Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Realize automated mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

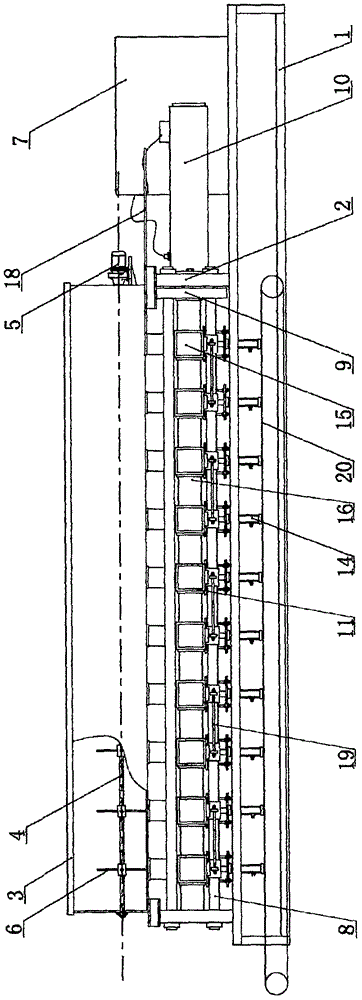

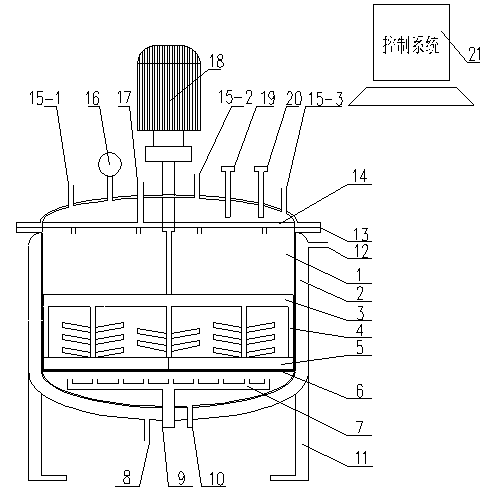

Solid state fermentation cylinder and solid state fermentation method

ActiveCN102839119AWell mixedAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsThermal insulationEngineering

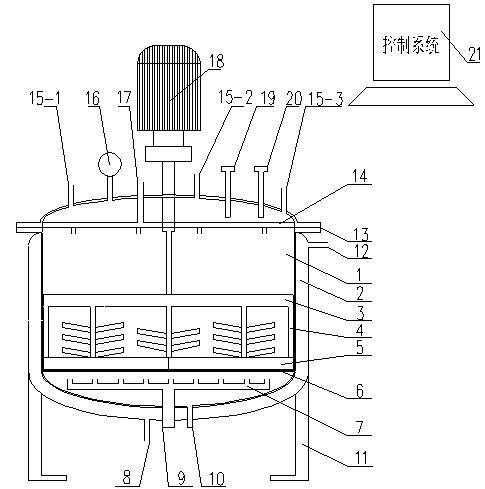

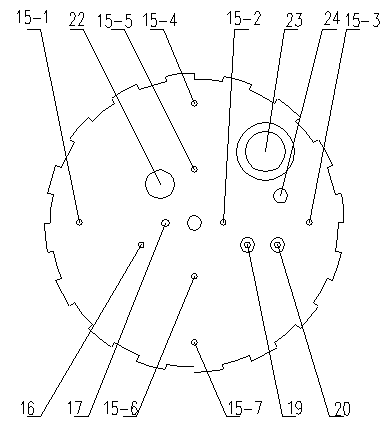

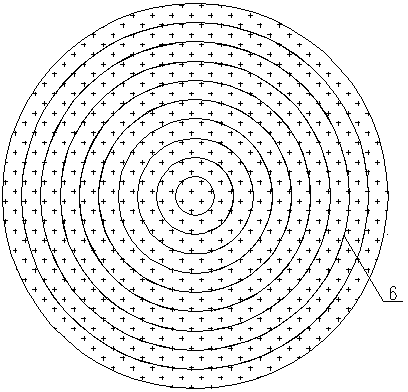

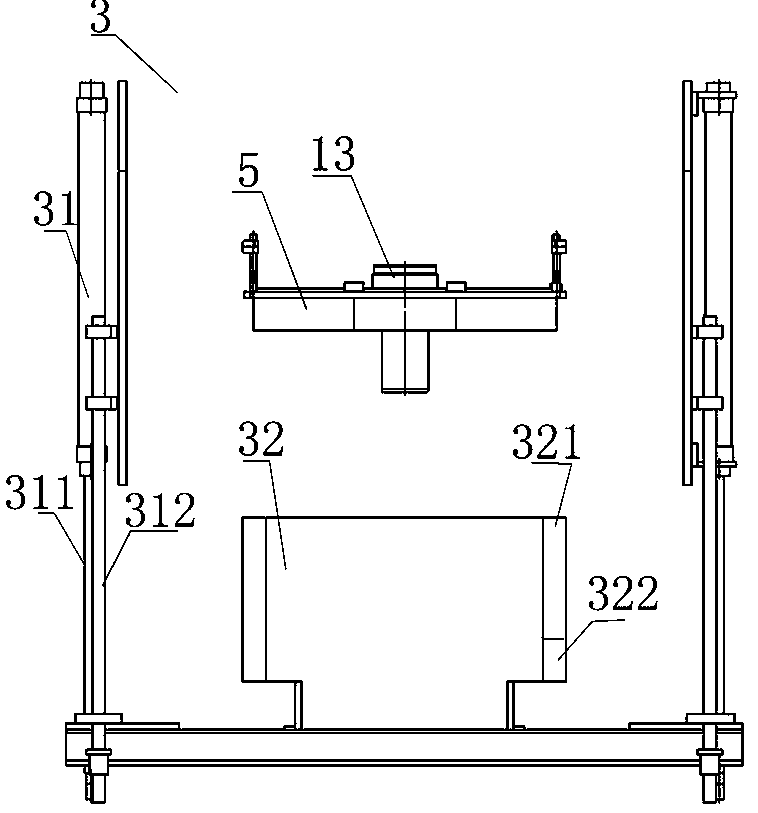

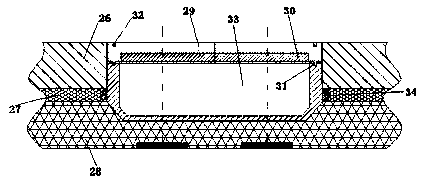

The invention discloses a solid state fermentation cylinder and a solid state fermentation method. The solid state fermentation cylinder comprises a cylinder body and a jacket provided with an upper port and a lower port, the upper end of the cylinder body is an upper end cover, a mixing system capable of lifting is arranged on the upper end cover, and according to the mixing system, a mixing frame is driven by a driving system. The mixing frame is formed by a wall surface scraper plate, a bottom surface scraper plate and mixing blades, the wall surface scraper plate and the bottom surface scraper plate form a frame-shaped structure, and the mixing blades are fixedly connected in the frame-shaped structure. The solid state fermentation cylinder and the solid state fermentation method effectively resolve the problem of low fermentation performance caused by uneven thickness and uneven heating of a feed layer. According to the solid state fermentation cylinder and the solid state fermentation method, all the processes from feeding to discharging are concentrated in the solid state fermentation cylinder, the process of transportation of materials is simplified, and the mixing system and a cooling thermal-insulation system of equipment are strengthened. Automatic bulk production of solid state fermentation can be achieved, the pure culture in the solid state fermentation process is effectively guaranteed, quality and safety of products are improved, and homogeneity property in the same bulk is guaranteed.

Owner:CHENGUANG BIOTECH GRP CO LTD

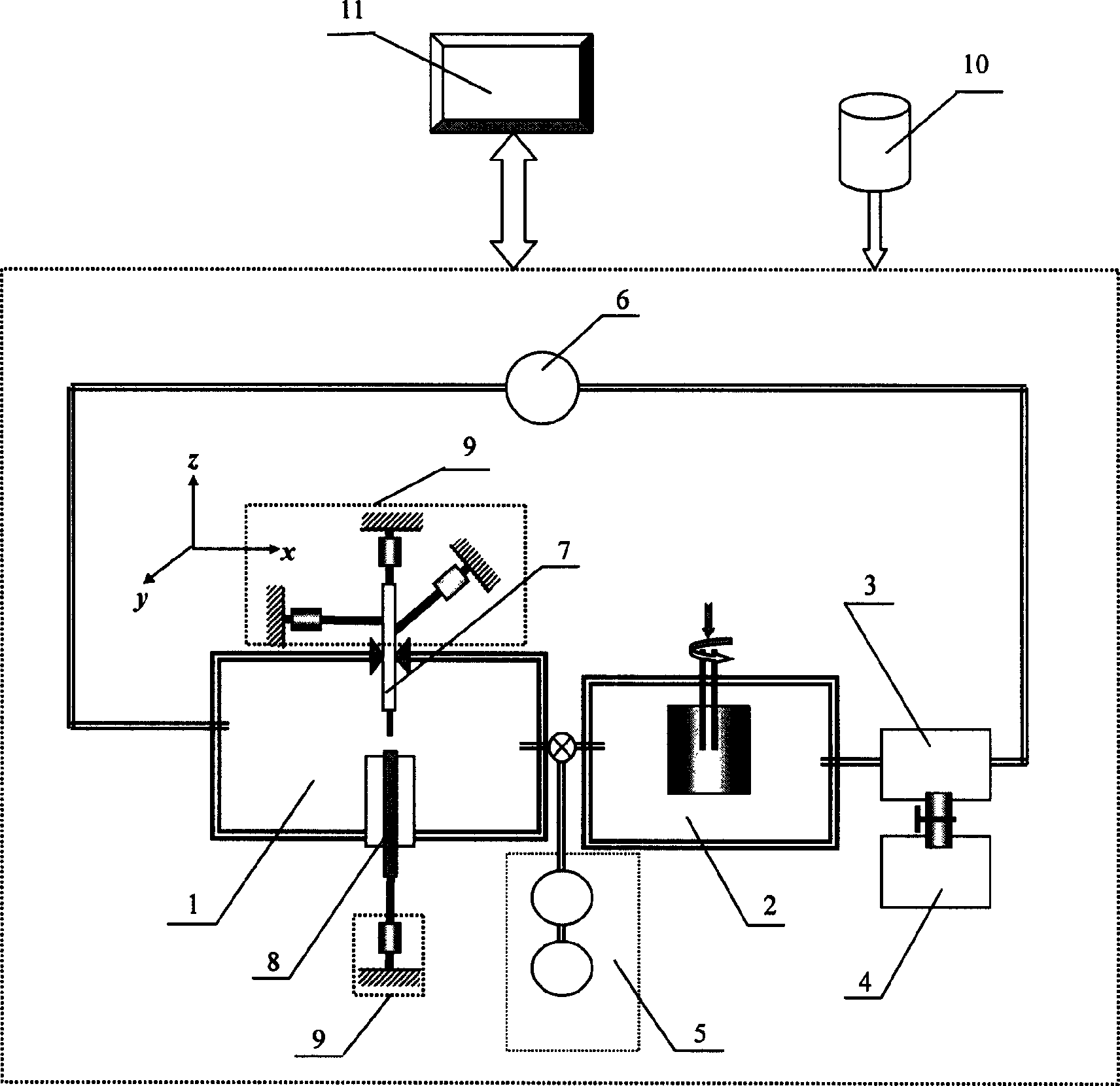

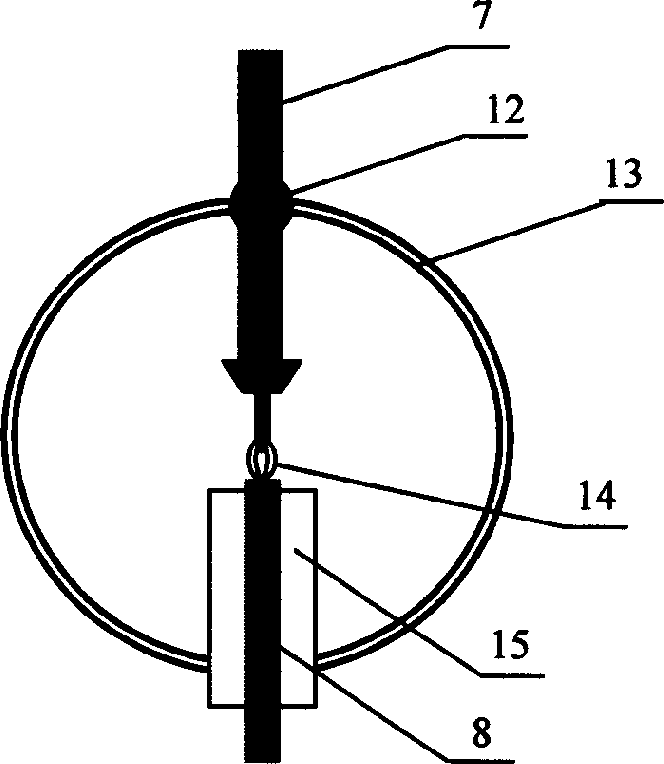

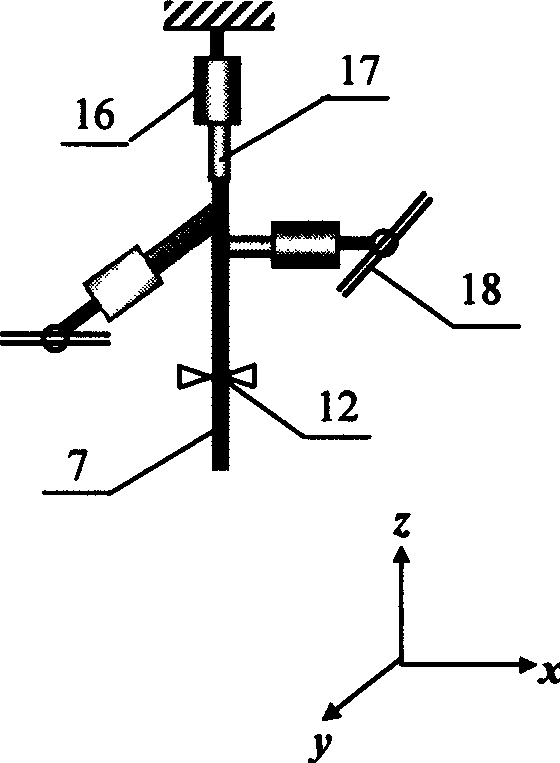

Equipment and method for producing metal nanometer power by automatic control DC electric arc

A method for preparing metallic nanoparticles features that 3D movement of DC arc cathode and the 1D movement of anode are automatically controlled for continuous and stable prodution and the products are classified according their granularities in vacuum condition. Its apparatus is composed of generating chamber, classifying chamber, gathering chamber and processing chamber.

Owner:DALIAN UNIV OF TECH

Preparation method of diamond segment

ActiveCN104399985AEasy to prepareImprove sharpnessTurbinesOther manufacturing equipments/toolsVolumetric Mass DensityHardness

The invention discloses a preparation method of a diamond segment. The preparation method comprises the following steps in sequence: a certain amount of prealloy powder or elemental metal powder, diamond and additives are weighed and mixed; the diamond segment is formed through pressing; the pressed diamond segment is sintered; and the sintered diamond segment is polished, wherein the sintering is high-temperature continuous sintering. The preparation method of the diamond segment is simple, wide in application range and low in processing cost, the sharpness of a product is good, the production efficiency is high, edge breakage is almost avoided, and automatic batch production can be realized. According to the diamond segment finishing high-temperature continuous sintering, the diamond can be firmly held by the prealloy powder or elemental metal powder matrix, so that the diamond segment has longer service life and higher sharpness, the relative density of the sintered diamond segment can be higher than 90%-98%, and the hardness can reach HRB 100-115.

Owner:广东新劲刚金刚石工具有限公司

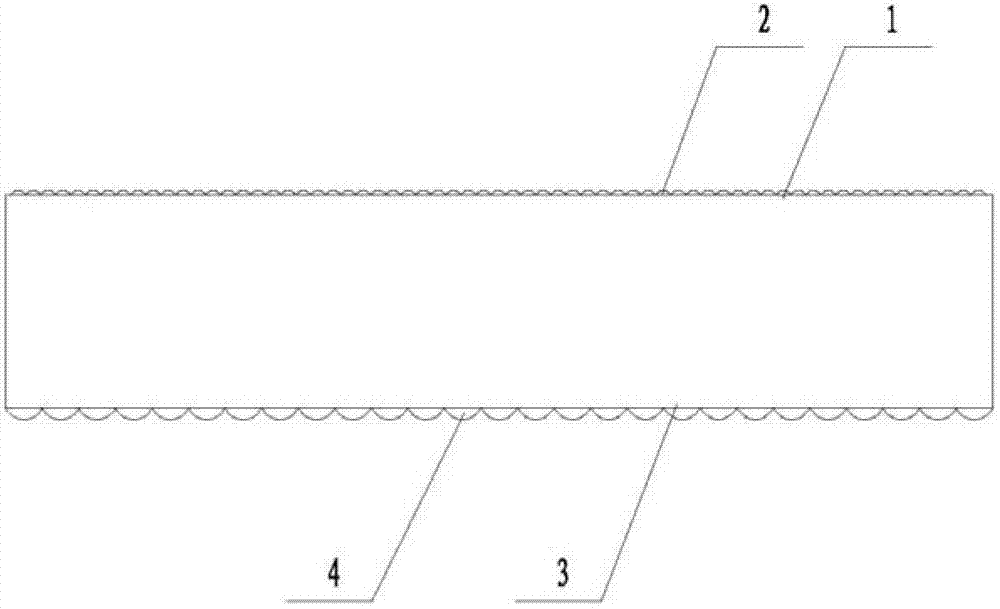

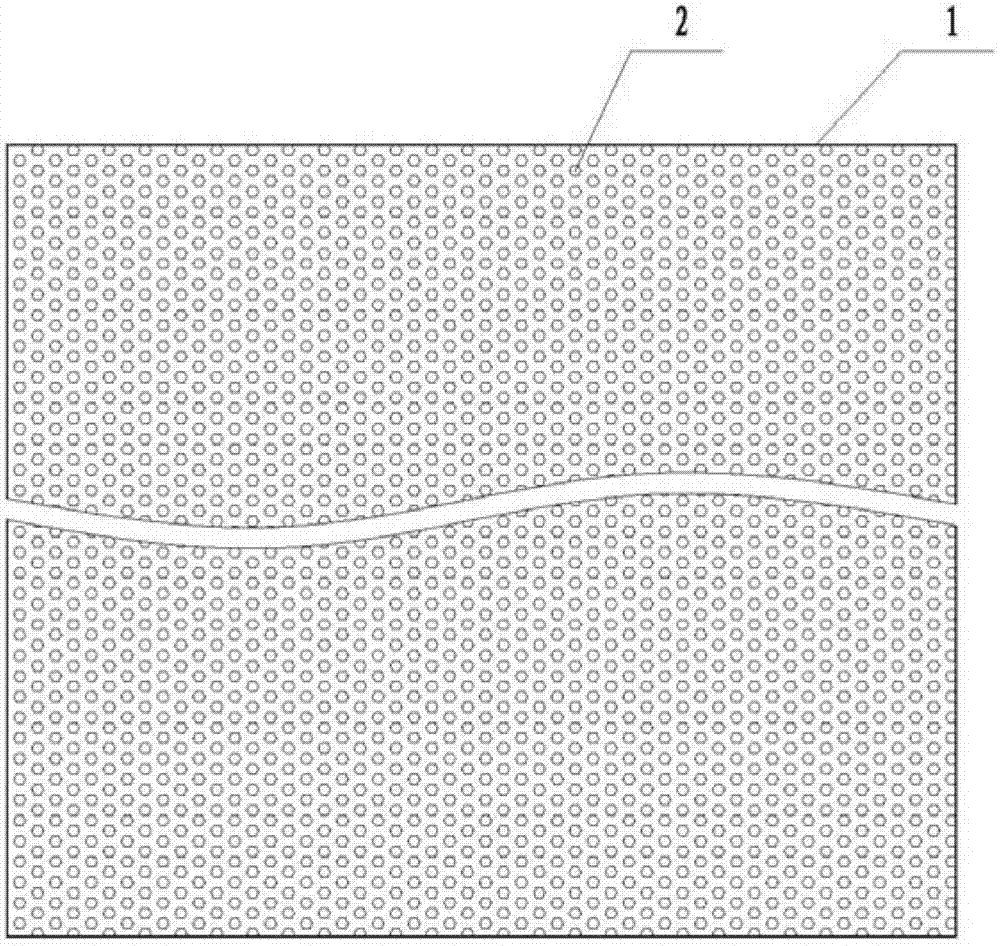

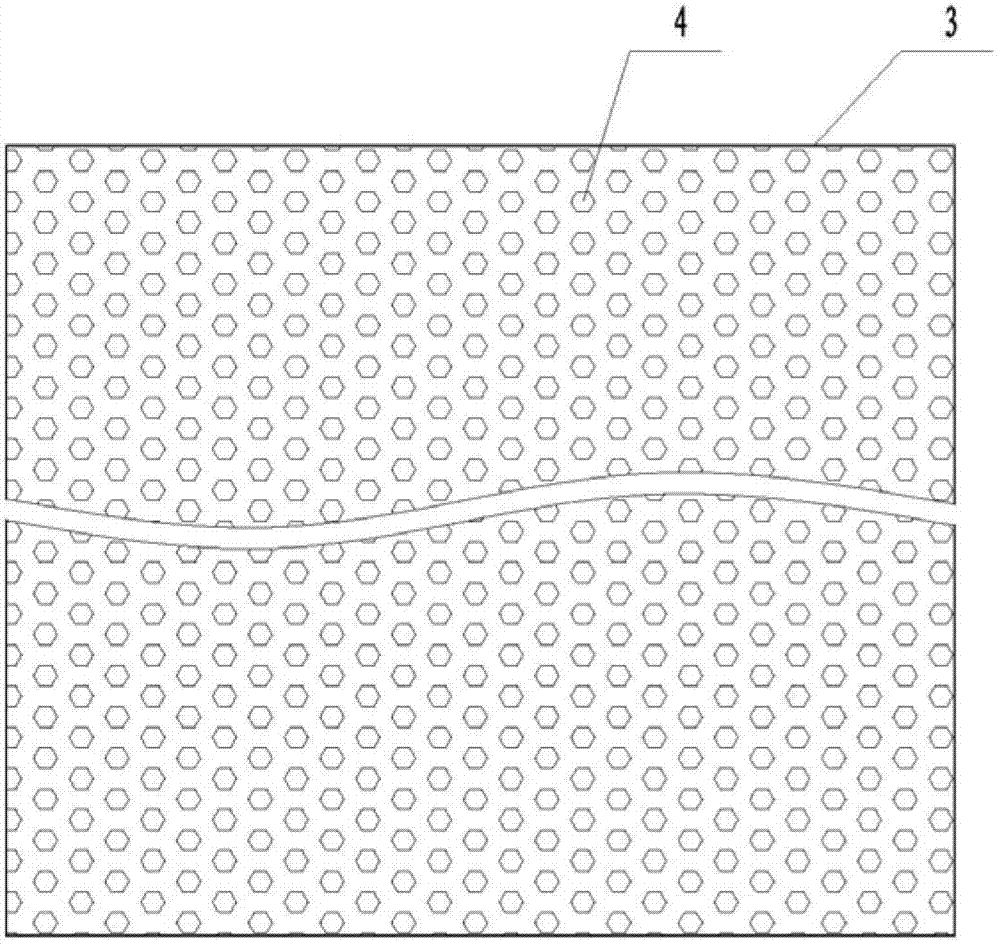

Light guide plate and manufacturing method of light guide plate as well as backlight module and display device

InactiveCN102928911AIncrease display brightnessImprove product qualityPolishing machinesPoint-like light sourceLight guideDisplay device

The invention relates to the technical field of display and particularly relates to a light guide plate capable of utilizing a micro-penetration surface to collect light and a manufacturing method of the light guide plate as well as a backlight module and a display device. An emergent surface of the light guide plate is the micro-penetration surface; the micro-penetration surface comprises a plurality of micro-penetration points and the micro-penetration points are provided with convex surfaces; and the bottom surface of the light guide plate is a net surface and the net surface comprises a plurality of net points and the net points are provided with convex surfaces. The manufacturing method of the light guide plate comprises the steps of: presetting a micro-penetration point distribution pattern by a precision engraving machine; putting a micro-penetration surface die core base plate into a precision engraving machine; engraving the micro-penetration surface die core base plate into a micro-penetration face die core according to the micro-penetration point distribution pattern; assembling the micro-penetration surface die core and a light guide plate die core into a light guide plate die; and injecting and molding into the light guide plate by the light guide plate die. A micro-penetration surface design is adopted and directions of all scattering lights in the light guide plate can be adjusted by using the micro-penetration surface to collect the scattering lights; and the development brightness and the influence definition of a liquid crystal liquid screen are improved and the product quality is improved.

Owner:BOE TECH GRP CO LTD +1

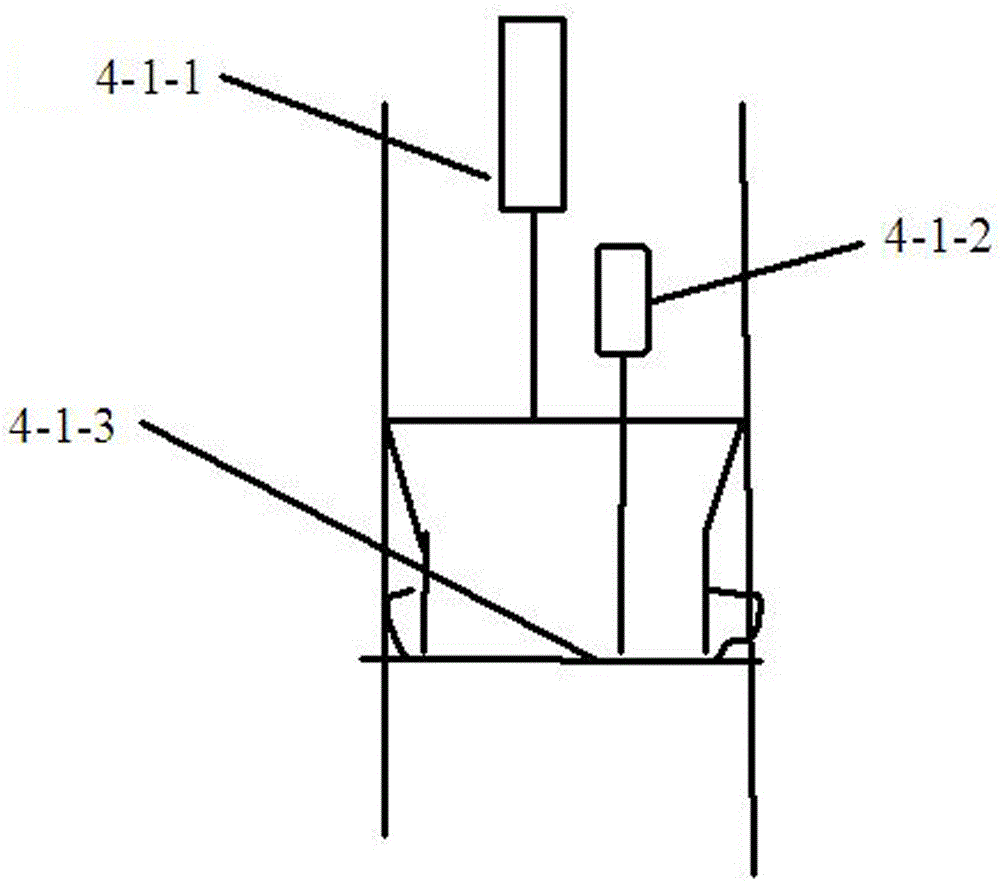

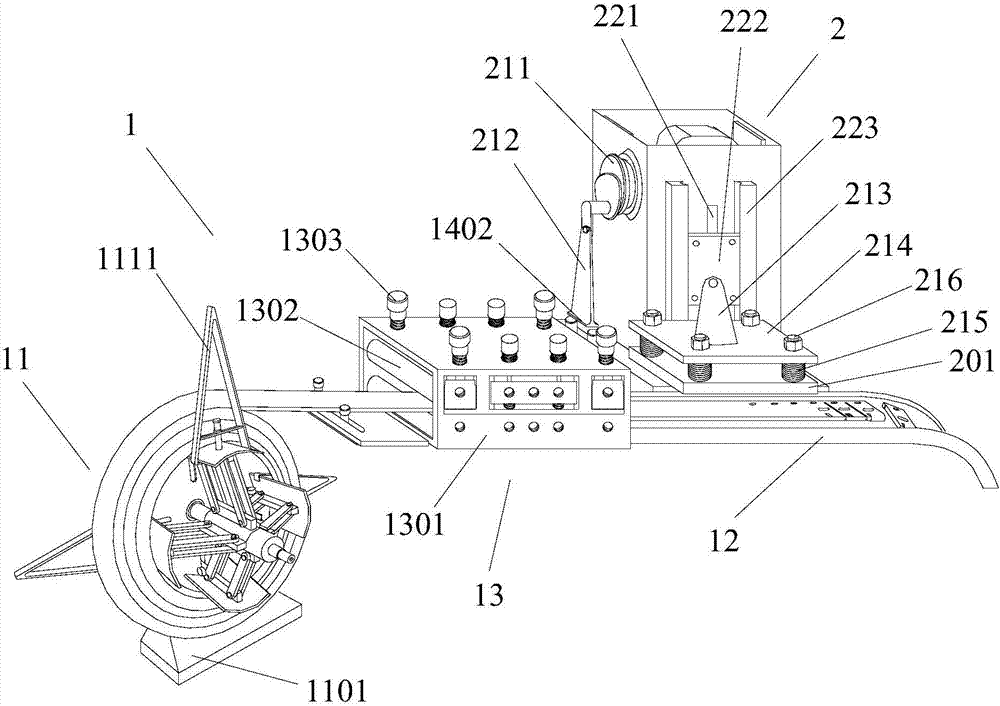

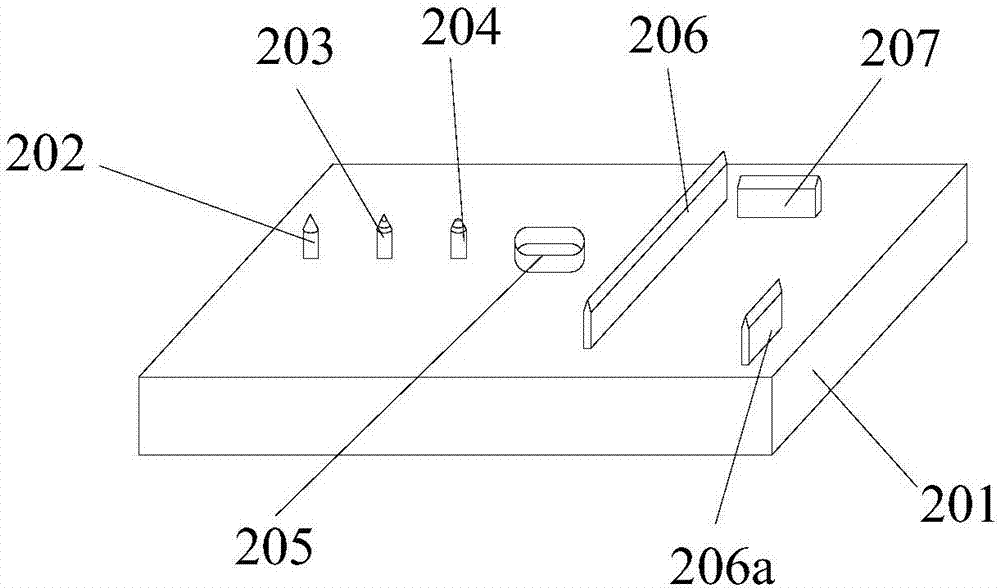

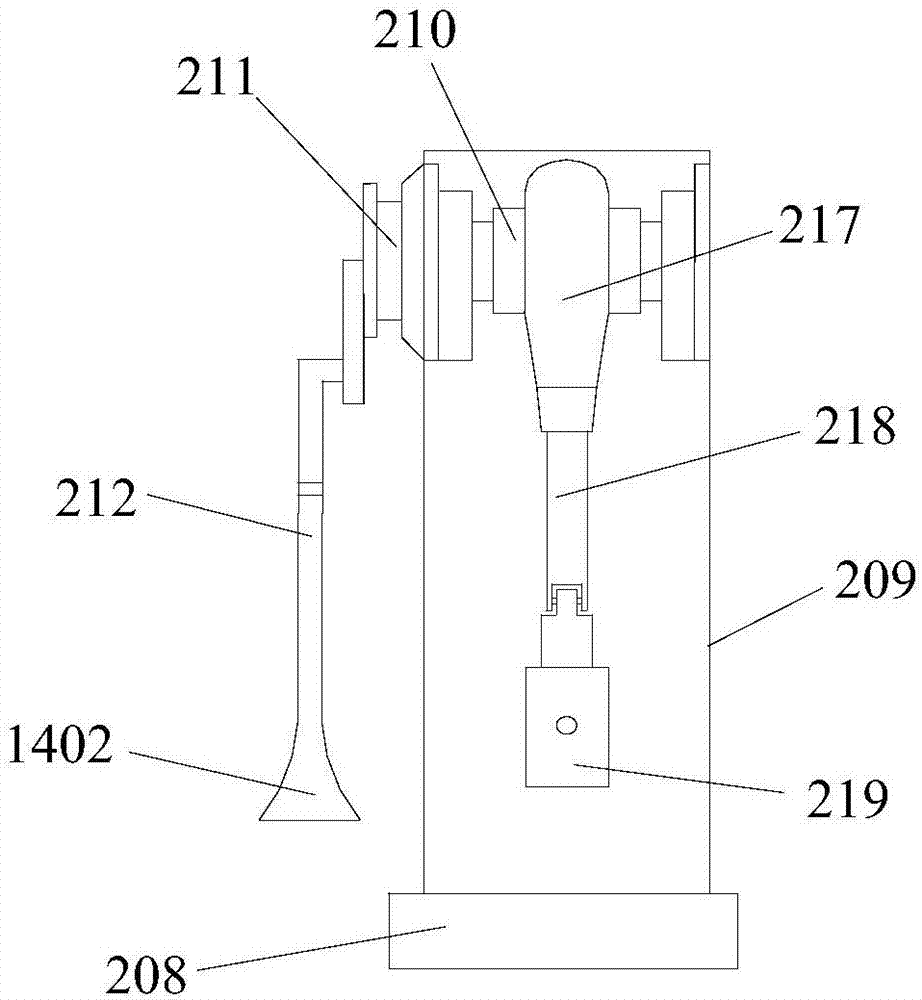

Automatic moxa stick rolling machine

ActiveCN105919798AConsistent weightBeautiful appearanceDevices for heating/cooling reflex pointsPulp and paper industryDistance sensors

The invention provides an automatic moxa stick rolling machine. The automatic moxa stick rolling machine includes a cylindrical measurement feeding mechanism, an outer wrapping paper conveying mechanism, an inner wrapping paper conveying mechanism, and a moxa stick forming mechanism, which are arranged successively; the cylindrical measurement feeding mechanism includes a measurement mechanism and a feeding mechanism; the measurement mechanism includes a cylindrical barrel, a stirring shaft, an upper scraping plate, a lower scraping plate, a partition plate, a motor, a sensor, and a feeding device; the inner wrapping paper conveying mechanism includes an inner wrapping paper storage groove, an inner wrapping paper suction disc, an inner wrapping paper conveying disc, an air cylinder and a distance sensor; the outer wrapping paper conveying mechanism includes an outer wrapping paper storage groove, an outer wrapping paper suction disc, an air cylinder, a distance sensor, and an outer wrapping paper gluing mechanism; and the moxa stick forming mechanism includes a moxa pushing compaction device and a moxa conveying forming device. The automatic moxa stick rolling machine can continuously produce moxa sticks, can achieve automatic batch production, can save human resource, and can improve the production efficiency.

Owner:NANYANG BENCAOAI DEV

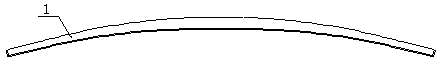

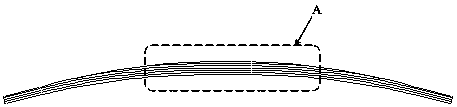

Process for high-efficiency molding of composite plate spring

ActiveCN108928012AIncrease productivityRealize automated mass productionDomestic articlesCompression moldingEngineering

The invention discloses a process for high-efficiency molding of a composite plate spring. The process comprises the following steps: (1) subjecting a plate spring to modeling and carrying out layeredmodeling on a plate spring model from bottom to top; (2) preparing a curved-surface workbench according to each single-layer model; (3) separately carrying out paving and pasting on each curved-surface workbench by using an automatic tape laying machine so as to form a whole piece of a blank material and cutting the whole piece of the blank material with a cutting machine so as to form a plurality of single blank materials with the same structure; and (4) piling up the plurality of single blank materials and carrying out compression molding so as to form the plate spring. With such a technical scheme, the process for high-efficiency molding of the composite plate spring greatly improves the production efficiency of the composite plate spring prepared through molding and can realize automatic batch production of the composite plate spring.

Owner:AVIC COMPOSITES

Quick-frozen meat pie and preparation method thereof

InactiveCN101889597ARealize automated mass productionEasy BakingBakery productsAssembly lineChemistry

The invention discloses a quick-frozen meat pie. The quick-frozen meat pie comprises a flour wrapper, wherein a stuffing is wrapped in the flour wrapper; the weight ratio of the flour wrapper to the stuffing is 1:1.5-2.5; the weight of the quick-frozen meat pie is 80 to 150 grams; the diameter of a formed green pie body is 70 to 130 mm; and the thickness of the formed green pie body is 12 to 18 mm. The invention also discloses a method for preparing the quick-frozen meat pie. In the method, assembly line automatic batch production of quick-frozen meat pies is realized; the production efficiency and the product quality are improved; the thickness of the flour wrapper of the quick-frozen meat pie is uniform, which contributes to baking the quick-frozen meat pies; and the quick-frozen meat pies can be stored for long time, usually can be stored in cold for more than eight months, which ensures that the quick-frozen meat pies can be transported and sold conveniently at different places.

Owner:王吉山

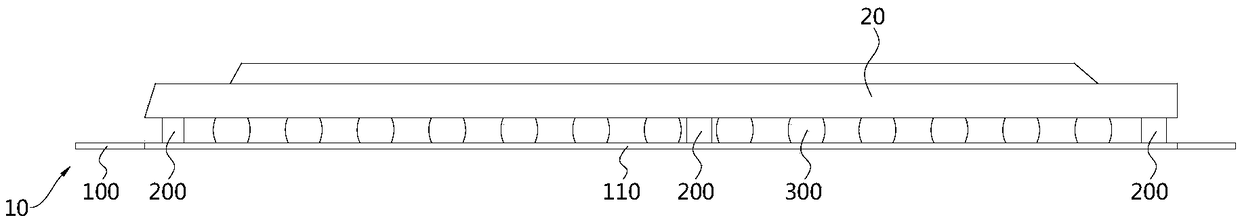

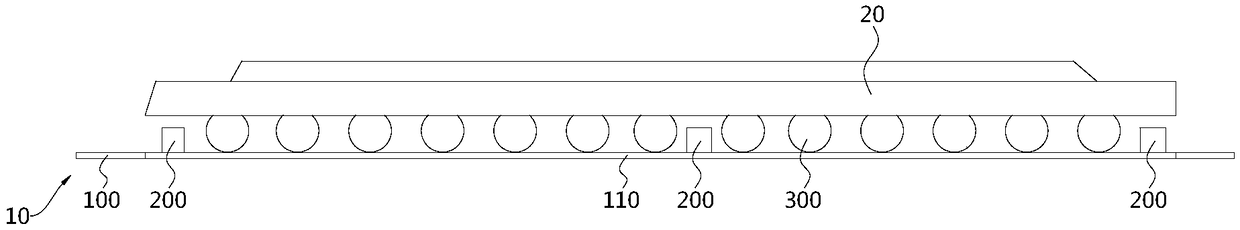

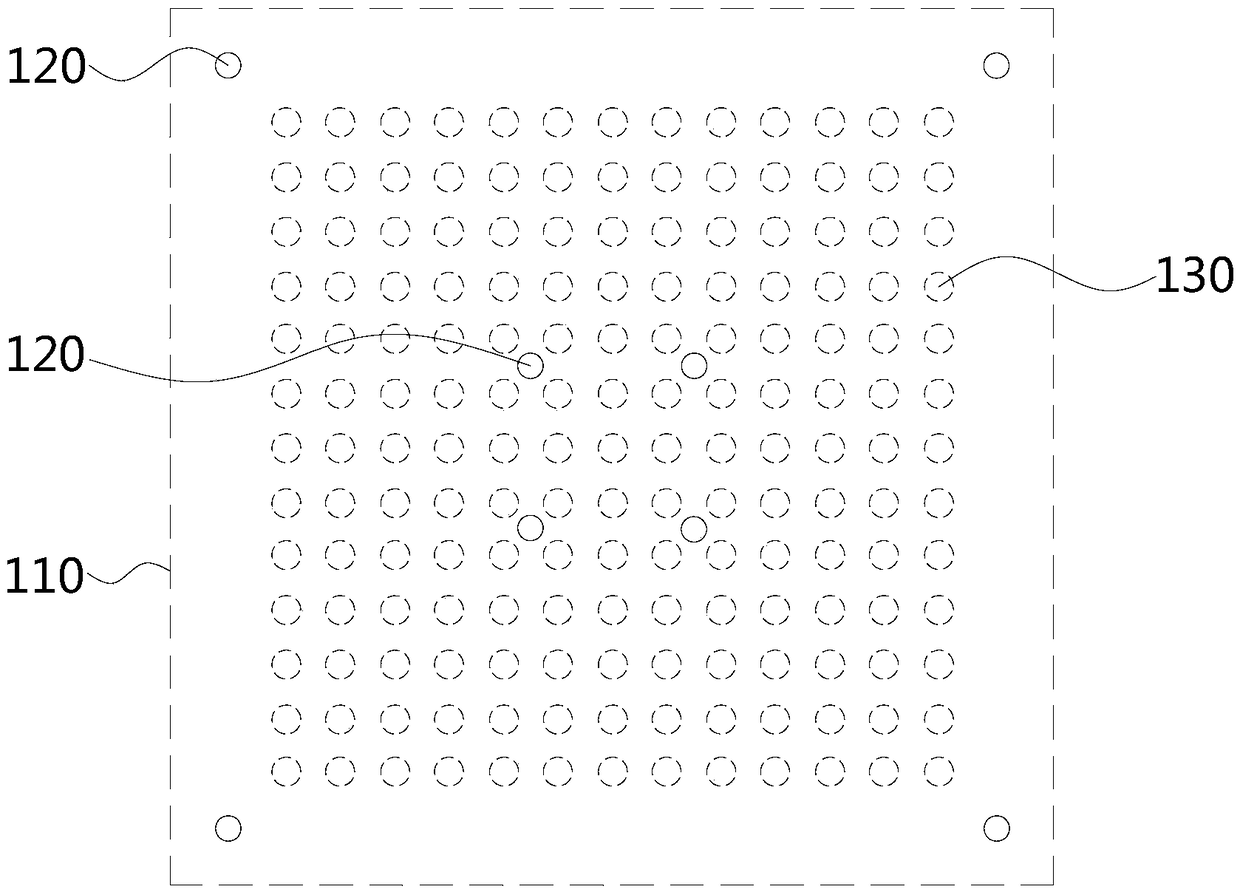

Printed circuit board, electronic device and production process thereof

InactiveCN109195353AMounting will not affectImprove the problem of LianxiPrinted circuit assemblingSolder ballEngineering

The embodiment of the invention provides a printed circuit board, an electronic device and a production process thereof, which relate to the field of electronic technology. The printed circuit board is used for mounting electronic devices, and comprises a board body and a plurality of supports. Wherein, a mounting area for mounting electronic devices is arranged on the board body. A plurality of supports are attached to the mounting area for supporting the electronic device. The printed circuit board, the electronic equipment and the production process thereof provided by the embodiment of theinvention can effectively improve the problem of tin connection caused by the solder ball crushed due to high-temperature deformation during the mounting of the electronic device by supporting the electronic device, and the supporting member does not affect the mounting of the electronic device. In addition, the support is mounted in the mounting area, which can realize automatic mass productionand improve the compression resistance of electronic devices in the assembly process.

Owner:NEW H3C TECH CO LTD

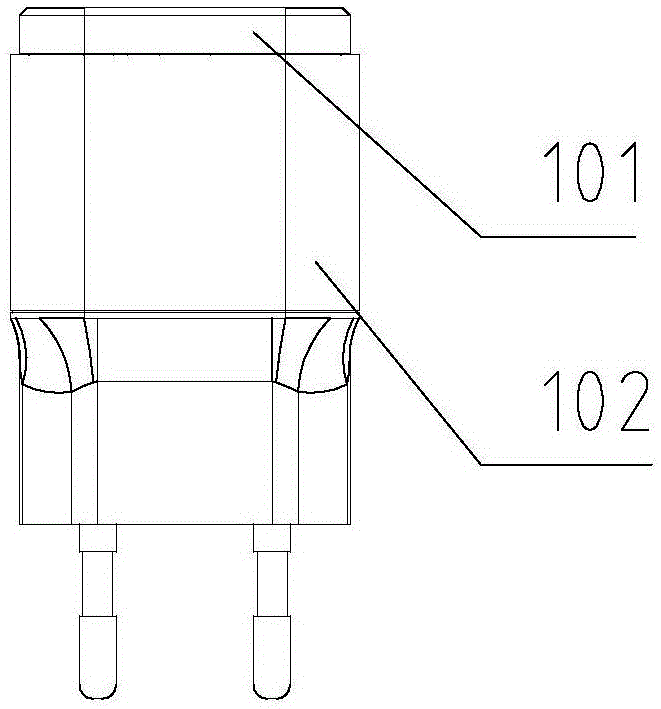

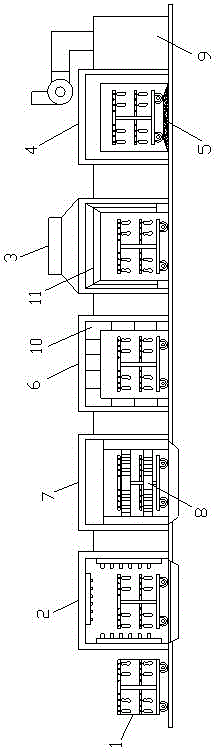

Automatic feeding device for upper cover shell of charger

ActiveCN106494881AEasy to grab individuallyIncrease productivityJigging conveyorsConveyor partsEngineeringUltimate tensile strength

Owner:威海志航机电科技有限公司

Environmentally friendly smoked meat production apparatus

InactiveCN106819067ARealize automated mass productionIncrease productivityMeat/fish preservationWind systemFlue gas

The invention discloses an environment-friendly bacon production device, which comprises a transmission track, a transport vehicle arranged on the transmission track and a power mechanism for driving the transmission vehicle to move, the transmission vehicle is provided with a suspension frame for hanging bacon, the A spray room, a drying room and a smoke room are also arranged on the conveying track, the drying room and the smoke room are all airtight rooms, a plurality of spray heads are arranged in the spray room, and a An electric heating device, a smoke system is provided at the bottom of the smoke room, the spray room, the drying room and the smoke room are airtightly connected, and an air-drying room is also provided between the spray room and the drying room , the air-drying chamber is provided with a circulating air system, the outlet of the smoke chamber is also provided with a smoke isolation room, and the top of the smoke isolation room is provided with a smoke discharge device. The environment-friendly bacon production device of the present invention can realize the automatic batch production of bacon, has high production efficiency, and is more environmentally friendly and safe.

Owner:RONGMU CHONGQING SCI & TECH CO CO LTD

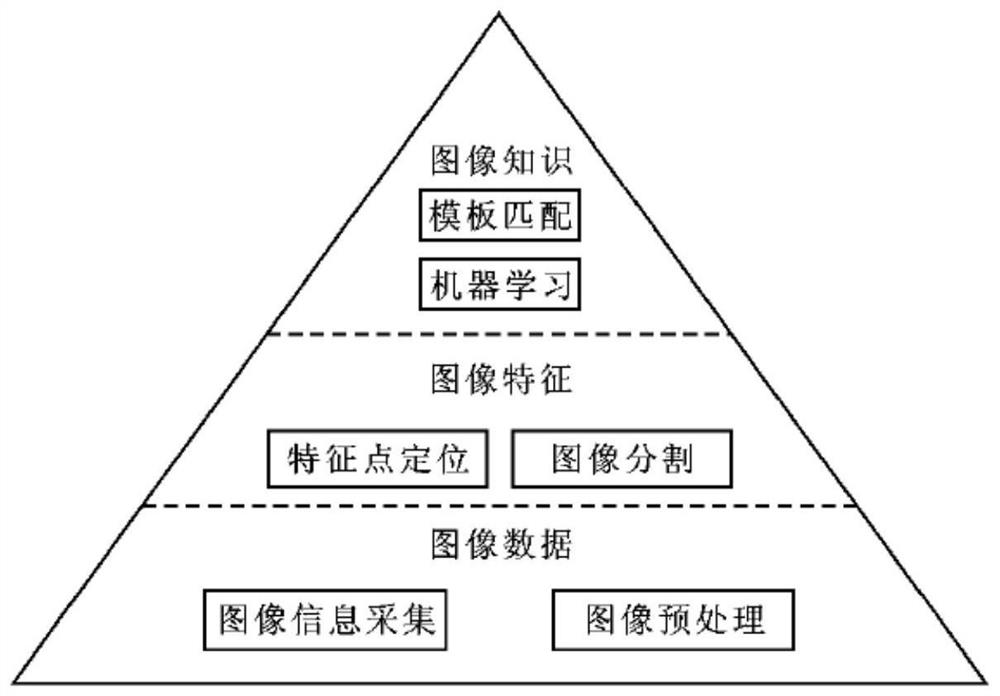

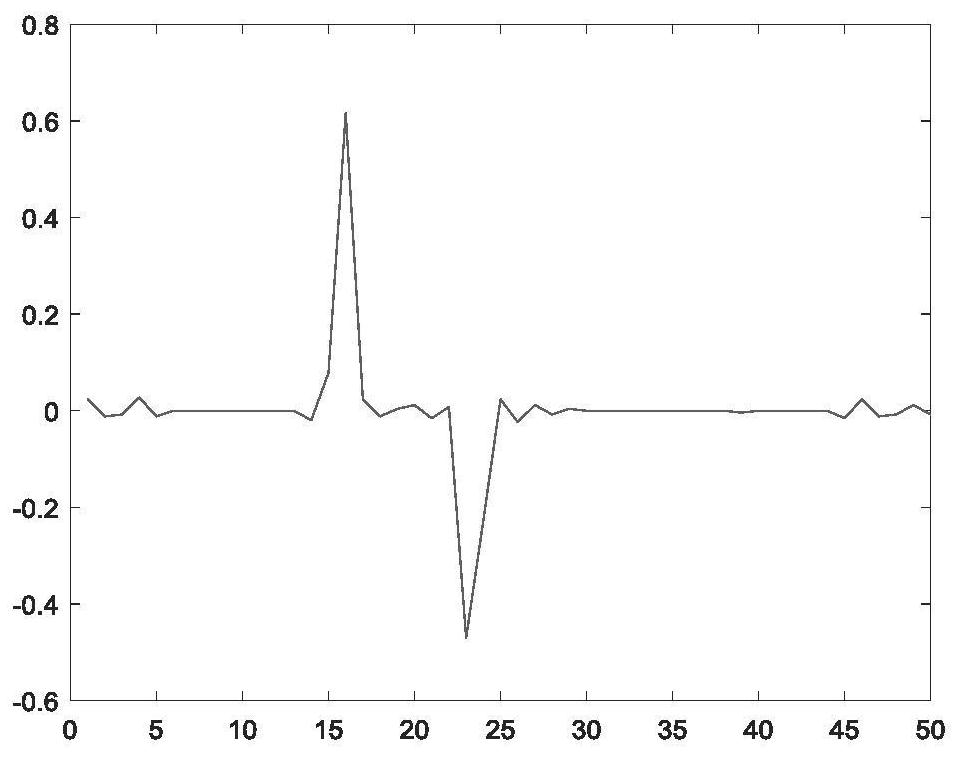

Intelligent rutile single crystal growth control method based on computer vision feedback

ActiveCN111754516APrecise growth controlIncreased growth success and purityImage analysisMachine learningEngineeringImage segmentation

The invention belongs to the field of new materials, and particularly relates to an intelligent rutile single crystal growth control method based on computer vision feedback, which comprises the following steps: acquiring image information by using a high-definition video acquisition system, and preprocessing an image by using the high-definition video acquisition system; using OPENCV to analyze image features by a computer to realize image segmentation and feature point positioning; performing crystal growth current real-time form analysis on crystal growth state characteristics of the processed image by using a convolutional neural network; comparing the analysis result with an edge coordinate curve of a healthy crystal growth form obtained by machine learning, and judging whether the crystal form is normal or not; and if yes, continuing to use the original given function curve to carry out growth control, and if not, adjusting the position of the combustion table and the feeding parameters through self-service adjustment, and implementing feedback images. Various parameters of crystal growth can be accurately controlled, and temperature distribution, composition distribution andmechanical distribution in the growth chamber are guaranteed.

Owner:SHENYANG INST OF ENG

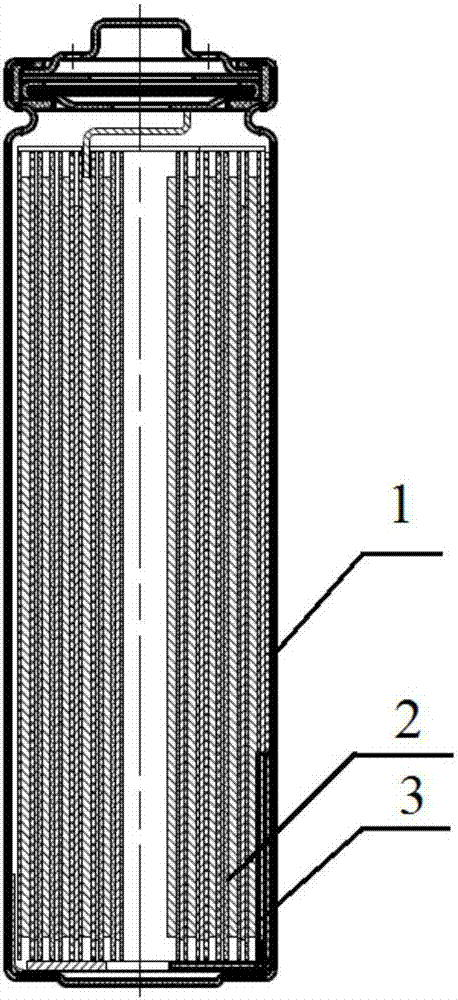

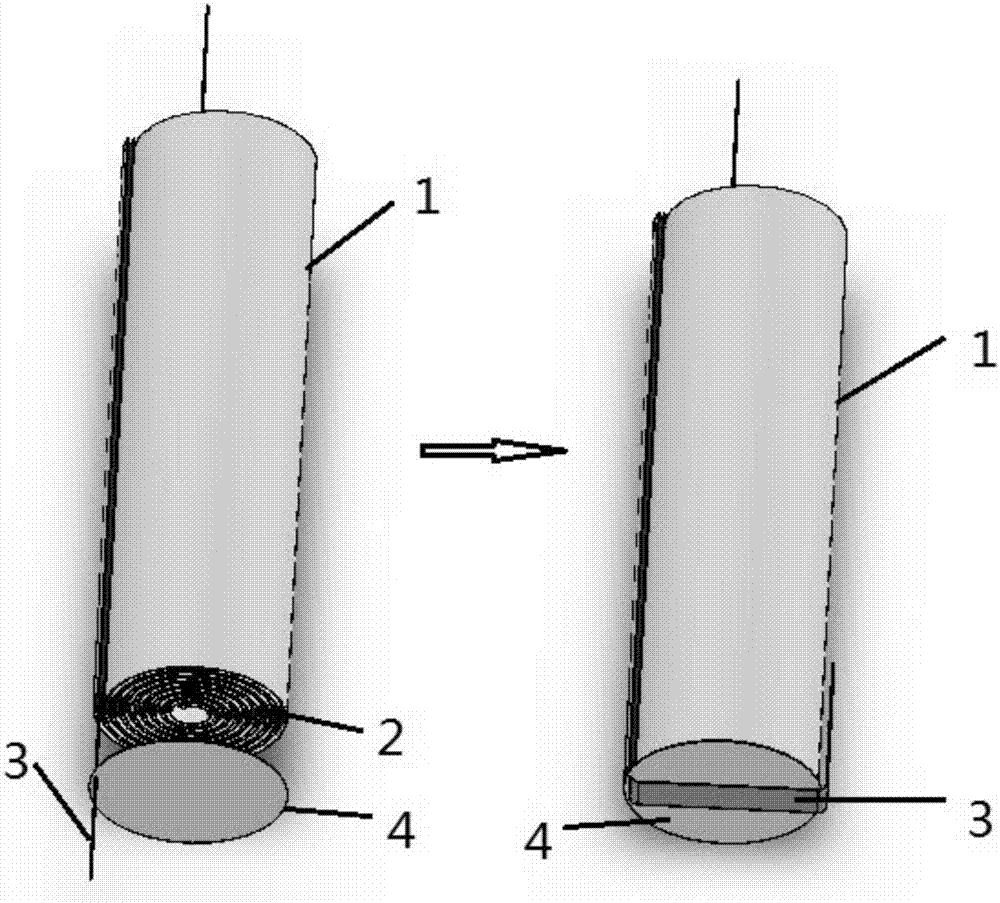

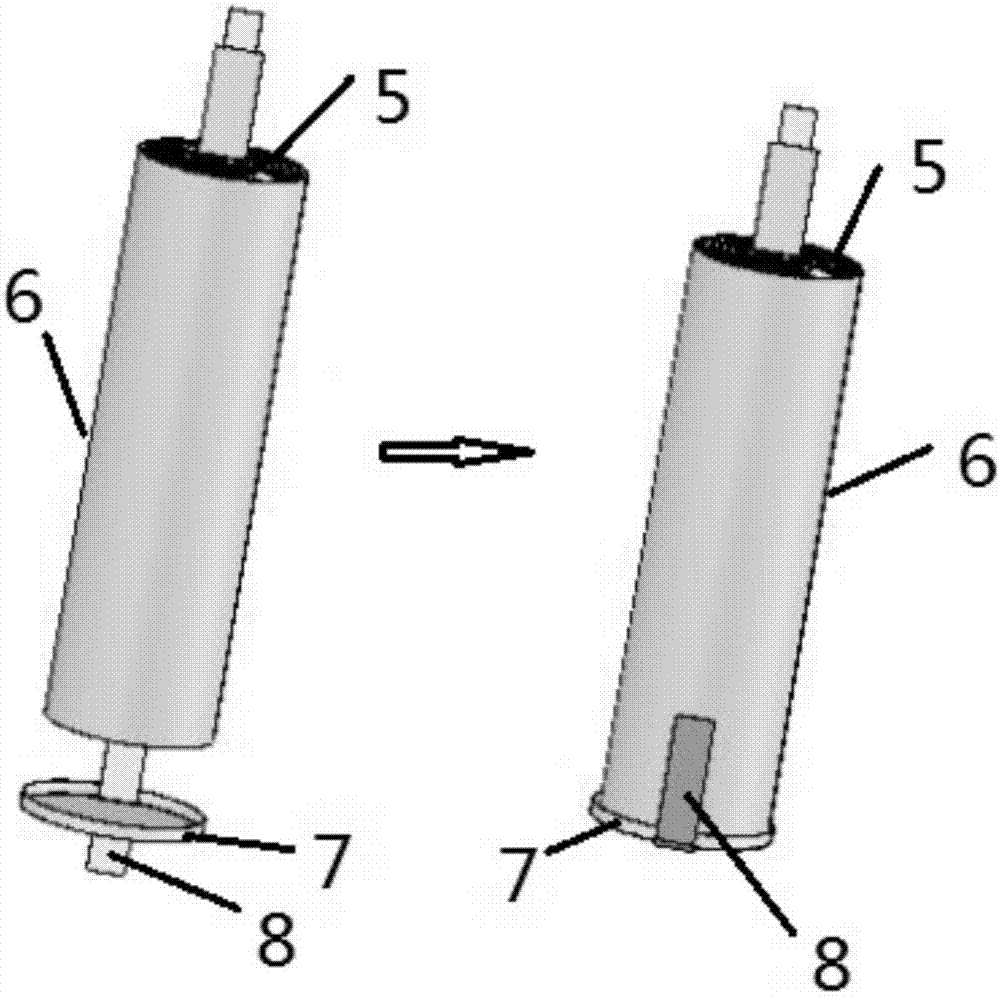

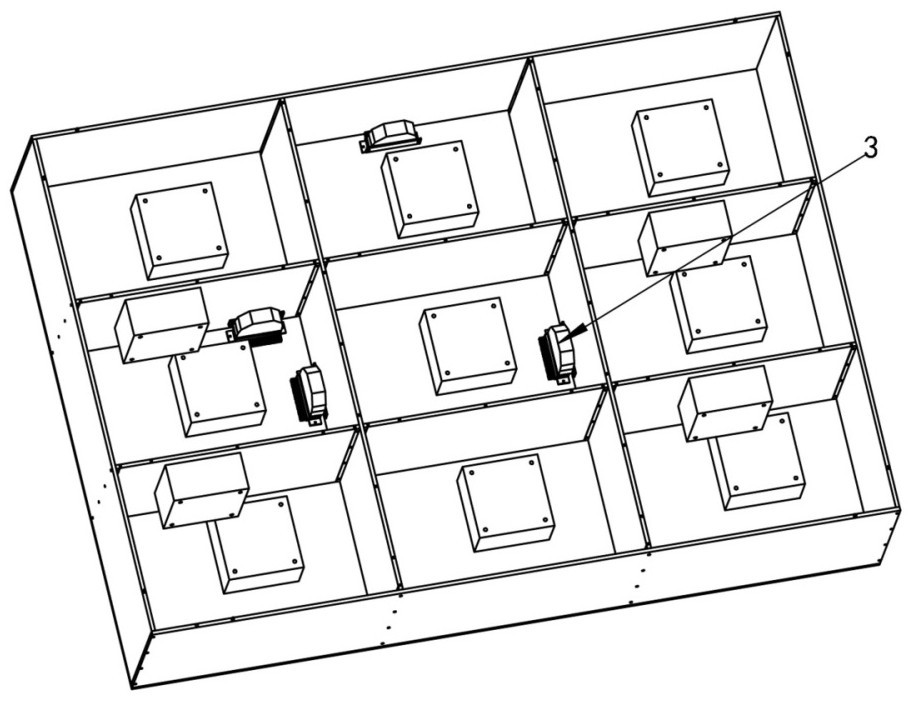

Lithium-ferrous disulfide battery and assembly method thereof

ActiveCN107887622AReduce manufacturing costRealize automated mass productionNon-aqueous electrolyte cellsContact modeControllability

The invention relates to a lithium-ferrous disulfide battery and an assembly method thereof. The battery comprises a winding battery cell and a shell, wherein a negative tab exposed out of the windingbattery cell is in contact connection with a side wall of the shell. The assembly method comprises the steps of firstly, allowing the negative tab of the winding battery cell to penetrate through a square hole of an insulation cushion piece, and bending the negative tab by 90 degrees; secondly, bending the tab exceeding the bottom of the battery cell by 90 degrees again to be in contact with thebattery cell; and finally, sleeving the battery cell in the shell to complete connection of the negative tab and the shell. A welding mode of the prior art is substituted by a contact mode, the defects of high unfavorable rate, potential risk, complicated process, poor controllability and the like of the welding mode are prevented, and the fabrication cost is reduced; and a test result shows thatthe lithium-ferrous disulfide battery has favorable performance.

Owner:EVE ENERGY CO LTD

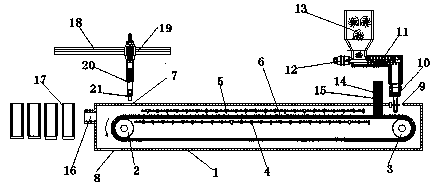

Aluminum-piece nylon coating machine and coating method

PendingCN109395982AUniform temperatureReduced strength damagePretreated surfacesCoatingsNumerical controlMedium frequency

The invention discloses an aluminum-piece nylon coating machine and coating method. Undercoat painting mechanisms are arranged on the two sides of a feeding conveying machine, a truss and a mechanicalarm are arranged at the tail end of the feeding conveying machine, and a medium-frequency heating furnace and a nylon powder box are arranged below the truss; a numerical-control and electronic-control operating table and a water cooling tower are arranged outside the truss, wherein the numerical-control and electronic-control operating table provides an electric wire to be connected to the feeding conveying machine, the undercoat painting mechanisms, the nylon powder box, the truss and the mechanical arm; the medium-frequency heating furnace is connected with a medium-frequency heating cabinet, and cooling is carried out through the water cooling tower. For achieving the aims that the strength loss of an aluminum piece is lowest, and melting of nylon powder is considered, the temperatureof the aluminum piece is controlled to be 250 DEG C to 255 DEG C in the medium-frequency heating furnace, two times of powder dipping are carried out, the aluminum piece enters the nylon powder box for the first time and is soaked into the nylon powder, and then time stays for 2 seconds to 3 seconds; powder dipping is carried out for the second time after the aluminum piece is separated from thenylon powder box and stays for 1.5 seconds, the aluminum piece enters the nylon powder box for the second time and is soaked into the nylon powder to also stay 2 seconds to 3 seconds, and it can be achieved that the coating thickness is controlled to be 0.5 mm to 0.6 mm.

Owner:东风汽车传动轴有限公司

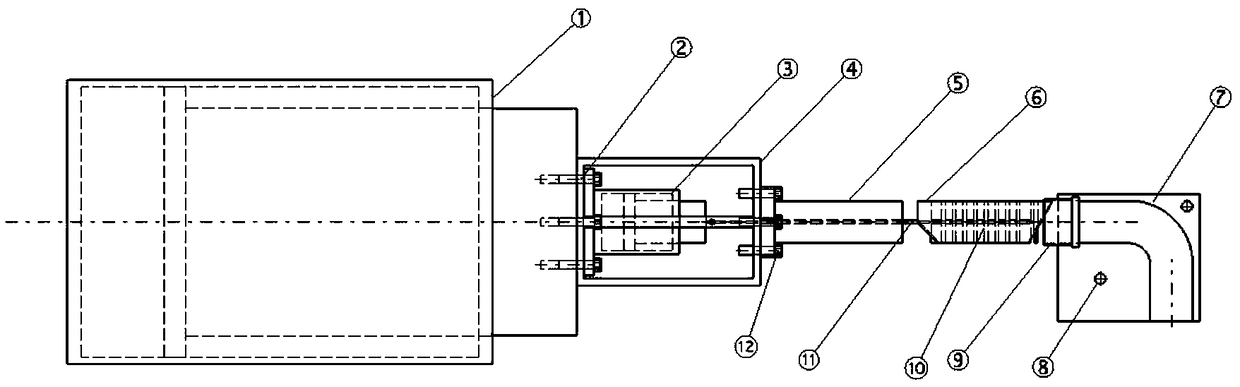

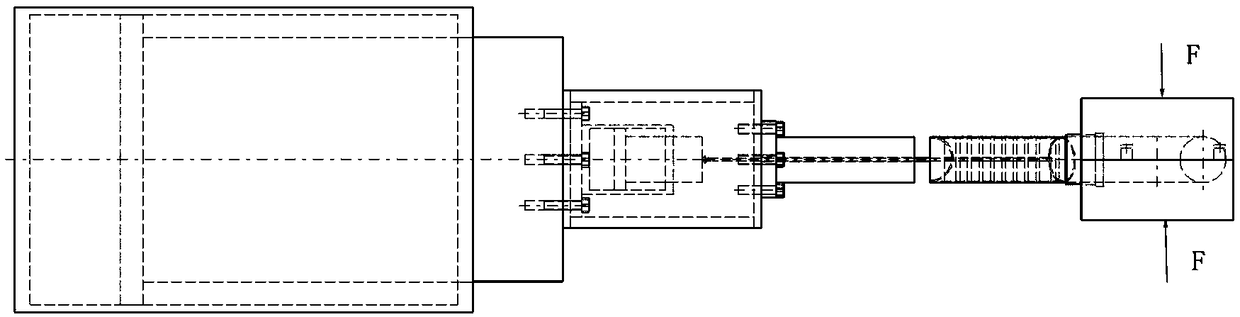

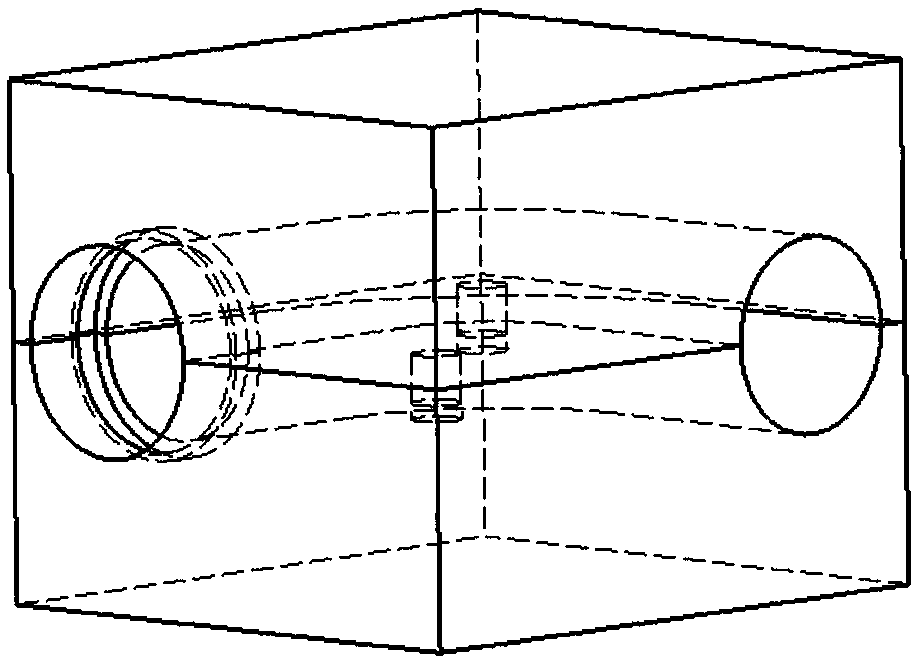

Push bending forming device adopting push-pull integrated loading and method

The invention discloses a push bending forming device adopting push-pull integrated loading and a method. The push bending forming device comprises a main push cylinder, a supporting device, a push rod, a blank pipe and a die, wherein the supporting device is installed at the output end of the main push cylinder, one end of the push rod is installed at the front end of the supporting device, and the other end of the push rod pushes the blank pipe to move towards the die; the die is positioned in front of the blank pipe, and the blank pipe is sequentially filled with a plurality of polyurethanefilling blocks; an auxiliary hydraulic cylinder is arranged in the supporting device, the tail part of the auxiliary hydraulic cylinder is fixed to the inner wall of the rear end surface of the supporting device, and the output end is arranged towards the push rod; and a steel wire rope is detachably connected to the output end of the auxiliary hydraulic cylinder, the other end of the steel wirerope penetrates through the push rod, and the polyurethane filling blocks are sequentially connected to the other end of the steel wire rope. According to the push bending forming device adopting push-pull integrated loading and the method, the push cylinder and a top cylinder are integrated, the angles of the push cylinder and the top cylinder do not need to be adjusted when pipes are bent with different angles, and the supporting mode of the polyurethane filling blocks is changed meanwhile, so that efficient push bending forming of the pipes is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

Shaping and drying device for processing and preparing highland barley into biscuits

ActiveCN109430324AImprove molding efficiencyImprove drying efficiencyDough shapingDough heat treatmentEngineeringControl valves

The invention discloses a shaping and drying device for processing and preparing highland barley into biscuits. Through the adoption of the shaping and drying device disclosed by the invention, the shaping and drying efficiency of highland barley biscuits can be greatly improved, and after shaping, drying is immediately performed; during shaping preparation of the highland barley biscuits, only performing controlling by a controller is needed; highland barley pulp for preparing the biscuits is loaded in a material storing hopper of a charging assembly, and then under the control of a control valve, the highland barley pulp is automatically discharged into a lower mold of a shaping mold by the material storing hopper; when the lower mold is transported to the next position by the a transporting assembly, an upper mold is automatically snap-fitted with the lower mold; the heated lower mold can perform shaping on the biscuits, and when the drying efficiency is improved by the temperatureof the lower mold, the shaping effect can also be improved; then when the biscuits are transported by the transporting assembly, a jet drying assembly is used for continuously jetting dry hot nitrogengas for performing drying treatment; grasping for mold opening is performed on the upper mold above the biscuits after drying treatment by a grasping assembly; and under the transporting of the transporting assembly, the biscuits arrive at a biscuit falling hole, and fall down into a biscuit recovering box.

Owner:TIBET AGRI & ANIMAL HUSBANDRY COLLEGE

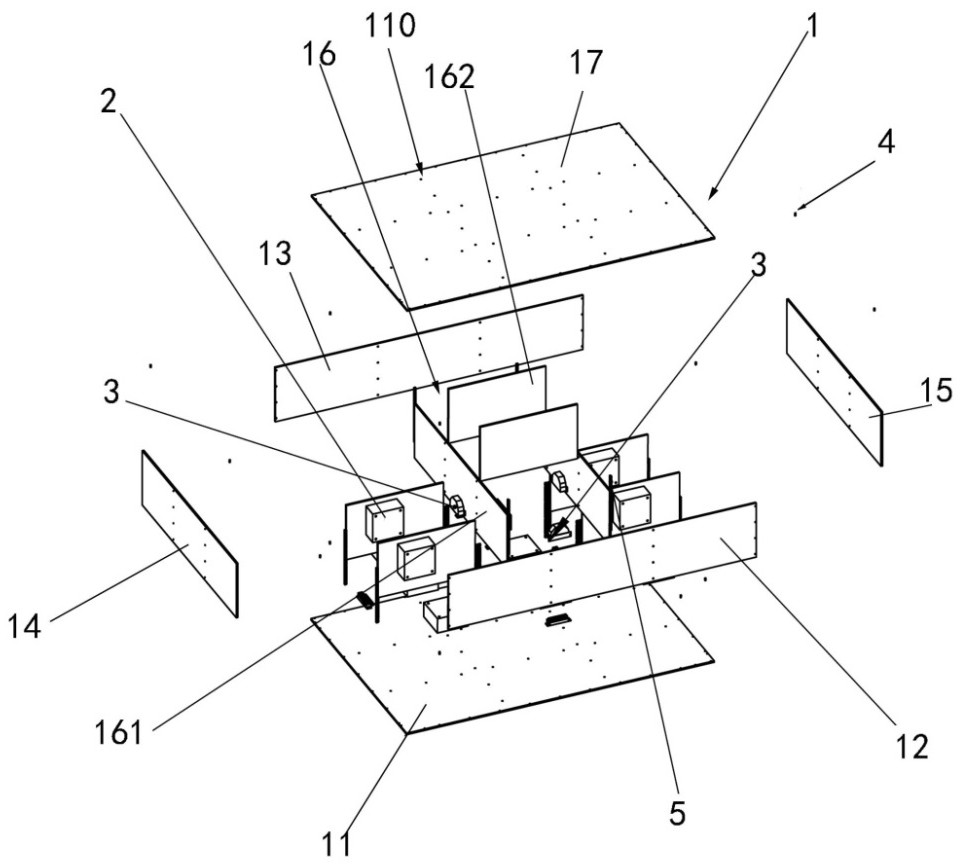

Satellite structure and satellite assembling method

ActiveCN113022888AWidely used valueImprove assembly efficiencyCosmonautic partsArtificial satellitesEngineeringMonoboard

The invention relates to a satellite structure and a satellite assembling method, the satellite structure comprises a plurality of satellite cabin plates, electronic equipment, a cable and a plugging assembly, when the satellite cabin plates are of a single-plate structure, the electronic equipment, the cable and the plug-in assembly are installed on the corresponding satellite cabin plates according to a preset satellite structure layout. On the same satellite cabin plate, one end of the cable is connected with the electronic equipment, and the other end of the cable is connected with the plugging assembly. Electric appliance connection is established between different satellite cabin plates through plugging of the plugging assemblies. The satellite assembling and disassembling efficiency is improved, and therefore automatic batch production of satellites can be achieved.

Owner:北京最终前沿深空科技有限公司

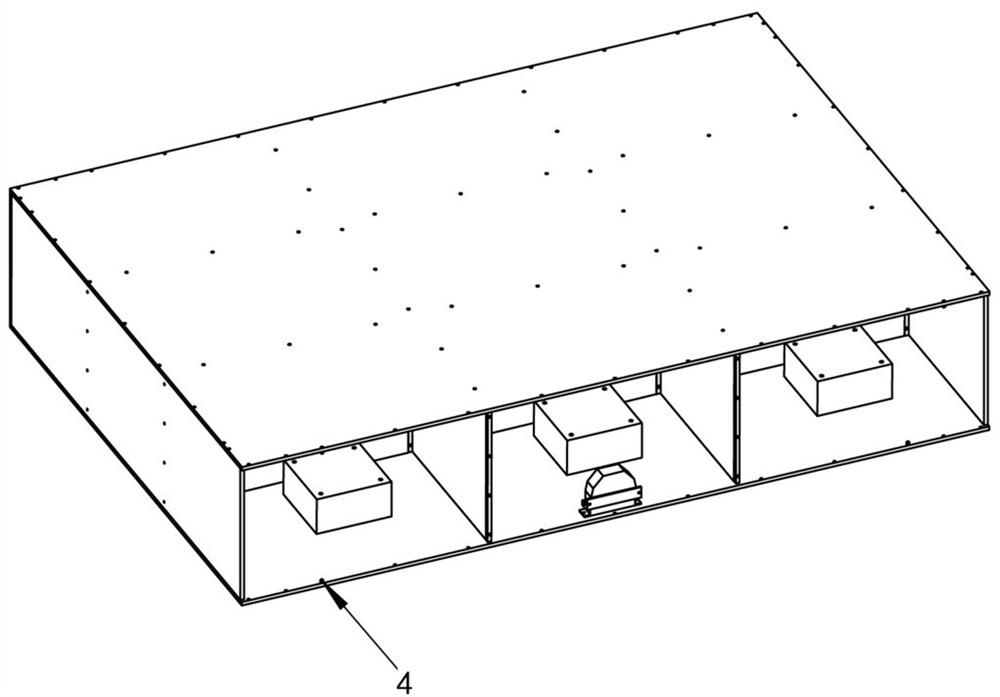

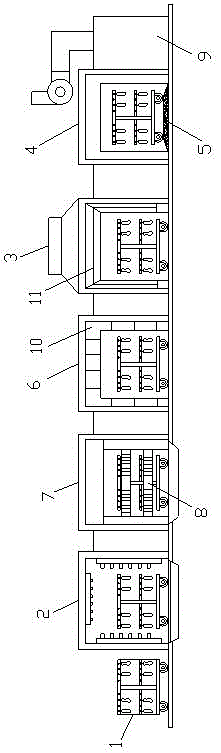

Biomass fuel briquetting forming machine

InactiveCN106427028ARealize automated mass productionEffective blankingPress ramShaping pressHydraulic cylinderControl system

The invention belongs to the technical field of biomass fuel. A biomass fuel briquetting forming machine comprises a rack, two vertical plates arranged at the two ends of the rack, a feeding hopper arranged on the tops of the two vertical plates in a supporting manner, a forming assembly arranged between the two vertical plates, and a hydraulic control system arranged on the rack. The feeding hopper is provided with a material scattering assembly. The material scattering assembly comprises a rotating shaft connected to the feeding hopper in a pivotal manner, a drive motor driving the rotating shaft, and a stirring rod arranged on the rotating shaft. The forming assembly comprises a plurality of supporting shafts arranged between the two vertical plates in parallel, a plurality of sets of forming die units arranged on the supporting shafts in a sliding and sleeving manner, an ejecting plate arranged on the inner side of the vertical plate on the left side, and a main pushing hydraulic cylinder driving the ejecting plate. The biomass fuel briquetting forming machine is reasonable and compact in structural design, and the phenomenon of material overhead bridging can be avoided; and meanwhile, automatic batched production can be achieved, the pressure applying effect is good, the quality of formed products is consistent, and very high market competitiveness is achieved.

Owner:湖南利邦生物科技股份有限公司

Multifunctional cooling fin preparation device

InactiveCN107263110ARealize automated mass productionHigh degree of automationOther manufacturing equipments/toolsManufactured apparatusEngineering

The invention discloses a multifunctional preparation device for heat sinks, which includes a feeding mechanism, a punching mechanism and a receiving mechanism. The feeding mechanism includes a feeding platform, a feeding rack capable of rotating and feeding, and a stepping motor. The feeding frame provides rotating power. The stamping mechanism includes a stamping plate. The stamping plate is equipped with an initial stirrup hole knife, a primary punch hole repair knife, a secondary punch hole repair knife, a waist hole trimming knife, and a trimming knife in sequence according to the stamping process. Knife, folding edge knife. The device of the present invention not only has a high degree of automation and can carry out multiple steps at the same time, it realizes the production of finished heat sinks from the raw material boards of heat sinks in one step, and accurately positions the raw material boards of heat sinks through double positioning, so the cutting accuracy is high. The defective rate is reduced.

Owner:苏州市高宏电子有限公司

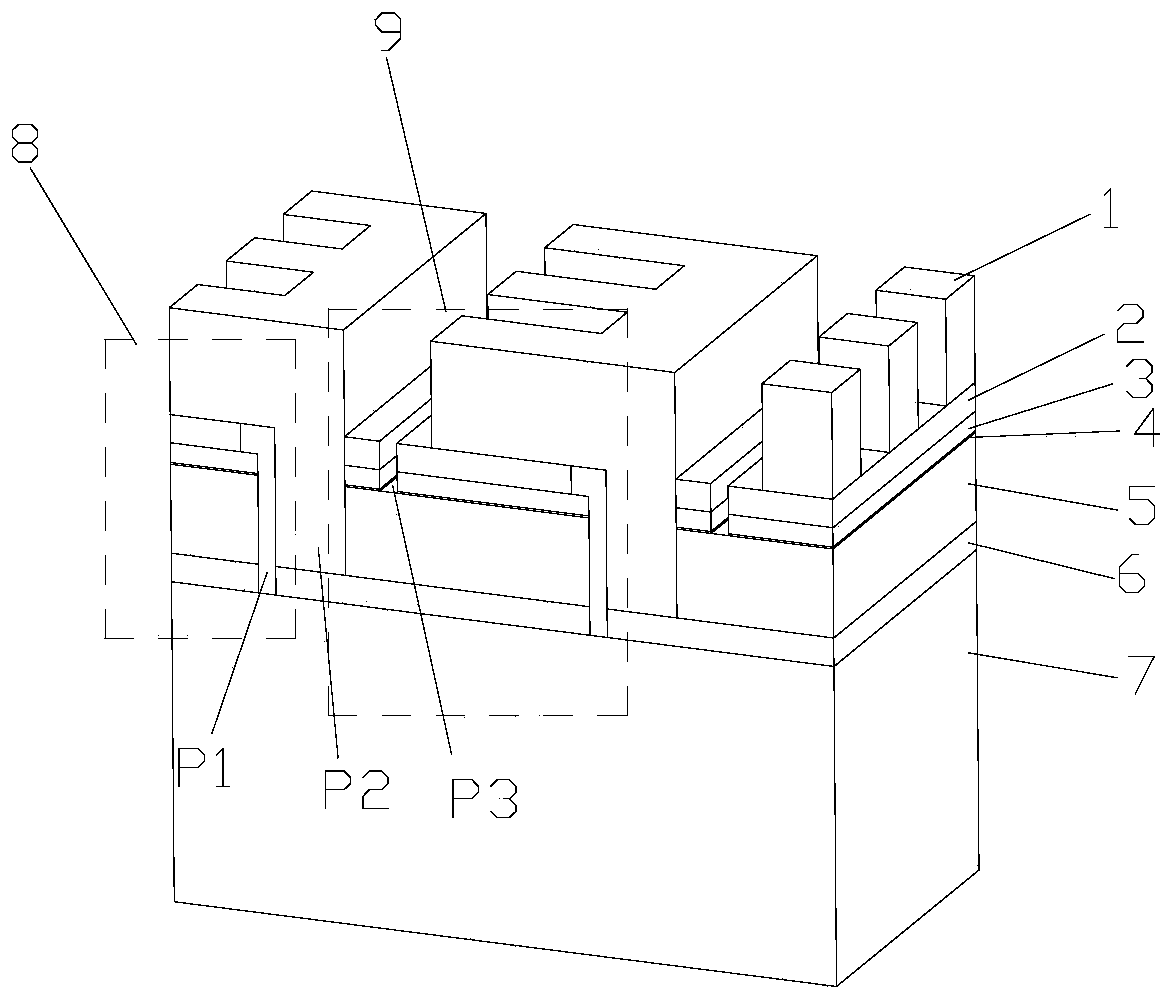

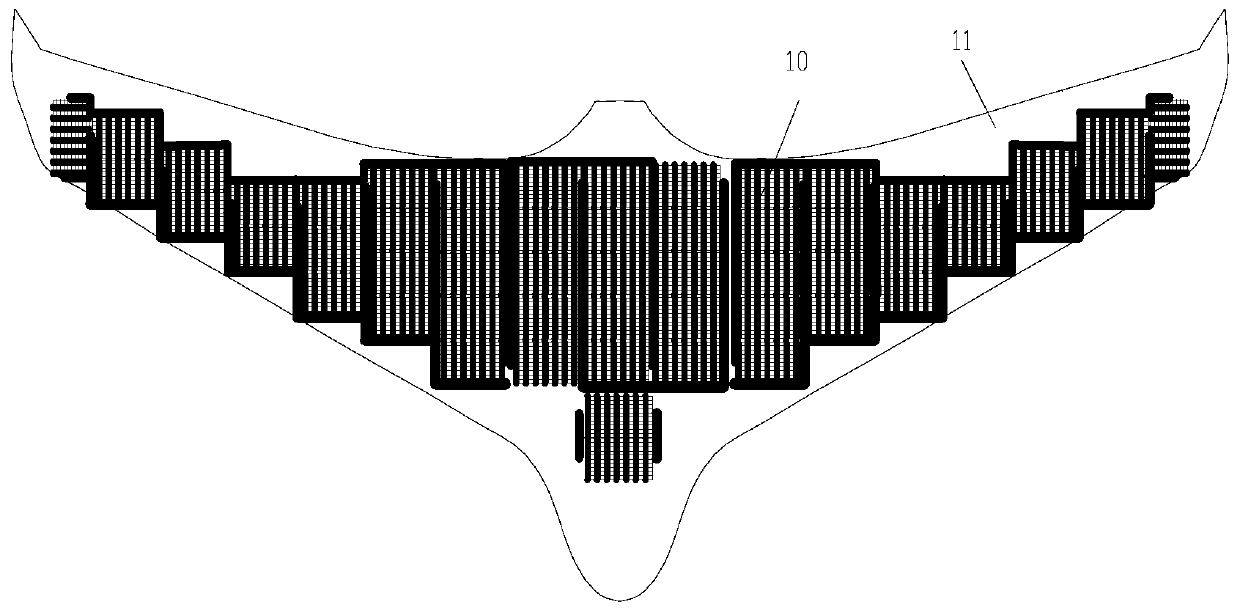

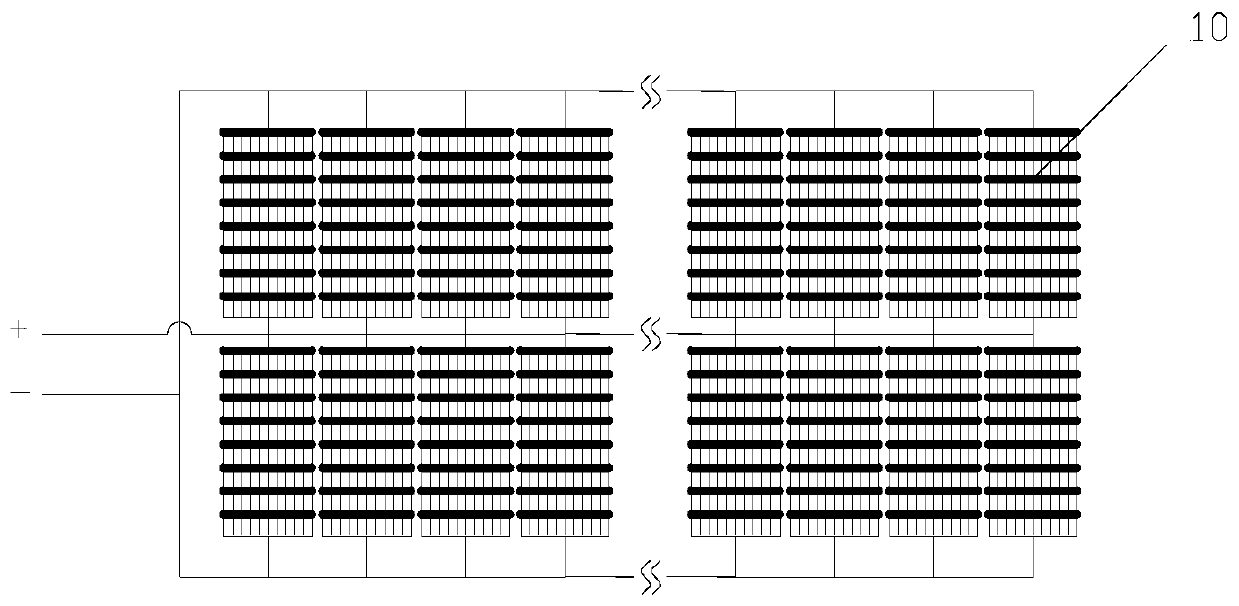

CIGS thin film assembly of solar unmanned aerial vehicle and internal-external cascading method thereof

PendingCN110649103AHigh specific powerEasy to cleanFinal product manufacturePhotovoltaic energy generationElectrical batteryInternal resistance

The invention provides a CIGS thin film assembly for a solar unmanned aerial vehicle and an internal-external cascading method thereof. The CIGS thin film assembly comprises laminated films and a plurality of sub-batteries arranged in parallel inside the laminated films, where each sub-battery is sequentially provided with a PI substrate, a Mo back electrode layer, a CIGS absorption layer, a CdS buffer layer, a ZnO window layer and a transparent conductive layer from bottom to top; a plurality of mutually independent top electrodes are uniformly distributed on each transparent conductive layer; one sides of the Mo back electrode layer, the CIGS absorption layer, the CdS buffer layer, the ZnO window layer and the transparent conductive layer are provided with penetrating insulating slurry;one sides of the ZnO window layer, the CdS buffer layer and the CIGS absorption layer are provided with penetrating P2 conductive slurry; and the Mo back electrode layer is exposed below a P2 scribingchannel. According to the CIGS thin film assembly for the solar unmanned aerial vehicle and the internal-external cascading method thereof, an internal-external cascading structure is adopted, an open-circuit voltage is high, current internal resistance loss is small, and output efficiency is higher.

Owner:天津华鼎科技有限公司

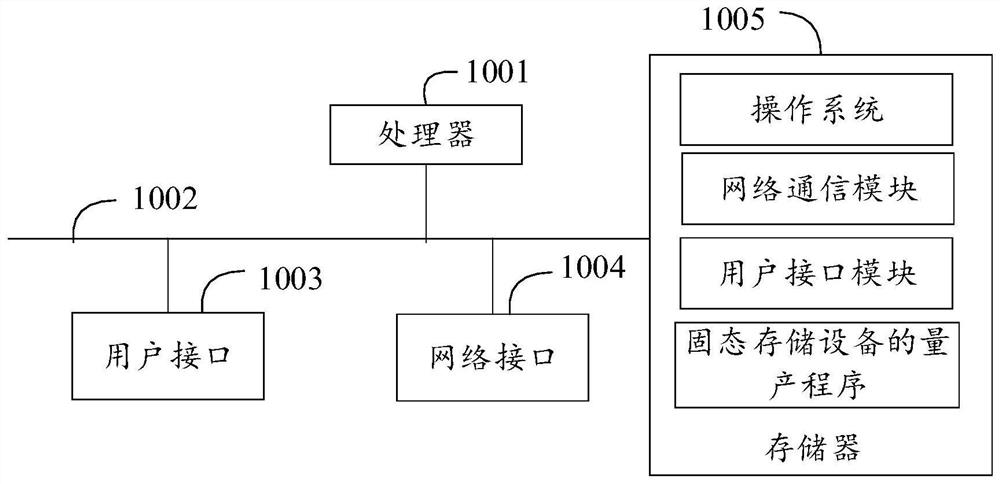

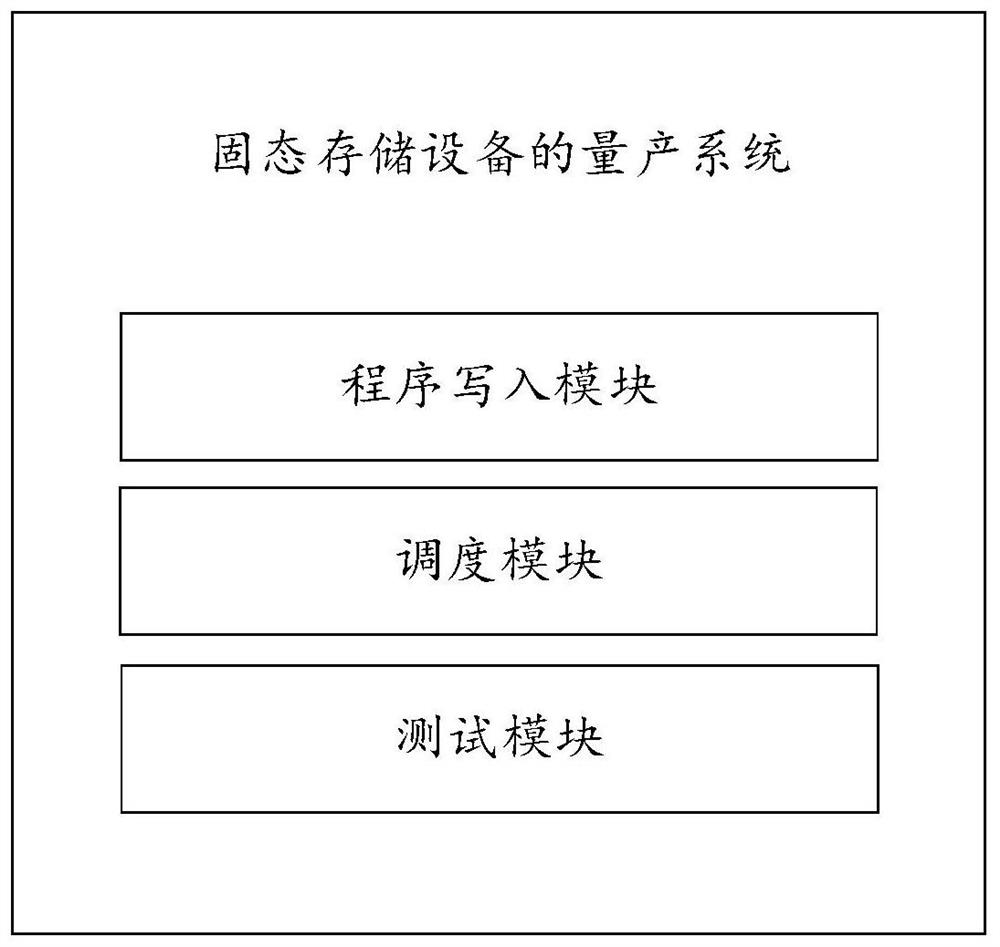

Mass production method and system of solid-state storage device, terminal device and storage medium

PendingCN112527329AEliminate operationRealize automated mass productionData processing applicationsRead-only memoriesSolid-state storageTerminal equipment

The invention discloses a mass production method and system of solid-state storage equipment, terminal equipment and a computer storage medium. A preset scheduling program and preset execution programs are written into the solid-state storage equipment at the same time based on a preset mass production tool; controlling the preset scheduling program to schedule each preset execution program to execute card opening on the solid-state storage device; and after it is detected that the solid-state storage device completes card opening, performing a systematic test on the solid-state storage deviceto complete mass production of the solid-state storage device. According to the invention, the scheduling program and each execution program for opening the card are simultaneously written to automatically schedule the program to execute the card opening process, so that the operation of manually and repeatedly plugging and unplugging the solid-state storage device can be avoided, the automatic mass production of the solid-state storage device is realized, the productivity is improved, the dependence of the mass production process on manpower is reduced, and the production efficiency is improved. Therefore, the overall production cost is reduced.

Owner:SLICONGO MICROELECTRONICS INC

Production system of preserved meat

InactiveCN106912806ARealize automated mass productionIncrease productivityMeat/fish preservationSpray nozzleEngineering

The present invention discloses a production system of preserved meat. The production system comprises a transmission track, a transmission vehicle arranged on the transmission track and a power mechanism driving movements of the transmission vehicle. A hanging rack used for hanging the smoked meat is arranged on the transmission vehicle, a spraying chamber, a drying chamber and a smoking chamber are arranged in the transmission track, the drying chamber and smoking chamber are both closed chambers, a plurality of spraying nozzles are arranged in the spraying chamber, an electric heating device is arranged in the drying chamber, a smoking system is arranged at the bottom part of the smoking chamber, the spraying chamber, drying chamber and smoking chamber are in closed communications, a water collecting tank is also arranged at the lower part of the spraying chamber, and a filtering mesh plate is arranged at the upper side of the water collecting tank. The production system of the preserved meat can realize the automatic mass productions of the smoked meat, and is high in production efficiency and also more environmentally friendly and safer.

Owner:RONGMU CHONGQING SCI & TECH CO CO LTD

Solid state fermentation cylinder and solid state fermentation method

ActiveCN102839119BWell mixedAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsThermal insulationEngineering

The invention discloses a solid state fermentation cylinder and a solid state fermentation method. The solid state fermentation cylinder comprises a cylinder body and a jacket provided with an upper port and a lower port, the upper end of the cylinder body is an upper end cover, a mixing system capable of lifting is arranged on the upper end cover, and according to the mixing system, a mixing frame is driven by a driving system. The mixing frame is formed by a wall surface scraper plate, a bottom surface scraper plate and mixing blades, the wall surface scraper plate and the bottom surface scraper plate form a frame-shaped structure, and the mixing blades are fixedly connected in the frame-shaped structure. The solid state fermentation cylinder and the solid state fermentation method effectively resolve the problem of low fermentation performance caused by uneven thickness and uneven heating of a feed layer. According to the solid state fermentation cylinder and the solid state fermentation method, all the processes from feeding to discharging are concentrated in the solid state fermentation cylinder, the process of transportation of materials is simplified, and the mixing system and a cooling thermal-insulation system of equipment are strengthened. Automatic bulk production of solid state fermentation can be achieved, the pure culture in the solid state fermentation process is effectively guaranteed, quality and safety of products are improved, and homogeneity property in the same bulk is guaranteed.

Owner:CHENGUANG BIOTECH GRP CO LTD

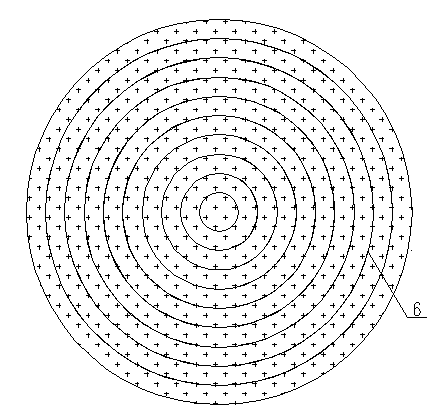

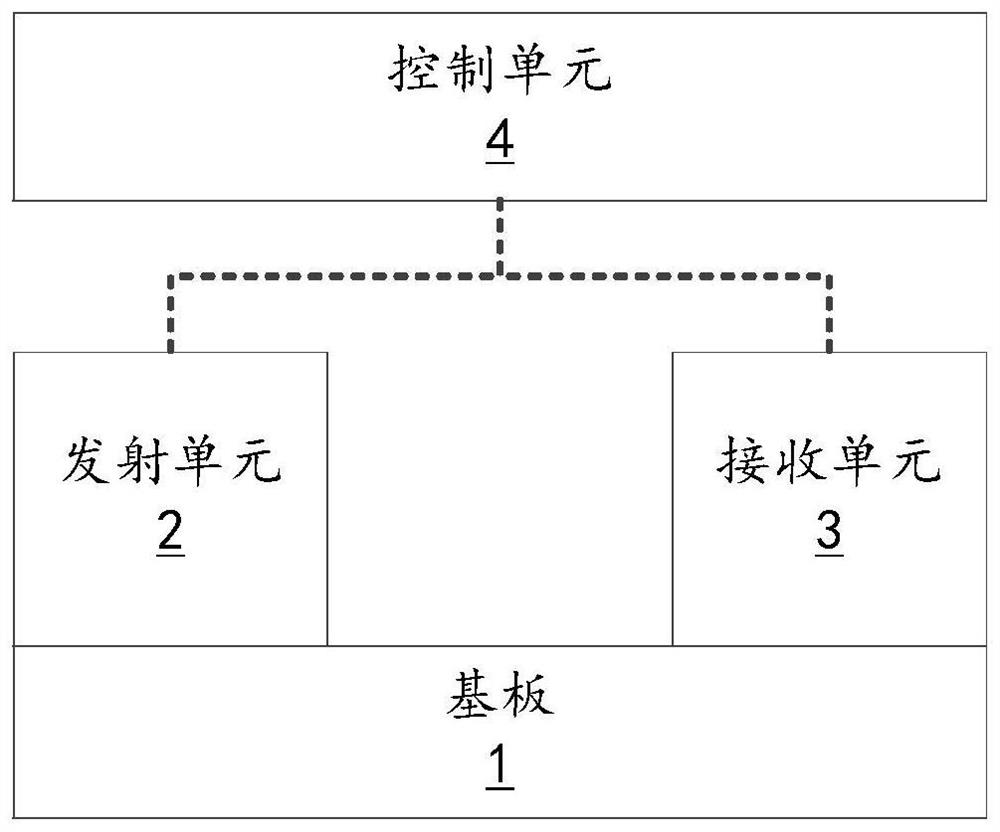

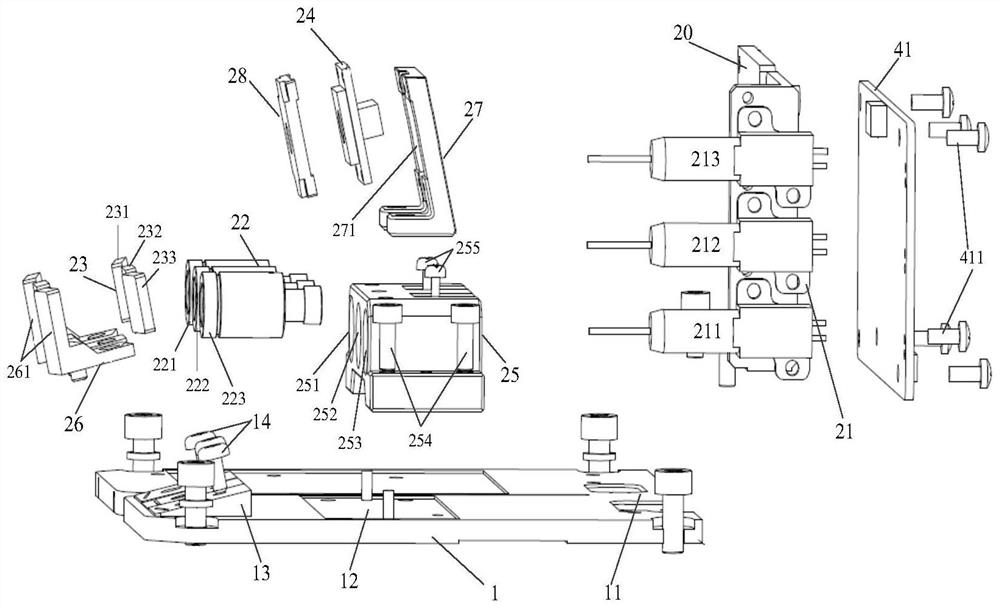

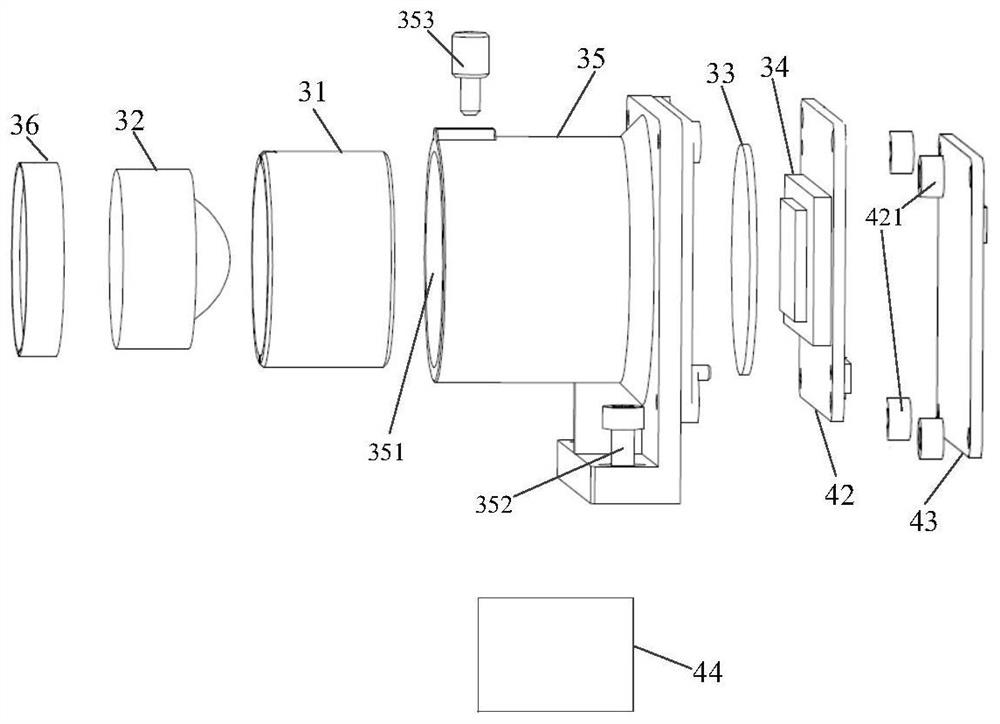

Solid-state radar device based on indium gallium arsenide detection

PendingCN114114208AImprove detection and conversion capabilitiesHigh strengthWave based measurement systemsIndiumIndium arsenide

The invention relates to a solid-state radar device based on gallium indium arsenide detection. The solid-state radar device mainly comprises a substrate, a transmitting unit, a receiving unit and a control unit. Wherein a short-wave infrared light source array in the transmitting unit can generate laser of a short-wave infrared band, and the structure details of a target object in an external space can be obtained after short-wave infrared laser echoes are processed and analyzed by utilizing the characteristics of high frequency, wide bandwidth, narrow beam and the like of the short-wave infrared laser; therefore, the active detection capability and the object recognition performance of the short-wave infrared solid-state radar are enhanced. Besides, a reflector group in the transmitting unit reflects and gathers the straightened short-wave infrared laser, so that the components are compactly arranged to achieve the purpose of reducing the size of the device, the energy intensity and polarization angle of the gathered laser can be improved, and the detection capability of the short-wave infrared laser to an external space is enhanced.

Owner:深圳市矽赫科技有限公司

Smoked meat production apparatus convenient for monitoring

InactiveCN106819066ARealize automated mass productionIncrease productivityMeat/fish preservation by dryingMonitoring systemEngineering

The invention discloses a smoked meat production apparatus convenient for monitoring, which comprises a transmission track, a transmission vehicle arranged on the transmission track, and a power mechanism for driving the transmission vehicle to move; a hanger bracket used for suspending the smoked meat is arranged on the transmission vehicle, a spray chamber, a drying chamber and a smoke chamber are arranged on the transmission track, the drying chamber and the smoke chamber are the sealed chambers, several nozzles are arranged in the spray chamber, an electric heater is arranged in the drying chamber, a smoking system is arranged at the bottom of the smoke chamber, the spray chamber, the drying chamber and the smoke chamber are communicated in an enclosed mode, and a monitoring room and a monitoring system used for observing the drying chamber and the smoke chamber are arranged on the meat production apparatus. The meat production apparatus can realize automation batch production of the smoked meat, and has the advantages of high production efficiency, environmental protection and safety.

Owner:RONGMU CHONGQING SCI & TECH CO CO LTD

Automatic production equipment of cooling fin

InactiveCN107243542ARealize automated mass productionPrecise positioningMetal-working feeding devicesHeat exchange apparatusPunchingEngineering

The invention discloses automatic production equipment of a cooling fin. The automatic production equipment comprises a feeding component, a stamping mechanism and a collecting mechanism in sequence according to preparation procedures, wherein the feeding component comprises a chuck feeding mechanism, a feeding table and a roller feeding mechanism. The device has the advantages of high degree of automation, time saving, high efficiency, accuracy in positioning by virtue of an aluminum plate and low defective rate, and stamping and cutting procedures can be processed at the same time.

Owner:苏州市高宏电子有限公司

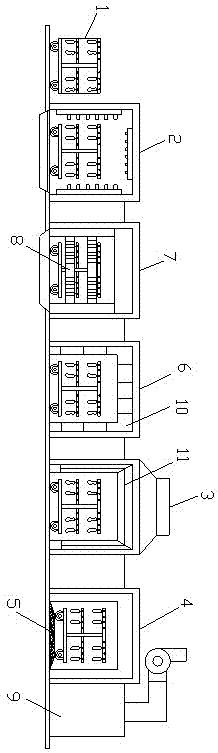

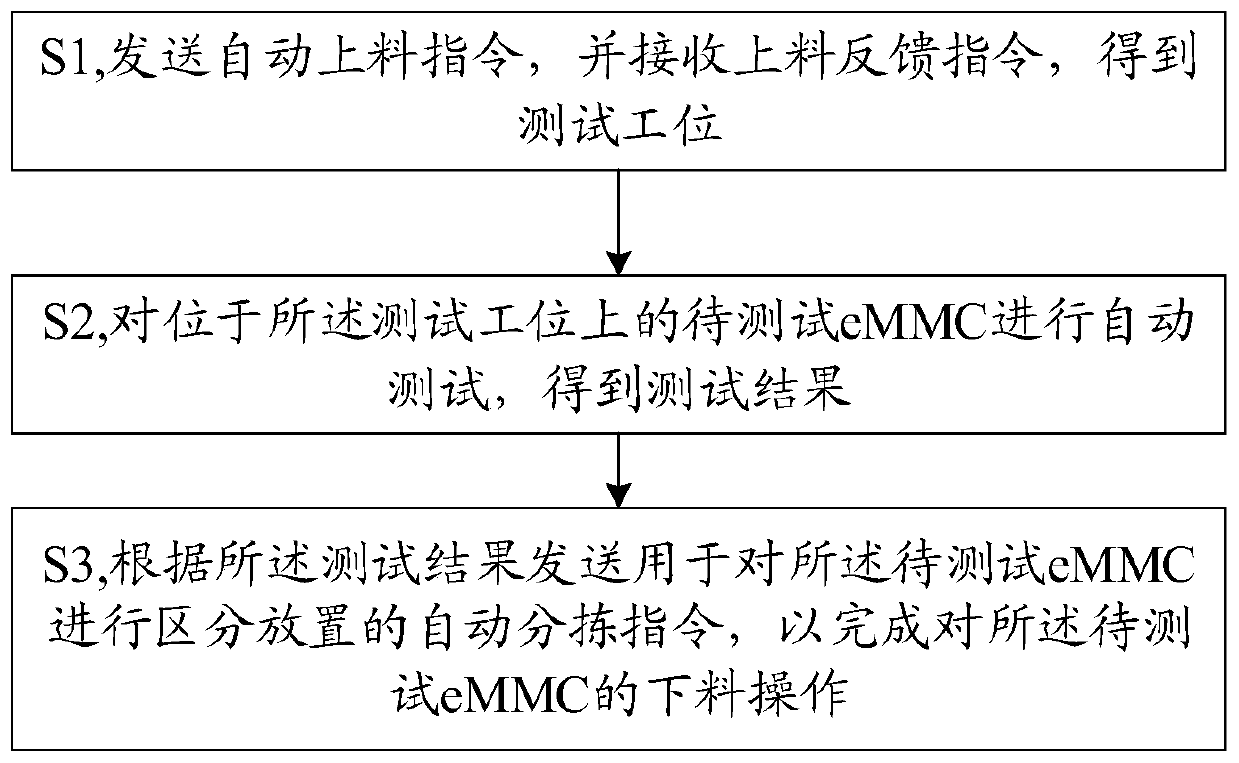

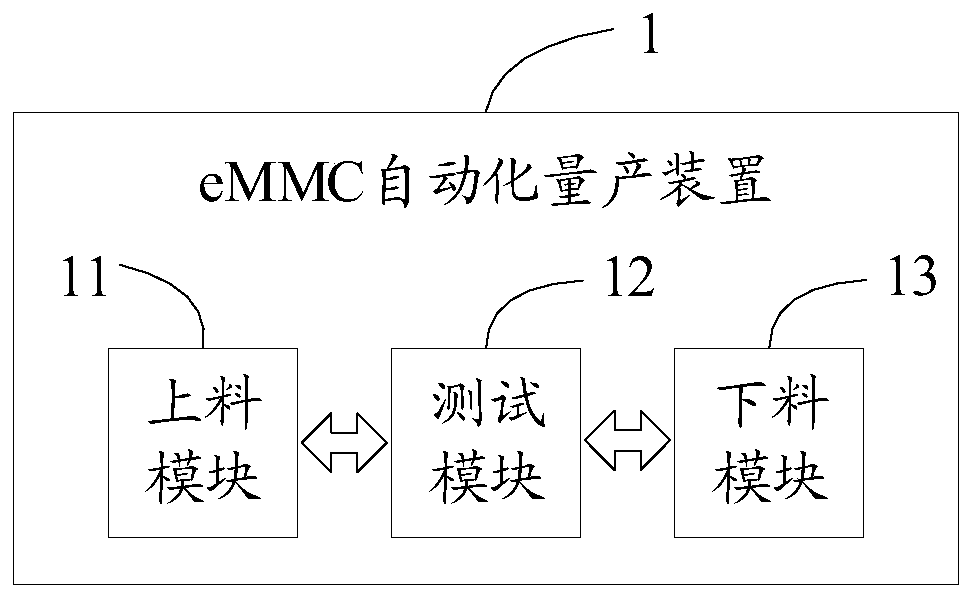

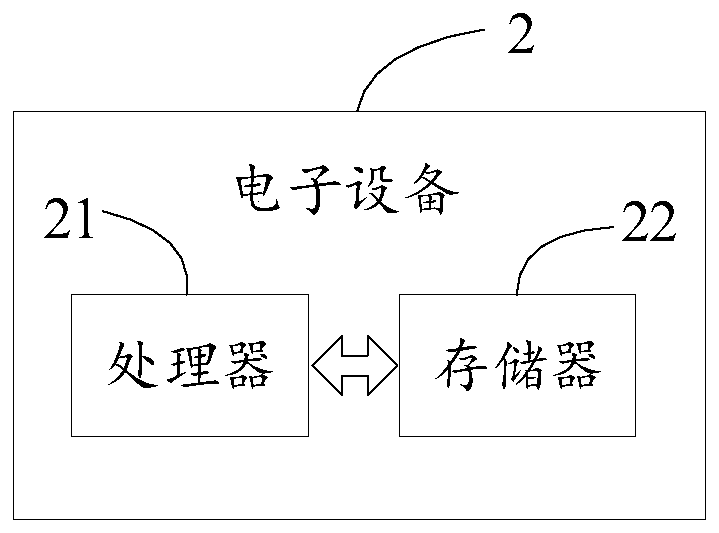

EMMC automatic mass production method and device, storage medium and electronic equipment

ActiveCN111142889ARealize automated mass productionIncrease productivityStatic storageSoftware deploymentProcess engineeringComputer science

The invention discloses an eMMC automatic mass production method and device, a storage medium and electronic equipment. The method comprises the following steps of sending an automatic feeding instruction and receiving a feeding feedback instruction to acquire a test station, automatically testing a to-be-tested eMMC located on the test station to obtain a test result, and sending an automatic sorting instruction used for differentially placing the to-be-tested eMMC according to the test result to complete discharging operation of the to-be-tested eMMC. By sending an automatic feeding instruction of the to-be-tested eMMC; a feeding feedback instruction is received. The the to-be-tested eMMC on the test station is automatically tested to obtain the test result, and the the to-be-tested eMMCis automatically distinguished and placed according to the test result, so that the automatic mass production of the eMMC is realized, the production efficiency is improved, the labor cost is reduced, and the loss caused by misoperation is avoided.

Owner:BIWIN STORAGE TECH CO LTD

Automatic feeding device for the lower cover of the charger

Owner:威海志航机电科技有限公司

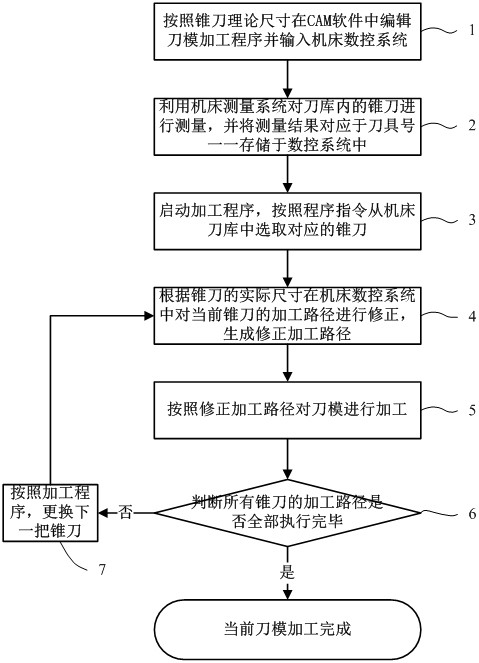

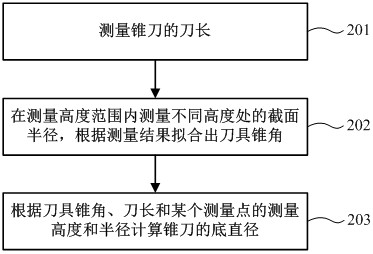

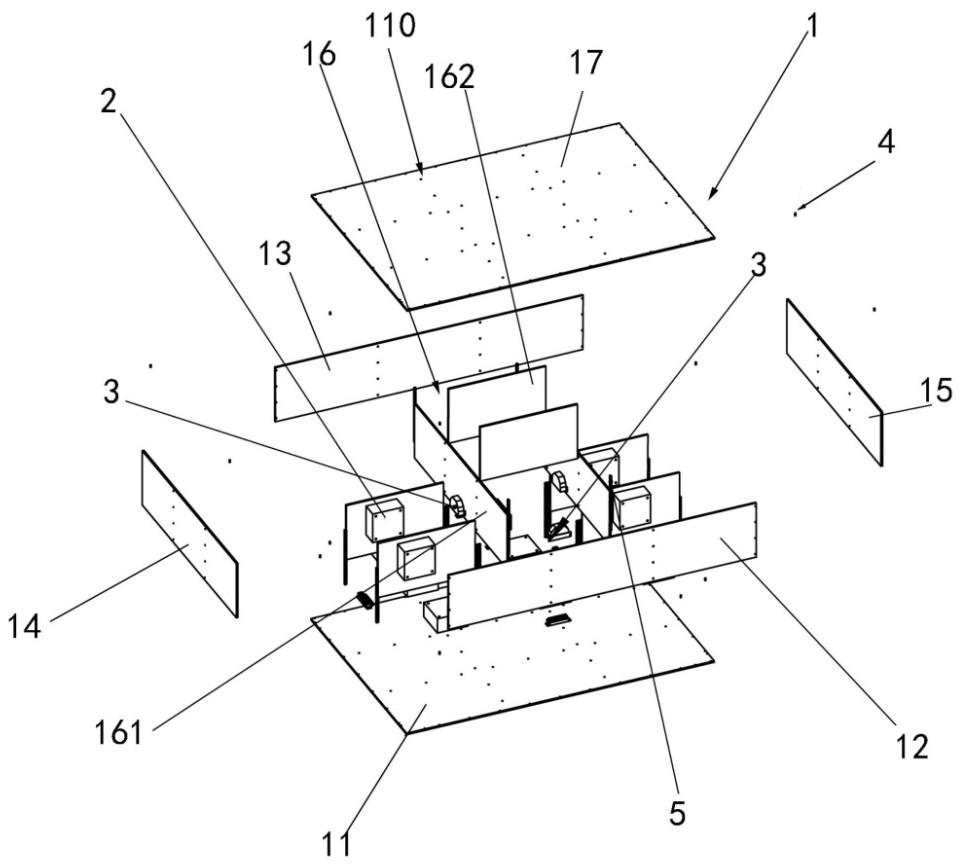

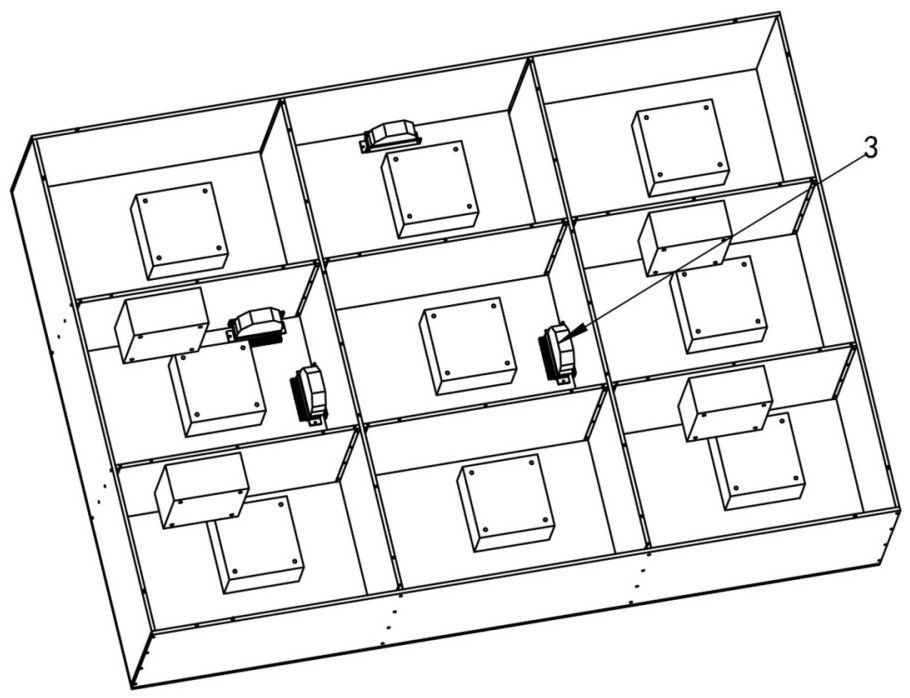

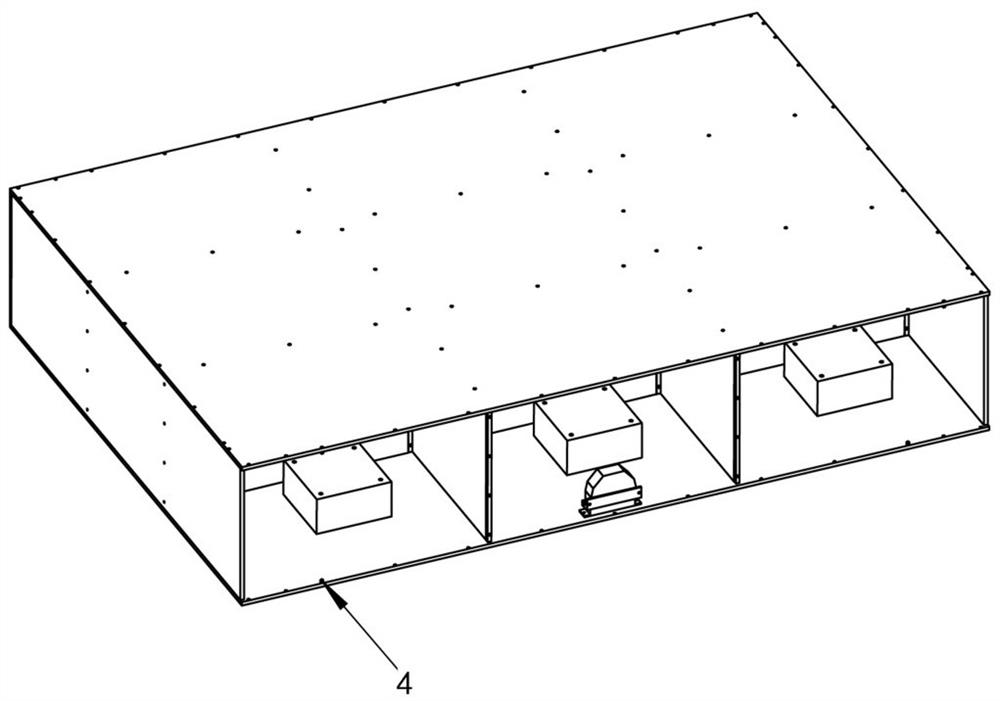

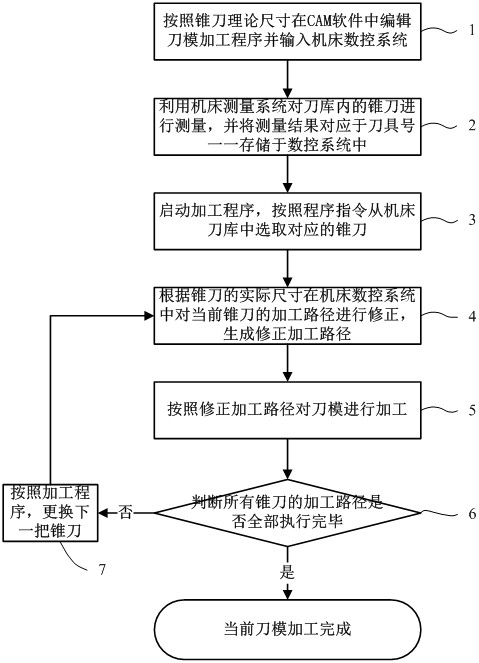

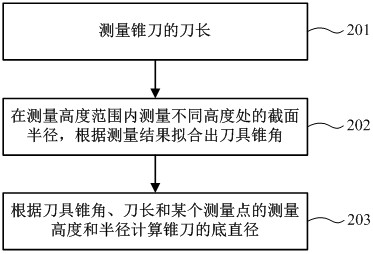

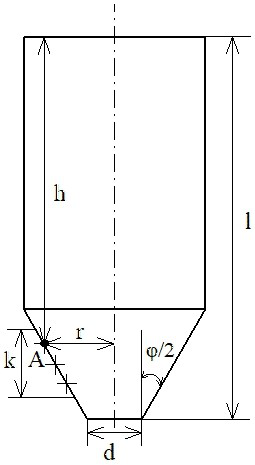

Cutting die automatic production method capable of achieving continuous machining

ActiveCN113110299AImprove machining accuracyImprove processing efficiencyProgramme controlComputer controlMachineMachine tool

The invention belongs to the field of numerical control machining, and particularly relates to an automatic cutting die production method capable of achieving continuous machining. The method is characterized in that a numerical control machine tool on-machine measurement system is used for measuring cutters in a cutter magazine, measurement results and cutter numbers are stored in a one-to-one correspondence mode, and during cutter changing machining, a machine tool numerical control system calls the measurement results of the corresponding cutters, and combines coordinates of contact points of conical cutters and workpieces in a theoretical machining path according to the actual sizes of the conical cutters to calculate actual cutter nose point coordinates of the conical cutter, so that the theoretical cutter path is corrected to generate a new machining path for actual machining. According to the invention, the method is easy to operate, the whole process is completed in a machine tool numerical control system, repeated shutdown is not needed, production continuity is guaranteed, the machining precision and machining efficiency of the cutting die are effectively improved, and automatic batch production of the cutting die can be achieved.

Owner:BEIJING JINGDIAO GRP CO LTD

Satellite structure and satellite assembly method

ActiveCN113022888BWidely used valueImprove assembly efficiencyCosmonautic partsArtificial satellitesEngineeringMonoboard

The invention relates to a satellite structure and a satellite assembly method. The satellite structure includes: a plurality of satellite decks, electronic equipment, cables and plug-in components, wherein, when the satellite decks are of a single-board structure, according to preset The satellite structure layout installs the electronic equipment, cables and plug-in components on the corresponding satellite cabin board; on the same satellite cabin board, one end of the cable is connected to the electronic equipment, and the other end is connected to the plug-in Components; between different satellite decks, electrical connections are established through the plug-in components. The invention improves the efficiency of satellite assembly and disassembly, thereby realizing automatic mass production of satellites.

Owner:北京最终前沿深空科技有限公司

A method for automatic production of cutting dies capable of continuous processing

ActiveCN113110299BImprove machining accuracyImprove processing efficiencyProgramme controlComputer controlMachineProcess engineering

The invention belongs to the field of numerical control machining, and particularly relates to an automatic production method of a die that can realize continuous machining. Use the CNC machine tool on-machine measurement system to measure the tools in the tool magazine, and store the measurement results and the tool numbers one by one. The coordinates of the contact point between the taper cutter and the workpiece in the machining path are calculated, and the actual point coordinates of the taper cutter are calculated to correct the theoretical tool path to generate a new machining path for actual machining. The invention is simple to operate, the whole process is completed in the CNC system of the machine tool, and there is no need to stop repeatedly, which ensures the continuity of production, effectively improves the machining accuracy and processing efficiency of the die, and can realize the automatic mass production of the die.

Owner:BEIJING JINGDIAO GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com