Process for producing absorbent charcoal loading titanium dioxide photocatalyst

A photocatalyst and titanium dioxide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of cheap raw materials, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) After commercial activated carbon is pulverized, it is sieved with 50-100 meshes to obtain granular activated carbon, which is washed several times with deionized water and dried.

[0026] (2) Under the condition of ice-water bath, 1.5g of metatitanic acid and 4.5ml of ammonia water were added into 20mL of 30% hydrogen peroxide, and after stirring for 50 minutes, a yellow-green sol was obtained.

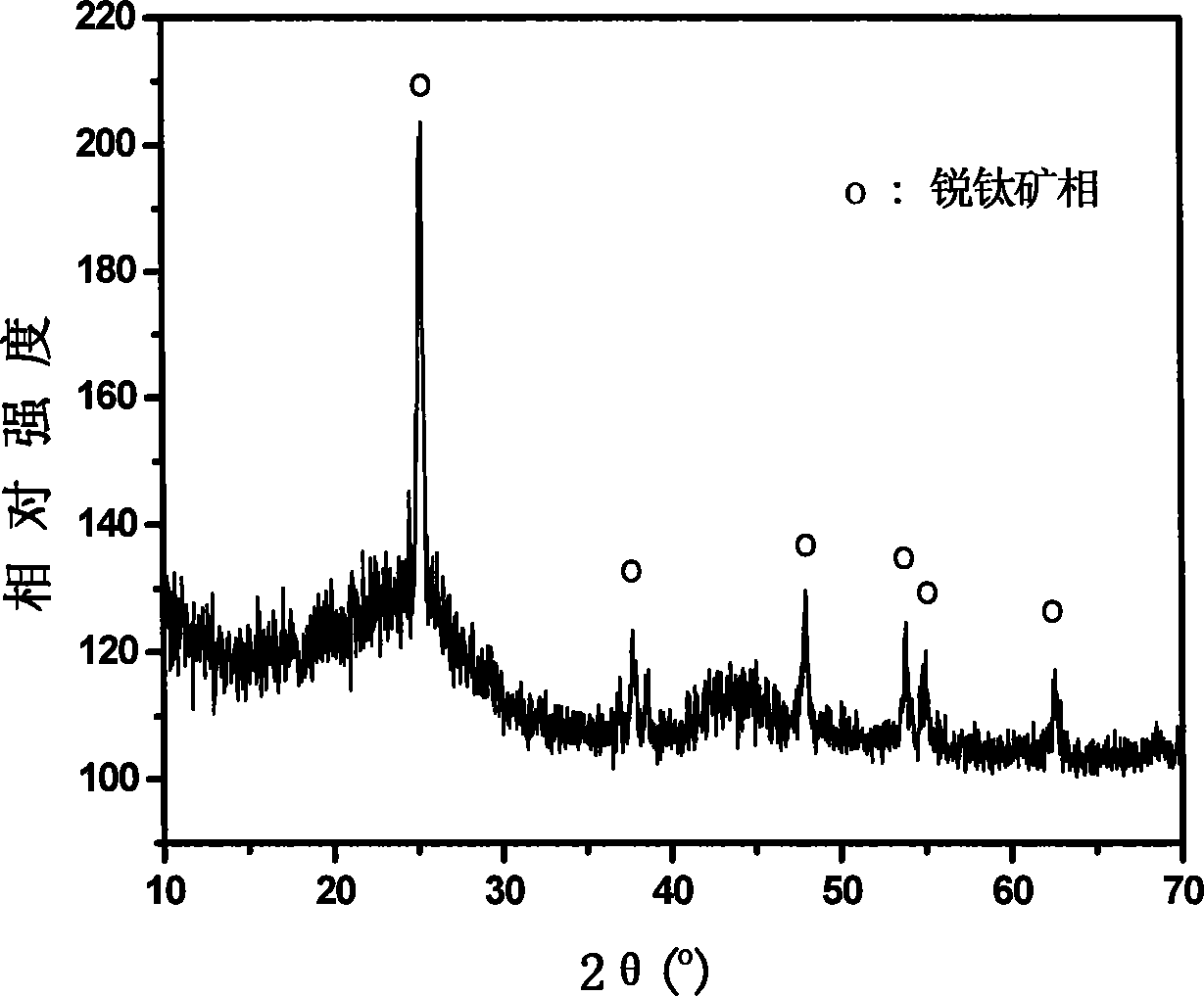

[0027] (3) Add 4 g of granular activated carbon obtained in step (1) to the sol obtained in step (2), stir for 4 hours, and then let stand for 24 hours. The activated carbon was filtered out and calcined at 600°C for 2h under the protection of an inert gas. The resulting product is anatase activated carbon supported titanium dioxide photocatalyst, TiO 2 Content 9wt%.

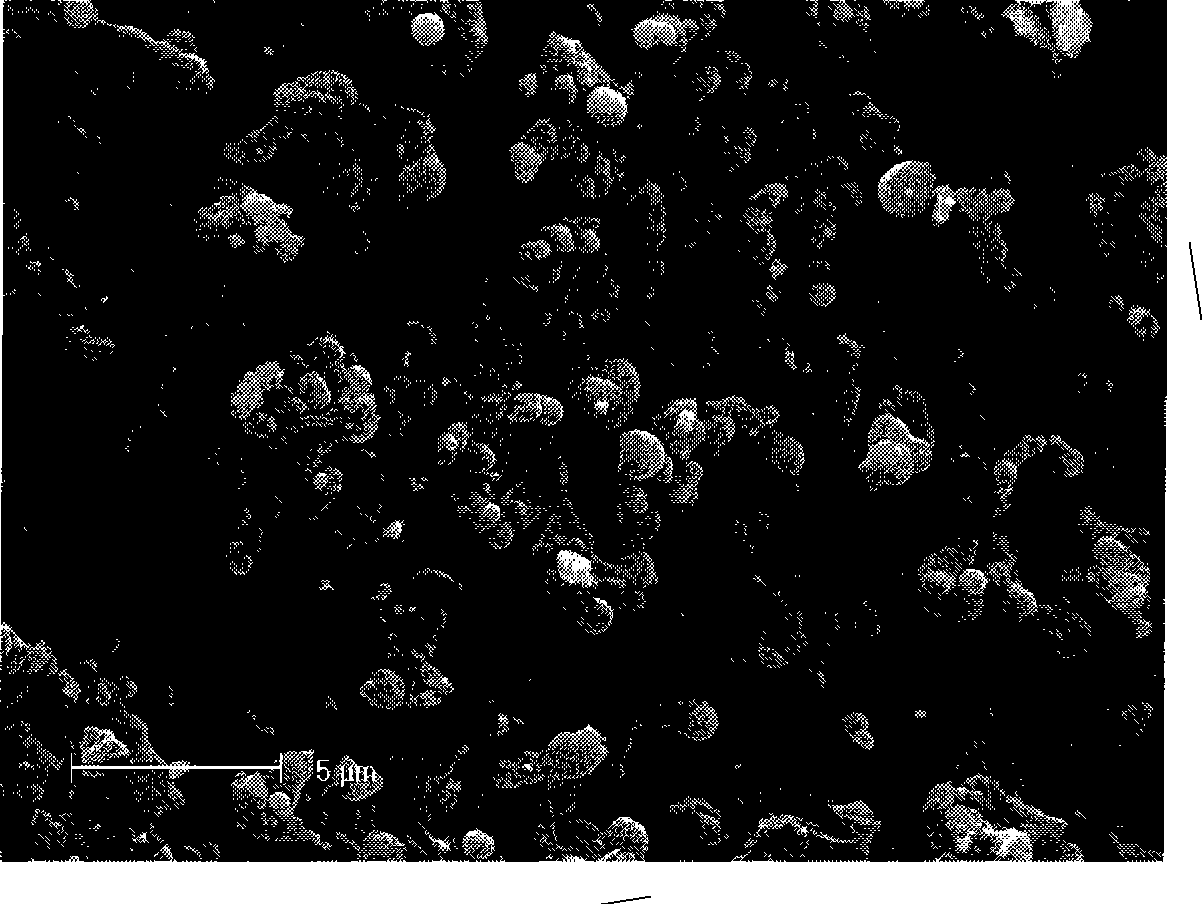

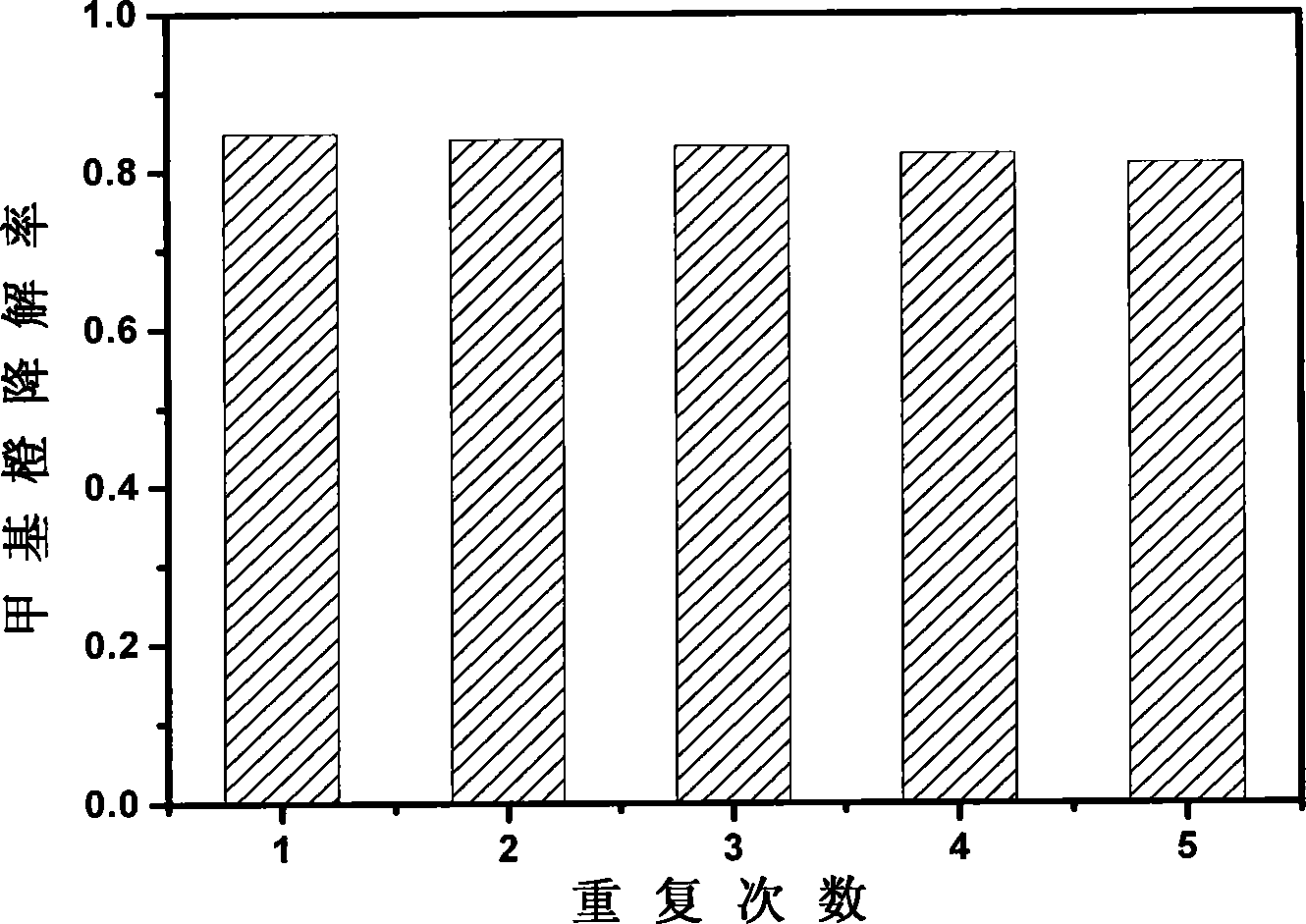

[0028] Product obtained in step (3) is characterized by XRD, SEM respectively, from figure 1 It can be seen that the product is anatase phase. from figure 2 Visible in TiO 2 The particles are evenly d...

Embodiment 2

[0030] (1) After the commercial activated carbon is pulverized, it is sieved with 50-100 meshes to obtain granular activated carbon which is passed through O 3 After 2 hours of treatment, wash with deionized water until neutral, and dry.

[0031] (2) Under the condition of ice-water bath, 1.5g of metatitanic acid and 4.5ml of ammonia water were added into 30mL of 30% hydrogen peroxide, and the yellow-green sol was obtained after stirring for 1 hour.

[0032] (3) Add 4 g of pretreated granular activated carbon into the sol, stir for 4 hours, and then let stand for 24 hours. The activated carbon was filtered out and calcined at 600°C for 2h under the protection of an inert gas. The resulting product is anatase activated carbon supported titanium dioxide photocatalyst, TiO 2 Content 13wt%.

Embodiment 3

[0034] (1) After the commercial activated carbon is pulverized, it is sieved with 100 to 150 meshes to obtain powdered activated carbon which is passed through O 3 After 2 hours of treatment, wash with deionized water until neutral, and dry.

[0035] (2) Add 1.0 g of metatitanic acid and 3 ml of ammonia water to 20 mL of 30% hydrogen peroxide in an ice-water bath, and stir to obtain a yellow-green sol.

[0036] (3) Add 3 g of pretreated powdered activated carbon into the sol, stir for 4 hours, and then let stand for 24 hours. The activated carbon was filtered out and calcined at 600°C for 2h under the protection of an inert gas. The resulting product is anatase activated carbon supported titanium dioxide photocatalyst, TiO 2 Content 10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com