spraying pipe and the loop fuel gas spraying pipe, and is provided with a center fuel gas nozzle communicated with the center fuel gas spraying pipe, more than two peripheral fuel gas nozzles positioned around the center fuel gas nozzle and communicated with the loop fuel gas spraying pipe and two air nozzles symmetrically arranged at the two sides of the center fuel gas nozzle; the two air nozzles are communicated with the two symmetric air spraying pipes; an annular projection is arranged at the front end of the flame stabilizing blunt body; the outer diameter of the annular projection is equal to the inner diameter of the loop air spraying pipe; and a distance is left between the annular projection and the front end of the loop air spraying pipe.

Owner:PEKING UNIV

Method for repairing core rods for rolling seamless steel pipes

PendingCN113478168ALower performance requirementsImprove performanceMetallic material coating processesWelding accessoriesAlloyPipe

The invention discloses a method for repairing core rods for rolling seamless steel pipes. The method comprises the following specific steps: (1), cleaning and detecting before repairing; (2), machining before repairing; (3), detecting before surfacing; (4), surfacing and preheating; (5), surfacing to recover the size; (6), carrying out heat treatment after surfacing; (7), machining after surfacing; (8), detecting before laser cladding; (9), carrying out high-speed laser cladding by carrying out strengthening treatment on the surfaces of core rods by adopting high-speed laser cladding, wherein the used powder material is alloy powder with excellent wear resistance, corrosion resistance and plasticity and toughness; (10), machining after cladding; and (11), detecting finished products. According to the method, the wear resistance, the corrosion resistance and the cold and hot fatigue resistance of the core rods can be greatly improved; the service life of the core rods reaches more than 1.5 times of that of a new product; meanwhile, the whole repairing and manufacturing process is green and pollution-free.

Owner:泰尔(安徽)工业科技服务有限公司

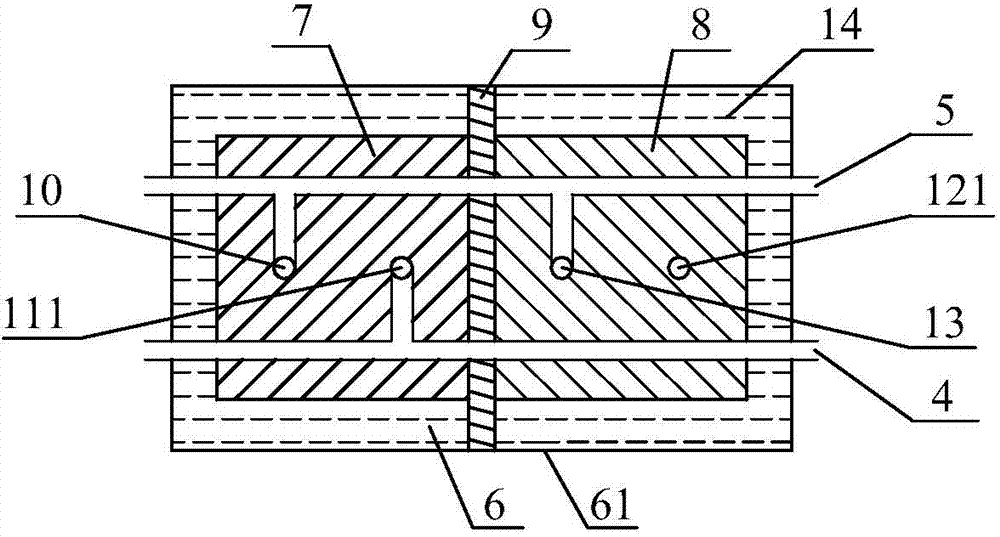

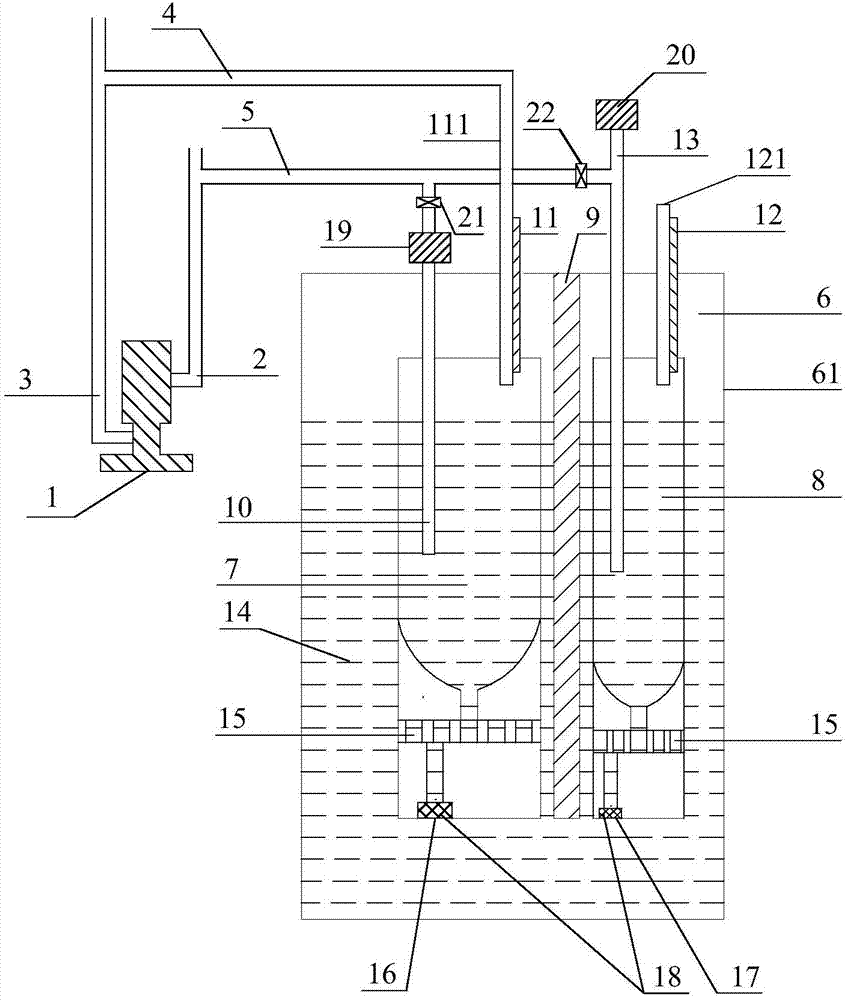

Serial-connection breath-type double-plate cabin solid carbon fuel cell stack and power generation method thereof

ActiveCN104733760AImprove efficiencyFast exchangeFuel cells groupingCell electrodesSolid carbonFuel cells

The invention provides a serial-connection breath-type double-plate cabin solid carbon fuel cell stack and a power generation method thereof, belonging to the technical field of fuel cells. According to the cell stack, a plurality of groups of cell units are connected in series; each group of the cell units comprises an electrolyte cabin, a positive electrode plate cabin and a negative electrode plate cabin, wherein each positive electrode plate cabin and each negative electrode plate cabin are arranged in the electrolyte cabin; positive and negative pressure of positive electrode input gas and negative electrode input gas of the first group of the cell units and positive electrode output gas of the final group of the cell units can be provided by a breath device, and the exchanging of electrolyte in the cell is accelerated; the breath device is sufficiently utilized; a manner of setting each positive electrode plate cabin and each negative electrode plate cabin is adopted; each positive electrode plate cabin and each negative electrode plate cabin adopt a spiral pipeline design and a fuel channel is lengthened; meanwhile, the fuel concentration is matched with the surface area of an electrode so that the electrode efficiency and the fuel efficiency are improved. A positive electrode exhausting pipe of the cell stack is connected with the breath device; water steam exhausted by the positive electrode exhausting pipe can return back to a positive electrode gas inlet pipe and a negative electrode gas inlet pipe through the breath device; and extra pre-heating or heating is not needed so that energy sources are saved.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

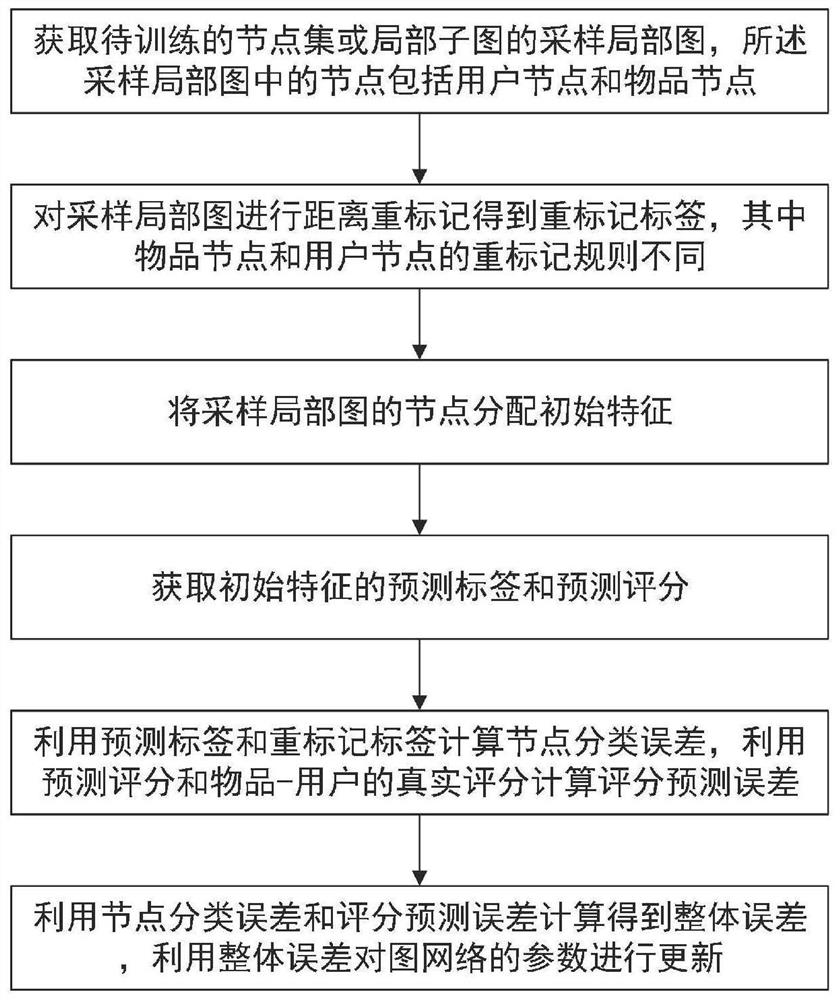

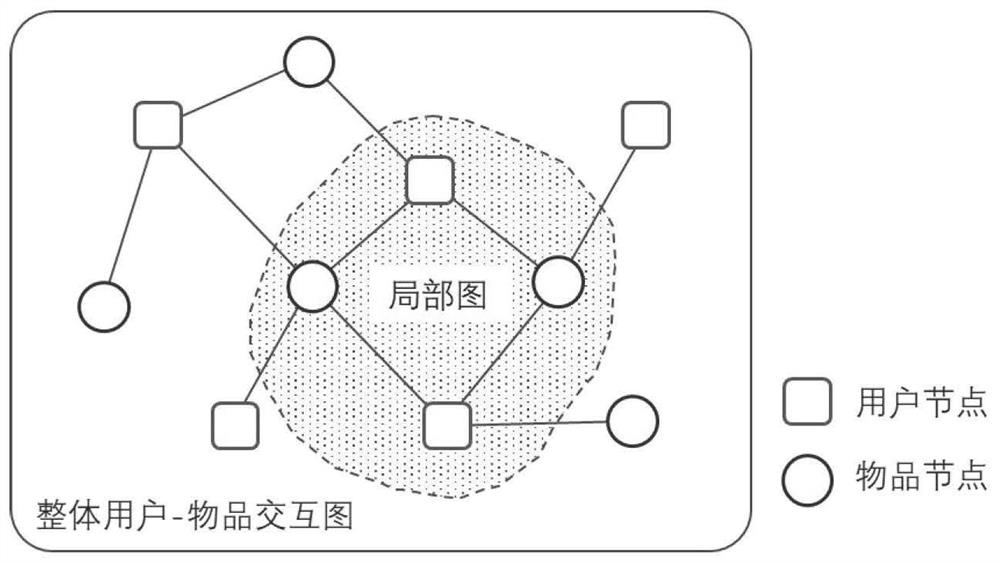

Graph network cold start recommendation method

ActiveCN112784123AEnable connectivityCapable of expressing featuresOther databases indexingEnergy efficient computingGraph inferenceGraph Node

The invention discloses a graph network cold start recommendation method, which comprises the following steps of: inputting pre-scored user-article data into a trained graph network to obtain a recommendation result, the training comprising the following steps: acquiring a sampling local graph of a node set or a local sub-graph to be trained; performing distance re-marking on the sampling local graph to obtain a re-marked label; distributing initial features to nodes of the sampling local graph; obtaining a prediction label and a prediction score of the initial feature; calculating a node classification error by using the prediction label and the remarking label, and calculating a score prediction error by using the prediction score and the real score of the article-user; and performing calculating by using the node classification error and the score prediction error to obtain an overall error, and updating parameters of the graph network by using the overall error. According to the method, through local graph sampling and double-task learning, inductive node reasoning and connection prediction capabilities are further realized on the basis of a deductive graph reasoning task, and the method has a feature representation capability for out-of-graph nodes.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for using initial reaction heat of crude gas transformation and hydrogen production process

InactiveCN101712460AGuaranteed conversion rateReduce humidificationHydrogenHigh carbonReaction temperature

The invention relates to a method for using initial reaction heat of a crude gas transformation and hydrogen production process. A plurality of reaction areas in series operation are set in the crude gas transformation reaction process, the cooling process of intermediate reaction effluent of a front reaction area in which the total transformation ratio of carbon monoxide is 30 to 50 percent comprises a water injection and vaporization process, and the temperature rise of each reaction area is generally less than 60 DEG C, preferably less than 40 DEG C. The method has the advantages of optimization of reaction temperature distribution, high utilization rate of reaction heat, scale reduction of a hot water cyclic moistening system and the like, and is particularly suitable for the crude gas transformation and hydrogen production process of high carbon monoxide content (for example, higher than 12 percent volume).

Owner:何巨堂

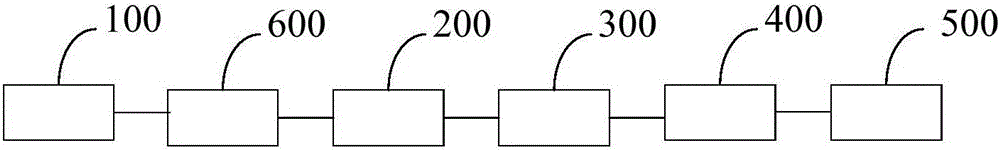

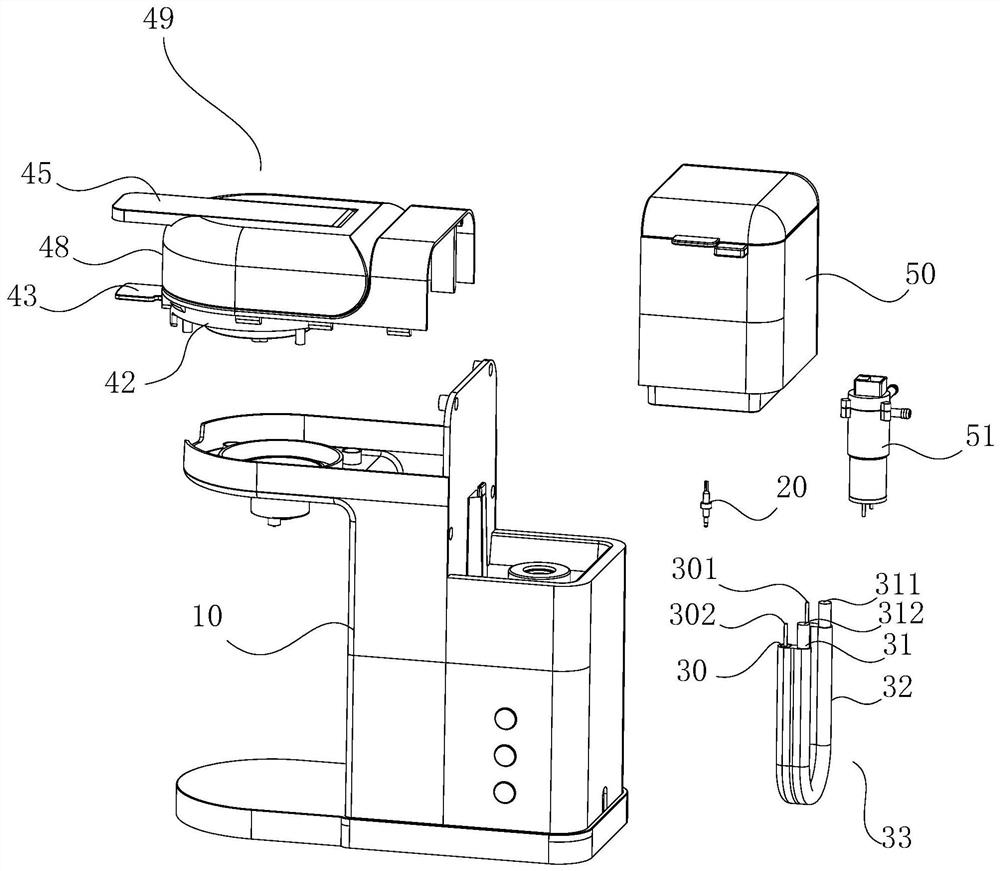

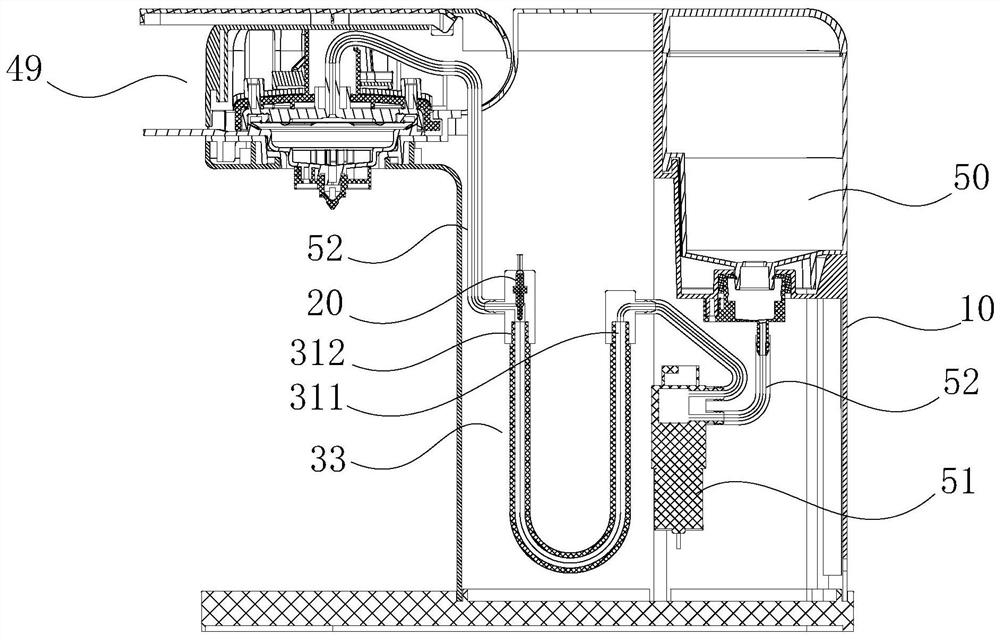

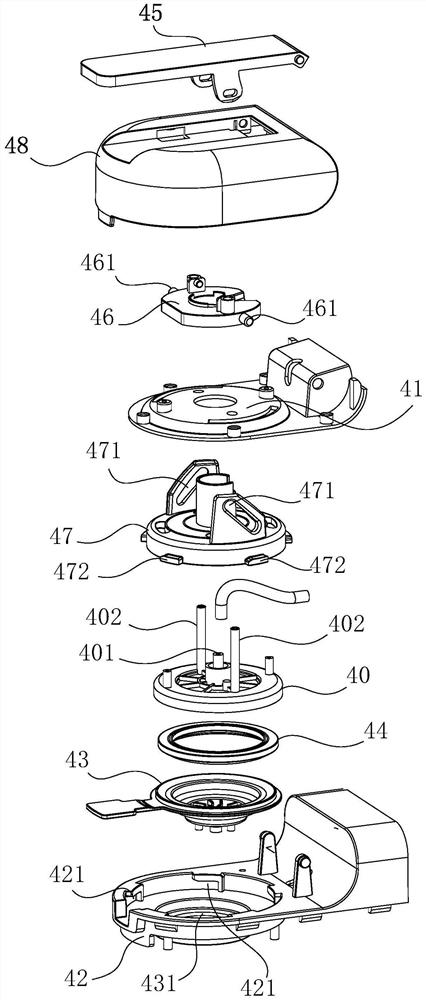

Coffee machine and working method thereof

PendingCN113040605AShort preparation timeShort timeBeverage vesselsTemperature controlProcess engineering

The invention discloses a coffee machine and a working method thereof. The coffee machine comprises a shell, a water supply mechanism, an instant heating mechanism, a temperature control device and a coffee extraction mechanism, the water supply mechanism, the instant heating mechanism, the temperature control device and the coffee extraction mechanism are all installed in the shell, and the instant heating mechanism comprises a water inlet part and a water outlet part; the water inlet part and the water supply mechanism are connected through a water conveying pipe, the water outlet part and the coffee extraction mechanism are connected through a water conveying pipe, and the temperature control device detects the water temperature of the water outlet part. The coffee machine is high in coffee making efficiency, long-time waiting of consumers is avoided, the requirements of the consumers can be better met, and the consumption experience is improved.

Owner:珠海鑫润智能家电有限公司

Parallel breath-type double-plate cabin solid carbon fuel cell stack and power generation method thereof

ActiveCN104733762AImprove efficiencyIncrease electrolyte exchange rateFuel cells groupingFinal product manufactureSolid carbonFuel cells

The invention provides a parallel breath-type double-plate cabin solid carbon fuel cell stack and a power generation method thereof, belonging to the technical field of fuel cells. According to the cell stack, a plurality of groups of cell units are connected in parallel; each group of the cell units comprises an electrolyte cabin, a positive electrode plate cabin and a negative electrode plate cabin; each positive electrode plate cabin and each negative electrode plate cabin are arranged in the corresponding electrolyte cabin; positive and negative pressure of positive electrode input gas, negative electrode input gas and positive electrode output gas is provided by a breath device, and the exchanging of electrolyte in the cell is accelerated; a manner of arranging each positive electrode plate cabin and each negative electrode plate cabin is adopted; each positive electrode plate cabin and each negative electrode plate cabin adopt a spiral pipeline design and a fuel channel is lengthened; meanwhile, the fuel concentration is matched with the surface area of an electrode so that the electrode efficiency and the fuel efficiency are improved; and the structure is simple, the manufacturing is easy and the cost is relatively low. A positive electrode exhausting pipe of the cell stack is connected with the breath device; water steam exhausted by the positive electrode exhausting pipe returns back to a positive electrode gas inlet pipe and a negative electrode gas inlet pipe through the breath device, so that the utilization rate of water is improved; and extra pre-heating or heating is not needed so that energy sources are saved.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

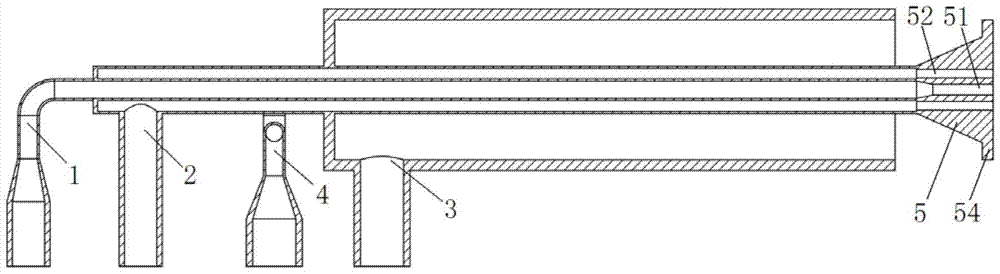

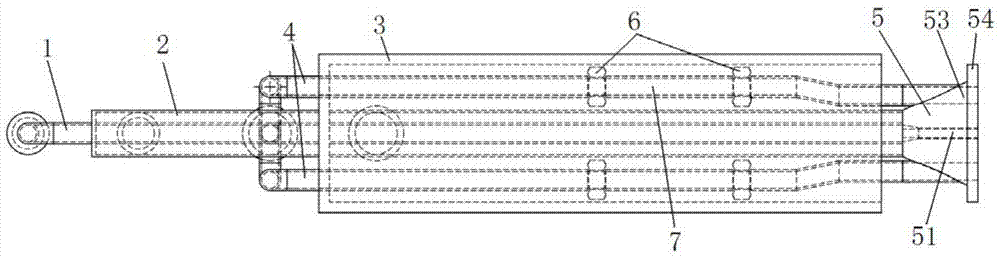

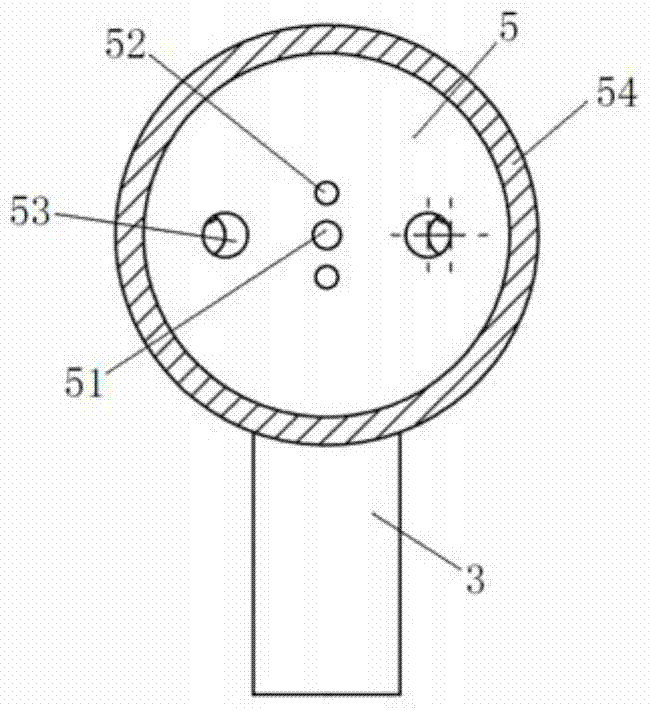

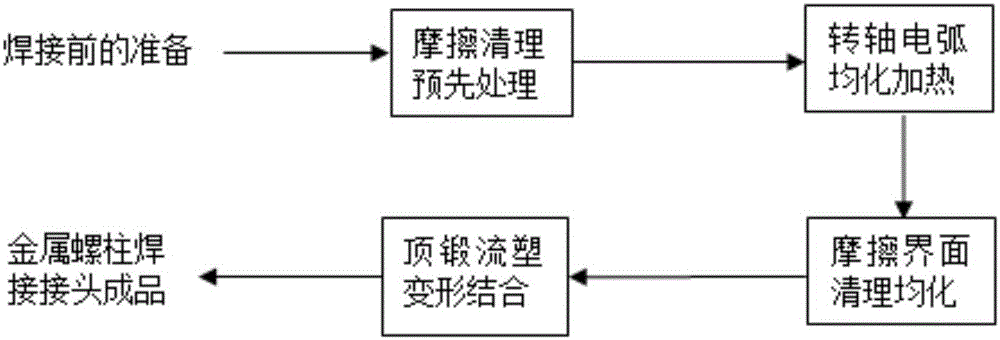

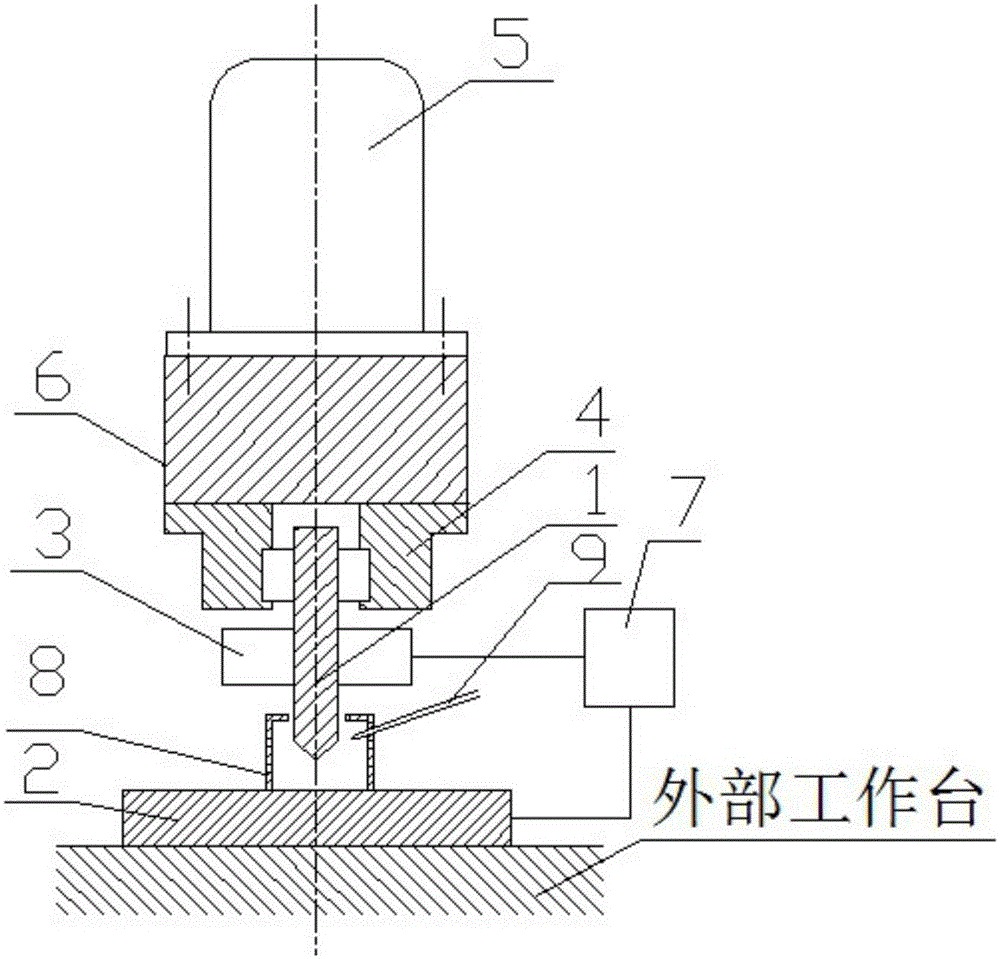

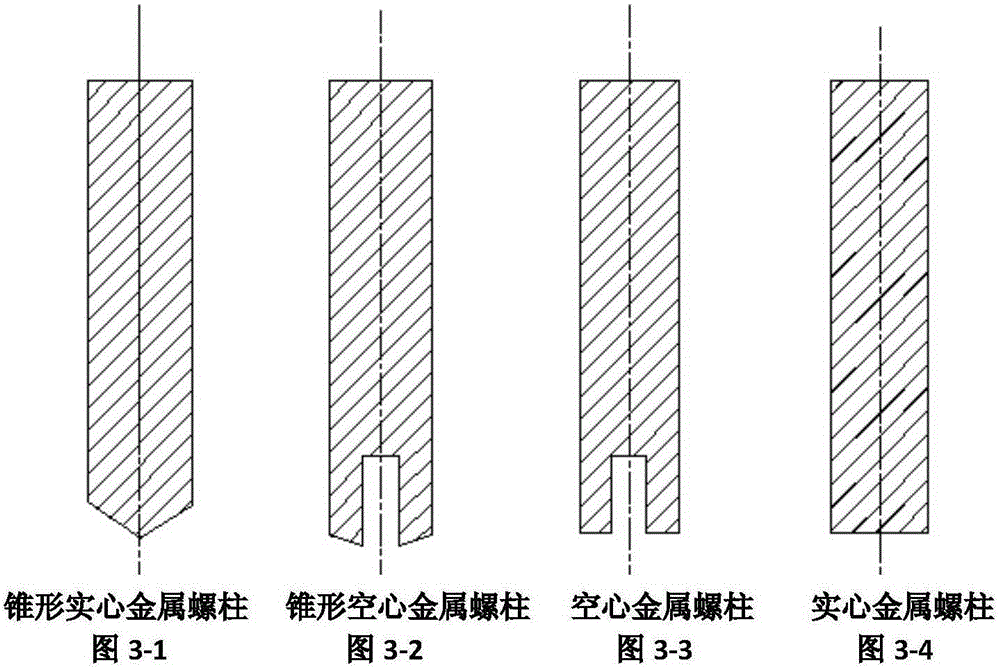

Arc metal stud welding method and device under friction cleaning and homogenization

ActiveCN103753029BClean thoroughlyGuaranteed cleanlinessArc welding apparatusNon-electric welding apparatusElectrical conductorEngineering

The invention relates to an electrical arc metal stud welding method and an electrical arc metal stud welding device under frictional cleaning homogenization. According to the electrical arc metal stud welding method and the electrical arc metal stud welding device under the frictional cleaning homogenization, a worker preprocesses the end face of a metal stud and the surface of a metal base plate through frictional cleaning, heats a spindle dynamic arc in homogenization mode, and combines cleaning homogenization and upset forging plastic flow deformation of a friction interface together, and accordingly a metal stud welding joint end product which is excellent in performance is obtained. The electrical arc metal stud welding method and the electrical arc metal stud welding device under the frictional cleaning homogenization can achieve welding of thick and large metal sheets and large diameter metal studs, are suitable for welding between a steel, nickel, copper, titanium, aluminum, or magnesium metal stud and a base plate made of metal material as same as or different from the metal stud, and are particularly suitable for welding of metal studs made of fragile conductor material which is difficult to weld and metal studs made of high carbon equivalent steel.

Owner:江苏靖宁智能制造有限公司

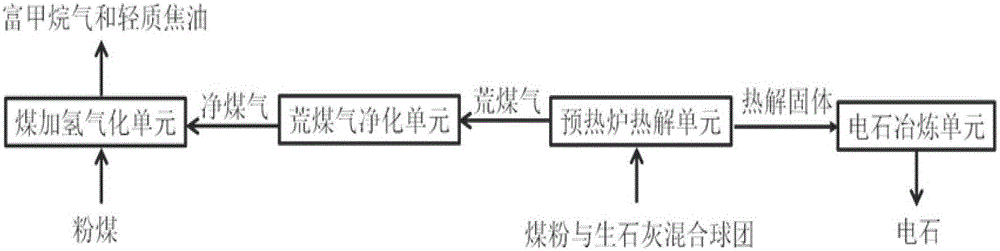

System and method for treating pulverized coal and calcium-based raw material

InactiveCN106635096ALow costHigh quality pyrolysis gasCoal charges mechanical treatmentCombustible gas catalytic treatmentSpray nozzleHydrogen content

The invention relates to a system and a method for treating pulverized coal and a calcium-based raw material. The system comprises a pyrolysis unit, a gas purification unit, a hydrogasification unit and a calcium carbide smelting unit, wherein the pyrolysis unit comprises a pulverized coal and calcium-based raw material mixed pellet inlet, a raw coke oven gas outlet and a pyrolysis solid pellet outlet; the gas purification unit comprises a raw coke oven gas inlet and a purified coke oven gas outlet; the raw coke oven gas inlet is connected with the raw coke oven gas outlet; the hydrogasification unit comprises a pulverized coal spray nozzle, a purified coke oven gas spray nozzle, a coke residue outlet and an oil gas outlet; the purified coke oven gas spray nozzle is connected with the purified coke oven gas outlet; the calcium carbide smelting unit comprises a high-temperature solid pellet inlet, a calcium carbide furnace gas outlet and a calcium carbide outlet; the high-temperature solid pellet inlet is connected with the pyrolysis solid pellet outlet. According to the system and the method disclosed by the invention, by using the advantage of high quality and high hydrogen content of pyrolysis gas obtained by copyrolysis of coal and quick lime in a preheating furnace, the pyrolysis gas can be used as a hydrogen source of coal hydrogasification when calcium carbide is produced, so that the cost of the hydrogen source is reduced, and the thermal efficiency of the system is improved.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

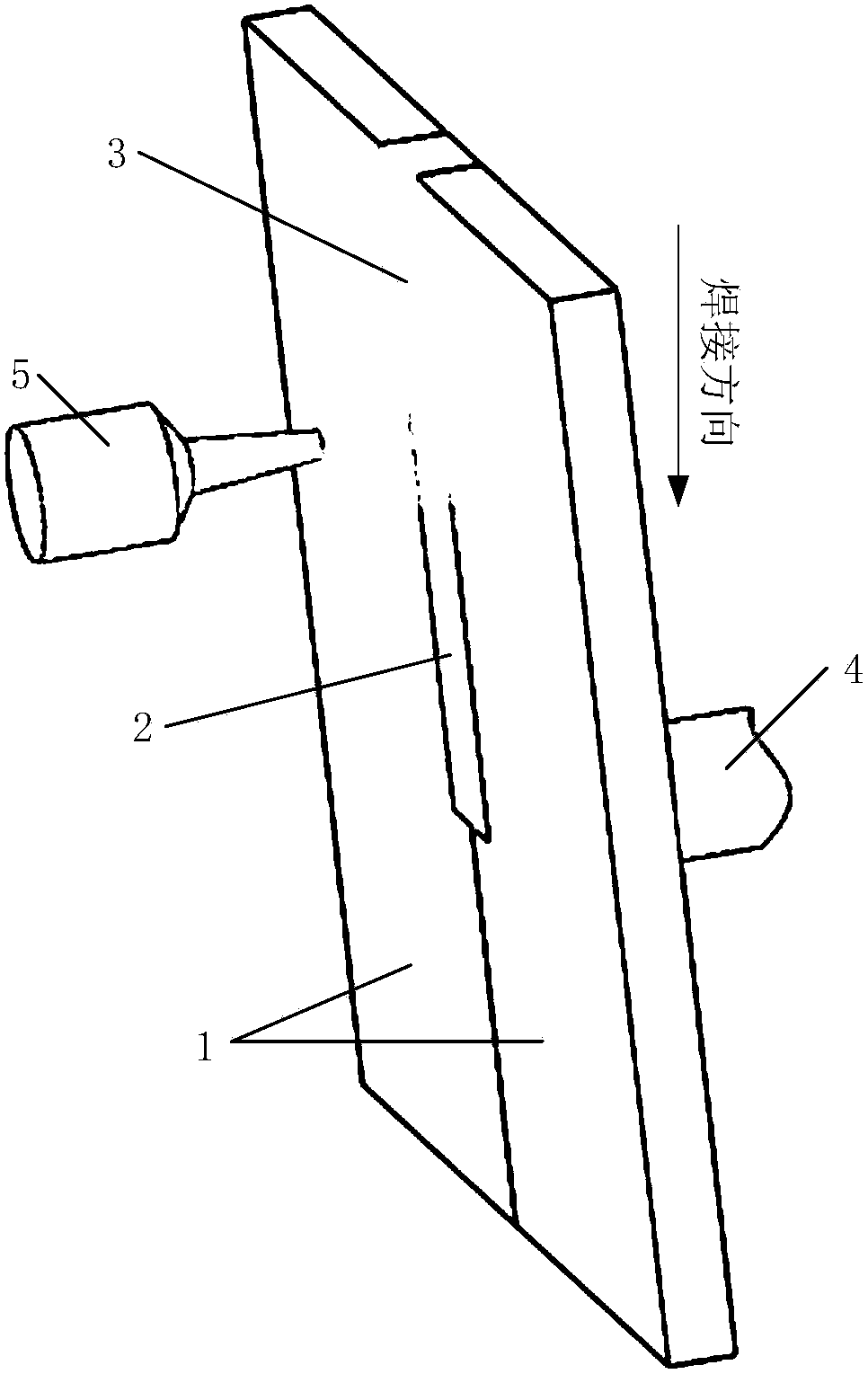

Forging method capable of reducing curvature of slender steel

ActiveCN111266504AAvoid bendingControl StraightnessForging/hammering/pressing machinesHandling devicesStress concentrationClassical mechanics

The invention relates to a forging method capable of reducing curvature of slender steel, and belongs to the technical field of steel forging. In order to solve the problem that a precision forging machine is liable to generate bending during slender steel forging, the invention provides the forging method capable of reducing the curvature of the slender steel. A deformation way of alternating forging passes and no-load passes in a precision forging process is adopted, an initial-stage forging pass adopt a regular forging method, the last two forging passes start to forge one end of a materialfrom the middle position, with certain distance from the end head of the material, return to the middle position with no load and forge to the other end of the material from the position. Structuralstress and deformation stress generated during forging are released through the no-load passes, so that the stress is prevented from being focused to generate bending; and the last two forging passesadopt pulling and punching to reduce bending caused by impact generated by the material and the edge of a hammer head in a pushing-in process, so that linearity of a slender rod or square steel forgedby the precision forging machine is effectively controlled, and a qualification rate of the product is increased.

Owner:建龙北满特殊钢有限责任公司

Solar preprocessing assembly in fresh air system of central air conditioner

InactiveCN108662697AReduce humidityReduce warm-upDucting arrangementsLighting and heating apparatusElectricityFresh air

The invention provides a solar preprocessing assembly in a fresh air system of a central air conditioner and belongs to the invention field. By adopting the fresh air system, the problem of poor stability in the prior art is solved. The solar preprocessing assembly in the fresh air system of the central air conditioner is arranged between a main pipe and an air blower and comprises a base, supportrods, a solar photovoltaic panel, a storage battery and a heating component, wherein the base is plate-shaped; the lower ends of the support rods are fixedly connected onto the base and the upper ends of the support rods are connected with the solar photovoltaic panel; the storage battery is fixedly connected onto the base and is electrically connected with the solar photovoltaic panel through aconducting wire; and the heating component is located between the outer end of the main pipe and the air blower. The solar preprocessing assembly in the fresh air system of the central air conditionerhas high reliability.

Owner:海宁市高级技工学校

Magnesium alloy waste regenerator

InactiveCN1207410CReduce recycling costsImprove refining effectCrucible furnacesCombustionSpiral blade

Owner:TSINGHUA UNIV

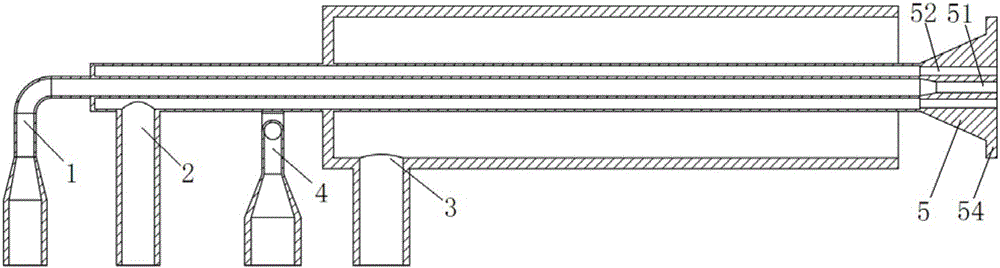

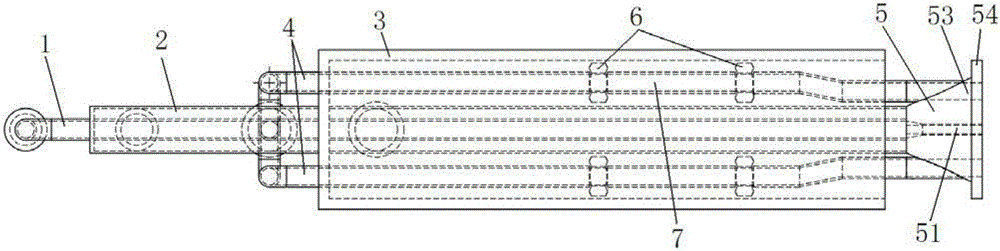

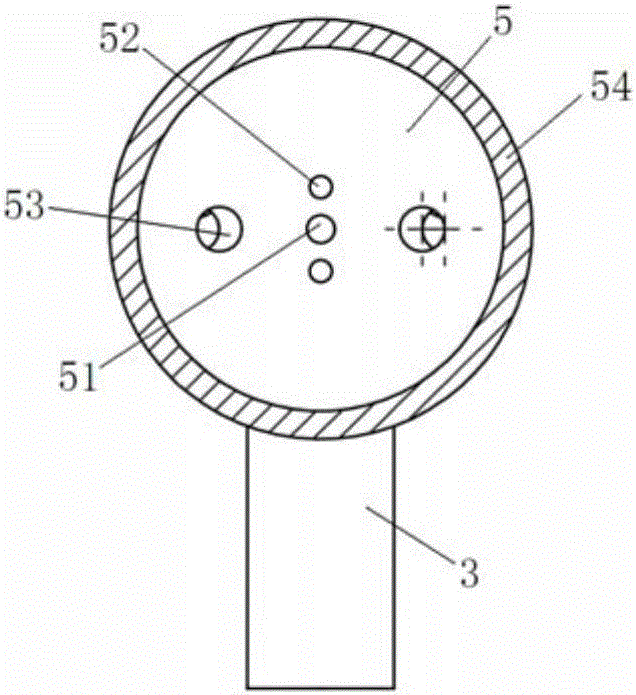

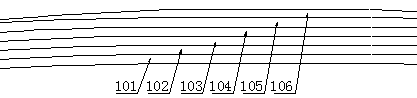

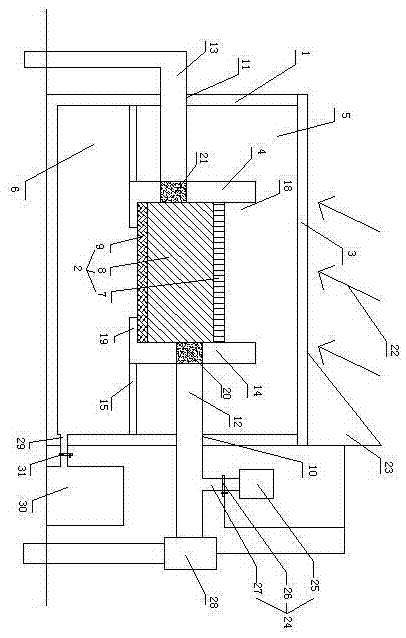

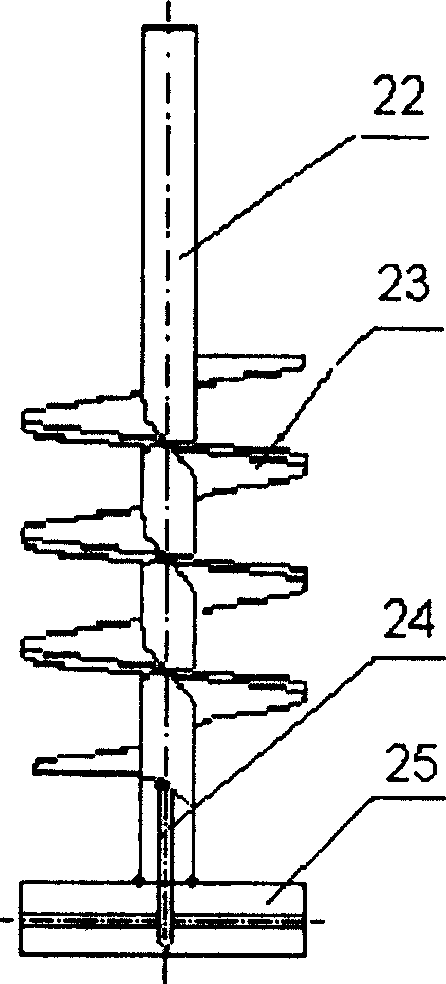

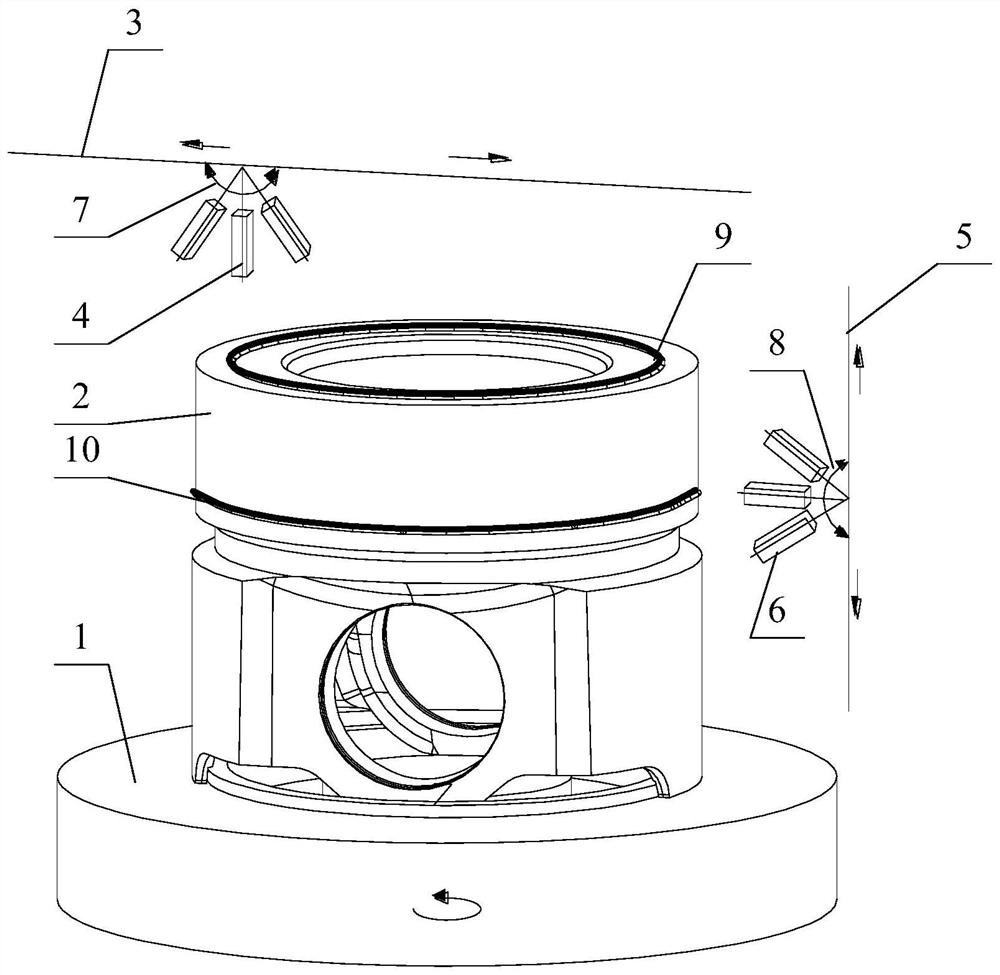

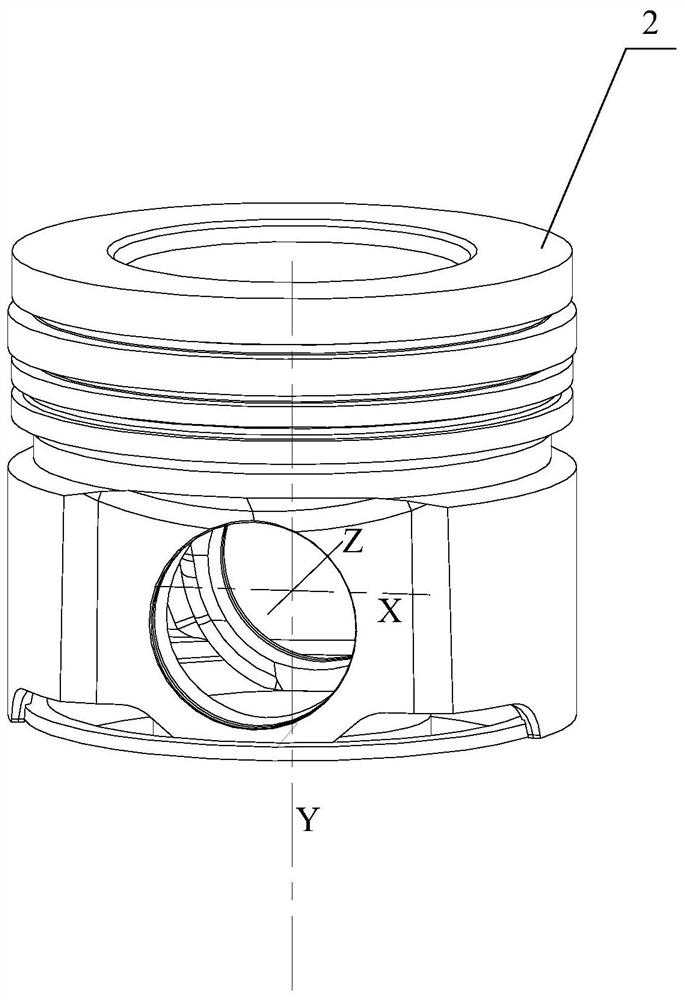

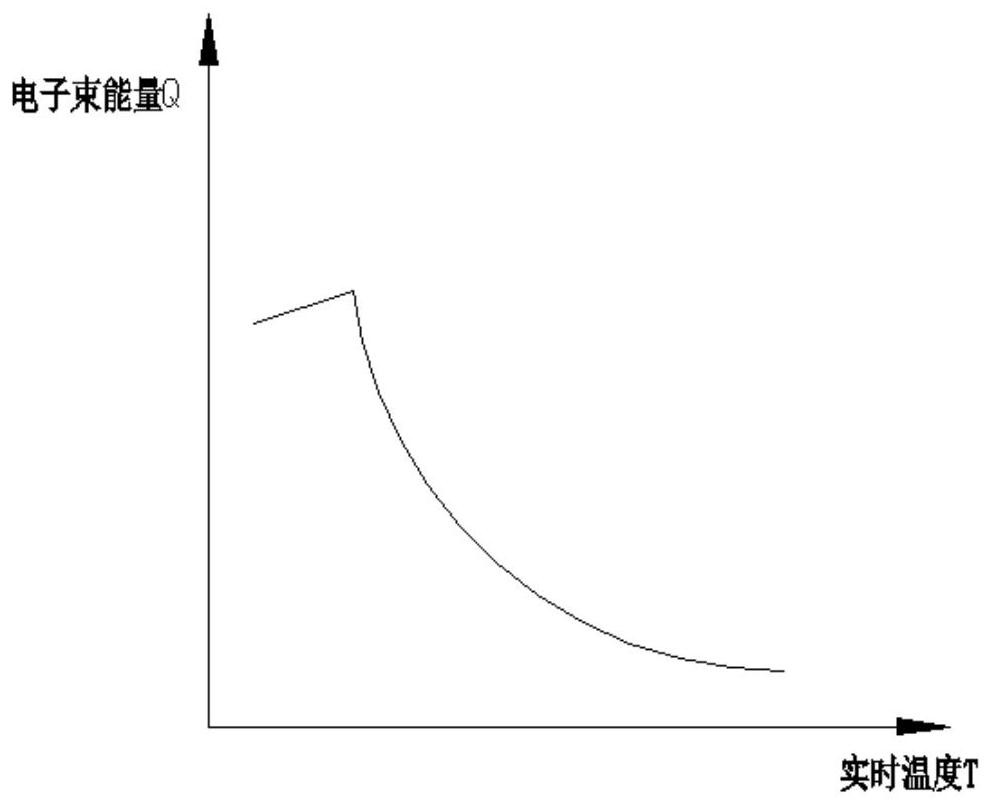

Piston welding device and method

ActiveCN112809155ASimplify the welding processReduce warm-upPistonsElectron beam welding apparatusPistonSoldering gun

The invention discloses a piston welding device and method. The device comprises a workbench, a first linear guide rail and a second linear guide rail. The workbench is provided with a fixing part matched with a lower end spigot of a piston and can drive the piston to rotate around the central axis of the piston. The first linear guide rail is located above the piston and is parallel to the long axis of the piston, a first welding gun used for welding a top seam is arranged on the first linear guide rail, and the first welding gun can move along the first linear guide rail. The second linear guide rail is parallel to the central axis and is located on the side face of the piston. The second linear guide rail is provided with a second welding gun used for welding a circular seam, and the second welding gun can move along the second linear guide rail. During actual use, the positions of the first welding gun and the second welding gun on the first linear guide rail and the second linear guide rail are adjusted respectively, then the top seam and the circular seam can be welded by rotating the workbench, and the working efficiency is improved.

Owner:湖南江滨机器(集团)有限责任公司

Waste plastic cracking device

InactiveCN104845655AReduce labor intensityGuaranteed continuous cracking productionLiquid hydrocarbon mixture productionSlagEngineering

The invention relates to a cracking device and specifically relates to a waste plastic cracking device. The waste plastic cracking device comprises a cracking furnace in which a cracking kettle is arranged, a cracking furnace support for supporting the cracking furnace and a plurality of burners arranged below the cracking furnace; a gas collecting pipe and a flue gas pipe are arranged at the top of the cracking furnace; a slag remover is arranged at the tail of the cracking furnace; a feeder is arranged in front of the cracking furnace; a feeder heating device is arranged under the feeder; a flame distribution pipe is arranged in the cracking furnace and located under the cracking kettle. The waste plastic cracking device is capable of overcoming the defects of the existing cracking device, realizing continuous and automatic feeding and reducing the labor intensity of a worker, and is high in cracking capability; large-scale production of the waste plastic cracking device can be realized.

Owner:SHANDONG BOAOHUA SHALE OVEN R&D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com