Preparation method and application of nitrogen-doped titanium dioxide heterojunction structure

A titanium dioxide and heterostructure technology, applied in the field of photocatalytic materials, can solve problems such as nanoparticle heterostructures that have not yet been seen, and achieve the effects of being conducive to the separation of photogenerated charges, high photocatalytic efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepare a mixed solution of 2.5 mL of tetrabutyl titanate and 47.5 mL of isopropanol. Under stirring at 300 r / min, add the mixed solution dropwise to 200 mL of distilled water at pH<2 at 1°C, and ensure that the time for dropping is not less than 0.5 h. Keeping warm and stirring continuously for 12 hours, a translucent titanium dioxide sol was obtained.

[0047] Take 35mL titanium dioxide sol, mix it with 35mL 80wt% hydrazine hydrate solution, and disperse it ultrasonically for 5 minutes to obtain a milky suspension; transfer all the milky suspension to a PTFE container with a volume of 100 mL, and then place Place in a stainless steel reaction kettle, seal the kettle, and conduct a static heat preservation reaction at 200°C for 48h. The obtained solid was washed twice with water, filtered with suction, and dried to obtain sample S-1.

[0048] The application of nitrogen-doped titanium dioxide heterostructure in the decolorization and purification of organic dye aqueou...

Embodiment 2

[0057] Take 18mL of the titanium dioxide sol prepared in Example 1, mix it with 54mL of 60wt% ethylenediamine solution, and disperse it ultrasonically for 5 minutes to obtain an emulsion suspension; transfer all the emulsion suspension to a polytetrafluoroethylene container with a volume of 100mL , and then put the polytetrafluoroethylene container in a stainless steel reaction kettle, seal the kettle, and conduct a static heat preservation reaction at 180°C for 72h. The obtained solid was washed three times with water, filtered with suction, and dried to obtain sample S-2.

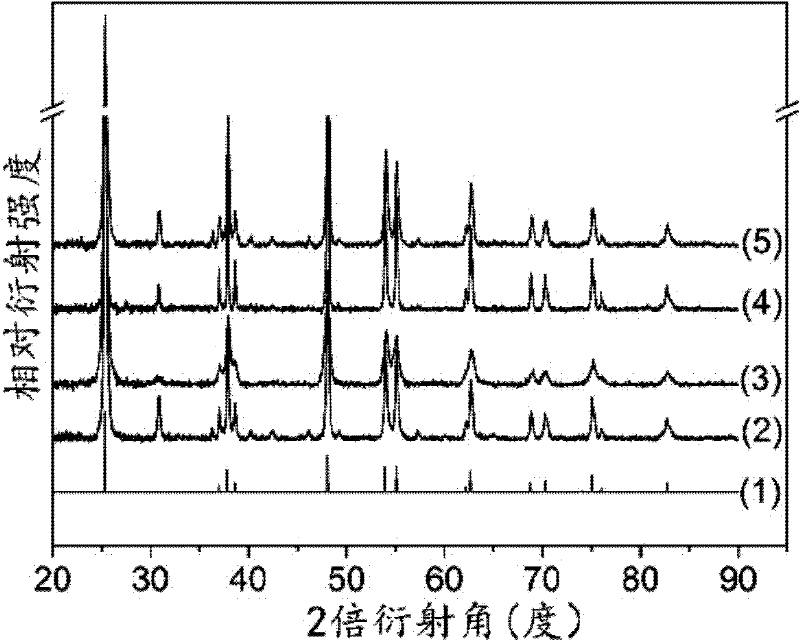

[0058] The composition and nitrogen content of the obtained sample S-2 are shown in Table 1; figure 1 ; image 3 ;

[0059] The application steps are as in Example 1.

[0060] Figure 6 UV photocatalytic degradation concentration 10 -3 The results for an aqueous solution of M methyl orange, Figure 7 The visible light catalytic degradation concentration of λ>400nm is 10 -4 M Results for Rhodamine B a...

Embodiment 3

[0062] Make a mixed solution of 2.5mL of titanium tetrachloride and 47.5mL of isopropanol, and add the mixed solution dropwise to 200mL of distilled water at 5°C with a pH<2 under stirring at 300r / min, and ensure that the dropping time is not less than 0.5h. Keeping warm and stirring continuously for 6 hours, a transparent titanium dioxide sol was obtained.

[0063] Take 30mL titanium dioxide sol, mix it with 50mL 40wt% hydrazine hydrate solution, and ultrasonically disperse it for 5 minutes to obtain a milky suspension; transfer all the milky suspension to a PTFE container with a volume of 100mL, and then place the Place it in a stainless steel reaction kettle, seal the kettle, and conduct a static heat preservation reaction at 180°C for 72h. The obtained solid was washed three times with water, filtered with suction, and dried to obtain sample S-3.

[0064] The composition and nitrogen content of the obtained sample S-3 are shown in Table 1; figure 1 ; Figure 4 ;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com