Complex Li-Mn-oxide, manufacture method and battery made of this material

A technology of composite oxides and lithium compounds, applied in the field of electrochemical materials, can solve problems such as capacity fading, achieve low production costs, improve rate charge and discharge performance, and be easy to industrialize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

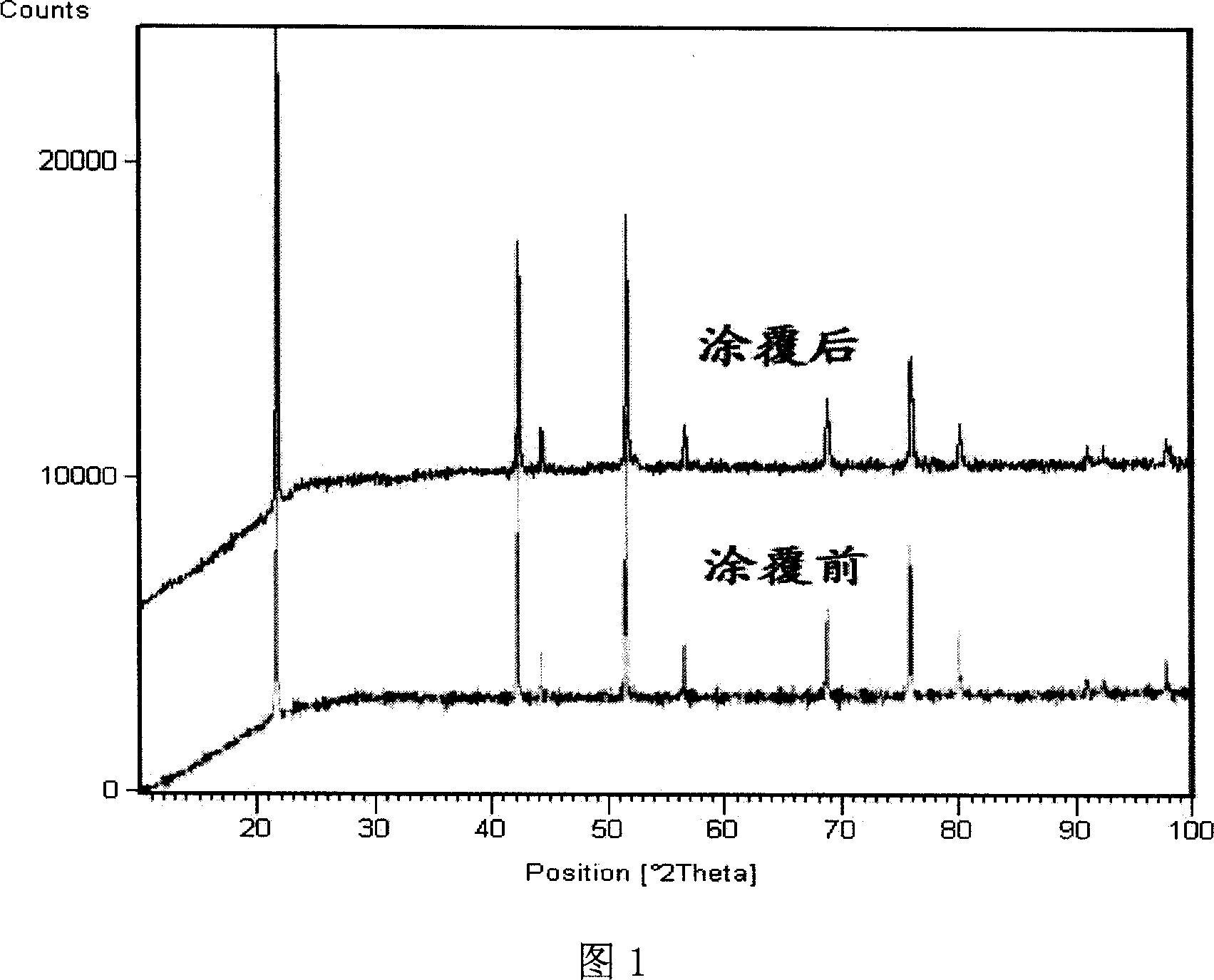

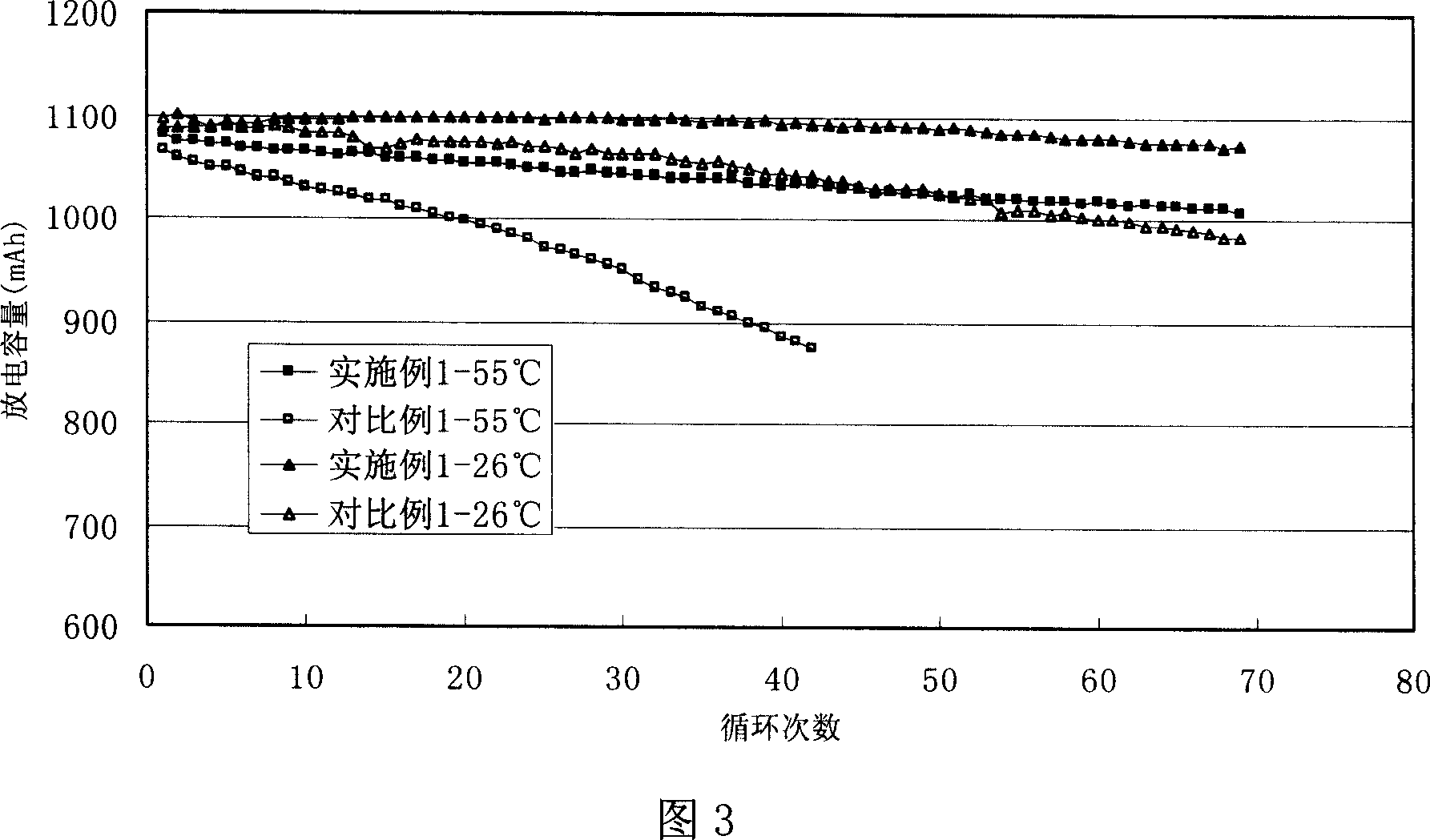

Embodiment 1

[0052] A kind of preparation method of novel potassium manganese composite oxide:

[0053] Preparation of coating solution

[0054] Weigh lithium hydroxide monohydrate and boric acid at a molar ratio of 1:2 and add them into methanol solvent, stir for 30 minutes to dissolve lithium hydroxide monohydrate and boric acid to prepare a uniform mixed solution.

[0055] clad

[0056] Lithium hydroxide monohydrate (in the above coating solution) and lithium manganese composite oxide Li with spinel structure 1.02 mn 1.98 Ti 0.01 Cu 0.01 o 4 (Core powder) Weigh Li at a molar ratio of 0.3:100 1.02 mn 1.98 Ti 0.01 Cu 0.01 o 4 Add it into the coating solution, and keep stirring (first at a low speed of about 100 rpm, then at a medium speed of about 300 rpm) for about 4 hours.

[0057] heat treatment

[0058] Dry the coated material in an air atmosphere at 80°C for 10 hours, and after sieving (300 mesh), heat it up to 600°C at a rate of 5°C per minute in an air atmosphere in an ...

Embodiment 2

[0065] The preparation method of another kind of novel lithium manganese composite oxide:

[0066] The coating solution used in this embodiment is an ethanol solution of cobalt oxalate and lithium nitrate (the molar ratio of the two is 1:1.06), and the coating amount is cobalt oxalate and spinel core powder Li 1.01 mn 1.97 Cr 0.01 Mg 0.02 o 4 The molar ratio was 0.5:100, and the coated lithium-manganese composite oxide was dried at 90°C for 9h and then calcined at 750°C for 8h. Except above content, all the other methods are identical with embodiment 1.

[0067] The structure and electrochemical performance of the material obtained in this example (the surface of the core powder is coated with lithium-cobalt composite oxide), the test method of the normal temperature and high temperature rate cycle performance are the same as in Example 1, and the results show that the structure of the material is significantly affected by the coating. No effect, the coating layer is main...

Embodiment 3

[0073] Another preparation method of novel lithium-manganese composite oxide:

[0074] The coating liquid adopted in this embodiment is an aqueous solution of aluminum nitrate, and the coating amount is aluminum nitrate and spinel core powder LiMn 1.96 V 0.01 co 0.02 Ga 0.01 o 4 The molar ratio is 0.02:100, and the coated lithium-manganese composite oxide is dried at 150°C for 8h and then calcined at 700°C for 12h. Except above content, all the other methods are identical with embodiment 1.

[0075] The structure and electrochemical performance of the material obtained in this example (the surface of the core powder is coated with aluminum oxide), the test method of the normal temperature and high temperature rate cycle performance are the same as that of Example 1, and the results show that the coating has no effect on the structure of the material. The coating layer is mainly coated on the surface of the core powder lithium manganese composite oxide in the form of an am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com