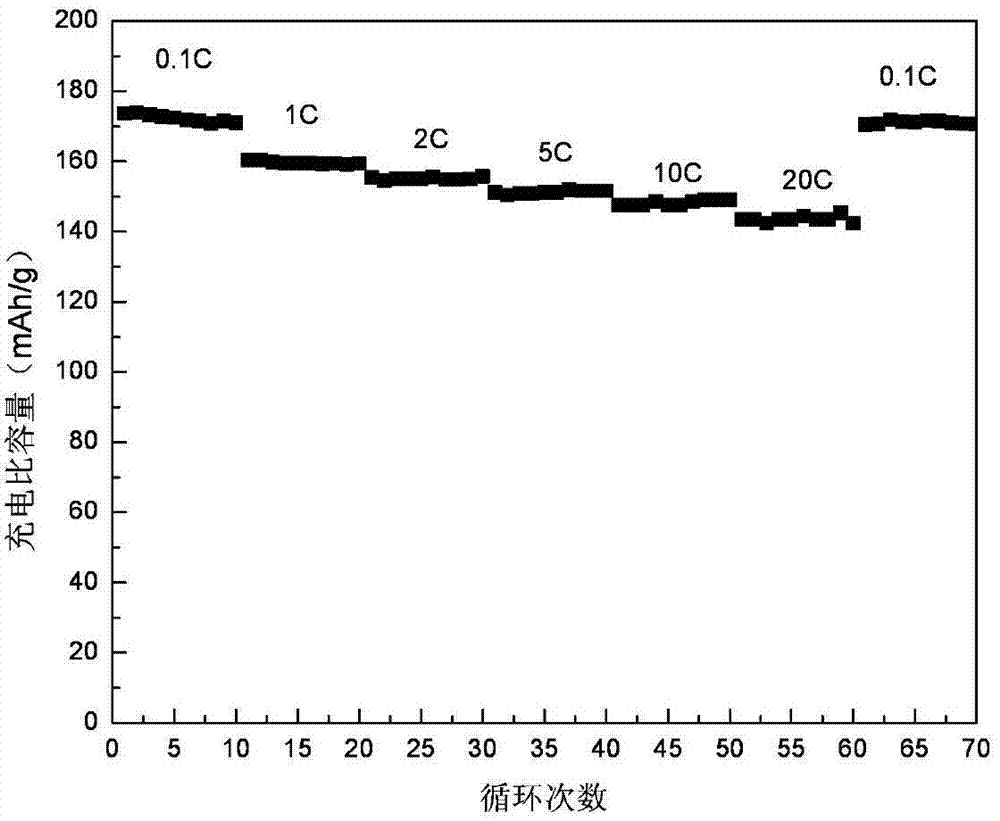

Method for preparing carbon modified lithium ion battery Li4Ti5O12 cathode material in one step

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of complex process and high cost of negative electrode materials, and achieve excellent electrochemical performance, enhanced conductivity, and controllable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] One-step preparation of carbon-modified Li-ion batteries Li 4 Ti 5 o 12 The process method of negative electrode material, concrete steps are:

[0025] 1) Weigh 13g of tetrabutyl titanate (TBT), and dissolve it in 20ml of absolute alcohol under continuous stirring. After it is completely dissolved, continue stirring for 30 minutes at room temperature, and record it as solution A; 1.3g of lithium hydroxide and 1.5g of sucrose were dissolved in 13ml of deionized water under continuous stirring. After completely dissolving, continue to stir at room temperature for 30 minutes, and record it as solution B;

[0026] 2) Add solution A to solution B drop by drop with a peristaltic pump in the state of continuous stirring until all solution A is added dropwise, and continue to stir for 2 hours to fully proceed the reaction;

[0027] 3) Move the obtained white suspension to an oven at 105°C for 24 hours and grind the obtained solid into powder;

[0028] 4) Calcining the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com